Biomass-gasifying hydrogen generating serial fluid bed apparatus and method

A hydrogen production device and biomass technology, applied in the direction of granular/powder fuel gasification, hydrogen production, etc., can solve the problem of low heat and mass transfer rate of biomass and catalyst, carbon surface area of catalyst particles, difficult to achieve high efficiency of biomass Hydrogen production and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

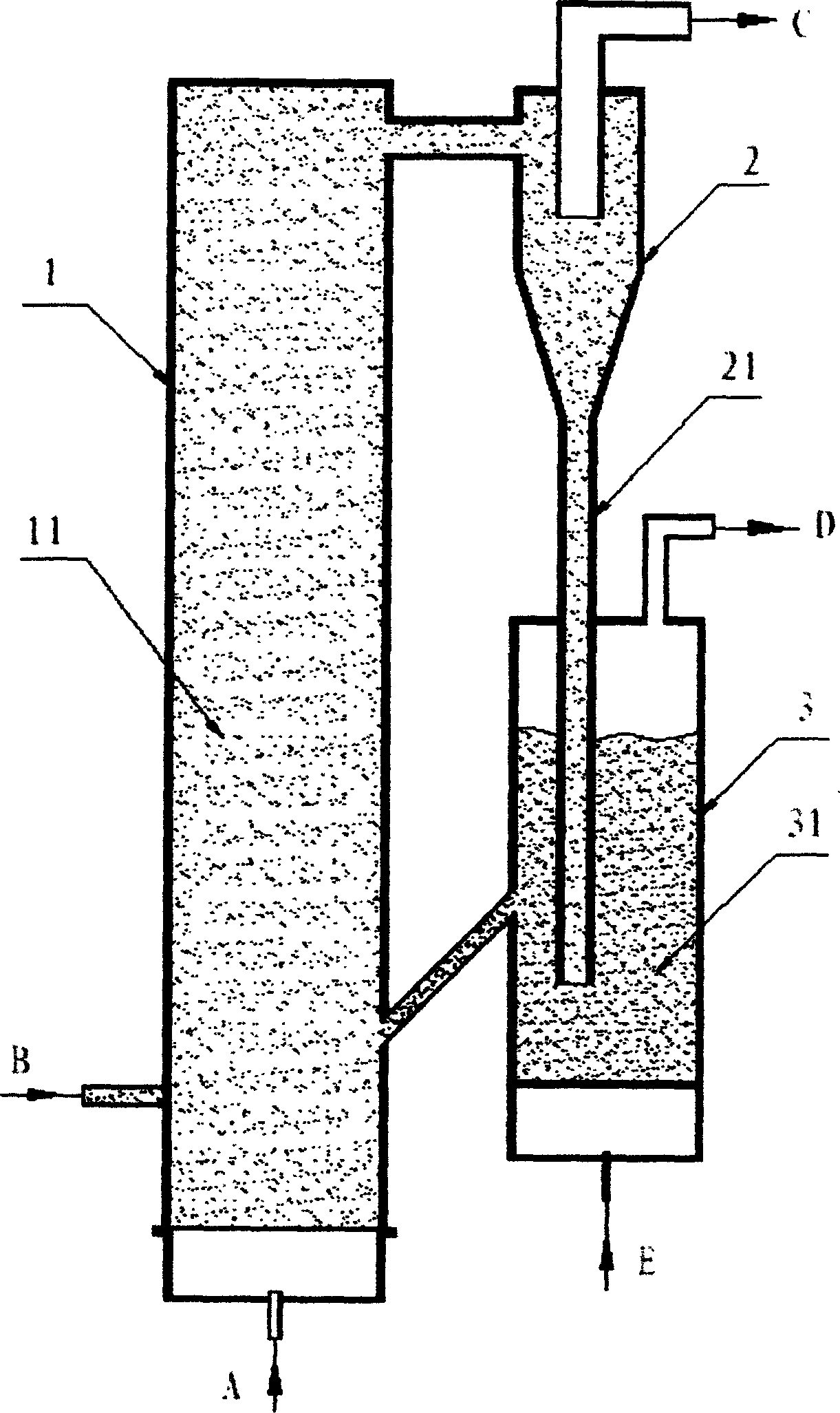

[0013] The serial fluidized bed biomass gasification hydrogen production device of the present invention is composed of a circulating fluidized bed 1 , a cyclone separator 2 and a bubbling fluidized bed 3 connected in series. The upper part of the circulating fluidized bed 1 is connected with the upper part of the cyclone separator 2, the lower part of the circulating fluidized bed 1 is connected with the bubbling fluidized bed 3, and the lower part of the circulating fluidized bed 1 is also provided with a biomass particle feeding port B, The bottom of the circulating fluidized bed 1 is provided with a water vapor inlet A, and the bed material in the circulating fluidized bed 1 is calcium oxide / magnesia catalyst particles 11; the top of the cyclone separator 2 is a hydrogen-rich gas outlet C, and the cyclone separates The discharge pipe 21 at the lower part of the device 2 is inserted into the bubbling fluidized bed 3; the top of the bubbling fluidized bed 3 is the flue gas ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com