Fish oil pumping device and pumping method

A technology for pumping devices and oil pumps, which is applied to pump devices, components of pumping devices for elastic fluids, pumps, etc., which can solve problems such as quality impact, easy heat generation, and fish oil quality damage, and achieve stable operation and improved Effect of pumping efficiency and reduction of area occupied by equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

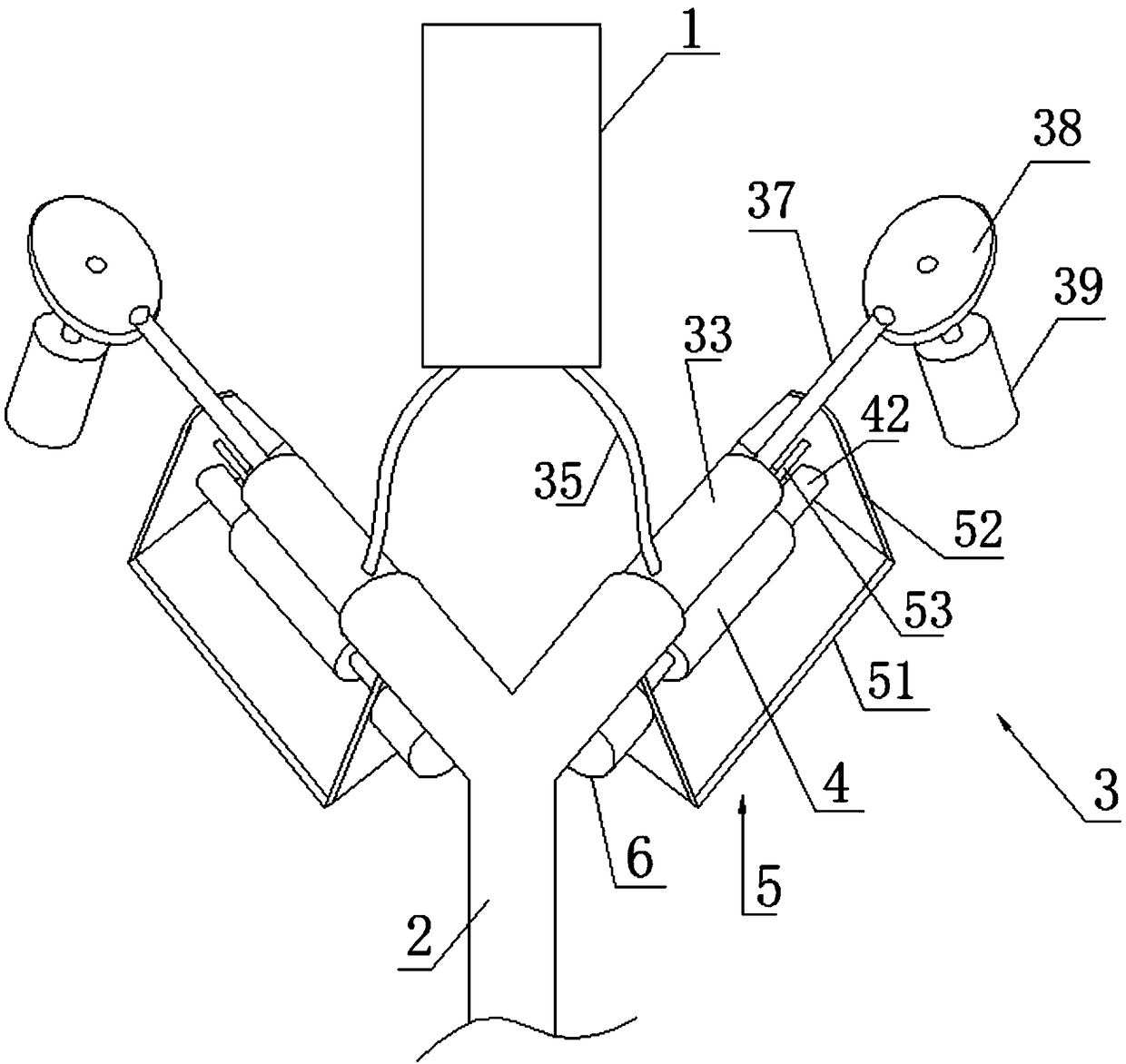

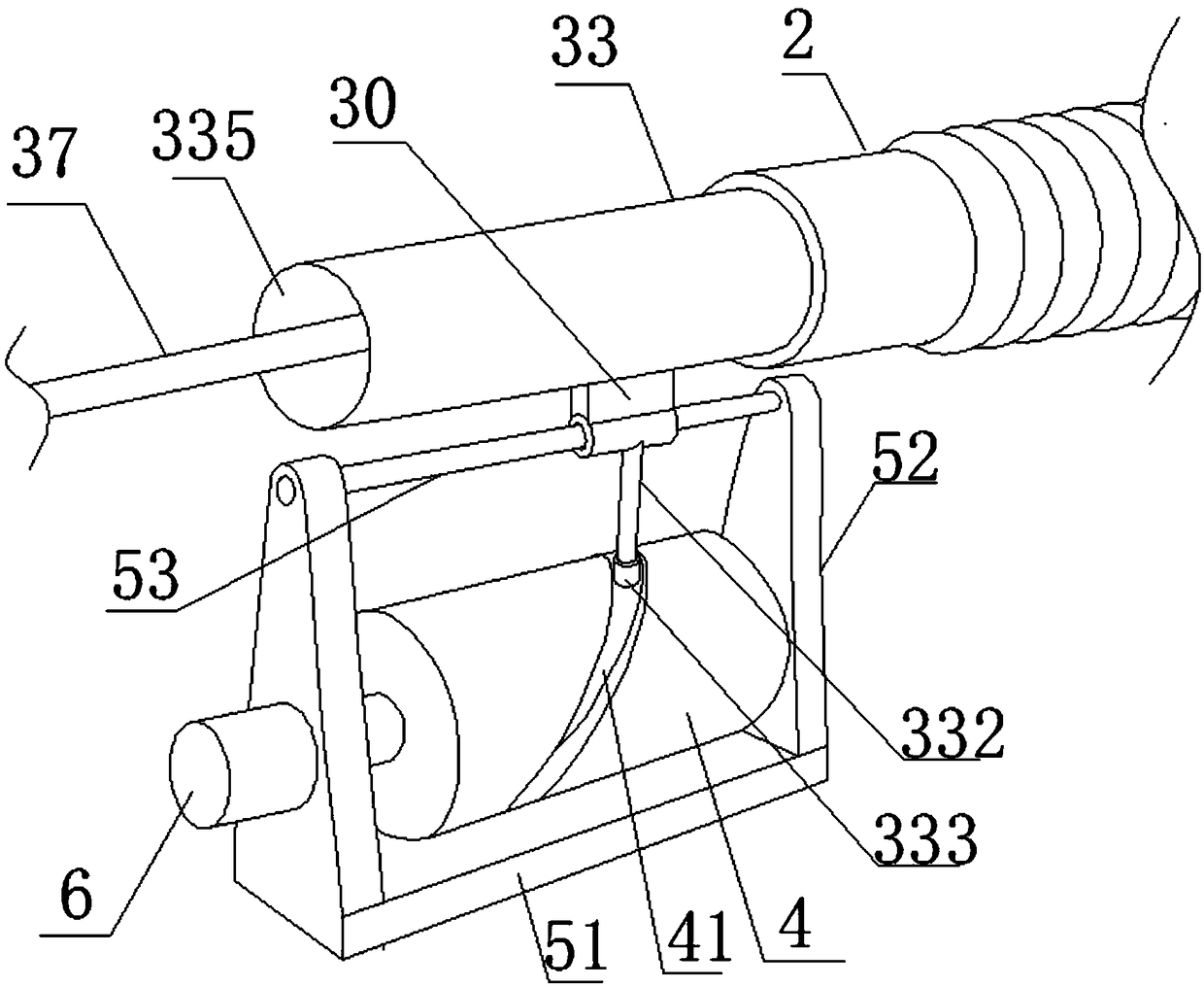

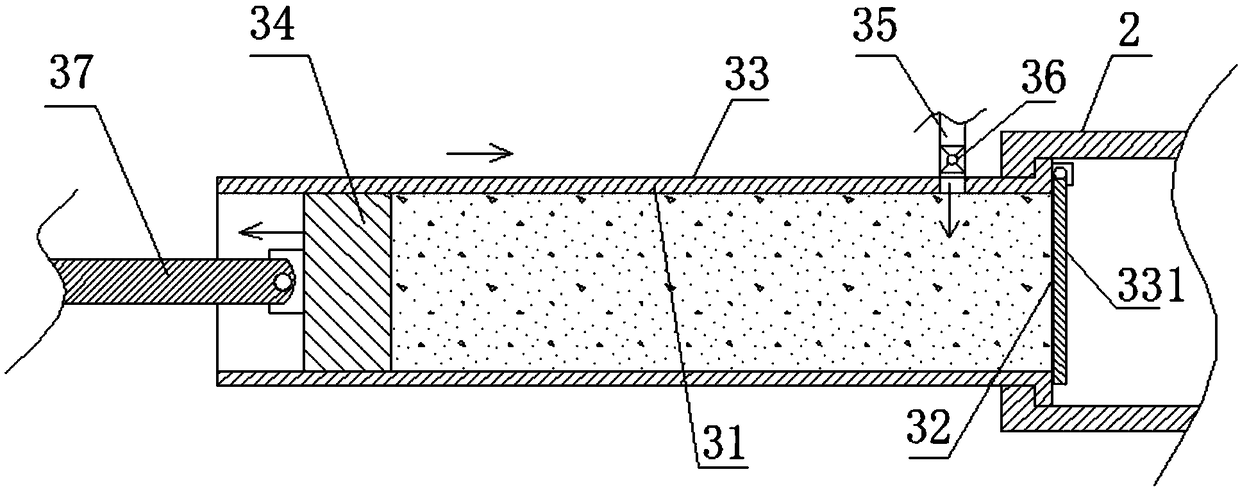

[0037] Such as Figure 1 to Figure 4 Shown, a kind of fish oil pumping device comprises fish oil temporary storage container 1, pump oil delivery pipeline 2 and two structurally identical pumping devices 3 connected in parallel between fish oil temporary storage container 1 and pump oil delivery pipeline 2; The oil inlets 31 of the pumping device 3 are connected to the fish oil temporary storage container 1 respectively, and the oil outlets 32 of the pumping device 3 are respectively connected to the pump oil delivery pipeline 2; the height of the bottom of the fish oil temporary storage container 1 is higher than that of the oil inlet The position of port 31; the pumping device 3 includes a cylinder 33 and a piston 34 that is sealed and slidably sleeved in the cylinder 33; an open end of the cylinder 33 is provided with the oil outlet 32, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com