Non-secondary-pollution elimination method of dedusting fluid during dedusting process

A secondary pollution and fluid technology, applied in the direction of separation methods, chemical instruments and methods, gas treatment, etc., to achieve the effect of strong adaptability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0019] A dedusting fluid and a pollution-free consumption method for the dedusting fluid and the controlled dust after the main dedusting process and the auxiliary dedusting process are completed. The working process and specific steps of the method are as follows:

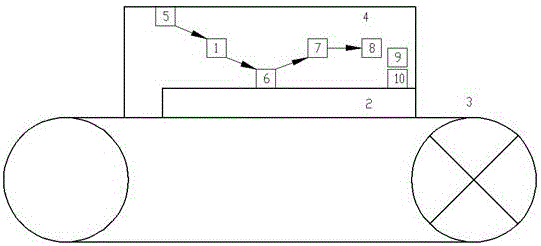

[0020] I. The accommodation device adopted is composed of dust source 1, material 2, conveying equipment 3, limited dust removal space 4, water-air vortex dust removal fluid generator 5, water-air vortex main dust removal fluid 6, water-air vortex auxiliary dust removal fluid 7. Composed of mesoscale fluid 8, absorbing black hole 9 and stable adsorption body 10, the dust source 1 above the conveying device 3 is used as the starting point and basis for decision-making to limit the layout of the dust removal space 4, and the conveying device 3 conveys the material 2, A supporting support is fixedly installed on the conveying equipment 3, and the limited dust removal space 4 and the conveying equipment 3 are fixedly i...

Embodiment approach 2

[0024] An independent support is set up next to the support support of the conveying equipment 3, and the dust removal space 4 and the conveying equipment 3 are fixedly installed on the independent support set up beside the support support of the conveying equipment 3. Others are the same as in Embodiment 1.

Embodiment approach 3

[0026] The dust produced by dust source 1 can only pass along the direction of conveying material 2. At 450 mm behind dust source 1, a water-air vortex dust removal fluid generator 5 is installed at the centerline position of the top of dust removal space 4, and the others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com