Preparation method of activated carbon-supported cobalt-nickel alloy material and electrochemical application of preparation method

A cobalt-nickel alloy and activated carbon technology, applied in electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of scarce reserves of platinum group metal materials, high prices, restricting large-scale production and application, etc., to improve hydrogen production efficiency and low cost. , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of activated carbon supported cobalt-nickel alloy material, its preparation method comprises the steps:

[0028] Step A. According to the molar ratio of cobalt source: nickel source = 1:0.1-10, both the cobalt source and the nickel source are dissolved in distilled water to obtain a clarified mixed solution. Wherein, the cobalt source is preferably at least one of cobalt chloride, cobalt nitrate or cobalt sulfate; the nickel source is preferably at least one of nickel chloride, nickel nitrate or nickel sulfate.

[0029] Step B, adding activated carbon to the clarified mixed solution prepared in step A, forming a slurry after the adsorption is saturated, and then heat-treating the slurry to obtain a cobalt-nickel alloy material supported by activated carbon. Wherein, the mass ratio of the consumption of activated carbon in step B to the consumption of distilled water in step A is preferably 1:0.8~8. The heat treatment of the slurry is to prepare the activated car...

Embodiment 1

[0038] A kind of activated carbon supported cobalt-nickel alloy material, its preparation method comprises the steps:

[0039] Step a1. Both 91 mg of nickel nitrate and 545 mg of cobalt nitrate were dissolved in 0.5 ml of distilled water to obtain a clear mixed solution.

[0040]Step b1, add 0.5 g of activated carbon powder to the clarified mixed liquid prepared in step a1, and ultrasonically oscillate to form a slurry after the adsorption is saturated, and then place the slurry in an environment of 100°C under nitrogen protection for 6 hours , and then maintained in an environment of 1000 ° C for 2 hours, thereby preparing an activated carbon-supported cobalt-nickel alloy material.

[0041] Specifically, the activated carbon-loaded cobalt-nickel alloy material prepared in Example 1 of the present invention was detected as follows:

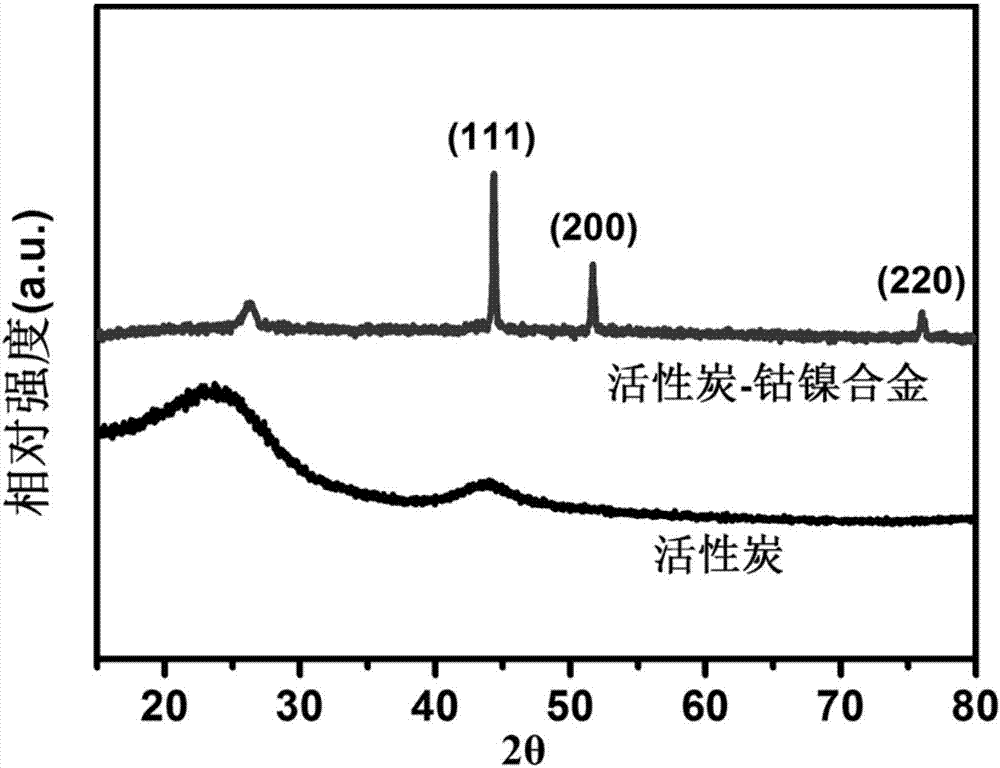

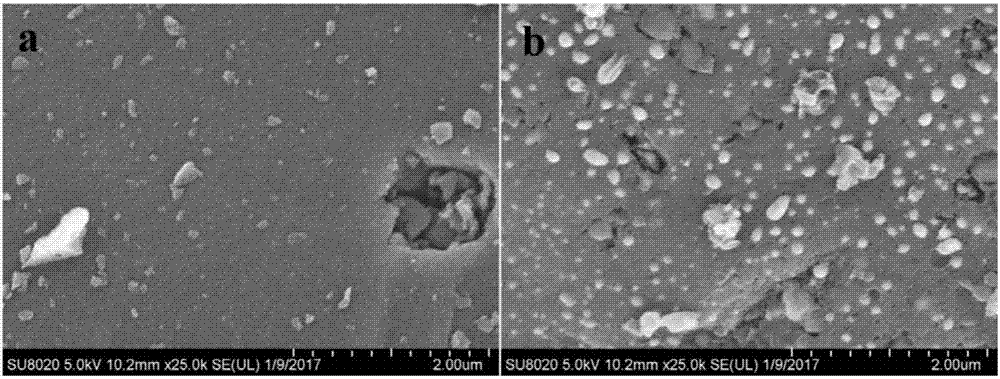

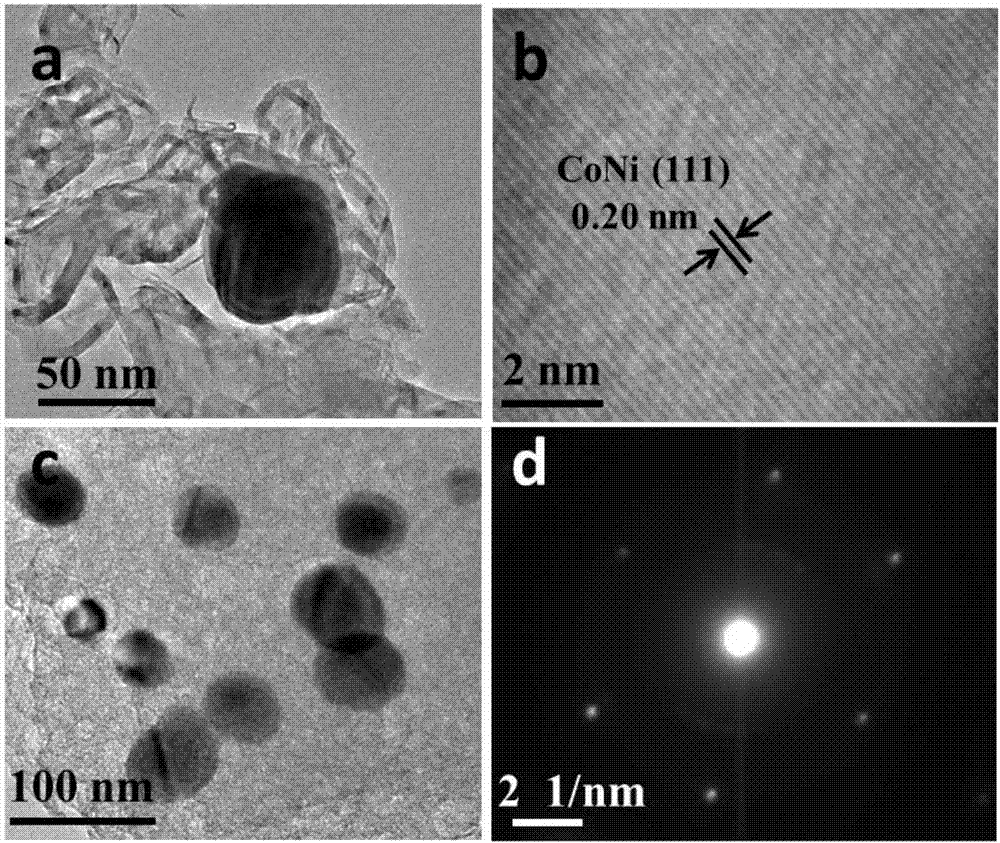

[0042] (1) The activated carbon powder used in step b1 in the embodiment of the present invention 1 and the activated carbon-loaded cobalt-nicke...

Embodiment 2

[0049] A kind of activated carbon supported cobalt-nickel alloy material, its preparation method comprises the steps:

[0050] Step a2, 136mg of nickel nitrate and 409mg of cobalt nitrate were all dissolved in 0.5ml of distilled water to obtain a clear mixed solution.

[0051] Step b2, add 0.5 g of activated carbon powder to the clarified mixed solution prepared in step a2, and ultrasonically vibrate to form a slurry after the adsorption is saturated, and then place the slurry in an environment of 100°C under nitrogen protection for 5 hours , and then maintained in an environment of 1000 ° C for 2 hours, thereby preparing an activated carbon-supported cobalt-nickel alloy material.

[0052] Specifically, by electrochemical characterization of the activated carbon-supported cobalt-nickel alloy material prepared in Example 2 of the present invention, it was found that: when the current density of the polarization curve reaches 10mA / cm 2 , electrocatalytic water splitting for hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com