A steel pipe beveling machine

A technology of beveling machine and steel pipe, which is applied to the details of milling machine equipment, metal processing equipment, milling machine equipment, etc., can solve the problems of small application range and unreasonable design of pipe fixtures, etc., and achieve the effect of simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

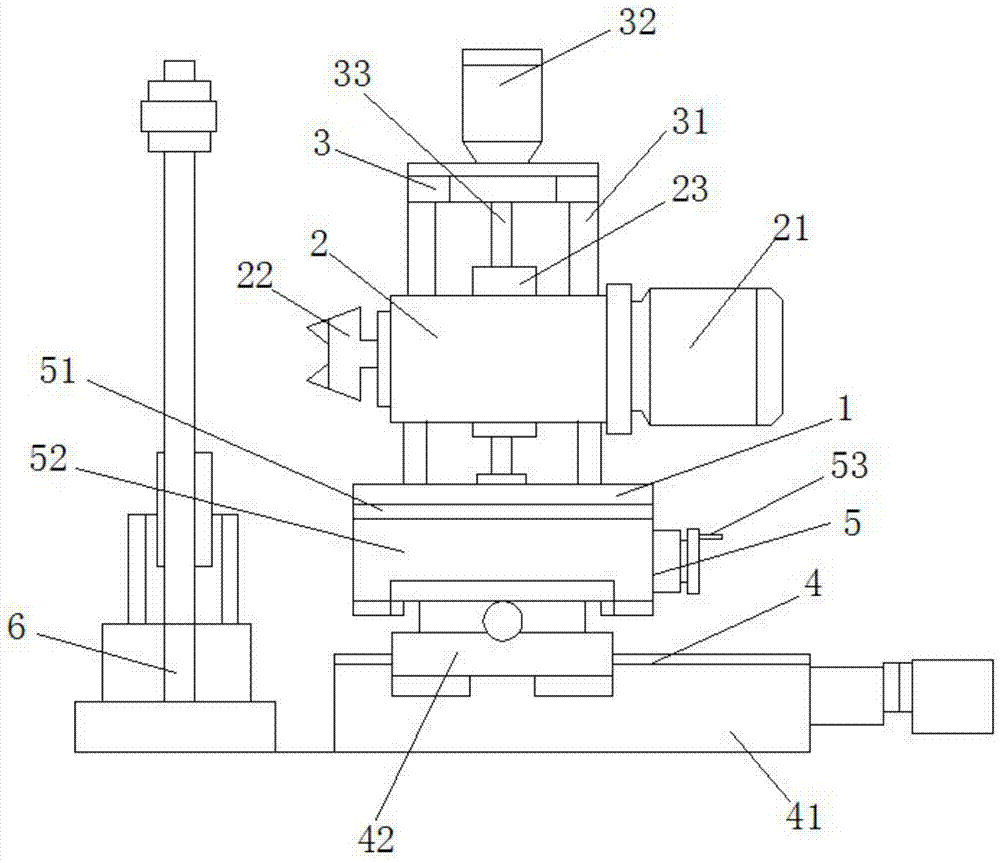

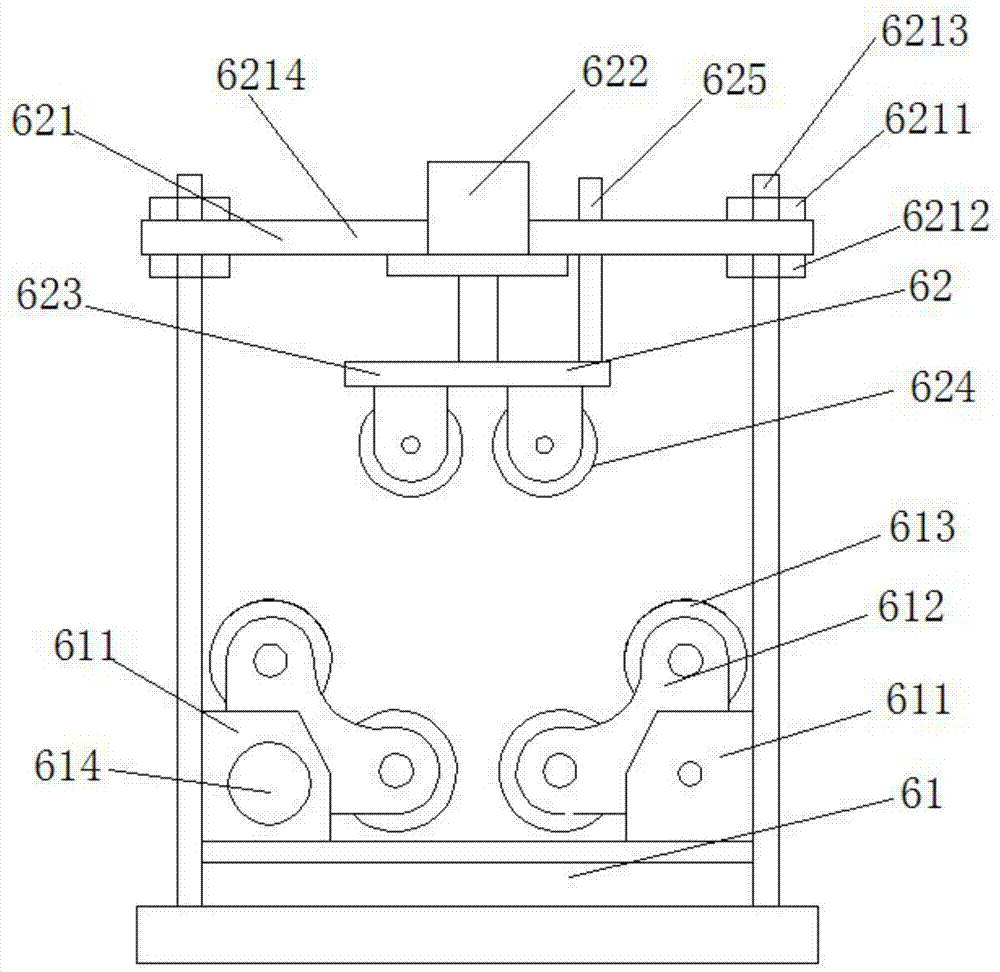

[0019] see Figure 1 to Figure 4 , The steel pipe beveling machine of this embodiment includes a support frame 1 , a milling device 2 , a lifting device 3 , a moving device 4 , a rotating device 5 and a fixing device 6 .

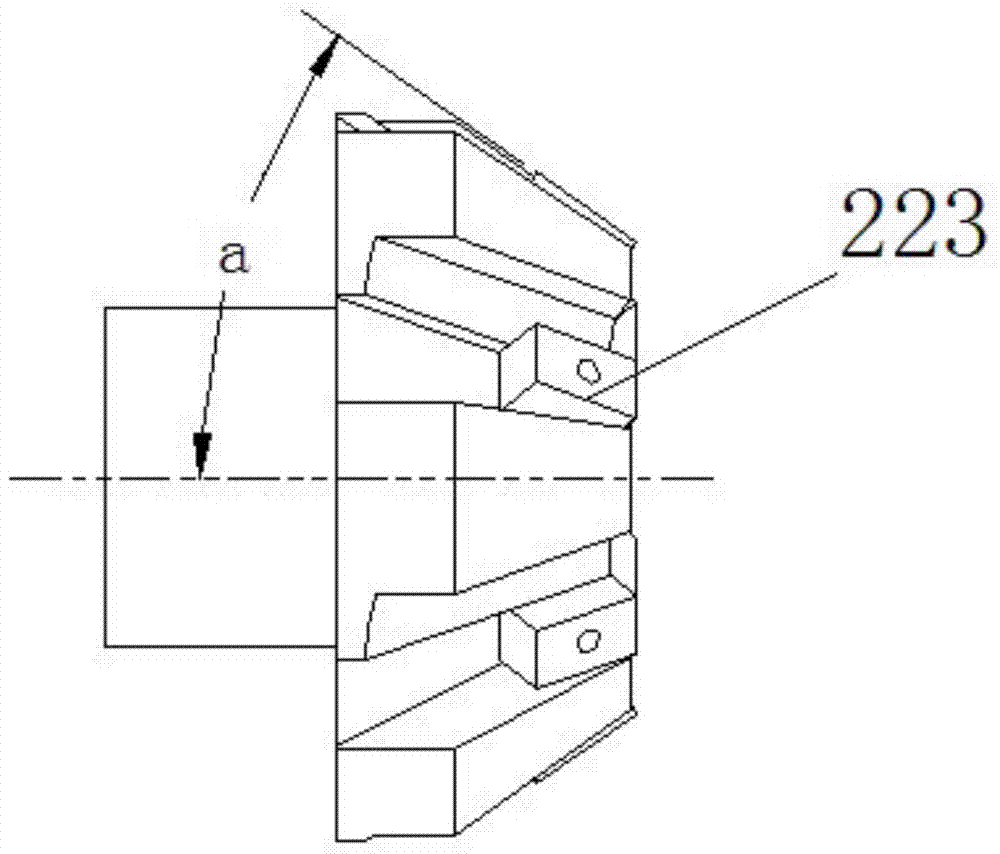

[0020] Milling device 2 among the present embodiment comprises drive motor 21 and machine head 22, and drive motor 21 drives machine head 22 to rotate, and machine head 22 comprises mounting base 221 and cutter 222, and the mounting base 221 is provided with several along its surface circular arrangement. Mounting groove 223, cutter 222 is installed in the mounting groove 223, cutter 222 has cutting edge 223, the included angle between the cutting edge 223 of cutter 222 and the axis of mounting base 221 is an acute angle, therefore, during use, needn't milling device whole Offset so that it forms a certain angle with the steel pipe, and a chip removal groove 224 is correspondingly provided on the mounting seat 221 adjacent to the mounting groove 223 . The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com