Welding equipment for copper processing

A welding equipment and platform technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of low production efficiency and insufficient continuity, and achieve the effect of improving production efficiency, wide application range, and realizing continuous welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

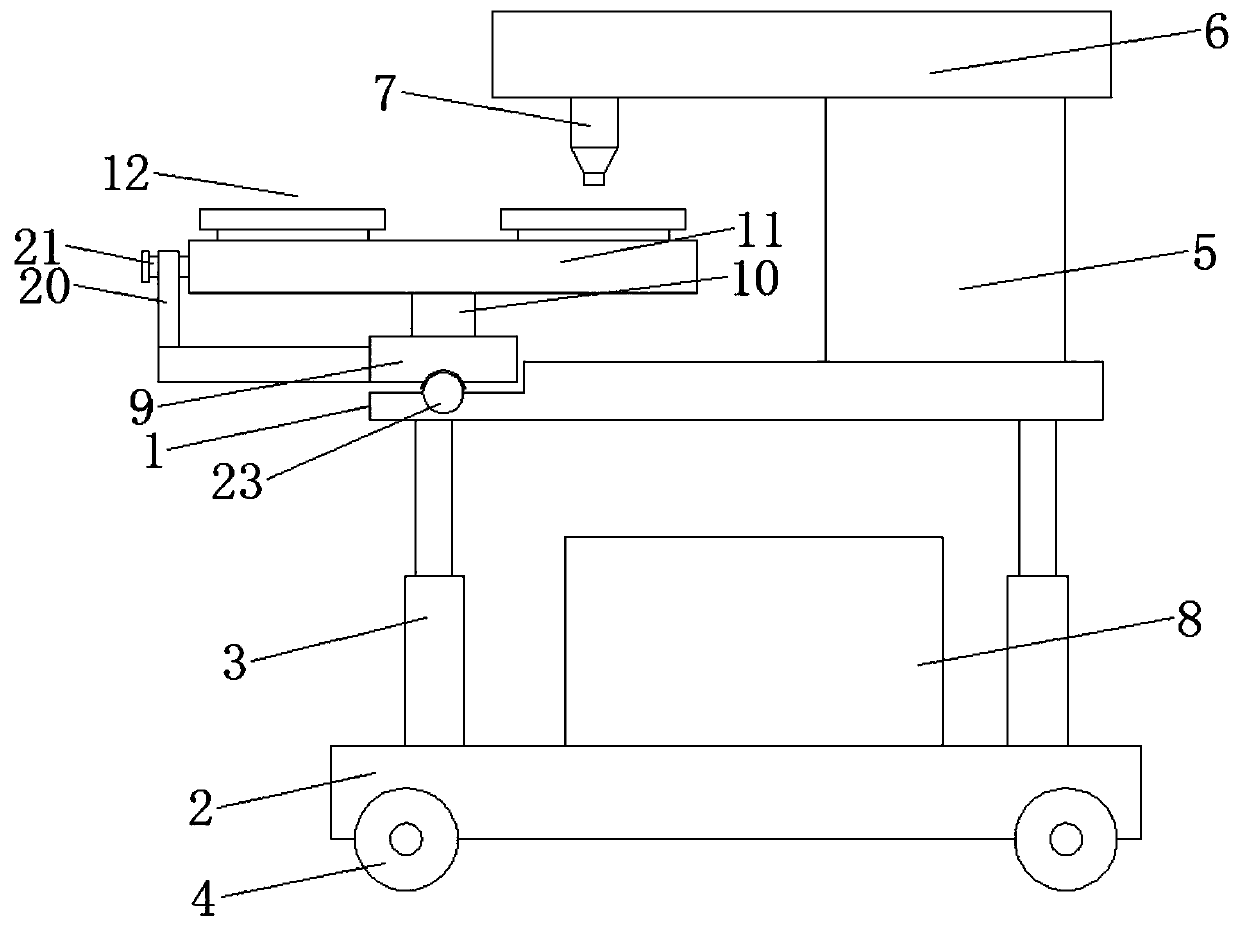

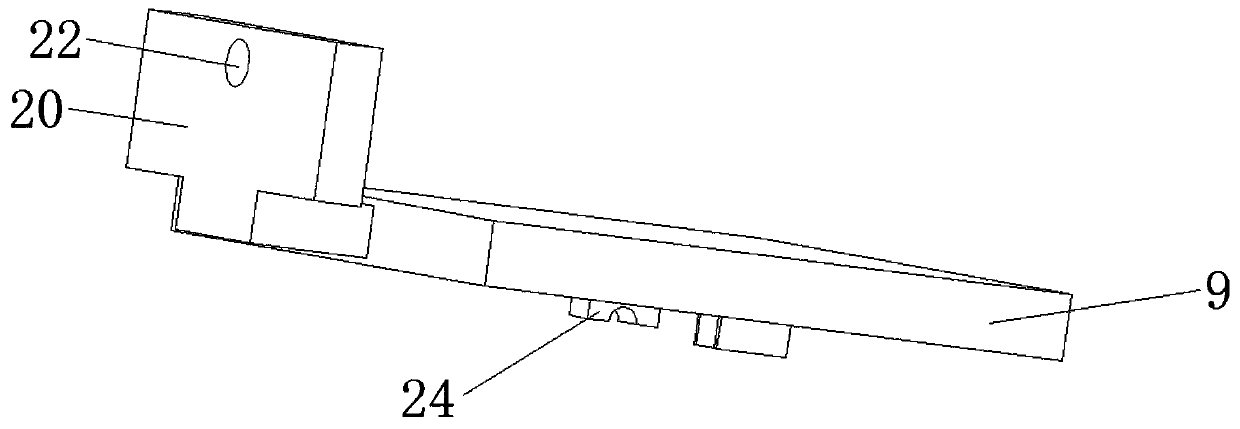

[0019] Please refer to the figure, in the embodiment of the present invention, a welding equipment for copper processing includes a platform 1, a base 2, a lifting leg 3, a roller 4, a support seat 5, a beam 6, an electric welding nozzle 7 and a control box 8; The platform 1 is located above the base 2, and is connected between the platform 1 and the base 2 through a plurality of vertical lifting legs 3. The lifting legs 3 are mainly composed of lifting cylinders, and the height of the platform 1 is driven by the lifting legs 3. , which is convenient for different operators to use; the underside of the base 2 is equipped with rollers 4, which makes the equipment move conveniently; On the beam 6 directly above the platform 1, a downward electric welding nozzle 7 for brazing is installed on the end of the beam 6 to perform welding operations on the workpiece below, and the control box 8 is fixed on the base 2 to control the startup and shutdown of the equipment components .

[...

Embodiment 2

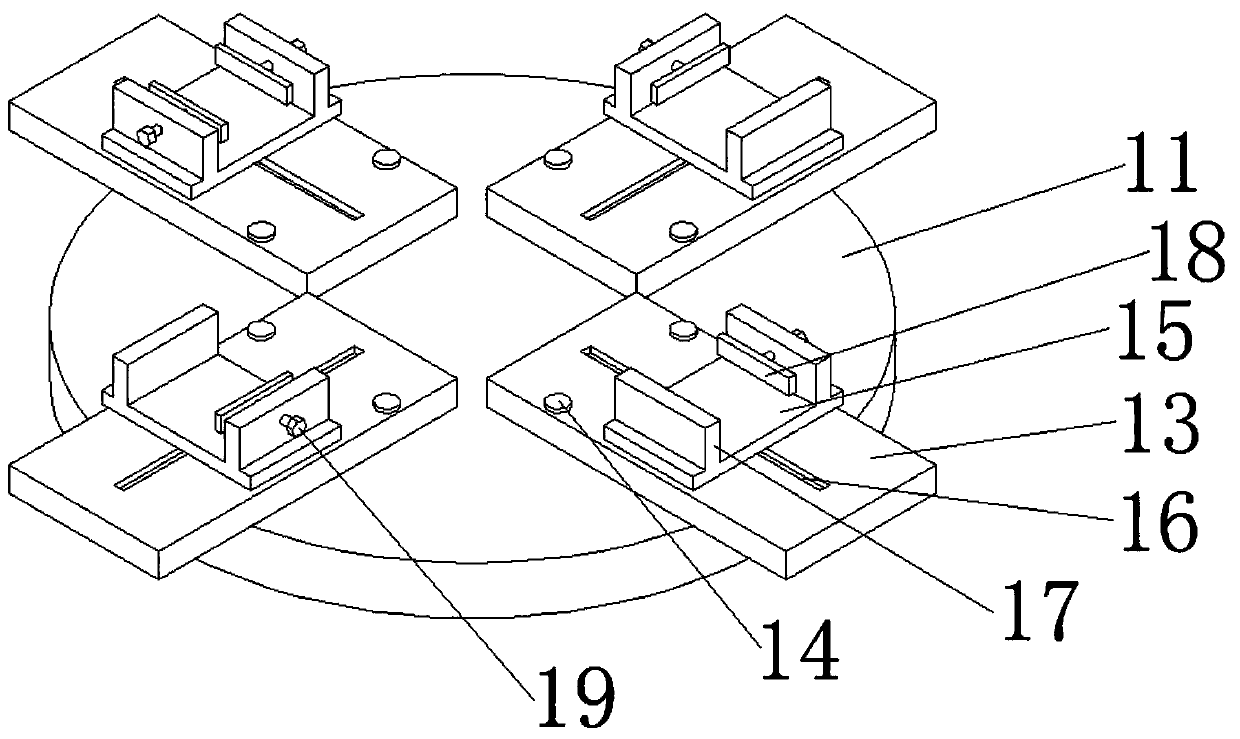

[0023] In Embodiment 1, the chute 16 can also be arranged in a direction perpendicular to the radial direction of the rotating disk 11, so that the moving seat 15 on it can move in another direction to realize welding in different directions, It is also possible to adjust the direction of the chute 16 as required, so that the electric welding nozzle 7 is convenient for welding the workpiece when the moving seat 15 is moved, so as to improve the flexibility of use.

[0024] When in use, the height of the platform 1 is adjusted through the lifting legs 3, which is convenient for operation. The clamping and moving mechanism 12 is selected according to the workpiece to be welded, and the workpiece is installed on the clamping and moving mechanism 12. By rotating the rotating disk 11, different clamping Hold the moving mechanism 12 directly below the electric welding nozzle 7, start the electric welding nozzle 7 to weld the bottom, and at the same time push the moving seat 15 to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com