Preparation method and application of cerium oxide loaded nickel catalyst

A technology of cerium oxide and nickel loading, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., which can solve the problem of easy carbon deposition and deactivation on the catalyst surface, and reaction selectivity No high problems, to achieve the effect of inhibiting the formation of carbon deposits, enhancing the catalytic effect, and enriching the active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

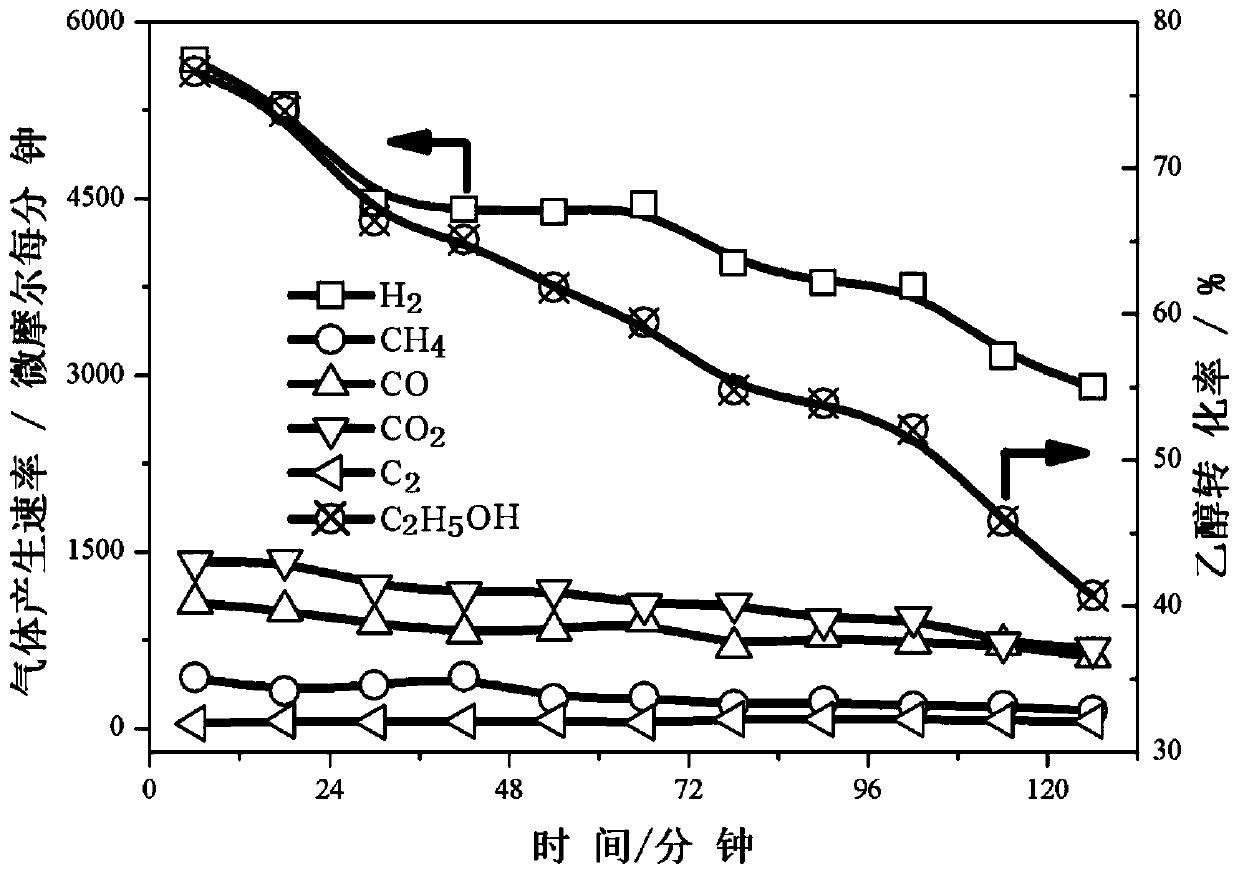

Embodiment 1

[0031] Weigh cerium nitrate hexahydrate, nickel nitrate, and citric acid, mix and dissolve in 17ml of water, stir at 60°C until clear, then transfer to a water bath at 90°C to evaporate the water to form a gel, and then transfer to an oven at 120°C Dry in medium for 24 hours to form a solid foam, put it in a muffle furnace at 600°C and bake for 4 hours after grinding to obtain nickel oxide supported by a cerium oxide carrier, and then in H 2 / Ar mixed gas pretreatment at 500 ° C for 1 hour, named Ni-CeO 2 , the loading of Ni in the final catalyst is 10wt%.

Embodiment 2

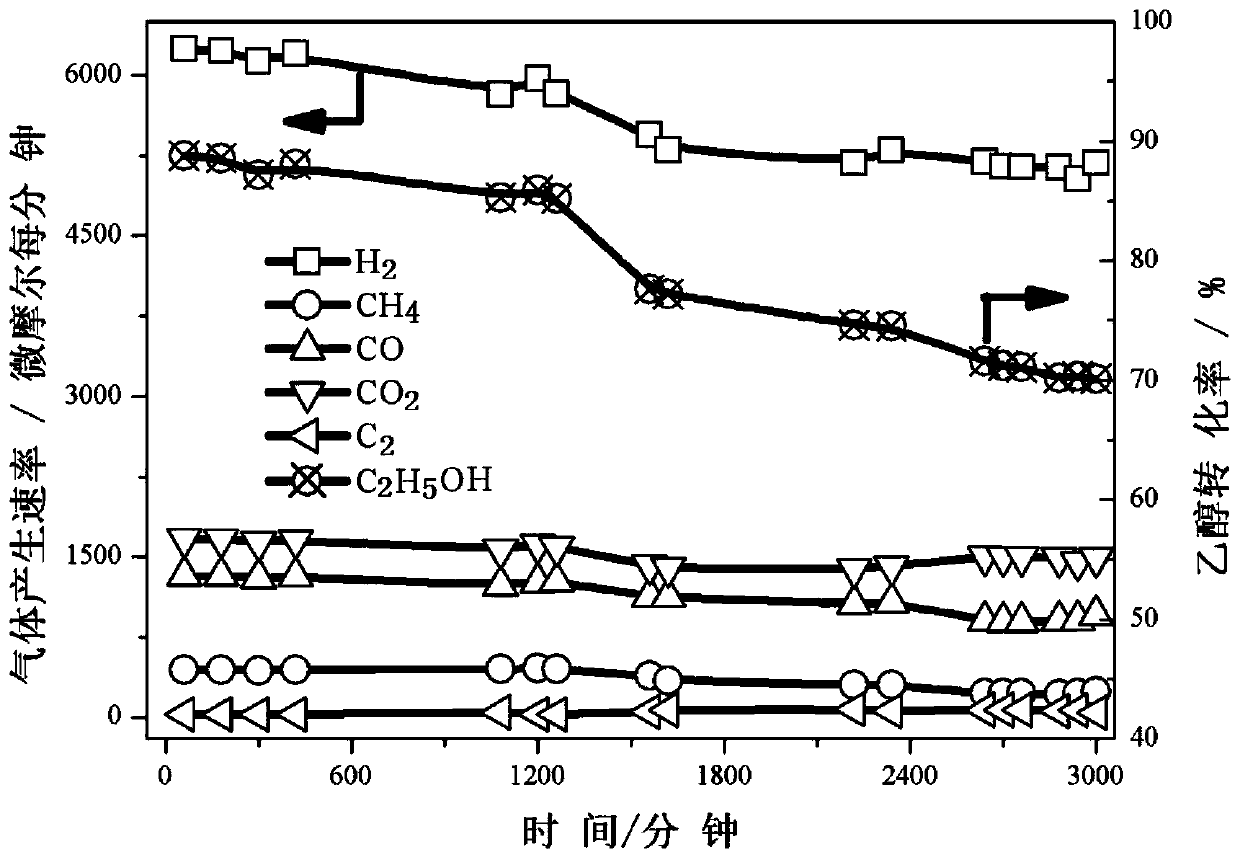

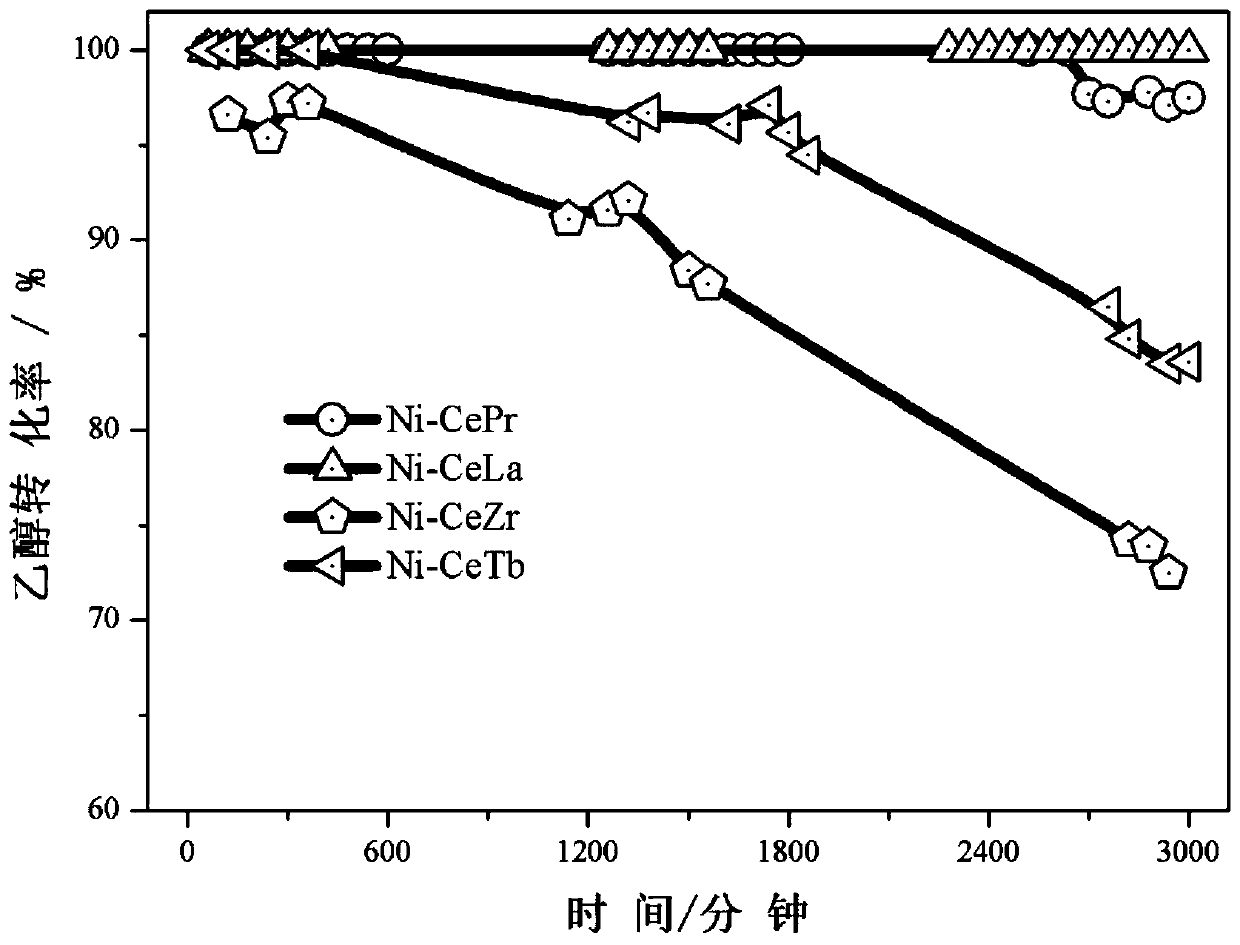

[0033] Weigh cerium nitrate hexahydrate, nickel nitrate, lanthanum nitrate hexahydrate, and citric acid, mix and dissolve in 17ml of water, stir at 60°C until clear, then transfer to a water bath at 90°C to evaporate the water to form a gel, then transfer Dried in an oven at 120°C for 24 hours to form a solid foam, then ground and baked in a muffle furnace at 600°C for 4 hours to obtain rare earth (La, Pr, Zr, Tb)-doped nickel oxide supported on a cerium oxide carrier , then in H 2 / Ar mixed gas pretreatment at 500°C for 1 hour, named Ni-CeLa, the loading of Ni in the final catalyst was 10wt%, and the molar ratio of cerium to rare earth elements was 4.

Embodiment 3-5

[0035] The preparation process of the catalyst is the same as in Example 2, except that lanthanum nitrate hexahydrate is replaced by nitric acid hexahydrate, nitric acid hexahydrate, and nitric acid hexahydrate successively, and the catalysts obtained are named as Ni-CePr, Ni-CeZr, and Ni-CeTb successively. The loading amount of Ni in the final catalyst is 10wt%, and the molar ratio of cerium element to rare earth element is 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com