Patents

Literature

30results about How to "Fast Chip Evacuation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

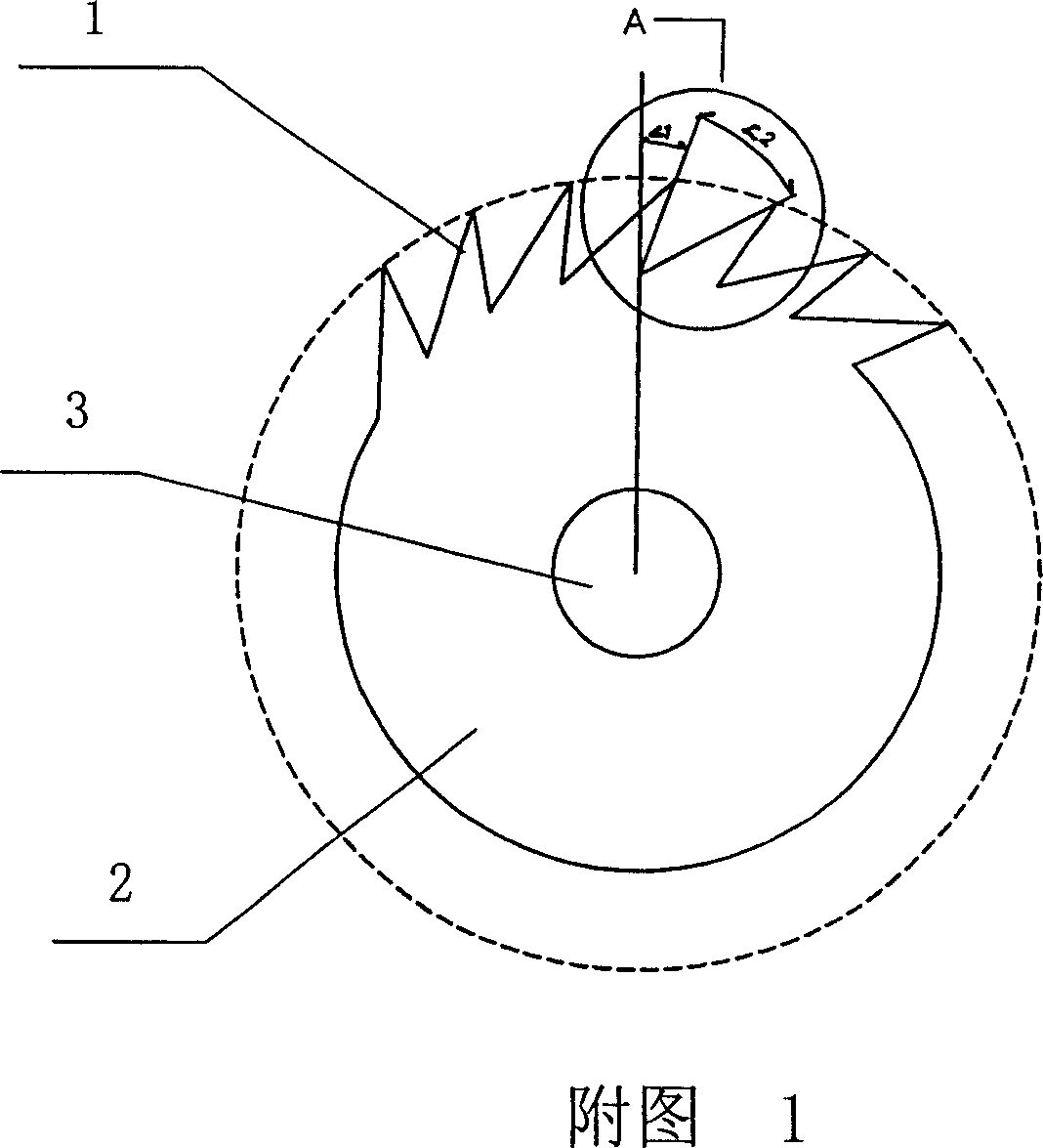

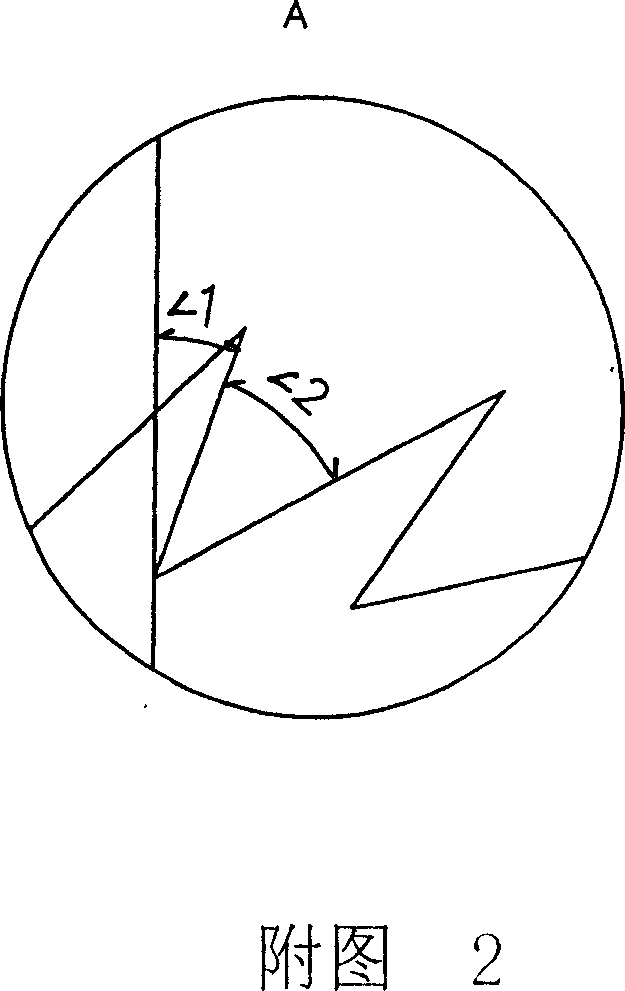

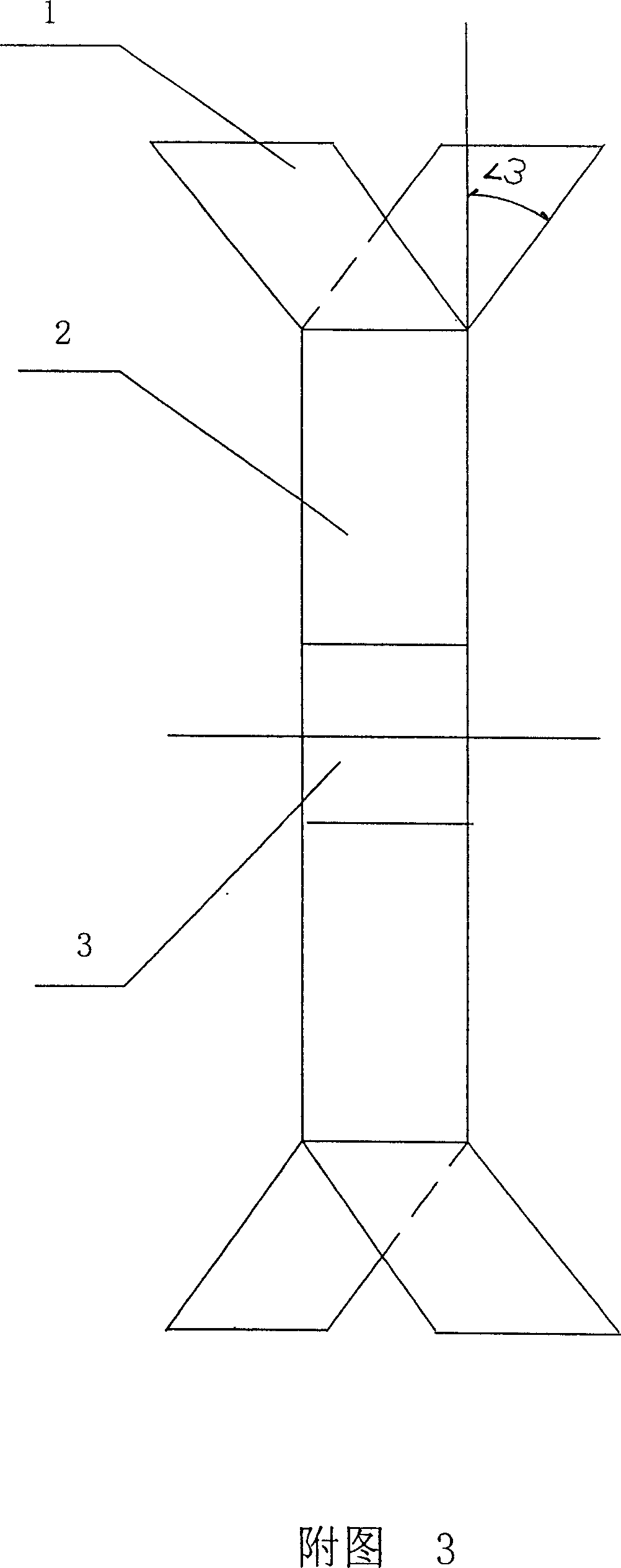

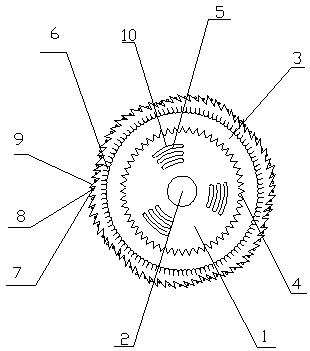

Cast-cutting saw slice and manufacturing technique thereof

InactiveCN1923418AIncrease speedFast Chip EvacuationMetal sawing tool makingMetal sawing toolsEngineeringMachining

The invention relates to a cutting saw, which is formed by round main body with round hole at center and continuous tooth at the edge. Wherein, the tooth sharps are alternatively formed at two sides of main body; the angles of said tooth are same, while the best is 3-6degree; it has better chip remove effect, without tooth breakage; the tooth are incline forwards at 3-20degree; the angle between two nearby tooth is 45-65degree; when cutting, said tooth can quickly discharge chip, therefore, it has high rotation speed, while the maximum speed is 8000n / min. And its production comprises shaping, rough machining, milling tooth, thermally processing, and grinding, without hurting processed tooth in grinding.

Owner:王鸿建

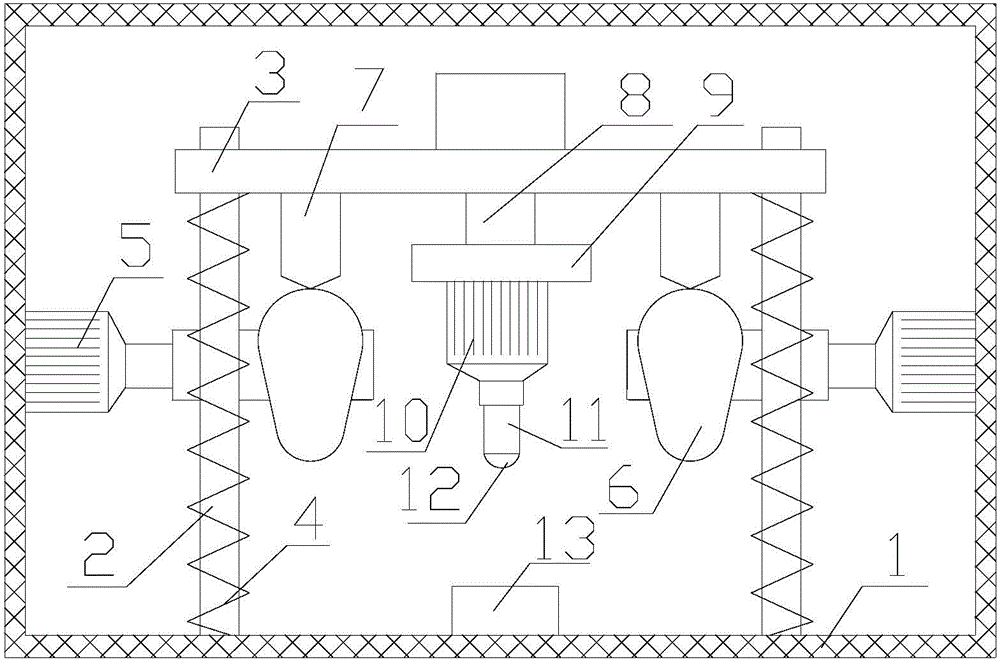

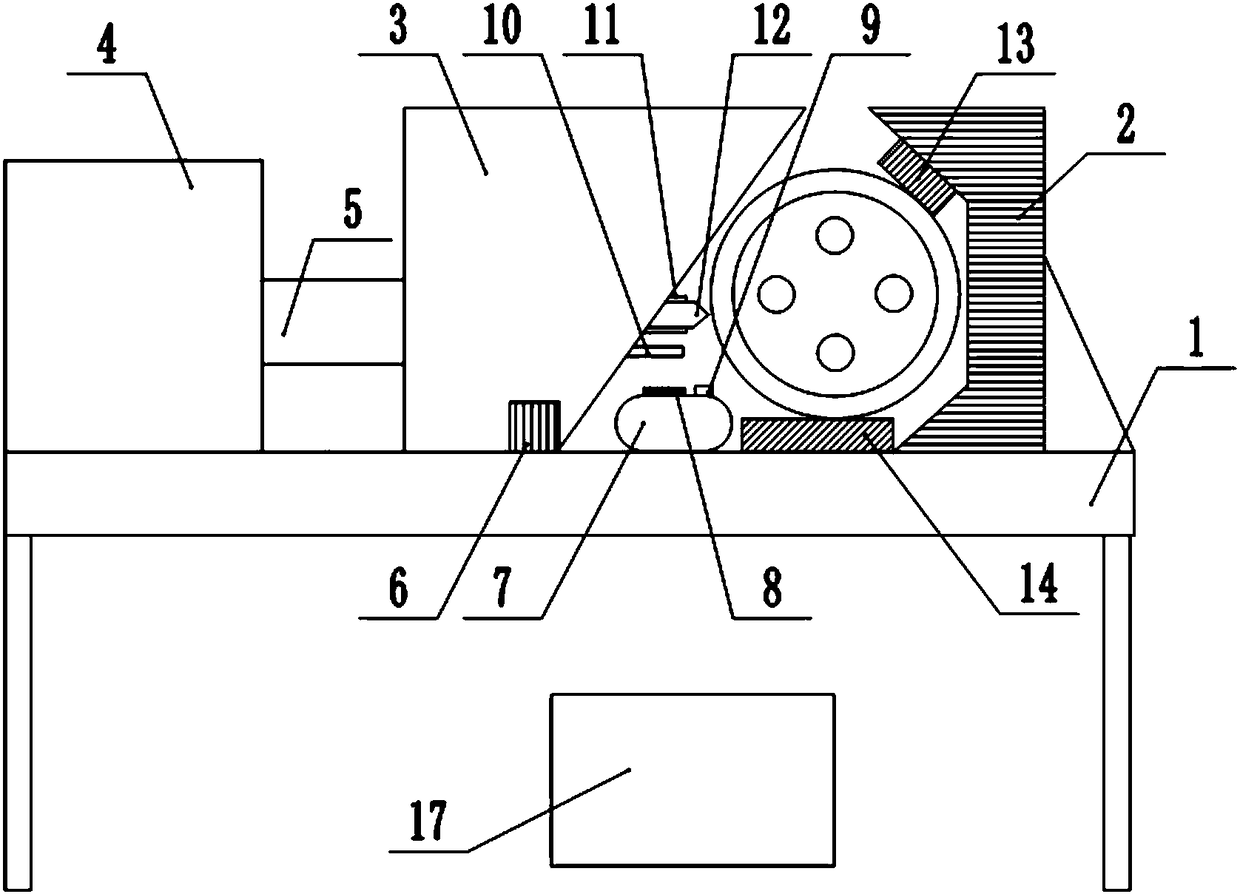

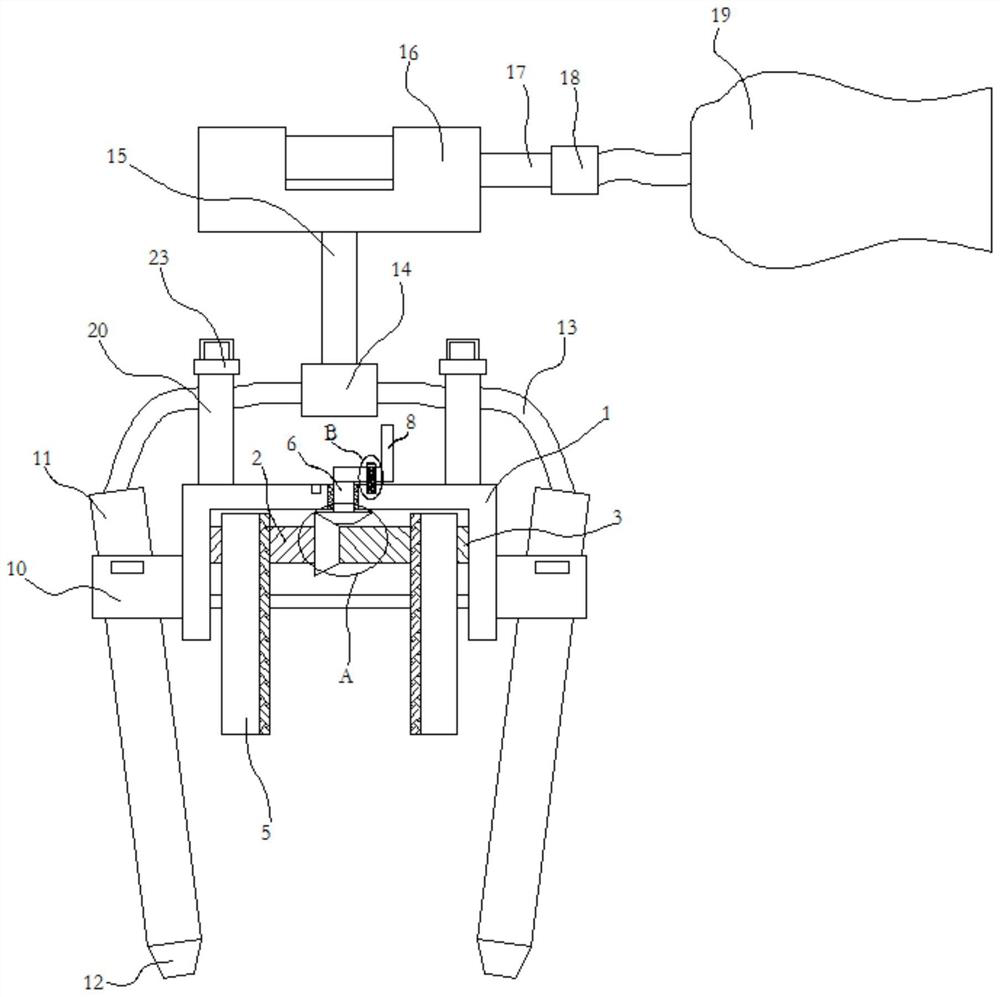

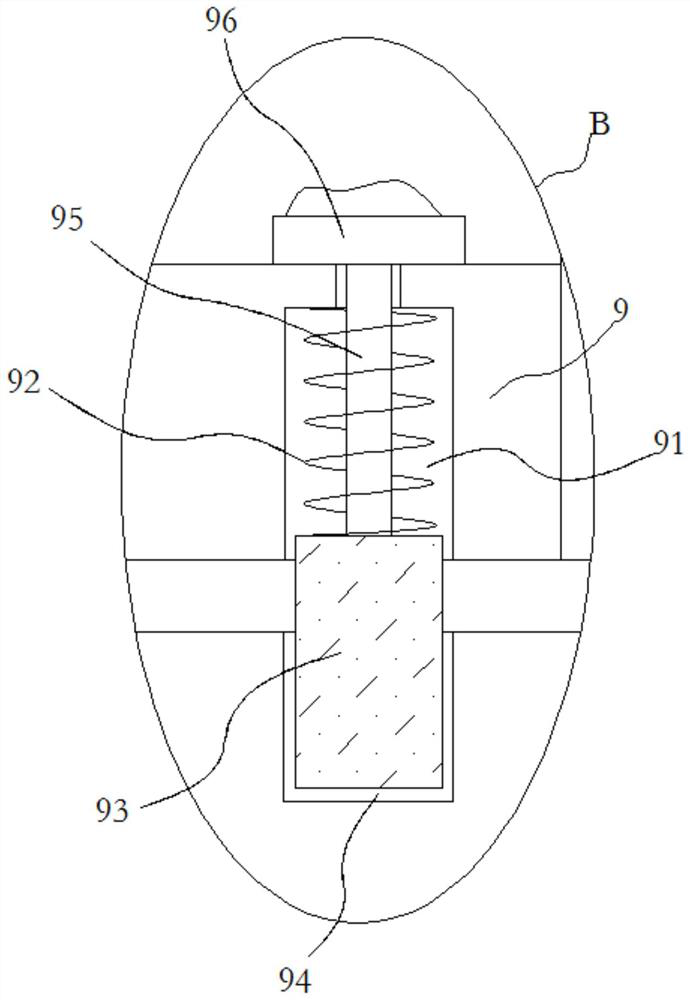

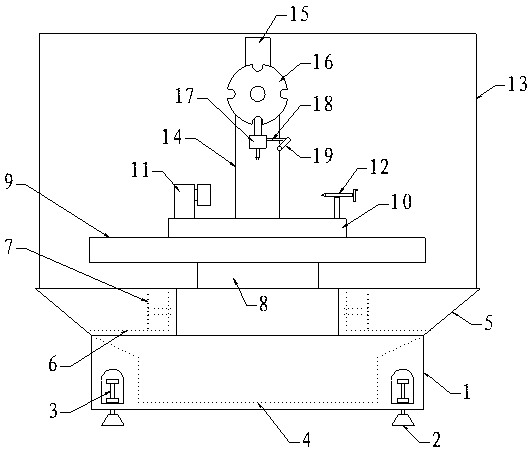

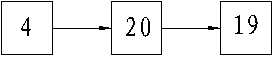

Novel self-chip-removal machine tool

InactiveCN104889445ASmooth chip removalFast Chip EvacuationFeeding apparatusDriving apparatusEngineeringCam

The invention provides a novel self-chip-removal machine tool. The cutting efficiency is effectively improved through vibrating drilling, and the novel self-chip-removal machine tool is smooth in chip removal and high in chip removal speed. A guide rod is arranged on the machine frame. An upper supporting plate is connected to the periphery of the guide rod in a vertical sliding and sleeving mode. The two ends of each spring are fixedly connected to the upper supporting plate and a machine frame respectively. A first drive device is arranged on the machine frame. A cam mechanism comprises a cam and a driven rod. The cam is connected to the periphery of an output shaft of the first drive device in a sleeving mode and is driven by the first drive device to rotate. One end of the driven rod is arranged on the upper supporting plate, and the other end of the driven rod abuts against the cam. A second drive device is arranged on the upper supporting plate and can drive a lower supporting plate to move in the axial direction of the guide rod. A third drive device is arranged on the lower supporting plate and can drive a drilling assembly to rotate. A drill stem is connected with an output shaft of the third drive device. A drill bit is arranged on the side, away from the third drive device, of the drill stem. The novel self-chip-removal machine tool is used for arranging a clamping piece on the machine frame, wherein the clamping piece is used for clamping workpieces.

Owner:蚌埠市金林数控机床制造有限公司

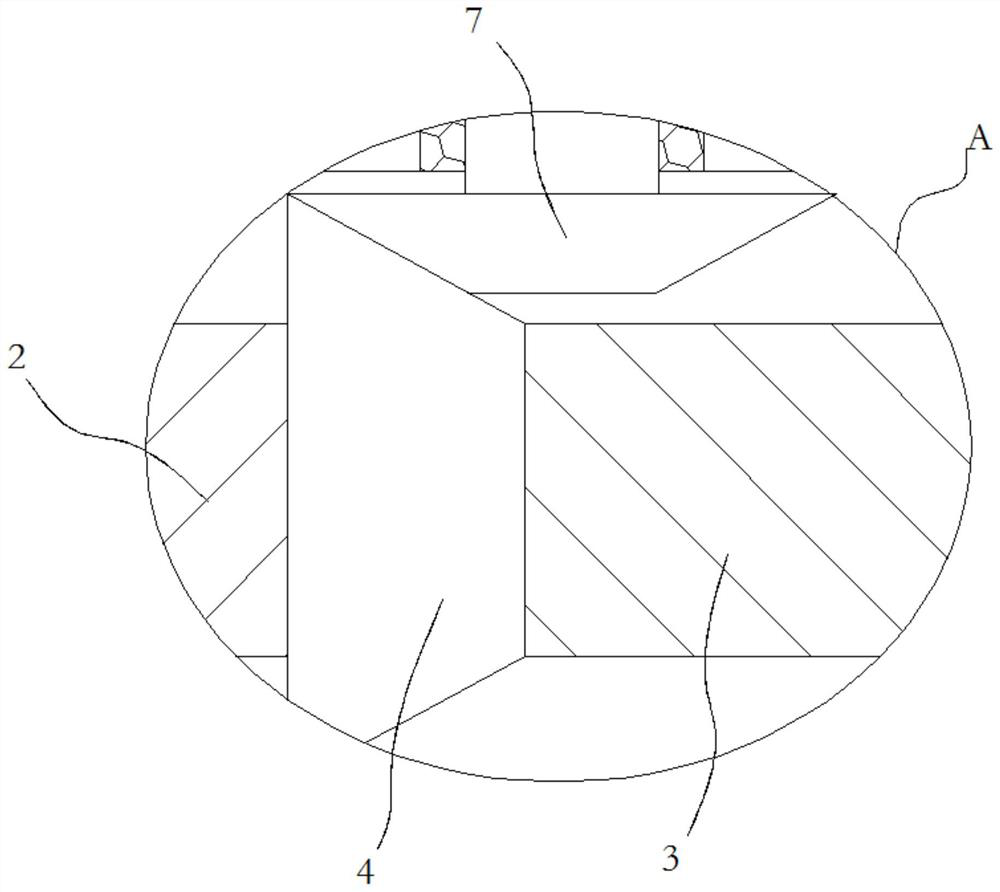

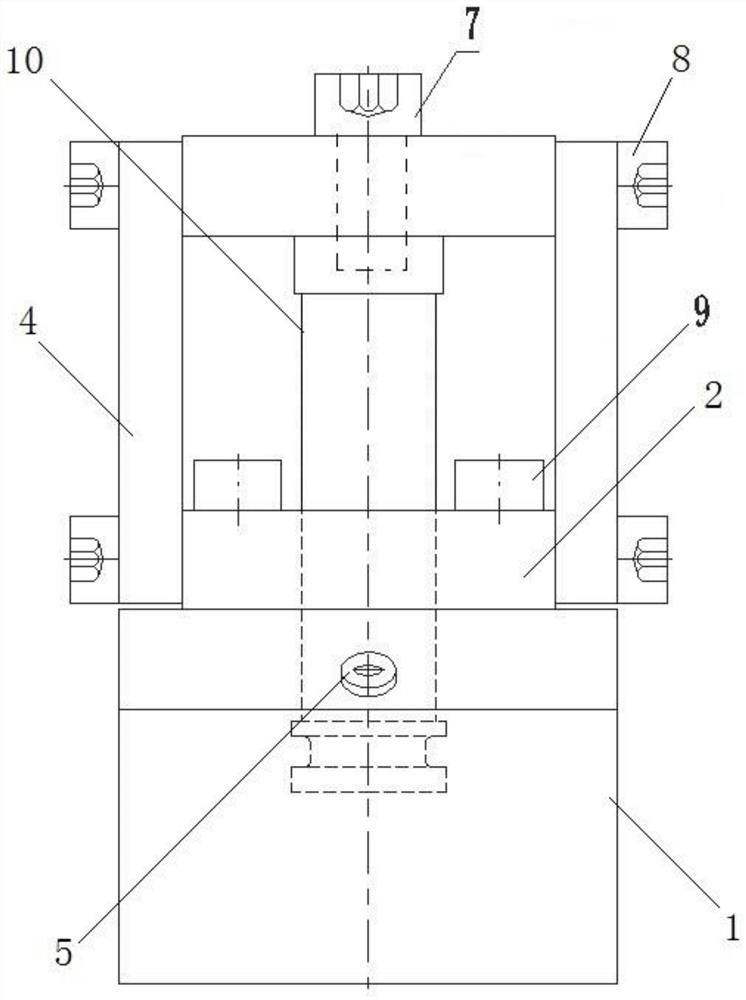

Shaft side drilling clamp

InactiveCN108127435AAvoid stickingAvoid the problem of overheating and scalding staffPositioning apparatusMaintainance and safety accessoriesCheck valveElectromagnet

The invention relates to a shaft side drilling clamp which comprises a base. A V-shaped block is fixed to the base. A pressing slider is arranged in the opening direction of the V-shaped block. The side, right opposite to the opening direction of the V-shaped block, of the pressing slider is provided with an inclined face. A check valve is arranged at the lower portion of the inclined face. The side, away from the V-shaped block, of the pressing slider is connected with a cylinder. A supporting plate is arranged between the V-shaped block and the pressing slider. A drill stem is rotationally connected into the pressing slider and connected with a motor. Teeth are formed in the outer wall of the drill stem. The drill stem is meshed with a hoop through the teeth. A plurality of scrap iron blades and a plurality of scrap discharge blades are hinged to the outer wall of the hoop. A first magnet is arranged on each scrap iron blade. A scrap stop piece is arranged on the inclined face of thepressing slider and located at the lower portion of the drill stem. A water bag is arranged on the base. A nozzle is arranged at the upper portion of the water bag. A second magnet is arranged on theupper portion of the water bag and is an electromagnet. The magnetic force of the second magnet is larger than the magnetic force of the first magnet. The problem that scrap discharging is not easy in the drilling process is solved by means of the shaft side drilling clamp.

Owner:CHONGQING HOUQUAN TECH DEV CO LTD

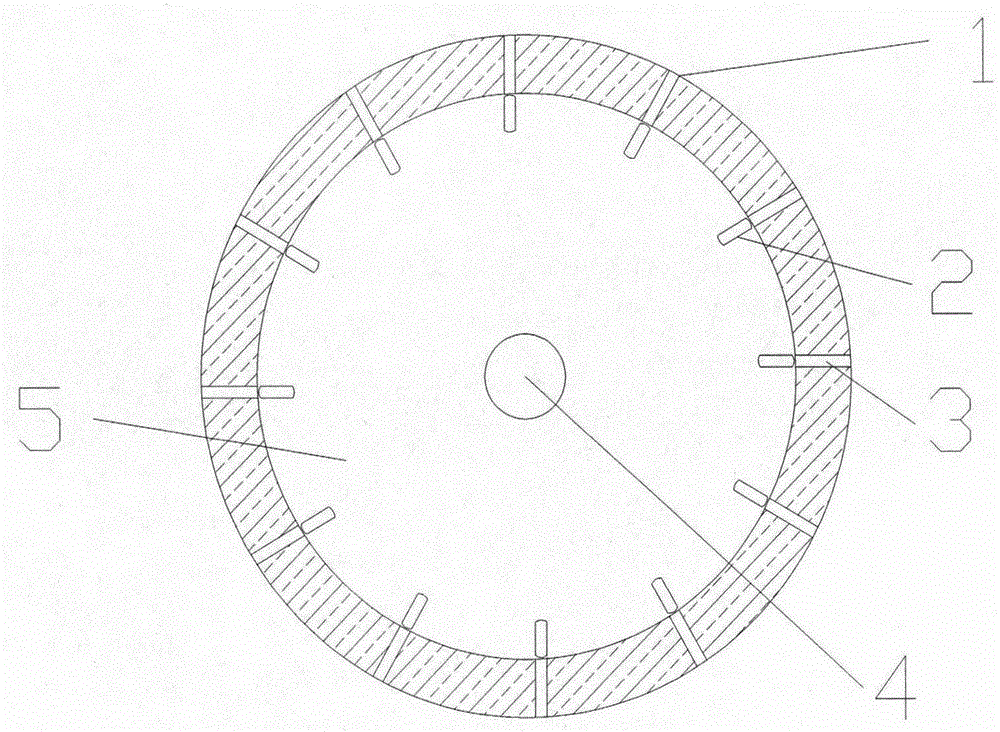

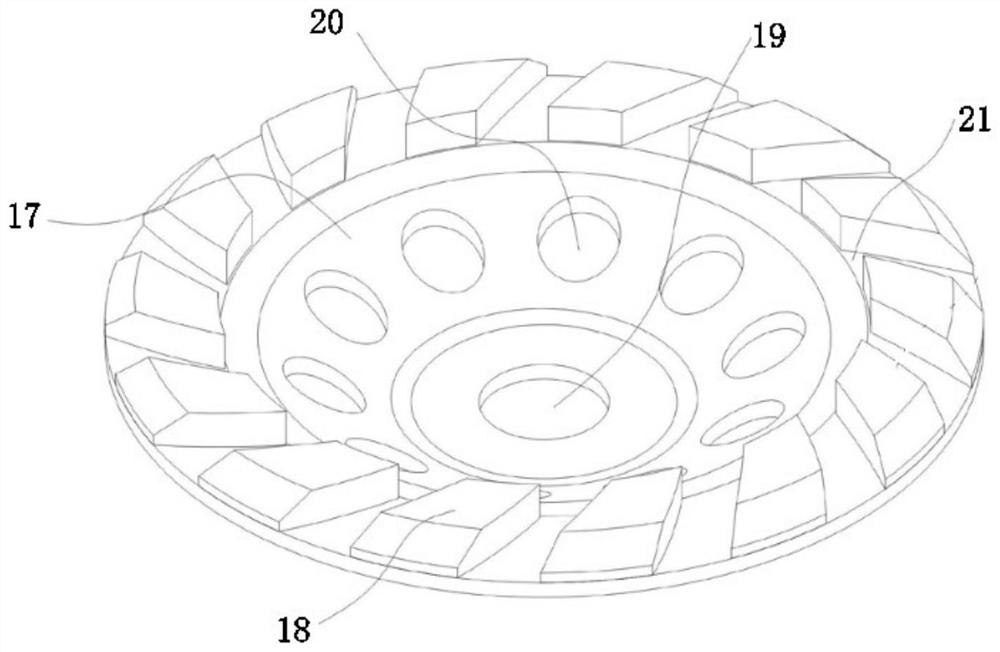

High-performance cutting disc

The invention discloses a high-performance cutting disc. The high-performance cutting disc is characterized by comprising a circular base disc; an annular cutting belt is arranged at the peripheral part of the base disc; a bearing hole for mounting a bearing is formed in the center position of the base disc; multiple strip-shaped holes are uniformly distributed between the bearing hole and the cutting belt; and a wedged groove is formed in the base disc. The high-performance cutting disc has the following advantages: the high-performance cutting disc adopts the annular cutting belt, is simple in modeling structure, and can realize effective cutting of such hard and brittle matters as ceramic and vitrification bricks; and through effective matching between the wedged groove and the strip-shaped holes, the quick chip removal and heat dissipation in the machining process are facilitated, and the service life of the cutting disc is further prolonged.

Owner:南通世纪电动工具有限公司

Improved diamond saw blade

InactiveCN107672047ASolve the problem of high friction and cutting blade not sharp enoughSmall cutting resistanceStone-like material working toolsEffective solutionEngineering

The invention discloses an improved diamond saw blade, which comprises a base body and a diamond cutter head. An installation hole is opened in the center of the base body. There are multiple flutes. Its advantage is that: the front end of the diamond cutter head of the present invention is a sawtooth structure, and the sawtooth structure has a working slope, which can reduce the cutting resistance, and effectively solve the problem that the traditional diamond saw blade has a large friction force when cutting and the cutting blade is not sharp enough. problems; by setting up turbine-shaped grooves on the diamond cutter head, chips can be quickly removed and heat dissipation can be improved; the connection between the cutter head and the substrate is connected in a zigzag structure, so that the combination between the substrate and the cutter head is tighter, and it is not easy to drop teeth ;Through the arc-shaped grooves in the fan-shaped area on the substrate, it plays the role of chip removal, reduces cutting noise, and accelerates the cooling of the saw blade.

Owner:南通豪鼎光伏科技有限公司

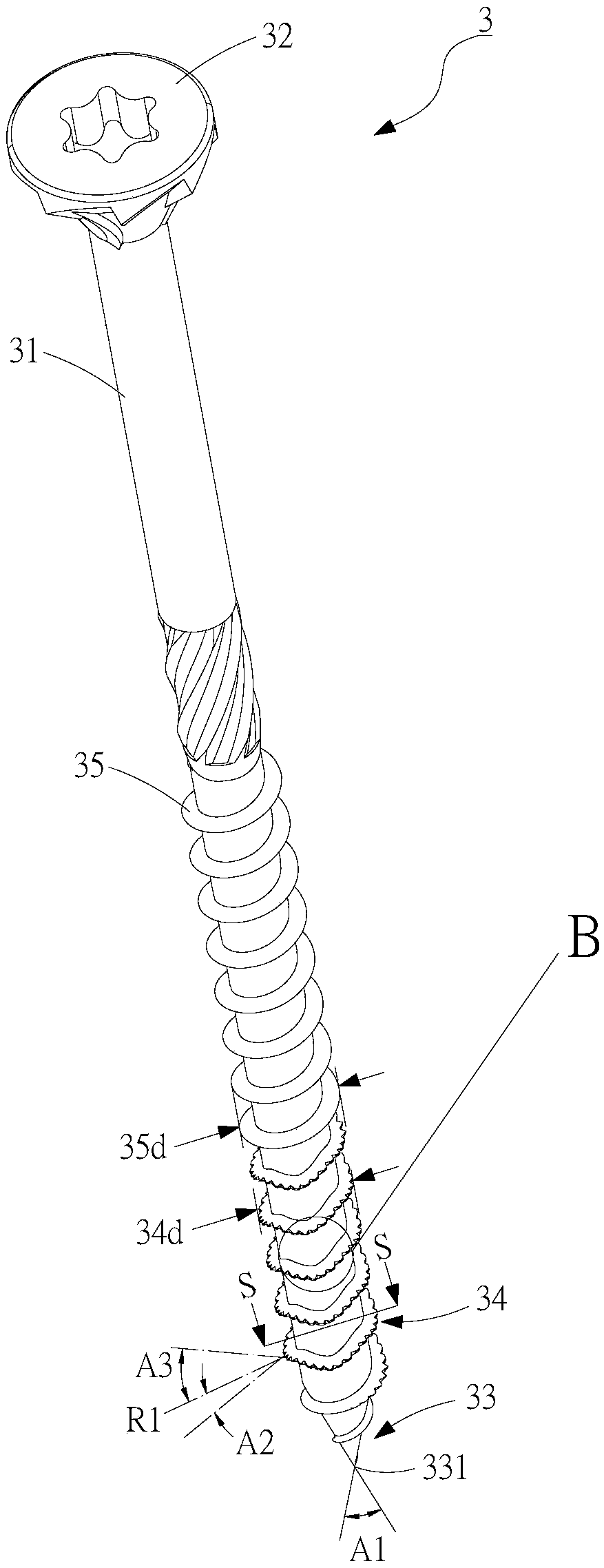

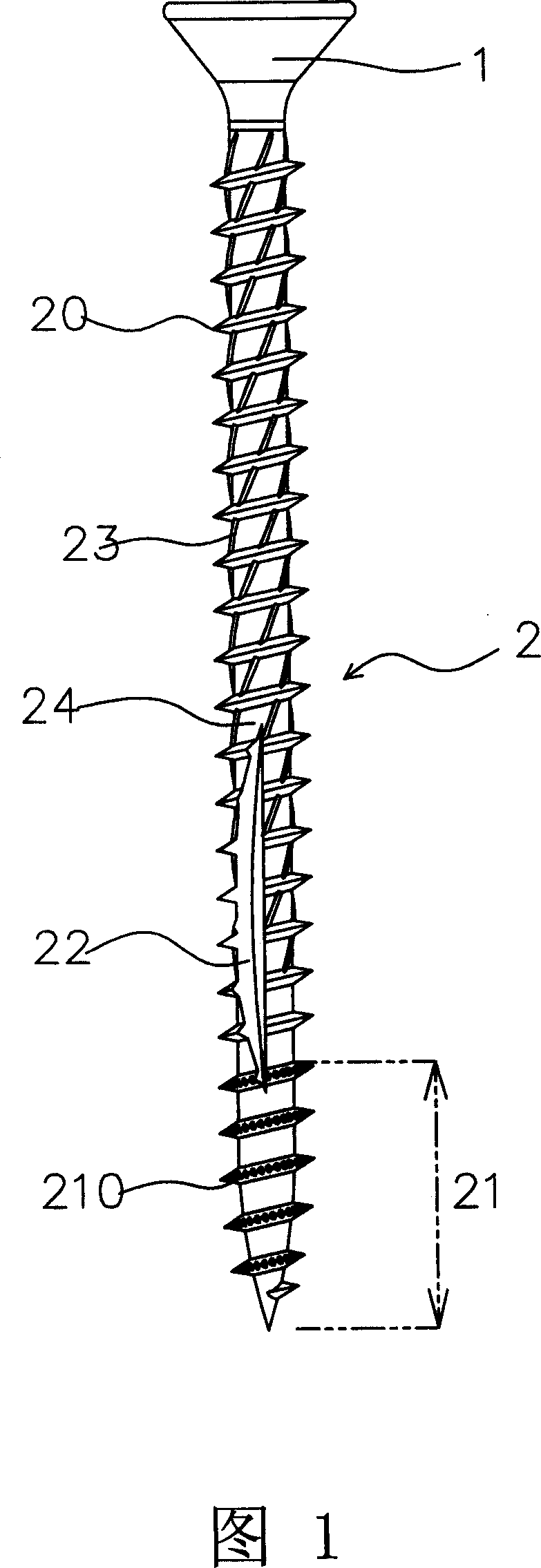

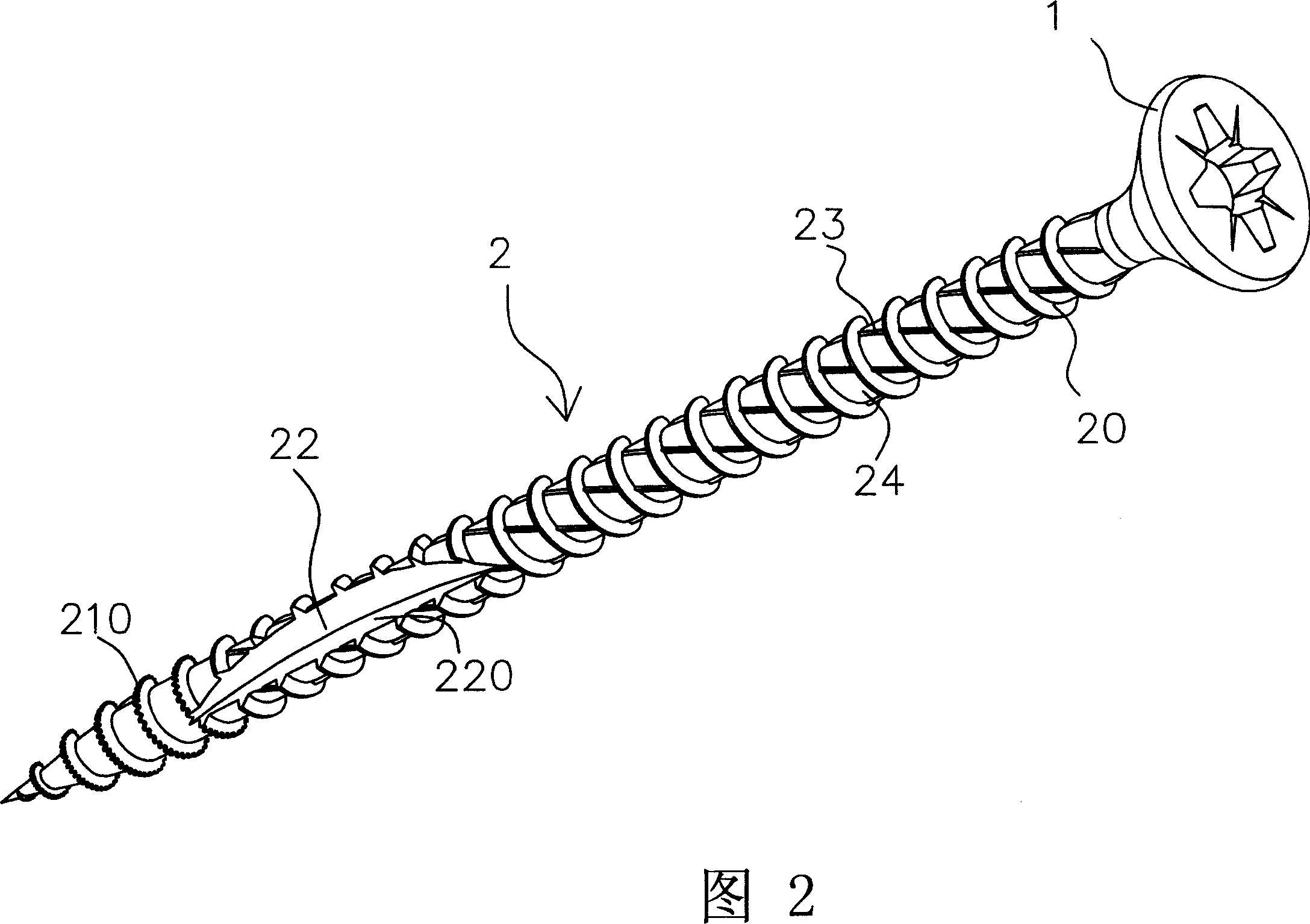

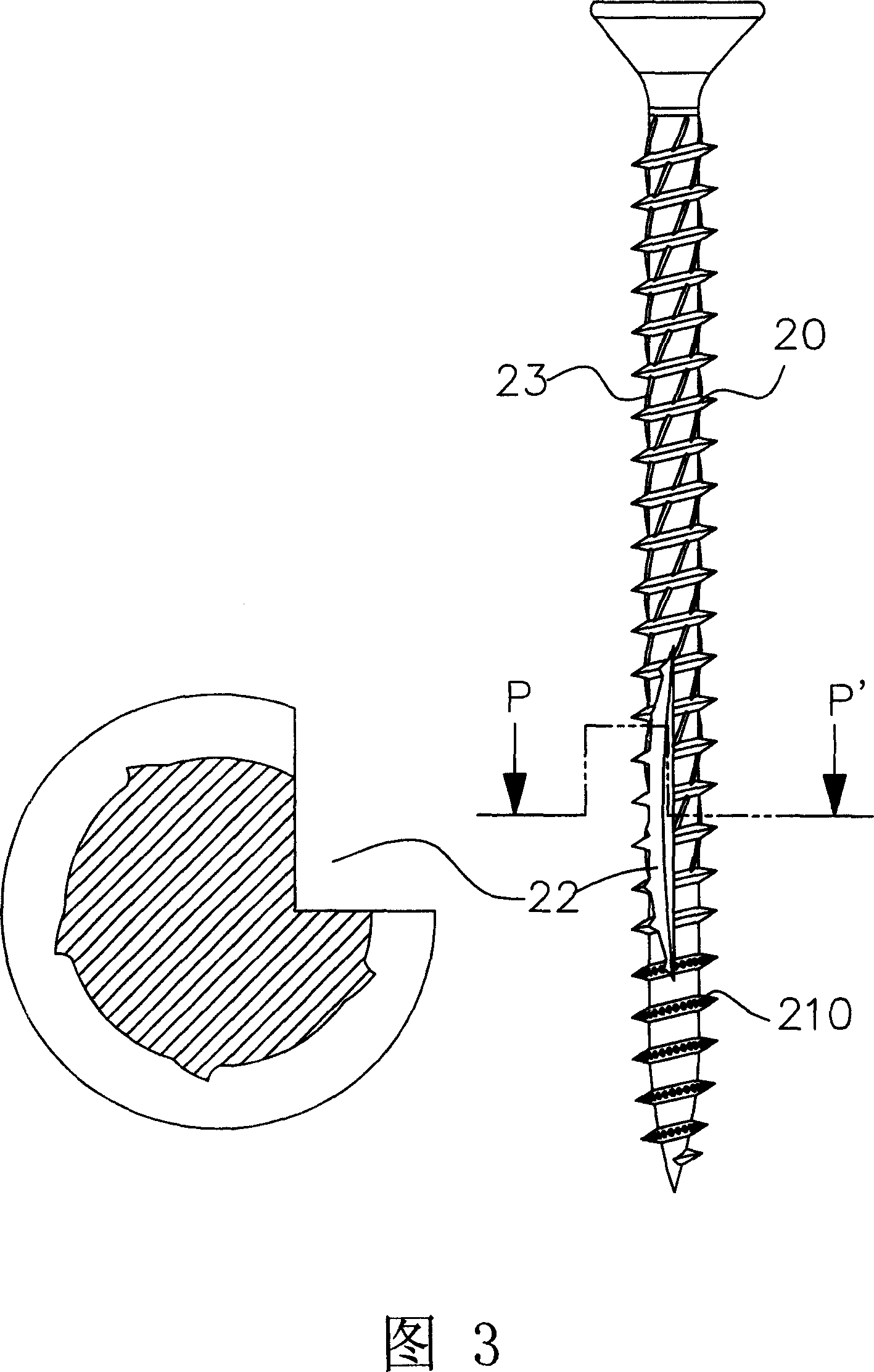

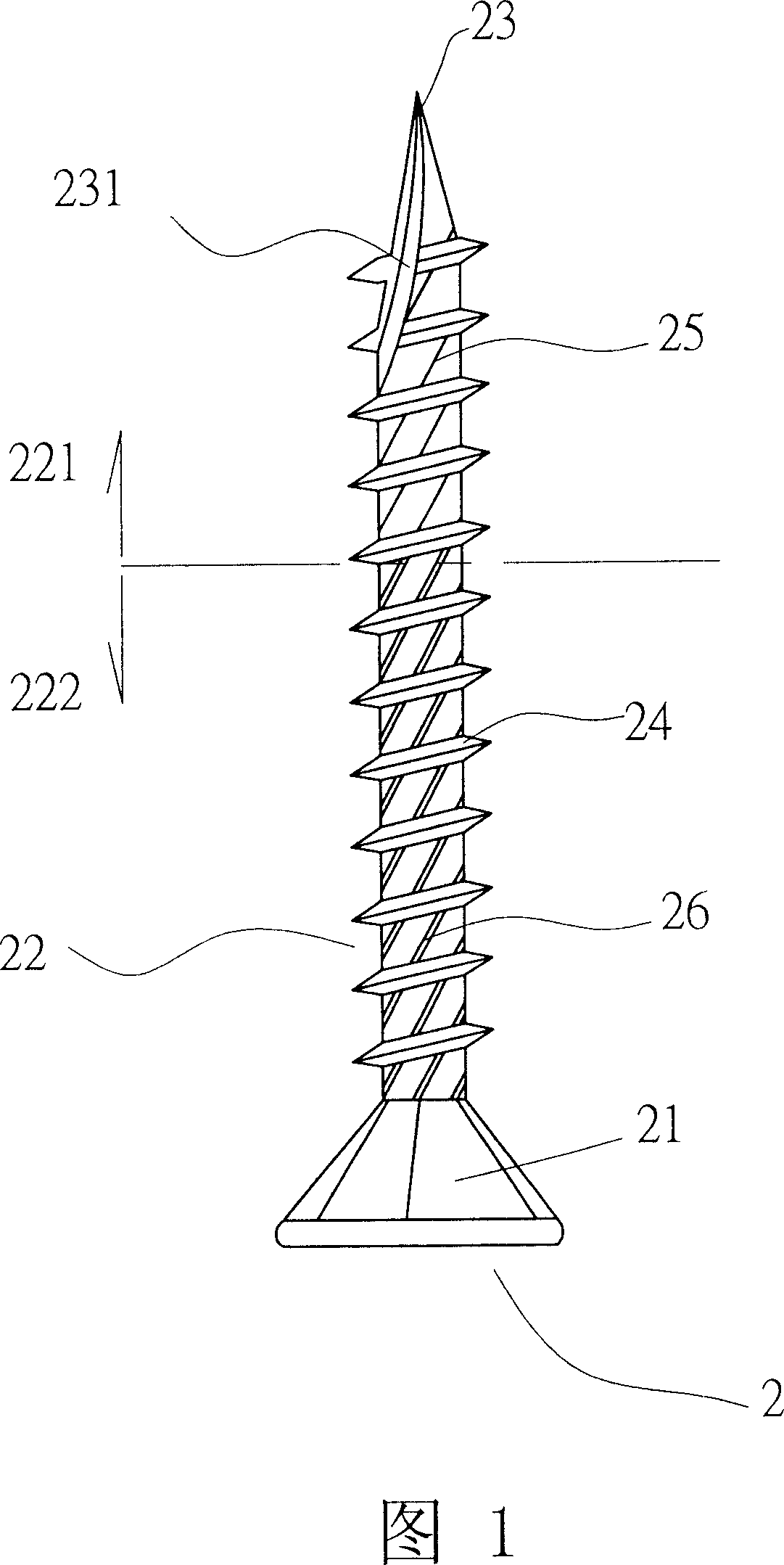

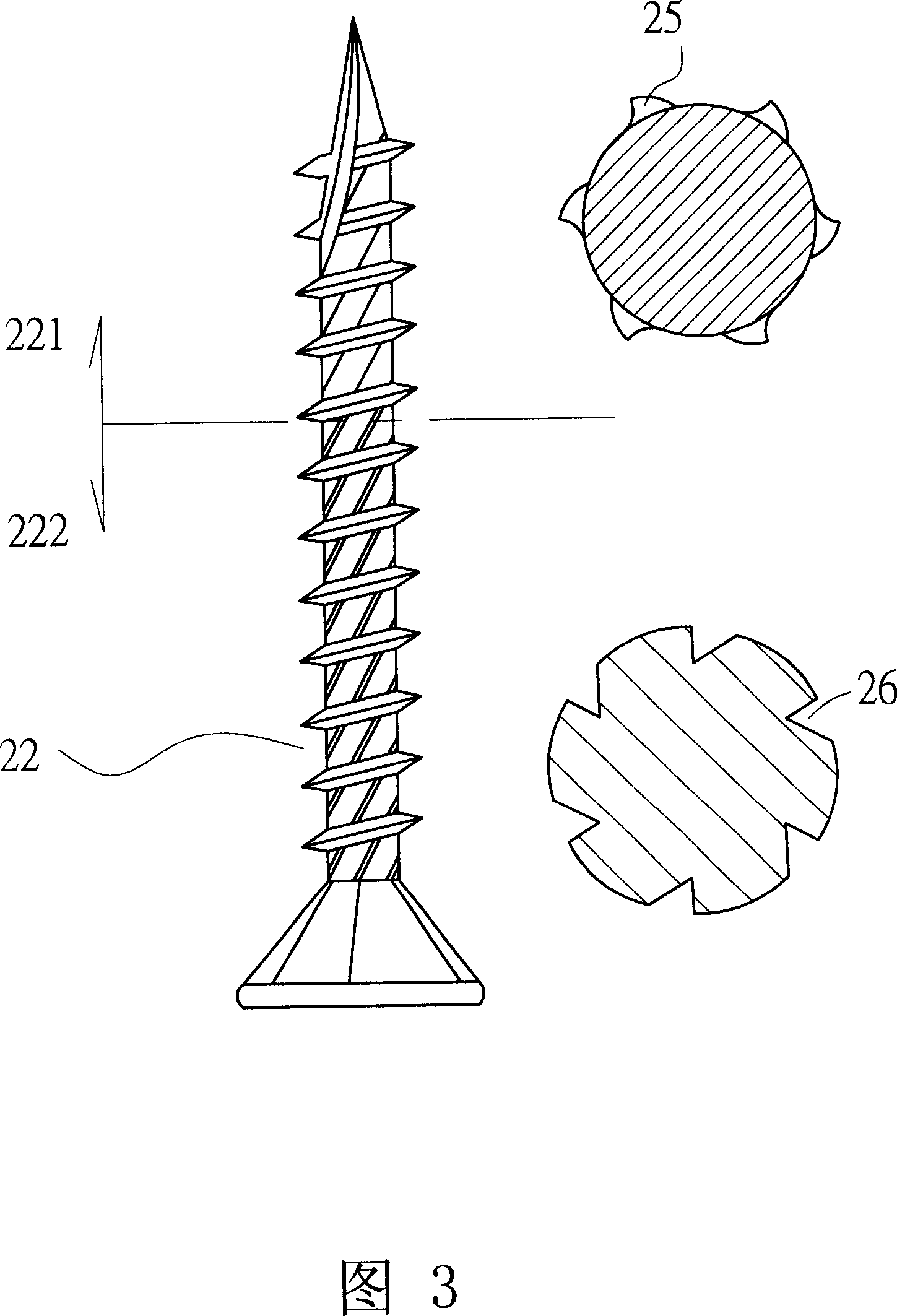

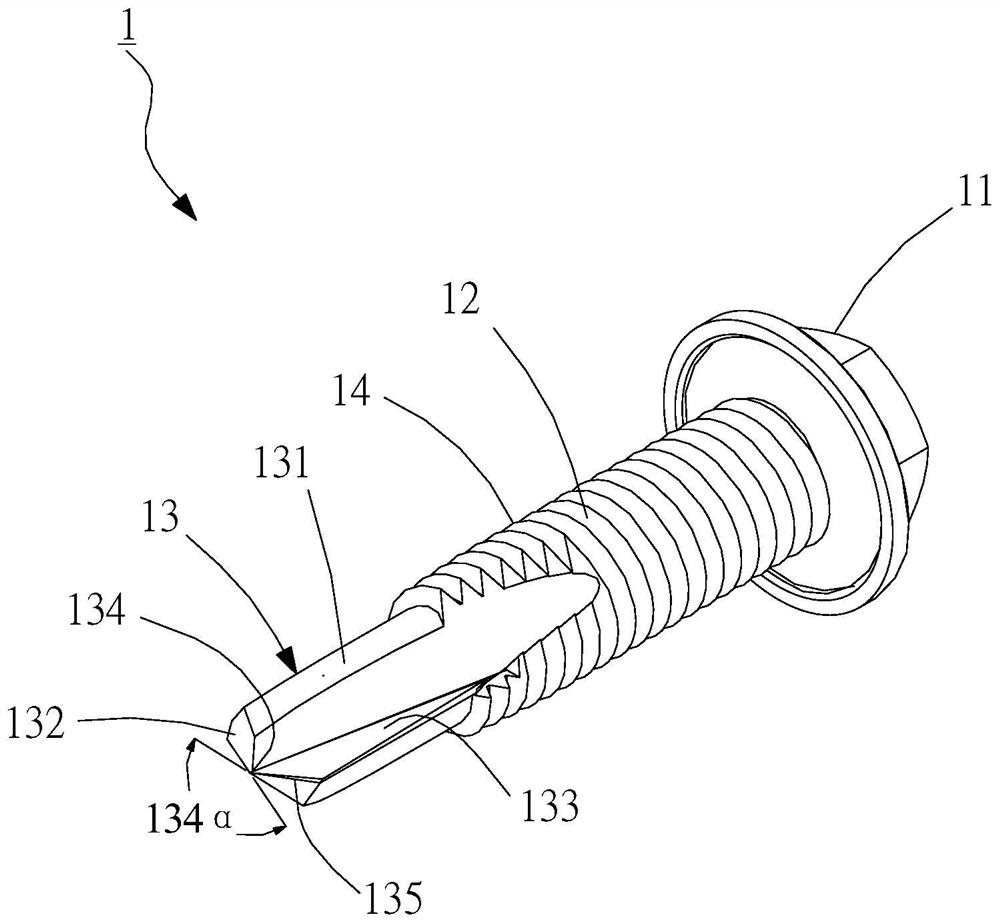

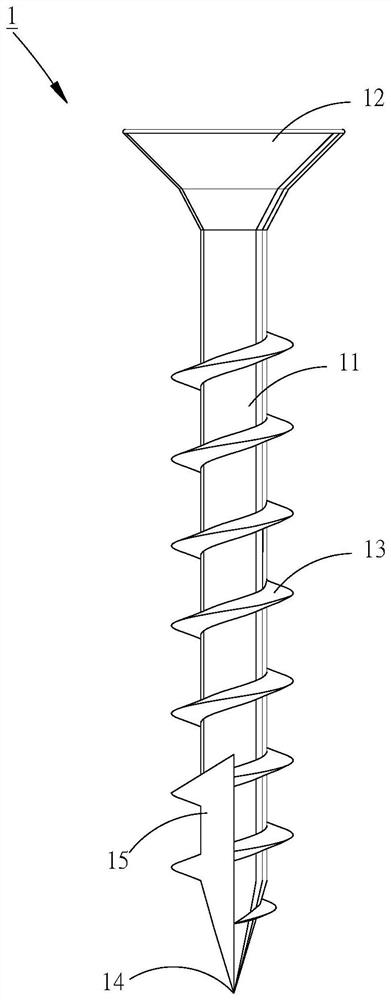

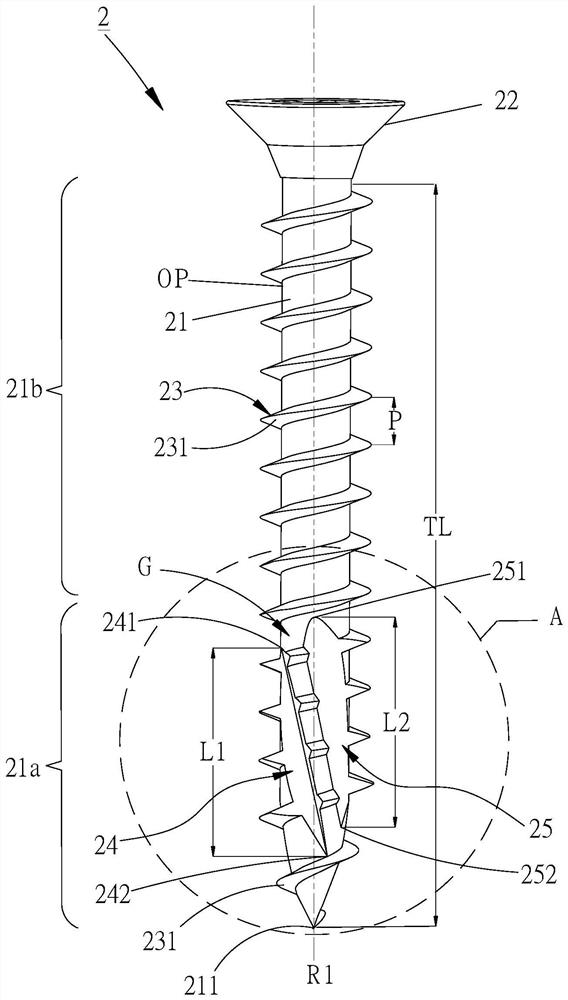

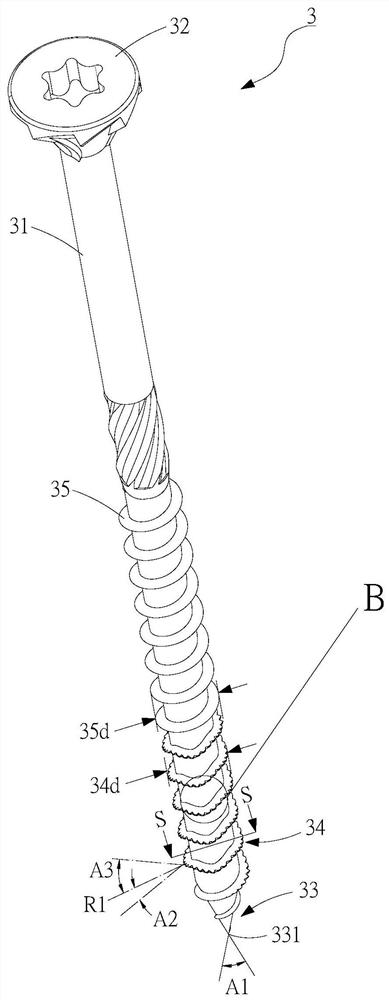

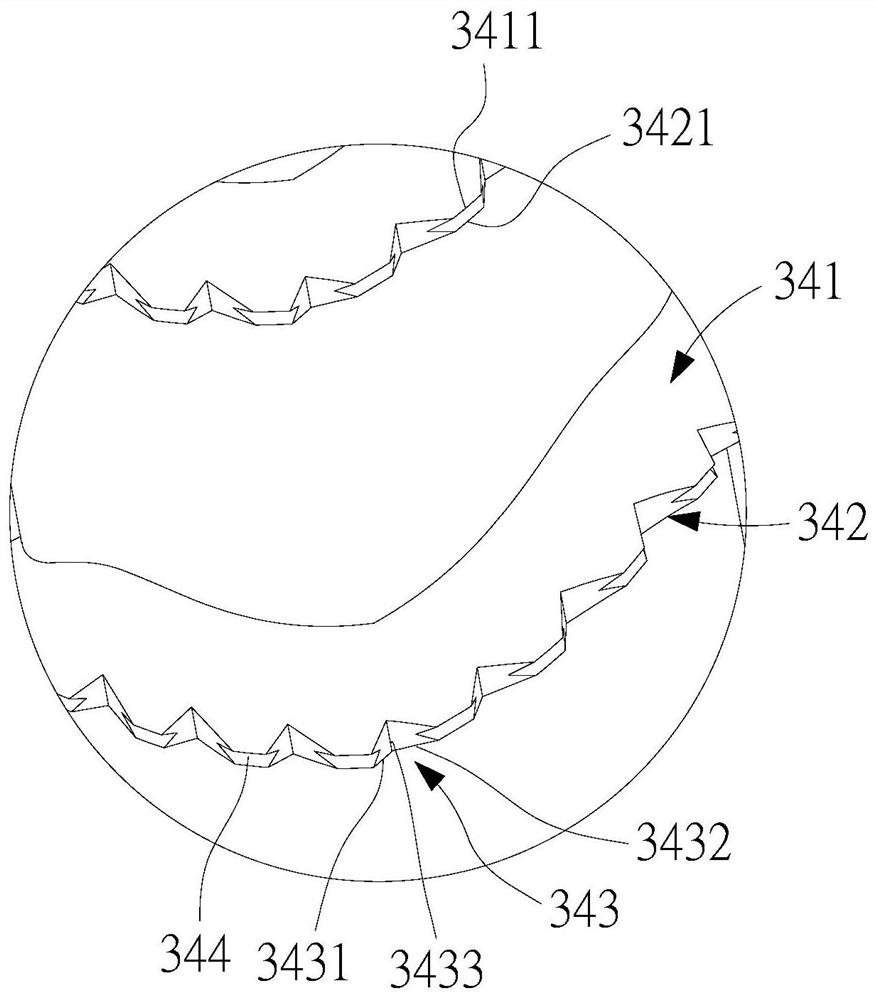

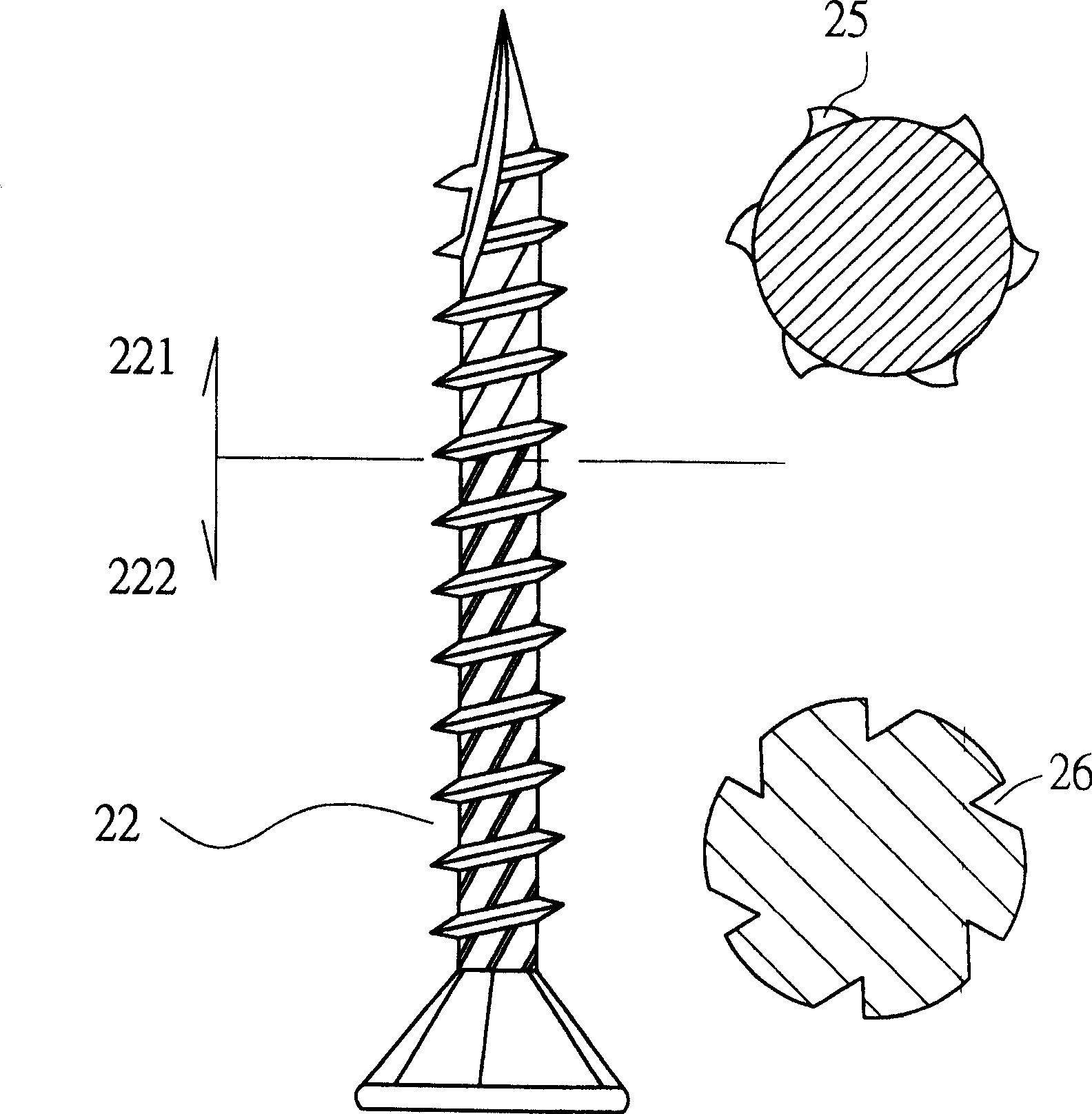

Screw with low spin lock torque

ActiveCN110886758AImproves occlusal stabilityEffective choppingBoltsScrewsPull forceClassical mechanics

Owner:TAIWAN SHAN YIN INT CO LTD

Construction ground punching device and method

InactiveCN111088946AQuick punchNovel structural designDrill bitsConstructionsPunchingArchitectural engineering

The invention discloses a construction ground punching device and method. The device comprises a fixed base, a rotating platform and a punching mechanism. Supporting legs are mounted on the bottom ofthe fixed base, lifting type rollers are mounted on the supporting legs, the rotating platform is fixedly mounted on the fixed base, a supporting stand column is arranged in the middle of the upper end face of the rotating platform, a cross beam is vertically mounted on the top of the supporting stand column, a transverse sliding rail is mounted on the lower end face of the cross beam, a fixed plate assembly is mounted below the transverse sliding rail, a first oil cylinder mounting base and a second oil cylinder mounting base are in sliding connection to the transverse sliding rail, a first oil cylinder and a second oil cylinder are mounted between the first oil cylinder mounting base and the fixed plate assembly and between the second oil cylinder mounting base and the fixed plate assembly correspondingly, and the punching mechanism is mounted below the fixed plate assembly. The construction ground punching device is novel in structural design, rapid punching of a construction groundcan be achieved, meanwhile, the punching interval can be adjusted, different positions are punched, punching stability is good, and the work efficiency can be effectively improved.

Owner:南通謇辉贸易有限公司

Lock body steel easy to drill and fast in chip removal and preparation method thereof

The invention discloses lock body steel easy to drill and fast in chip removal and a preparation method thereof, and belongs to the technical field of locks. The steel comprises the following chemical components in percentage by mass of 0.01-0.03% of C, 0-0.04% of Si, 1.6%-2.0% of Mn, 0.010%-0.030% of P, 0.40%-0.55% of S, 0.15%-0.22% of Bi, 0.005%-0.01% of Se, 0.003%-0.006% of T[O], 0.004%-0.006% of B and the balance of Fe and inevitable impurities. According to the steel, a certain amount of Bi and Se are compositely added, and the content of Mn and S in the steel is optimized, so that the sizes and forms of Mn (S, Se), ferrite and pearlite of the lock body steel are effectively controlled, the hardness of the steel is further reduced, the chip removal and breaking capabilities in the drilling process of the steel are improved, and the service life of a drill bit is prolonged; and in the preparation process, through forging, hot rolling, staged cooling and shot blasting processes, a lock body steel product with a matrix ferritic structure, a small amount of pearlite structures and excellent drilling performance is finally obtained, and the product is low in hardness, easy to drill, fast in chip removal, fast in heat dissipation and small in abrasion to a high-speed drill bit and can be widely used for manufacturing padlocks and calabash lock bodies.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

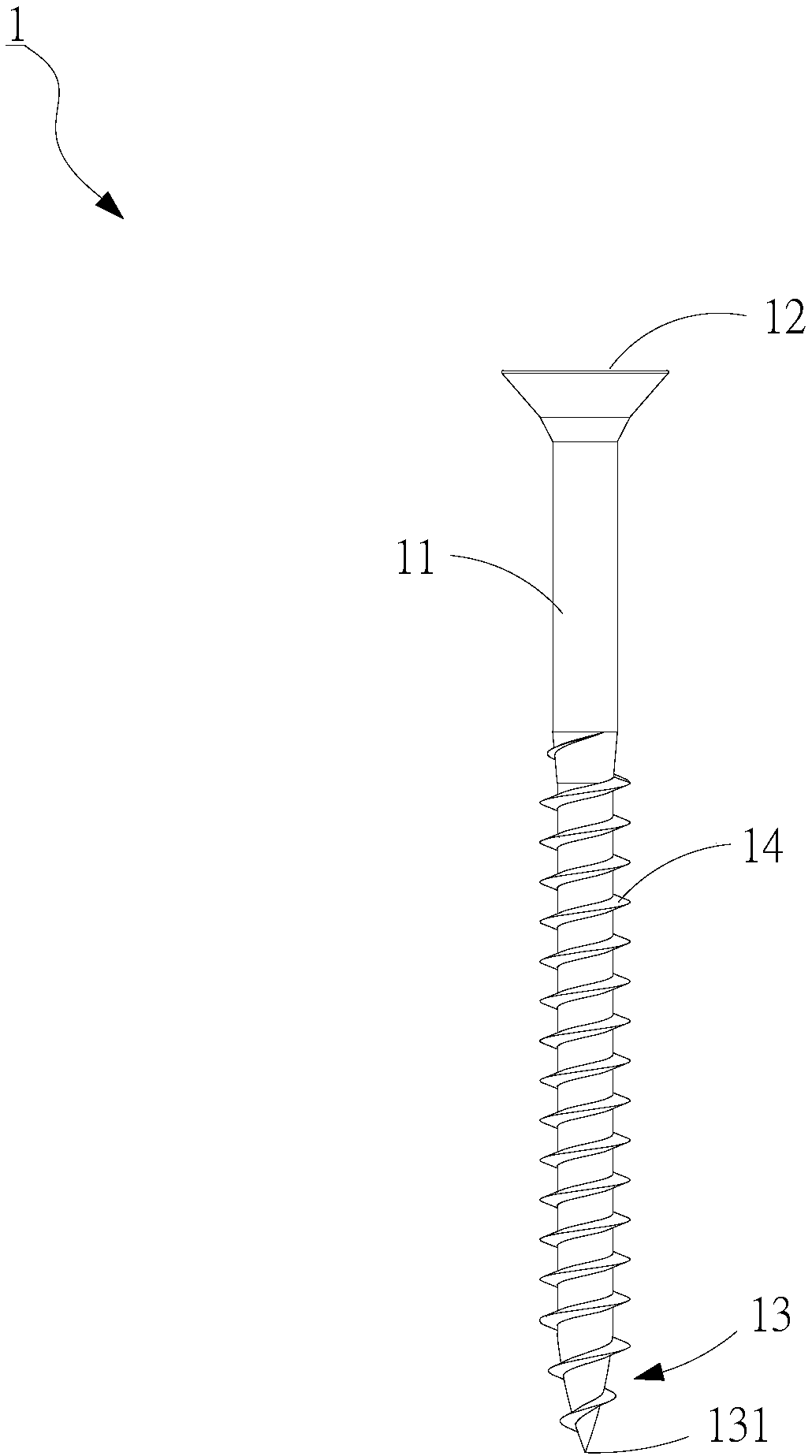

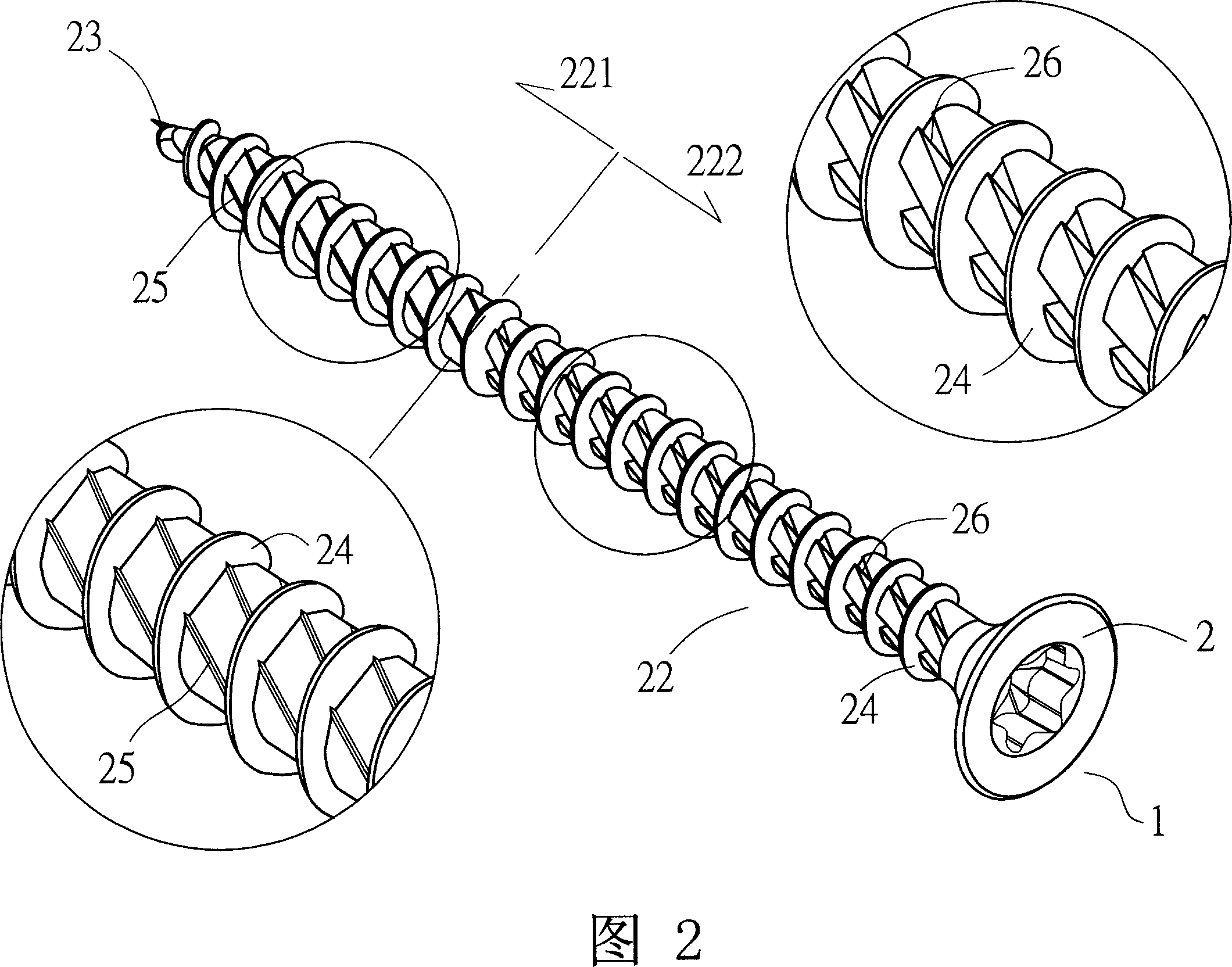

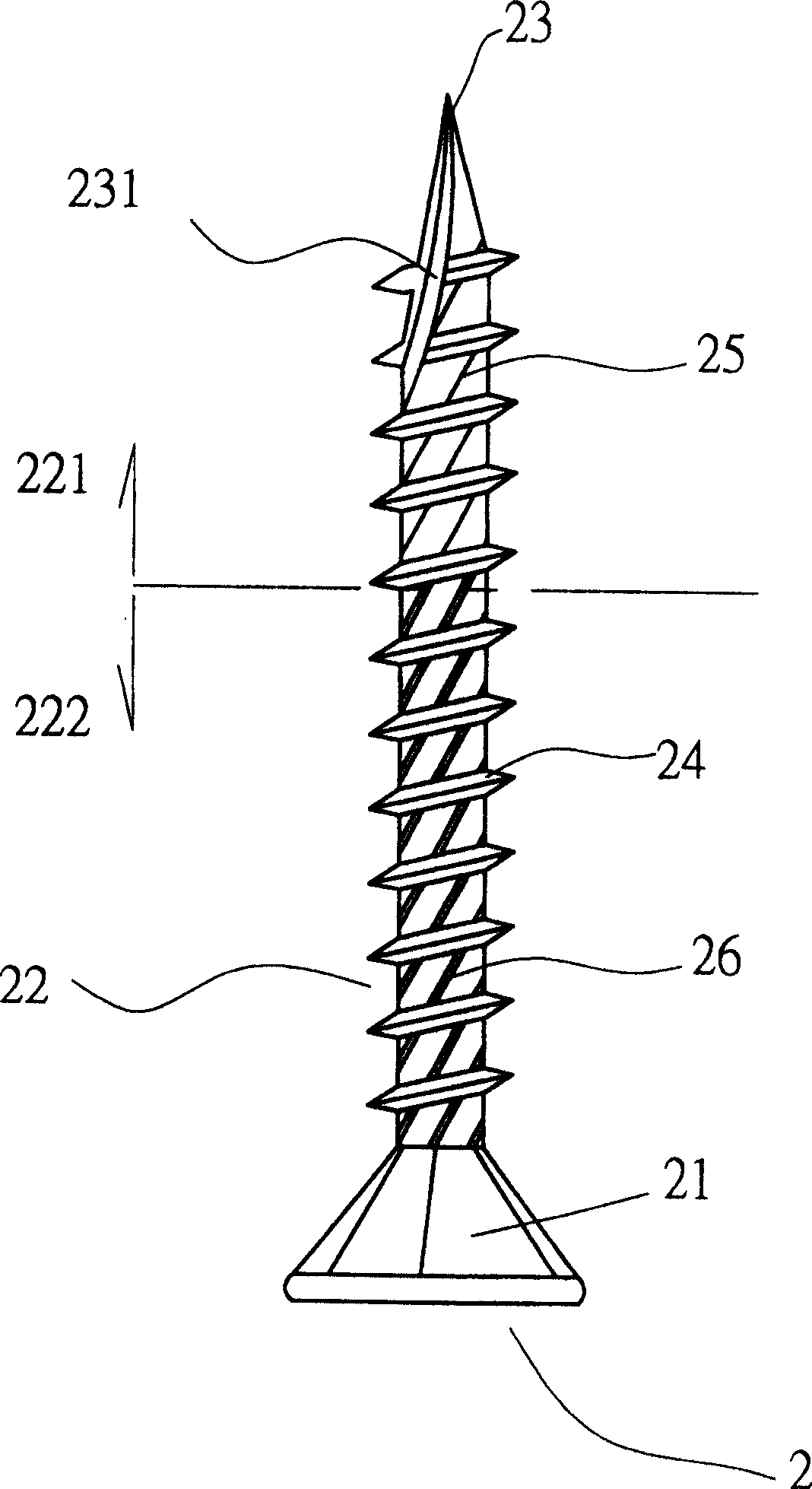

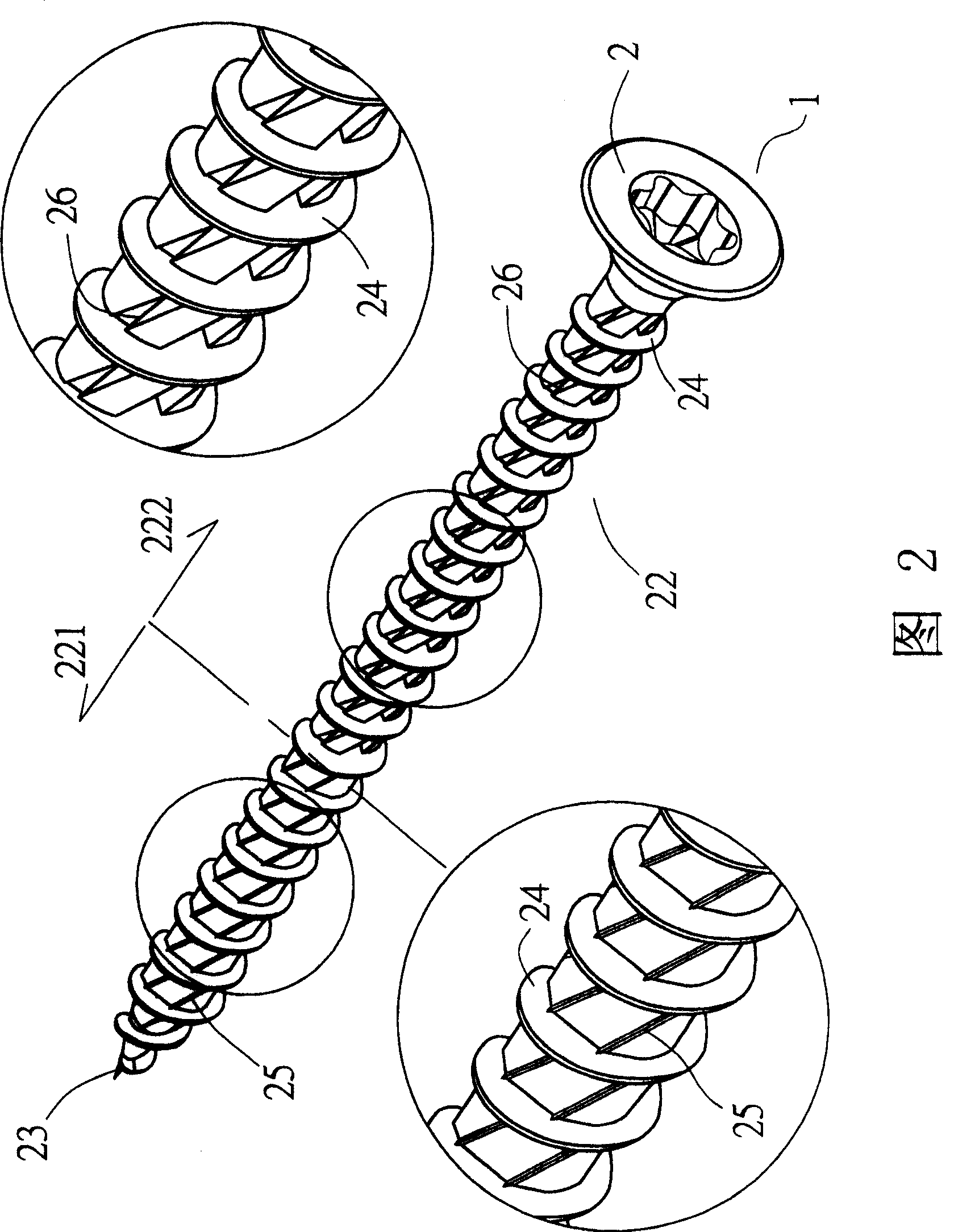

Wooden screw nail structure

The invention discloses a wood screw structure. The wood screw comprises head part, bar part and plural screw thread formed on the bar part and extending along the axial direction. Thereinto, multiple cutting teeth are set on the screw thread of screw-in end of bar part and cutting teeth extend backward to the tooth bottom of head part among plural screw thread. Convex ribs arranged obliquely are set in circle. Chip collecting groove is dug in vertical direction after cutting teeth of the screw-in end and a cutting face is formed at two sides of groove. The cutting face collects sawdust of screw-in end and carries discharging efficiency of back segment of bar part. Because of design mentioned above, the screw is provided with cutting in saving labor, collecting chip and discharging chip quickly so on.

Owner:徐国泰

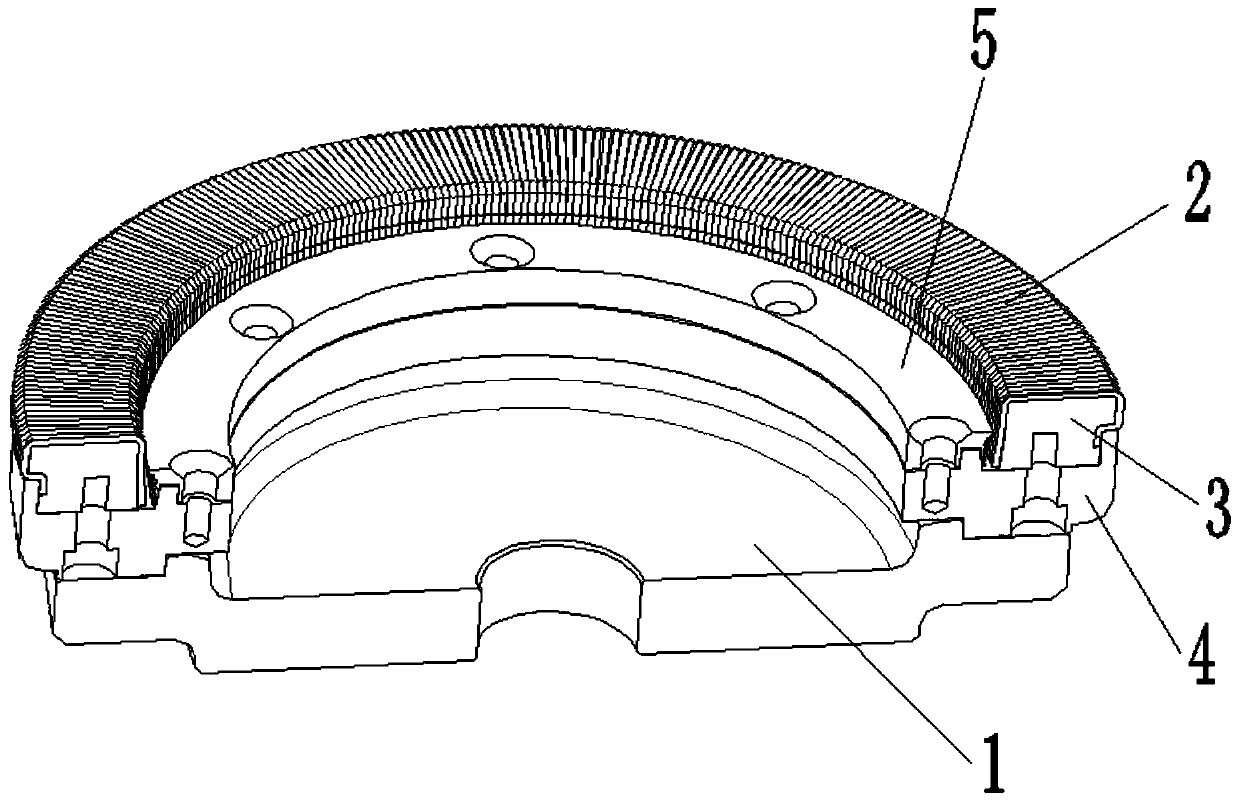

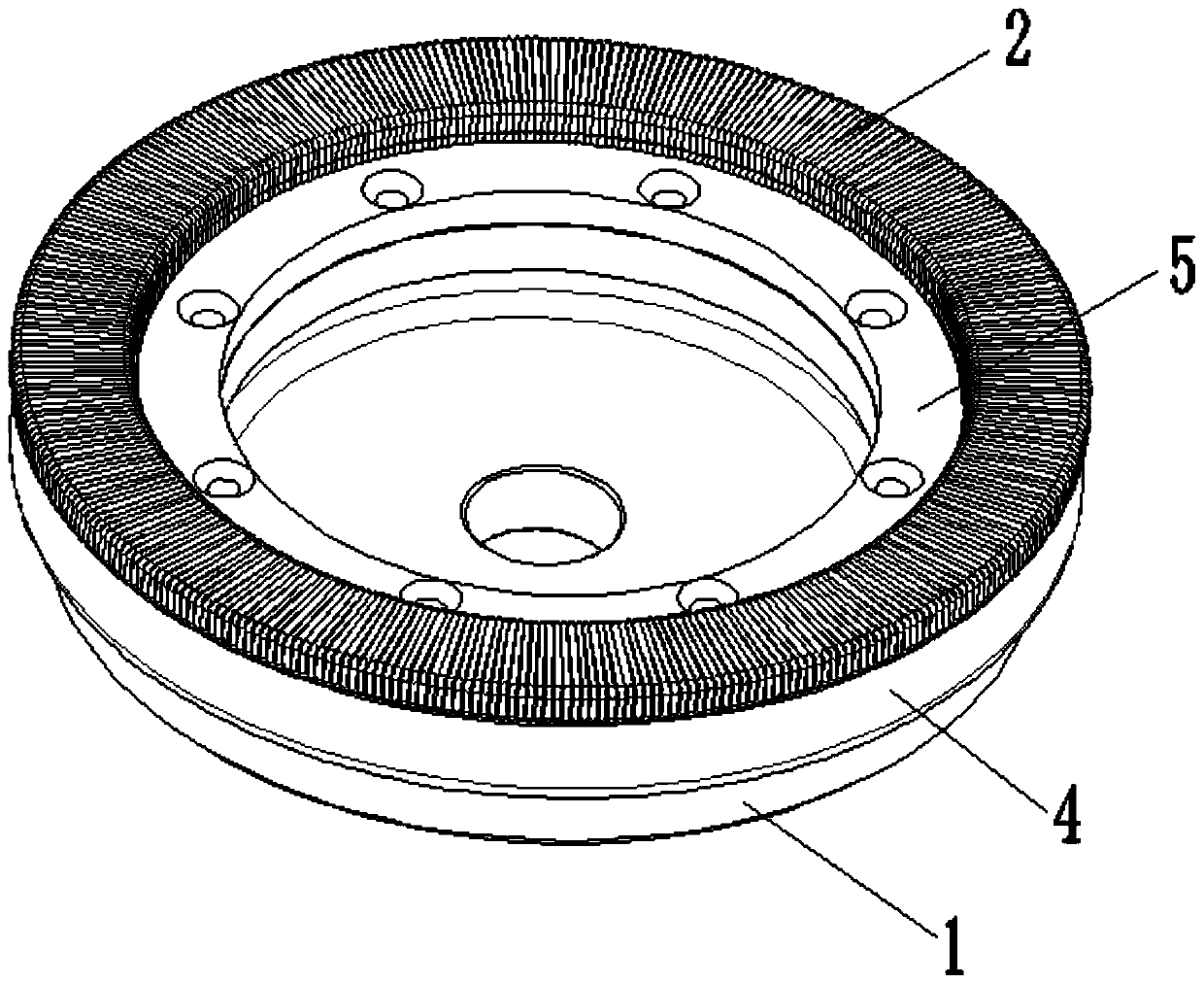

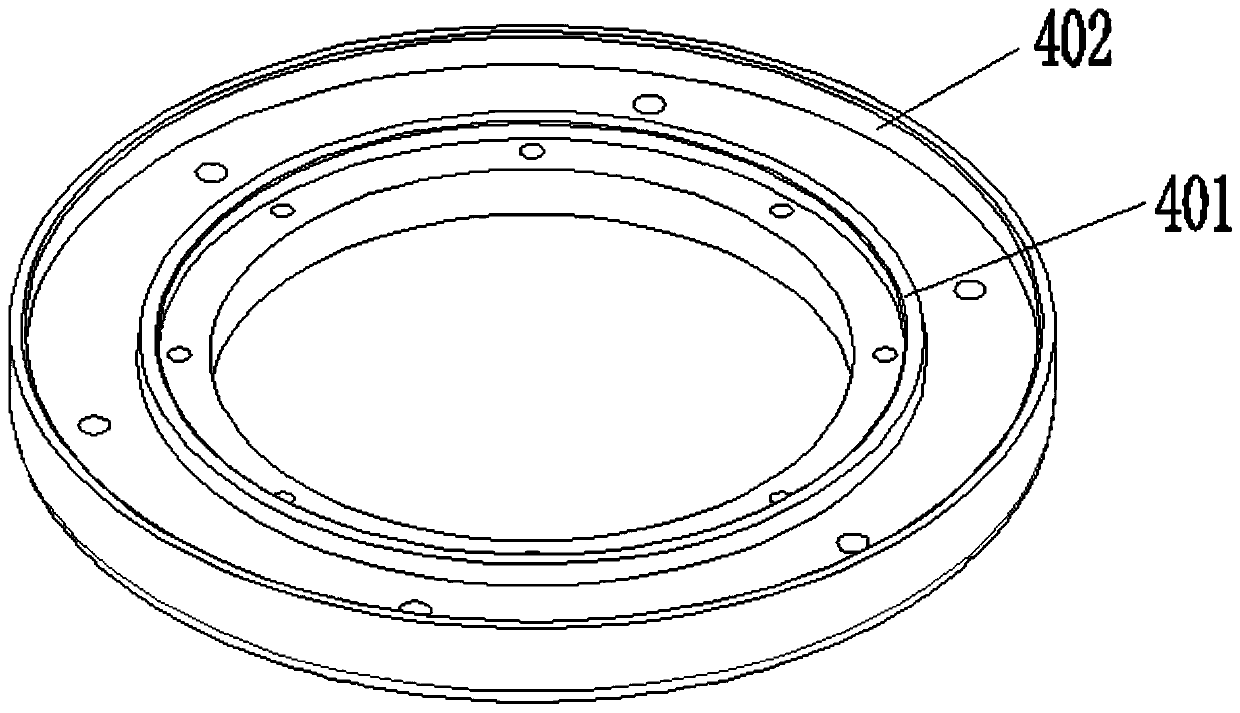

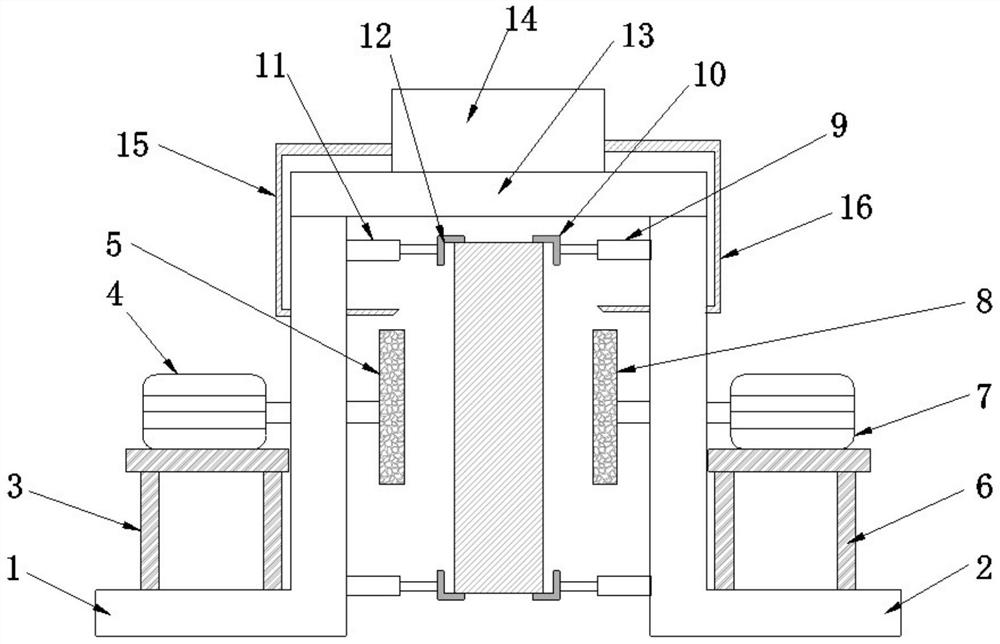

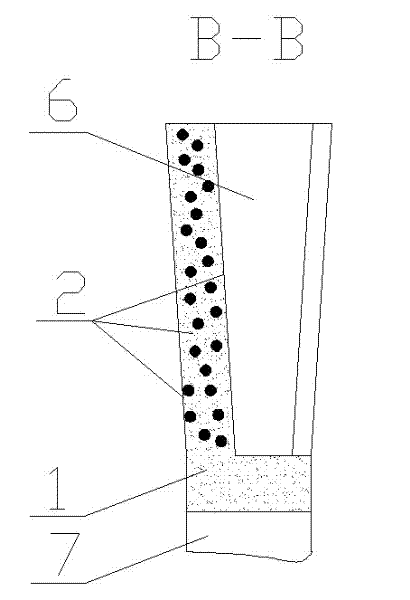

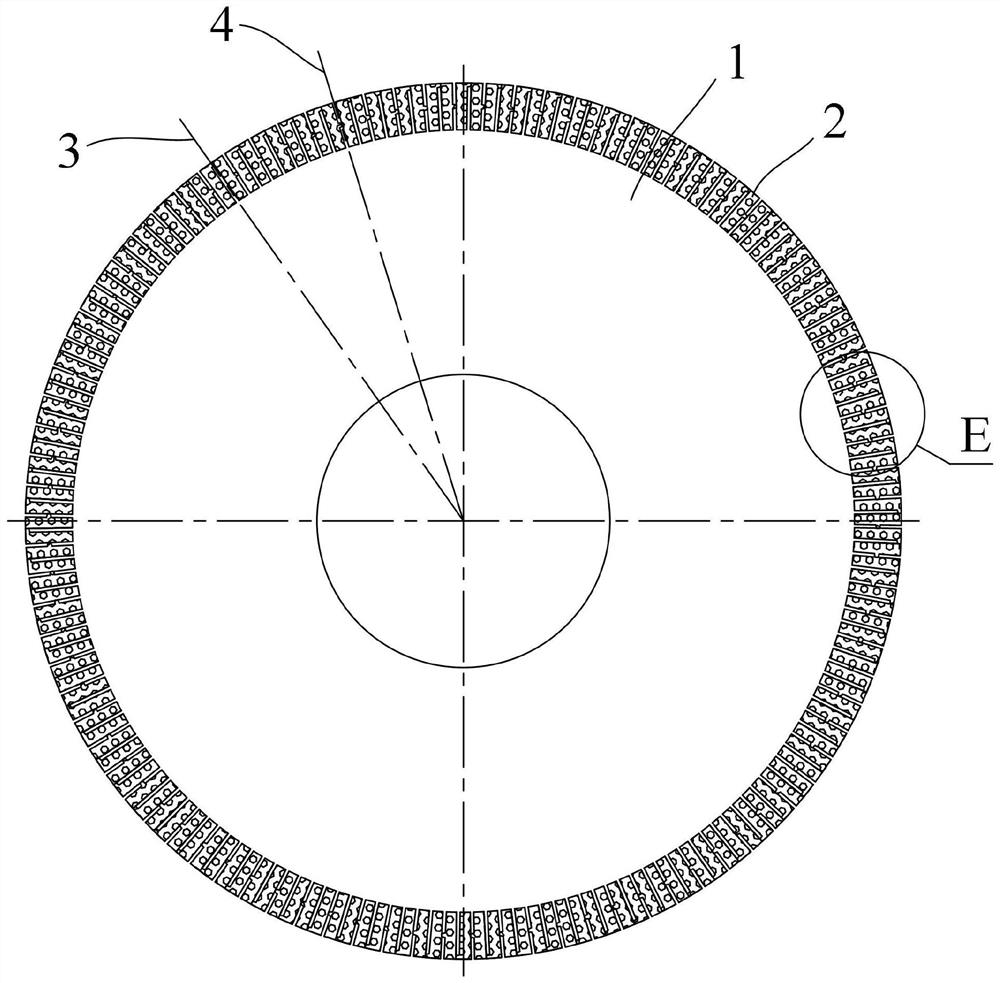

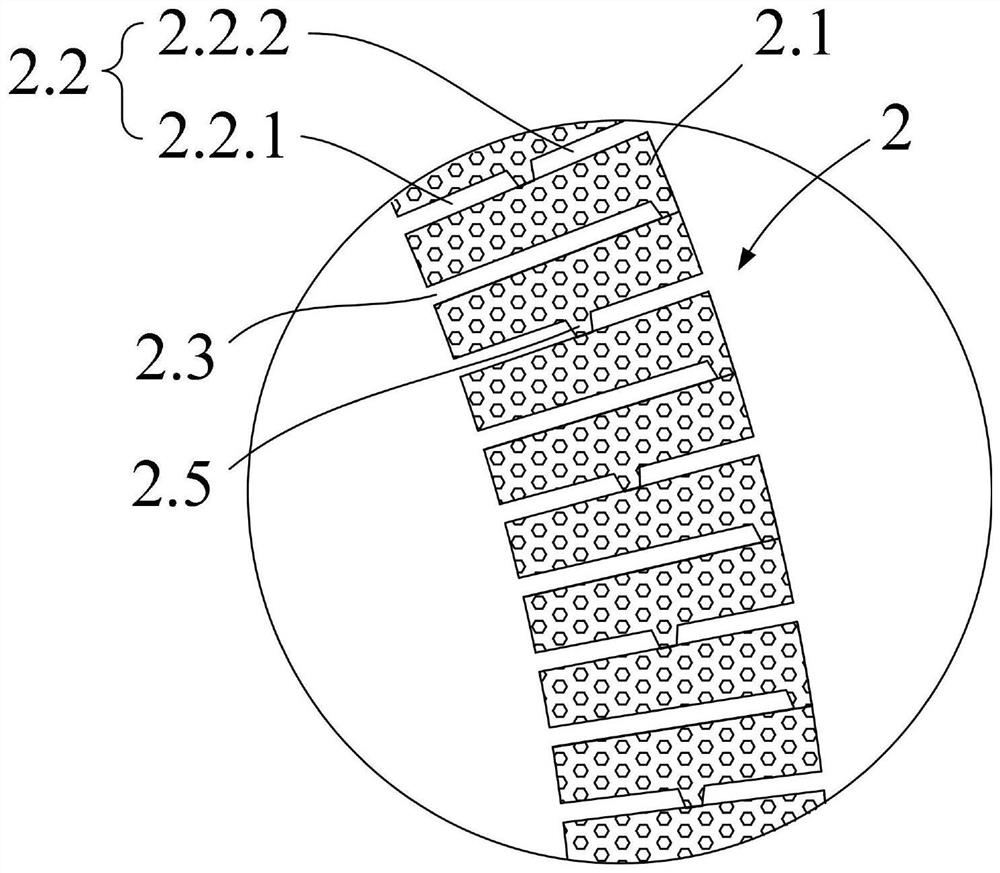

Electroplated steel wire tooth splice type cup-shaped abrasive wheel

PendingCN111113286AEasy to replaceReduce refurbishment costsBonded abrasive wheelsEngineeringStructural engineering

The invention relates to an electroplated steel wire tooth splice type cup-shaped abrasive wheel. The abrasive wheel comprises a first matrix, a plurality of steel wire teeth, a supporting ring for supporting the steel wire teeth, a second matrix used to fix the supporting ring to the first matrix, and a clamping portion used to tightly clamp the steel wire teeth. The second matrix is axially arranged on the first matrix in a stacking manner. The clamping portion and the supporting ring are arranged on the second matrix in parallel. Diamond is plated on the outer walls of the steel wire teeth.The steel wire teeth are arranged on the supporting ring to form a grinding surface. One end of each steel wire tooth is arranged in a seam between the clamping portion and the supporting ring in a clamped manner. The steel wire teeth are assembled on the supporting ring in a mechanical splice manner. The matrixes are reusable tools which can be used repeatedly; the grinding surface formed by splicing the steel wire teeth are convenient to replace, and therefore, the renovation cost of the abrasive wheel is greatly reduced; and according to the cup-shaped abrasive wheel formed by splicing thesteel wire teeth, an axial working face is formed, a water feeding channel is formed between every two adjacent teeth, and it is beneficial for cooling and quick scrap removal.

Owner:宋京新 +1

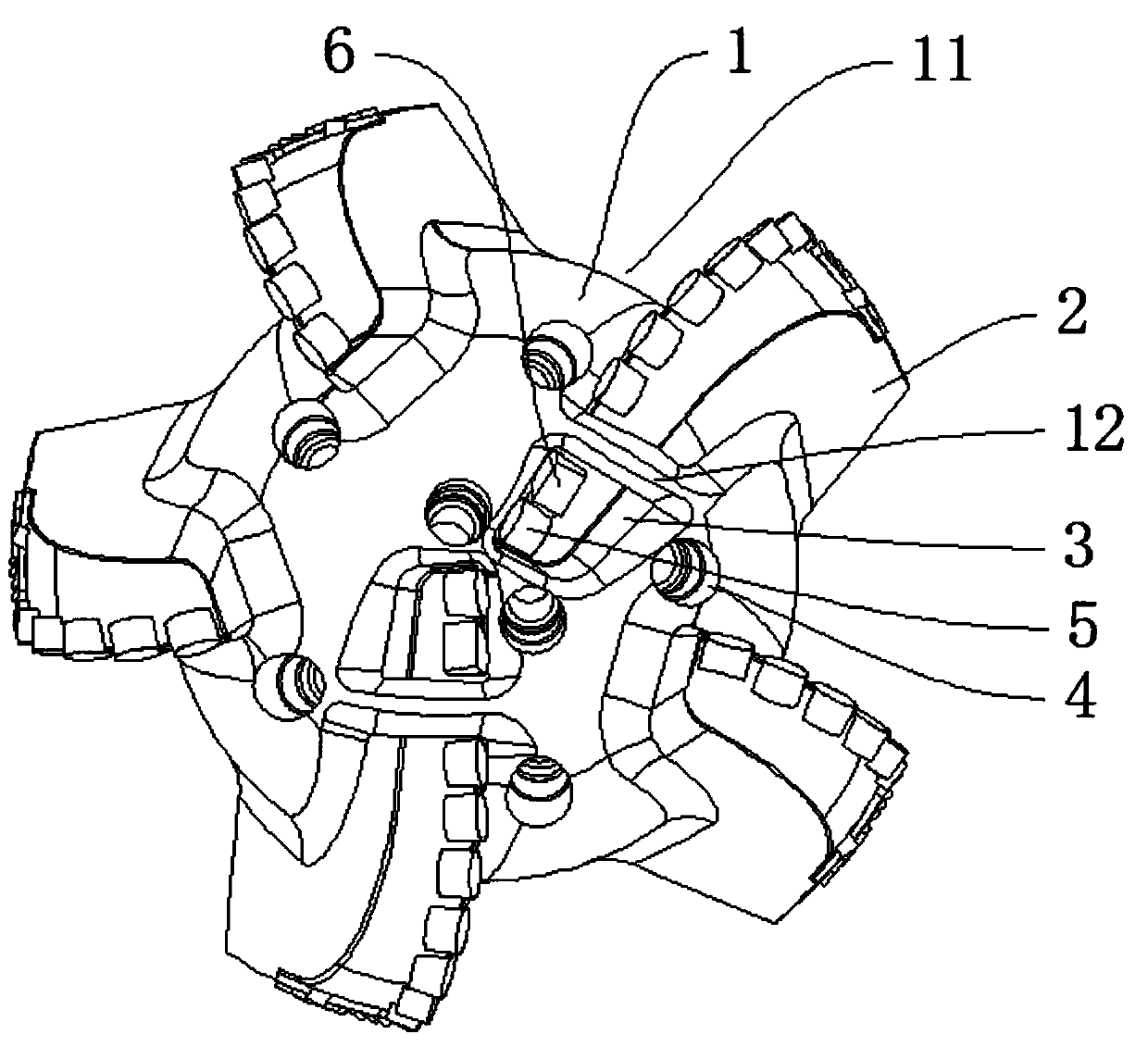

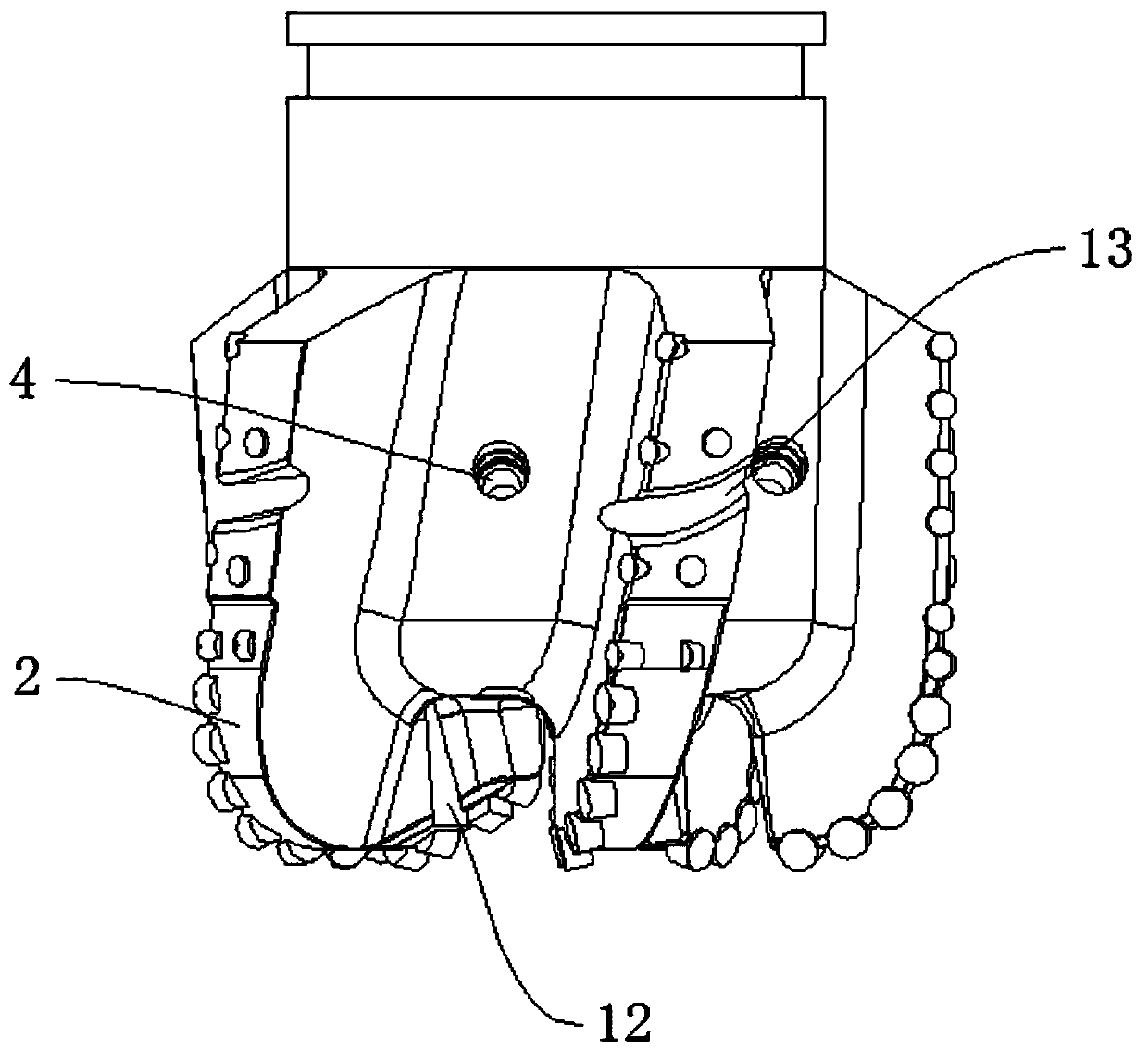

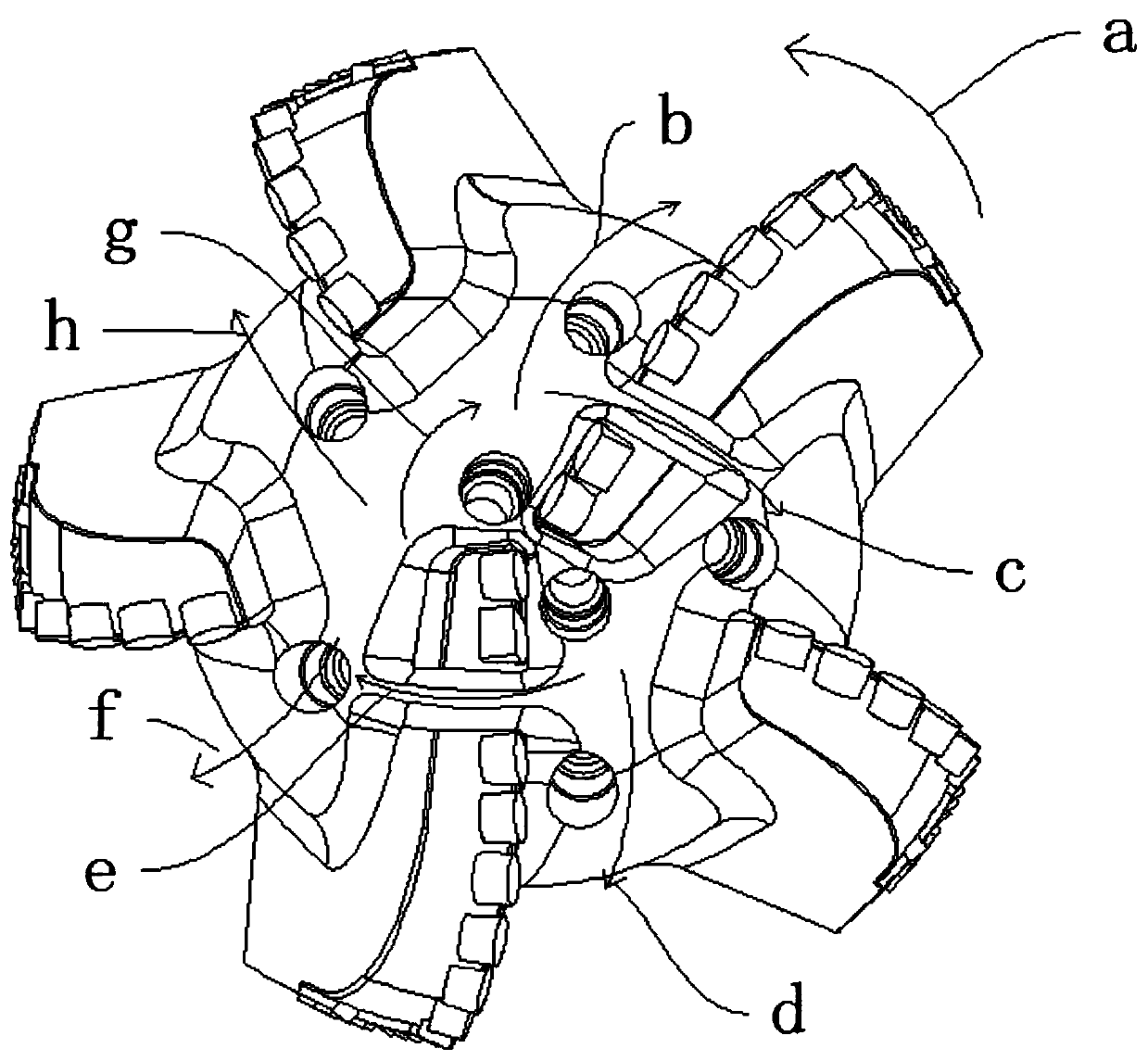

Polycrystalline diamond compact drill bit and machining method thereof

InactiveCN110374515AFast Chip EvacuationAvoid Debris BuildupDrill bitsPolycrystalline diamondDrill bit

The invention discloses a polycrystalline diamond compact drill bit. The polycrystalline diamond compact drill bit comprises a main body, and multiple main cutter wings arranged on the main body; mainchip discharge grooves are formed between the main cutter wings; the front ends of the main cutter wings extend to an inner cone part of the main body; a secondary cutter wing is arranged at the center part of the main body, and is arranged on the inner side of the main cutter wing; a secondary chip discharge groove is formed between the secondary cutter wing and the main cutter wing; and the twoends of the secondary chip discharge groove communicate with the adjacent main chip discharge grooves. The polycrystalline diamond compact drill bit can quickly discharge chips to prevent the chip accumulation and the bit balling. The invention further discloses a machining method of the polycrystalline diamond compact drill bit for machining the polycrystalline diamond compact drill bit; and graphite pieces are placed in tooth holes before heating of blanks, and are taken out after the blanks are cooled to the normal temperature to prevent incapability of installing polycrystalline diamond compacts or other teeth after deformation of the tooth holes.

Owner:立府精密机械有限公司

Screw nail

The invention publicizes a screw that comprises a head, a rod, a tip and multi continuous coiling screw threads formed on the rod. A protruding cutting section is set on the threaded front facing the tip on the rod to allow the front successfully finishing the first stage of process for cutting and quick chip removal while screwing to the working piece. An inward concave cutting section is set on the threaded back to allow the back part inserted into the working piece with smooth completion of the second stage process of cutting and quick chip removal. Apart from that, a cutting groove can be set at the tip of the screw or set several cutting teeth outside of the thread to enhance the ability of quick screwing the tip of the screw. With the above design, a screw fastening device is formed with the features of laborsaving cutting, quick chip removal and chip collecting.

Owner:徐国泰

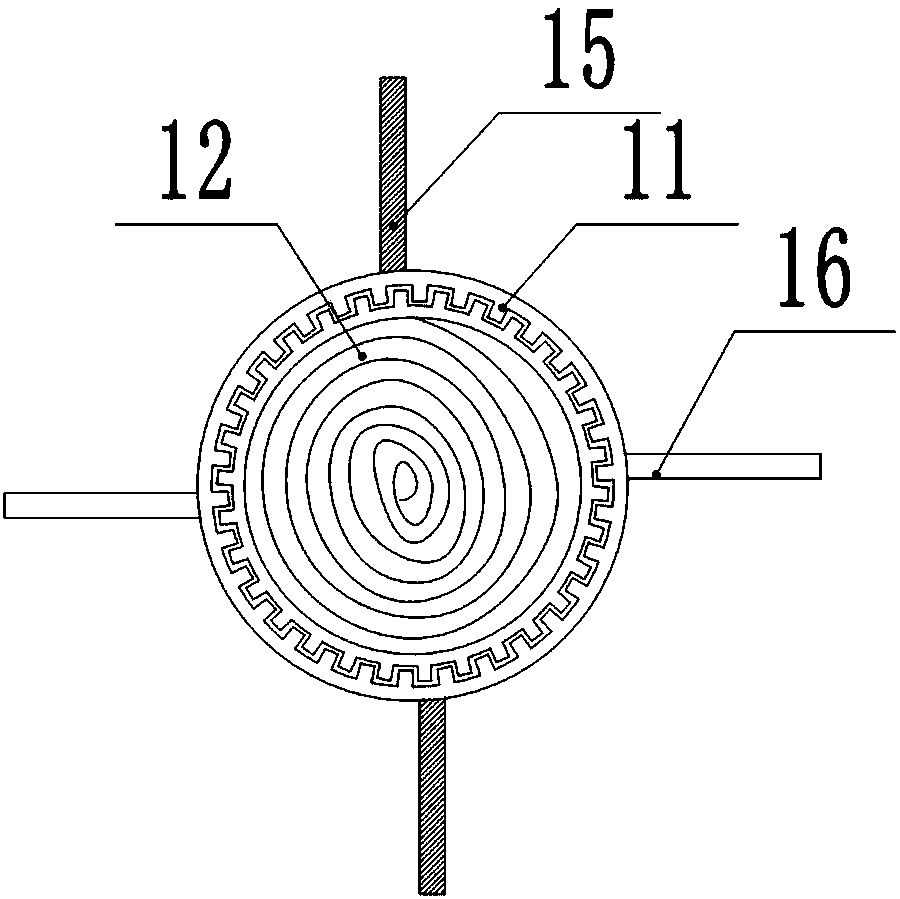

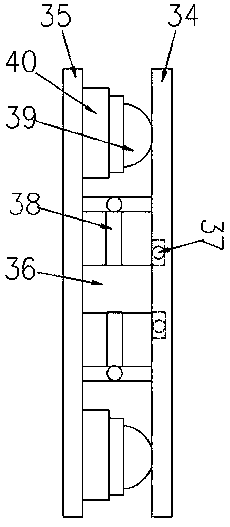

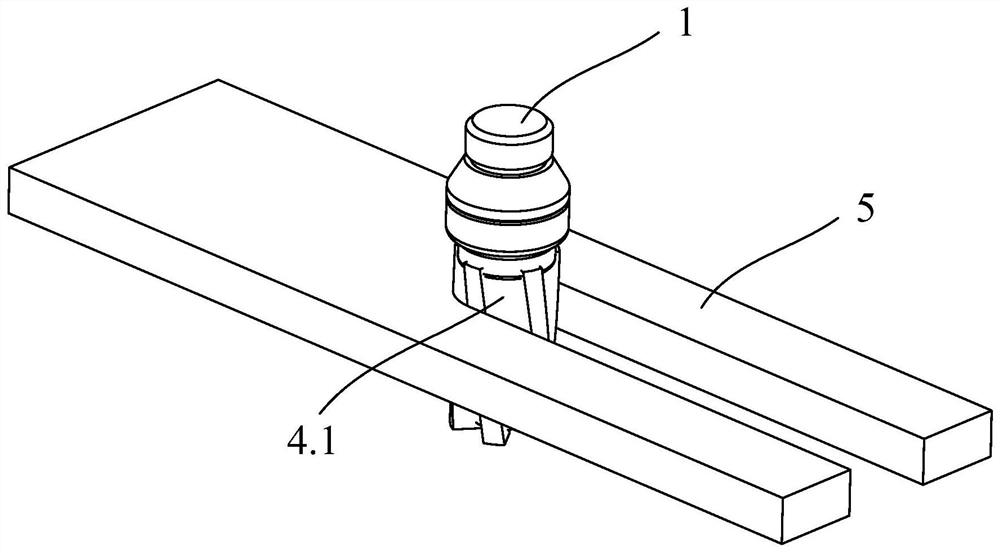

A chip removal device for an electric tool

ActiveCN110434401BFast Chip EvacuationSimple and fast operationMetal sawing accessoriesBall bearingGear wheel

The invention relates to the technical field of electric tools, and discloses a chip removal device of an electric tool. The chip removal device comprises a U-shaped fixing plate, the inner walls of the left side and the right side of the U-shaped fixing plate are correspondingly and rotationally connected with a first screw rod and a second screw rod through ball bearings, threads of the wall ofthe first screw rod and the wall of the second screw rod are mutually opposite threads, one end of the first screw rod and one end of the second screw rod are welded together, a driven bevel gear is fixedly connected to the welding position in a sleeve mode, a through hole is formed in the upper end of the U-shaped fixing plate, a rotating rod is rotationally connected in the through hole througha ball bearing, a driving bevel gear meshed with the driven bevel gear is fixedly connected to the lower end of the rotating rod, an L-shaped handle is fixedly connected to the upper end of the rotating rod, and the L-shaped handle is clamped with the U-shaped fixing plate through a positioning mechanism. The chip removal device of the electric tool has the advantage of being suitable for rapid chip removal work of electric cutting tools with different sizes.

Owner:YANGZHOU GAOSHENG MACHINERY

Electroplating coating slotting grinding tool

PendingCN112959182AImprove cooling effectReduce oxidationGrinding machinesGrinding/polishing safety devicesMetallurgyWater flow

The invention relates to an electroplating coating slotting grinding tool. The grinding tool comprises a base body, a grinding end fixedly connected with the base body and a water flow channel penetrating through the base body and the grinding end, wherein a plurality of grinding tooth sets arranged in the axial direction of the grinding end are fixedly arranged on the grinding end, and the multiple grinding tooth sets are sequentially arranged at intervals in the circumferential direction of the grinding end; a plurality of water outlet holes are formed between every two adjacent grinding tooth sets, and the multiple water outlet holes are sequentially arranged at intervals in the axial direction of the grinding end and all communicate with the water flow channel; and each grinding tooth set comprises a plurality of grinding teeth, the multiple grinding teeth are sequentially arranged at intervals in the axial direction of the grinding end, and the grinding teeth on the multiple grinding tooth sets are arranged to form a grid structure. Compared with the prior art, chips can be rapidly discharged, the grinding teeth can be efficiently cooled, the grinding capacity is kept, and the shape preserving life is greatly prolonged.

Owner:宋京新 +1

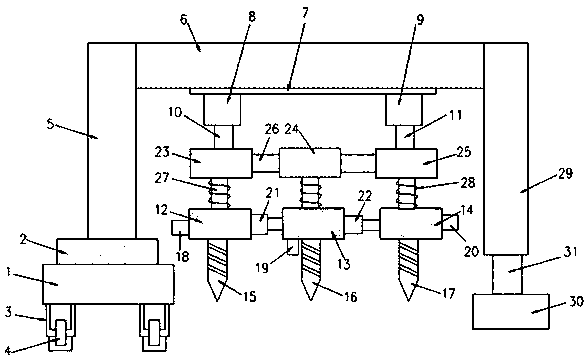

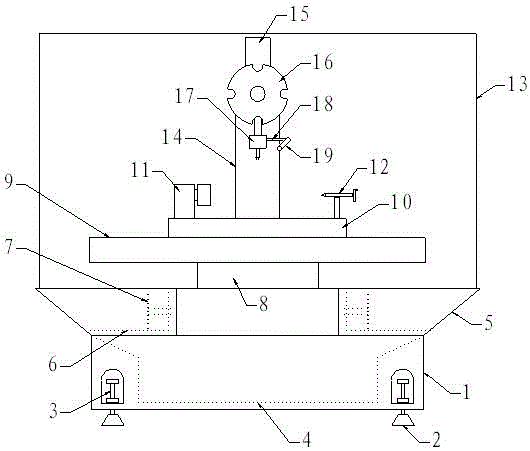

An automatic control multifunctional engraving machine

ActiveCN106379096BGuaranteed cleanlinessEasy chip removalOther artistic work equipmentsModel makingAutomatic controlStructural engineering

The invention relates to an automatic-control multi-functional carving machine. The automatic-control multi-functional carving machine comprises a machine base; supporting bolts are arranged at the lower end of the machine base; foot margins are arranged at the lower portion of the machine base and are connected with the supporting bolts; a water tank is arranged inside the machine base; a scrap collecting box is arranged at the upper side of the machine base; a protective plate is arranged at the upper side of the scrap collecting box; a filter screen is arranged inside the scrap collecting box; an electric scrap discharging plate is arranged inside the scrap collecting box; an X-axis arm is also arranged at the upper side of a working platform; a Y-axis arm is arranged at the upper side of the X-axis arm; the working platform is arranged at the upper side of the Y-axis arm; an electric dividing head and a thimble are arranged at the upper side of the working platform; an upright post is also arranged at the upper side of the machine base; a Z-axis arm is arranged at the upper side of the upright post; a cutter replacing disc is arranged at the front side of the lower part of the Z-axis arm; the lower end of the Z-axis arm is connected with a main shaft; a bracket is arranged at the side surface of the main shaft; a spraying pipe is arranged at the tail end of the bracket and is connected with a power pump. The automatic-control multi-functional carving machine disclosed by the invention has the advantages of being simple in structure, simple and convenient to operate, high in work efficiency, high in precision and capable of conveniently and quickly discharging scraps.

Owner:扬州市生态科技新城润业中小企业服务中心有限公司

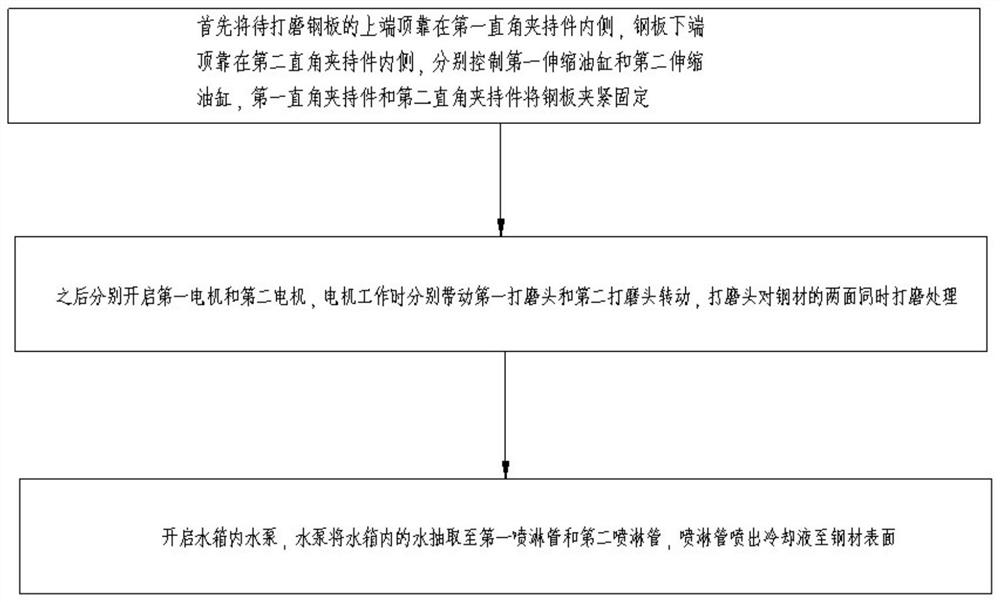

Steel grinding device for constructional engineering and method

InactiveCN112454118AImprove stabilityLow costGrinding work supportsPlane surface grinding machinesStructural engineeringMechanical engineering

The invention discloses a steel grinding device for constructional engineering and a method. The device comprises a first positioning support, a second positioning support, first clamping assemblies and second clamping assemblies. The first positioning support and the second positioning support are symmetrically arranged and are each of an L-shaped structure. The number of the first clamping assemblies is two sets, and the two sets of first clamping assemblies are installed on the inner side of the upper end of the first positioning support and the inner side of the upper end of the second positioning support correspondingly. The number of the second clamping assemblies is two sets, and the two sets of second clamping assemblies are installed on the inner side of the lower end of the firstpositioning support and the inner side of the lower end of the second positioning support correspondingly. The device is novel in structural design and convenient to operate, the two faces of steel can be simultaneously ground, the grinding efficiency is high, the labor cost is reduced, and the grinding efficiency is improved.

Owner:江苏盐西景轩建筑工程有限公司

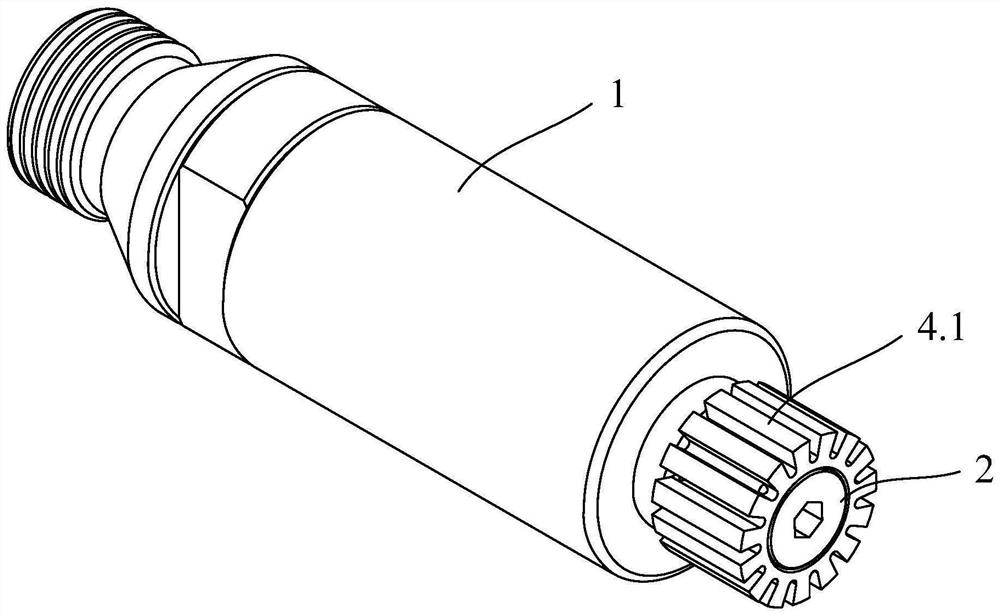

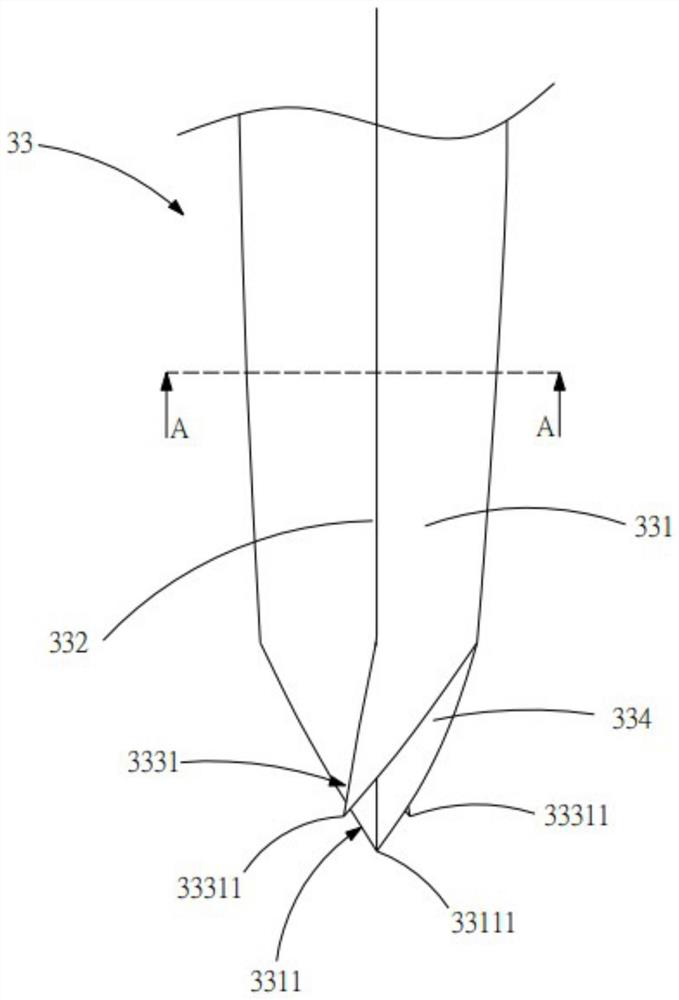

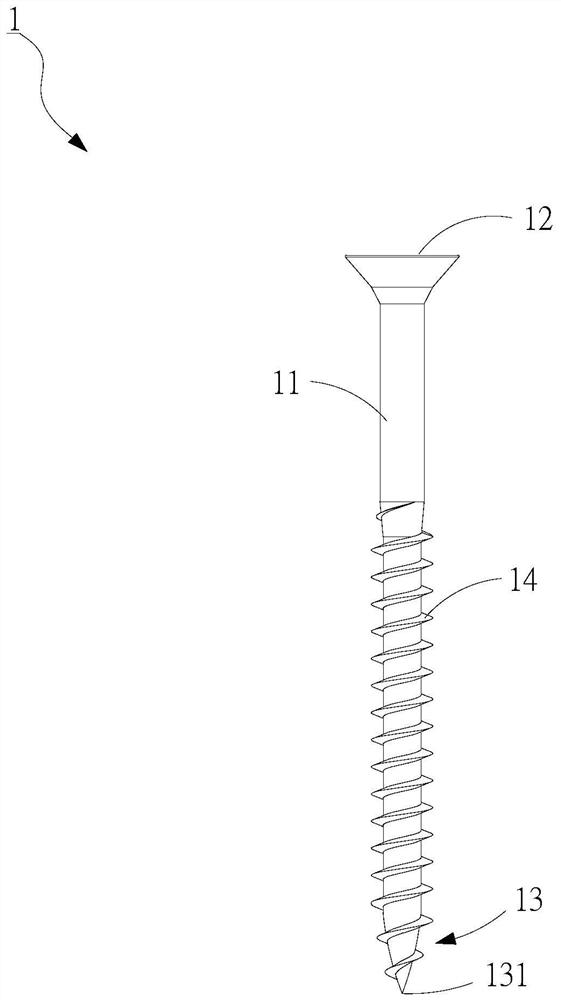

Drilling screw

ActiveCN113062910BFast Chip EvacuationAvoid resistanceScrewsMining engineeringStructural engineering

The invention discloses a tail-drilling screw, which mainly consists in that a drill part is formed at the end of the drill body, and the tip parts which are respectively formed on both sides of the drill body and connected with the cutting edge are respectively recessed on the drill body. And a concave arc surface extending from the drill part to the tip; wherein the drill part is located on the center of the rod body, and the angle between the drill parts does not exceed 60 degrees, and the protrusion length of the drill part is greater than that of the tip parts At the same time, the angle between the tips does not exceed 50 degrees; therefore, through the design of the drill part, the tip and the concave arc surface, the tail end of the drill body forms a chord cutting state, so that the two cutting edges and the tip can be in the Under the positioning of the drill part, the drill part is positioned accurately and quickly, and the sharp cutting is screwed into the outside, and the concave arc surface and the chip removal groove can quickly provide chip removal, effectively avoiding the resistance and cracking caused by chip accumulation.

Owner:TAIWAN SHAN YIN INT CO LTD

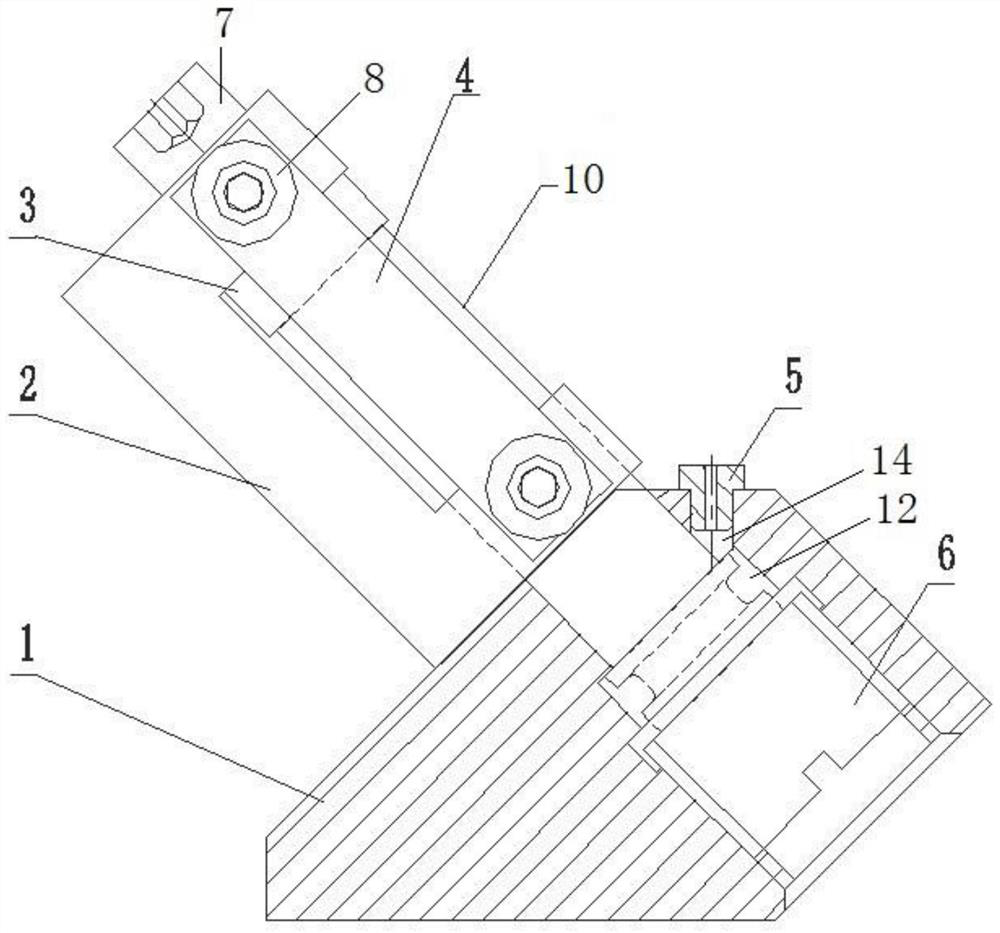

Machining method for inclined micro hole in outer circle and machining device

InactiveCN112621294AAvoid breakingSolution to short lifeOther manufacturing equipments/toolsPositioning apparatusEngineeringDrill bushing

The invention discloses a machining method for inclined micro hole in an outer circle and a machining device. The method comprises the steps that a replaceable drill bushing is taken down, and the bottom surface of a tool base is placed on the upper end surface of a sizing block and is pressed; a workpiece is installed in a step through hole of the tool base of the assembled machining device, the top of the workpiece makes contact with a locking nut to be limited, a pressing screw abuts against the bottom of the workpiece, and the pressing screw and an adjusting screw are finely adjusted till the inclined micro hole is aligned with a guide positioning hole; positioning is carried out through the guide positioning hole, and rapid movement to a cutting point is realized; after cutting, the milling depth is about 1mm; a micro drill bit is replaced, the replaceable drill bushing is installed, the inclined micro hole is drilled, and the inclined micro hole is connected with a step through hole; the top of the workpiece makes contact with the locking nut to be limited, the pressing screw and the step through hole are in close fit to abut against the bottom of the workpiece, the pressing screw and the adjusting screw are finely adjusted to align to the inclined micro hole, the position size L of the inclined micro hole is roughly determined, and the workpiece is pressed; and the workpiece cannot shake along with a cutting tool, the cutting position is easy to control, and the tool is not prone to being broken.

Owner:贵州凯星液力传动机械有限公司

Automatic-control multi-functional carving machine

ActiveCN106379096AGuaranteed machining accuracyQuality improvementOther artistic work equipmentsModel makingAutomatic controlScrap

The invention relates to an automatic-control multi-functional carving machine. The automatic-control multi-functional carving machine comprises a machine base; supporting bolts are arranged at the lower end of the machine base; foot margins are arranged at the lower portion of the machine base and are connected with the supporting bolts; a water tank is arranged inside the machine base; a scrap collecting box is arranged at the upper side of the machine base; a protective plate is arranged at the upper side of the scrap collecting box; a filter screen is arranged inside the scrap collecting box; an electric scrap discharging plate is arranged inside the scrap collecting box; an X-axis arm is also arranged at the upper side of a working platform; a Y-axis arm is arranged at the upper side of the X-axis arm; the working platform is arranged at the upper side of the Y-axis arm; an electric dividing head and a thimble are arranged at the upper side of the working platform; an upright post is also arranged at the upper side of the machine base; a Z-axis arm is arranged at the upper side of the upright post; a cutter replacing disc is arranged at the front side of the lower part of the Z-axis arm; the lower end of the Z-axis arm is connected with a main shaft; a bracket is arranged at the side surface of the main shaft; a spraying pipe is arranged at the tail end of the bracket and is connected with a power pump. The automatic-control multi-functional carving machine disclosed by the invention has the advantages of being simple in structure, simple and convenient to operate, high in work efficiency, high in precision and capable of conveniently and quickly discharging scraps.

Owner:扬州市生态科技新城润业中小企业服务中心有限公司

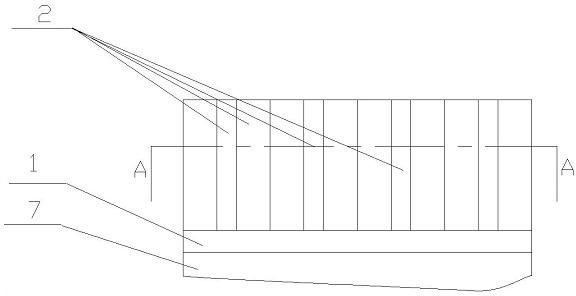

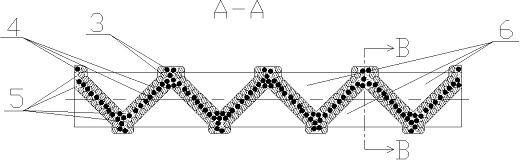

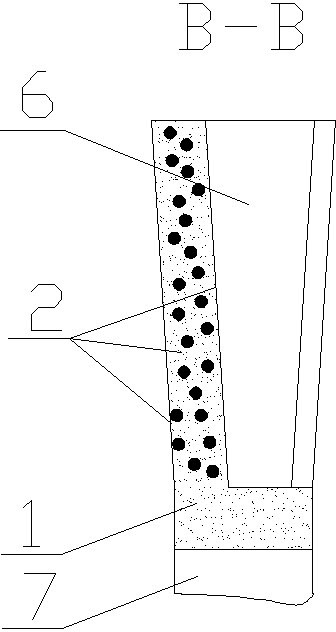

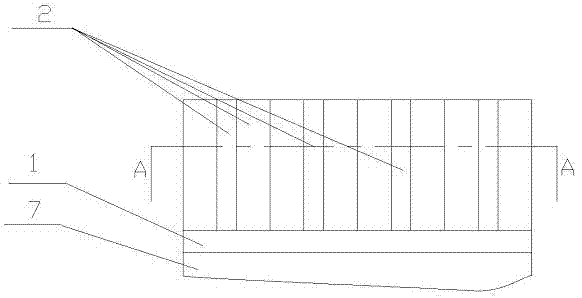

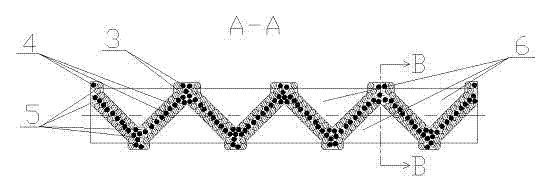

CBN cutting tool bit for sintered steels

The invention relates to a cubic boron nitride (CBN) cutting tool bit for sintered steels, and belongs to cutting tool bits. The CBN cutting tool bit is characterized by mainly comprising working layers (cutting bodies) and a non-working layer (a non-cutting body) which are manufactured into a whole, wherein the non-working layer which is in a cuboid shape is arranged on the lower end part of the cutting tool bit and consists of metal bonding agent powder; the working layers (the cutting bodies) which are in a corrugated shape are arranged on the upper part of the non-working layer vertically from left to right; the adjacent bevel edges of the corrugated working layers are intersected with one another at an included angle of between 30 and 120 DEG, and intersected parts are distributed on the non-working layer uniformly in a front and back misplaced mode; the included angle of between 60 and 90 DEG among the adjacent bevel edges of the corrugated working layers is the optimum; gaps among the intersected bevel edges are used as chip grooves; steel wires or steel sheets are vertically arranged on front and rear side parts in the corrugated working layers sequentially; CBN serving as hard materials is arranged between front and rear rows of steel wires or steel sheets; and the steel wires or the steel sheets and the CBN are coated by a metal sintered layer, so that the steels can be cut stably at high speed, and the work efficiency is high.

Owner:MAANSHAN GOLDEN EAGLE SUPER HARD MATERIAL

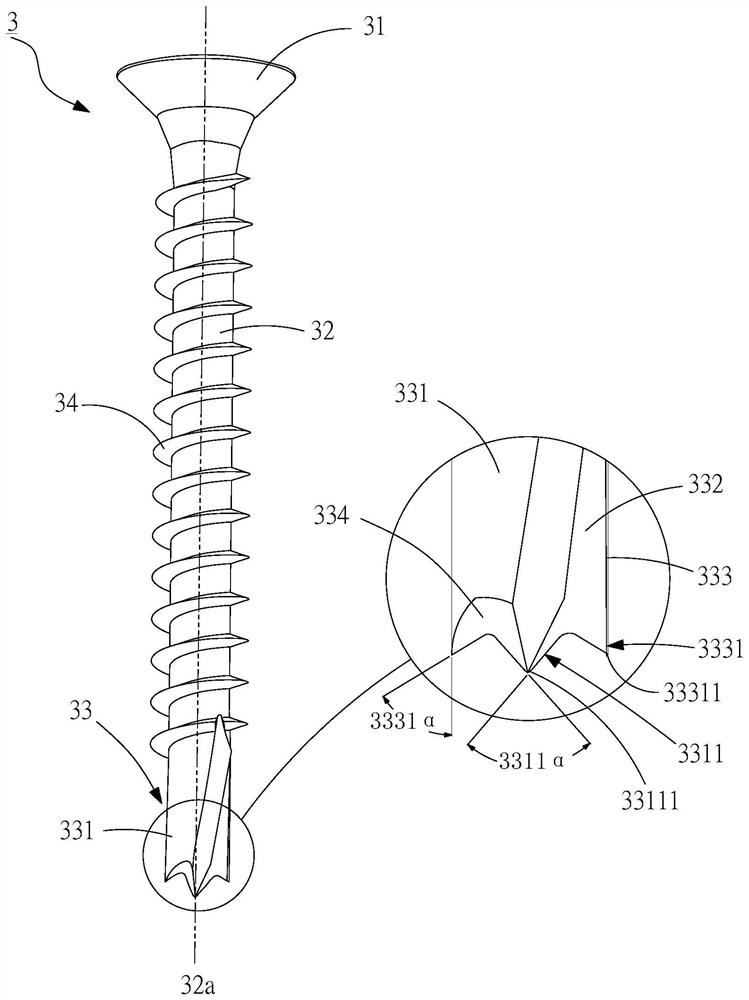

Slotted point-tail screws

ActiveCN113027890BFast Chip EvacuationReduced locking resistanceScrewsClassical mechanicsEngineering

The invention discloses a pointed-tail screw with a notch, which mainly has a tip on a rod body and defines a longitudinal axis passing through the tip. The rod body is screwed with a plurality of rightward helical threads and is provided with a first spaced apart first screw. A slot and a second slot, a first edge of the first slot is parallel to a second edge of the second slot, while the first edge extends toward the head of the screw , and its extension direction is opposite to the right-handed direction of the threads; the reverse extension of the above-mentioned grooves is beneficial to the initial cutting of the drill and lock, so as to achieve rapid chip removal, avoid cracked materials and press the chips to improve the locking force. .

Owner:ESSENCE METHOD REFINE

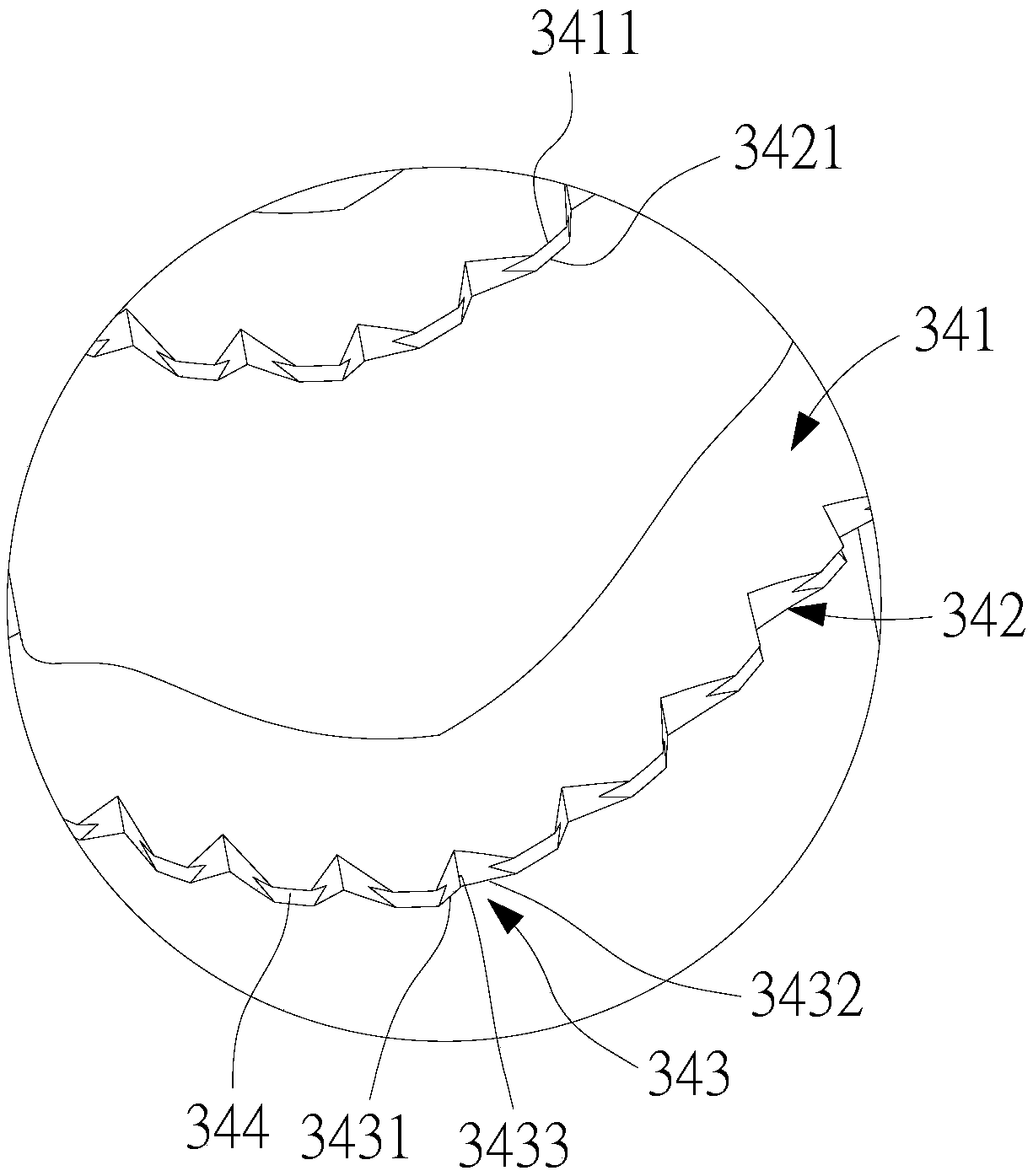

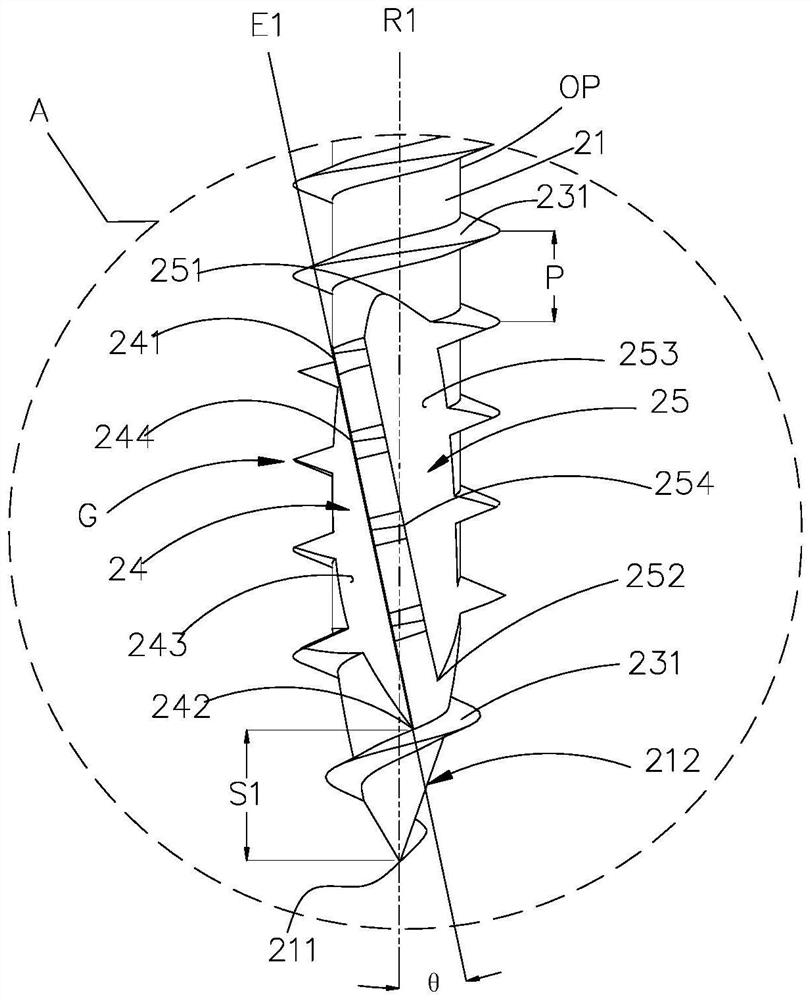

Screws with low twist-lock torque

The present invention provides a screw with low twist-locking torque. The main feature is that a plurality of cutting threads are provided on the rod body, and each cutting thread is provided with a plurality of slots to form a first cutting edge and a second cutting edge. At the same time, the joint between the first cutting edge and the second cutting edge is provided with a groove to form two crests. Therefore, the cooperation of the first and second cutting edges with the crests is more conducive to rapid Reaming, while increasing the overall cutting speed, can also effectively cut the fibers of the lock, so as to avoid the fiber entanglement and hinder the lock, and greatly reduce the torque of the twist lock, and then cooperate with the grooves and the lock These slots moderately accommodate and hold down part of the chips, which is more helpful to improve the locking engagement between the screw and the lock, not only effectively increasing the pulling force, but also improving the engagement stability of the screw screwing in.

Owner:TAIWAN SHAN YIN INT CO LTD

A screw nail

The invention publicizes a screw that comprises a head, a rod, a tip and multi continuous coiling screw threads formed on the rod. A protruding cutting section is set on the threaded front facing the tip on the rod to allow the front successfully finishing the first stage of process for cutting and quick chip removal while screwing to the working piece. An inward concave cutting section is set on the threaded back to allow the back part inserted into the working piece with smooth completion of the second stage process of cutting and quick chip removal. Apart from that, a cutting groove can be set at the tip of the screw or set several cutting teeth outside of the thread to enhance the ability of quick screwing the tip of the screw. With the above design, a screw fastening device is formed with the features of laborsaving cutting, quick chip removal and chip collecting.

Owner:徐国泰

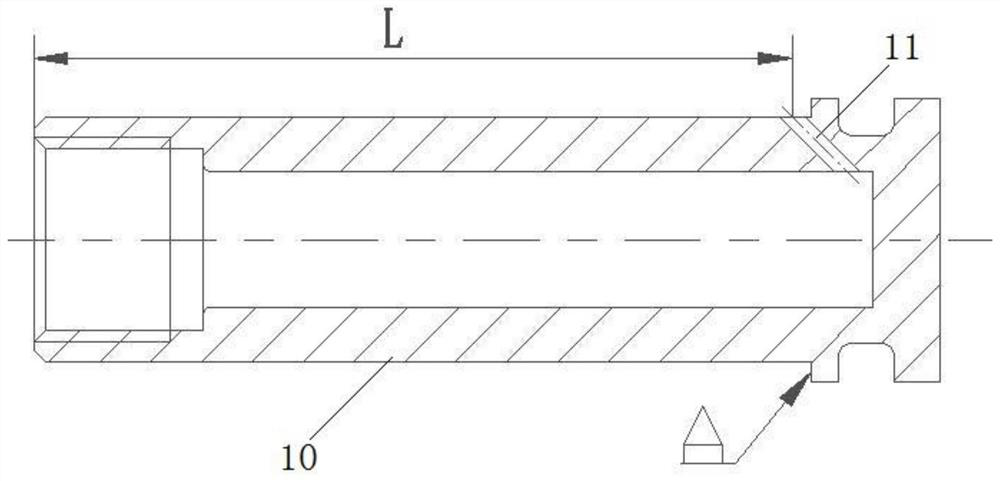

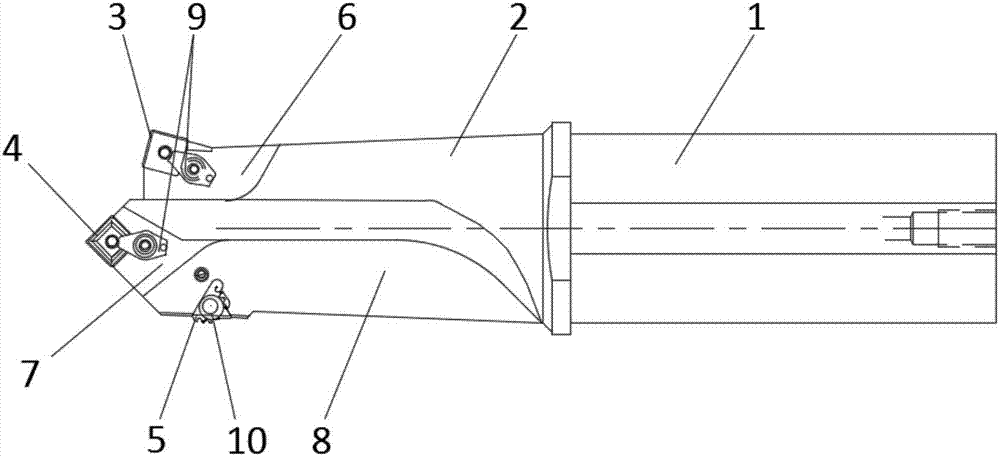

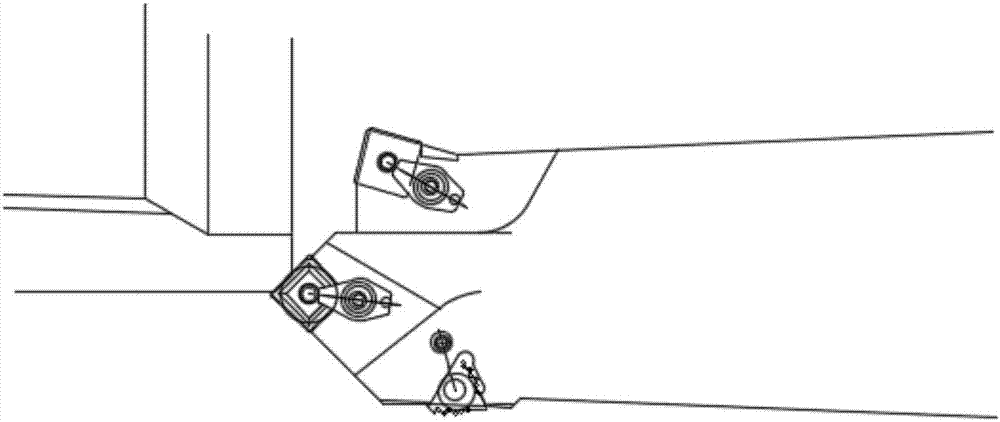

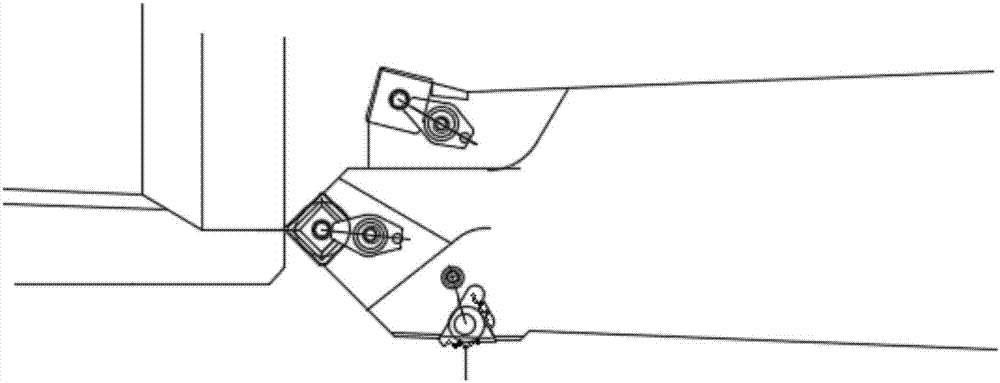

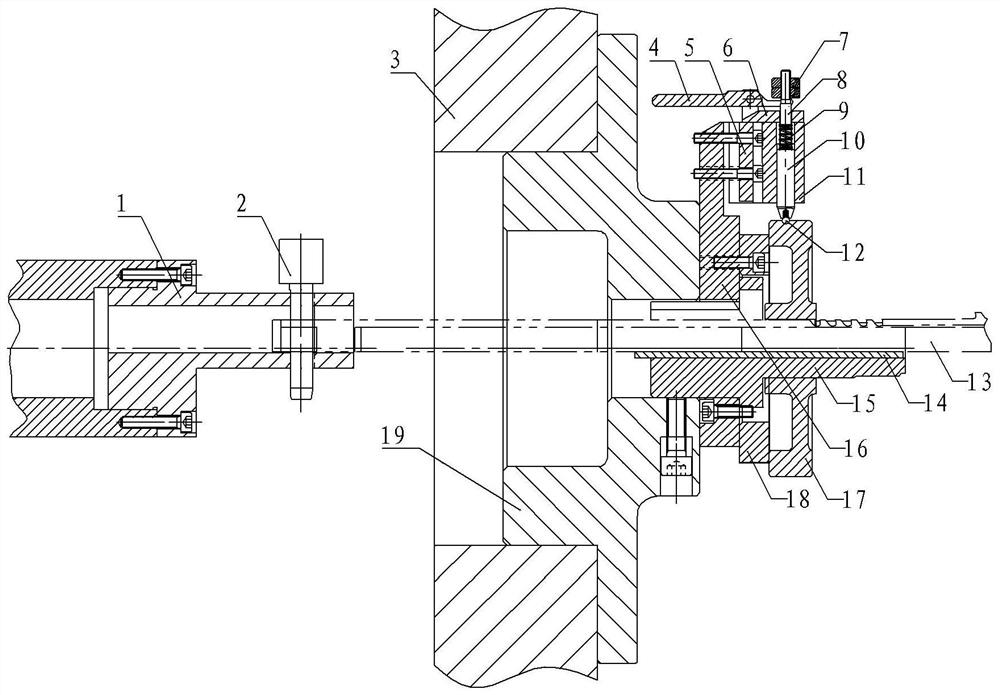

Full-station composite cutter bar for processing petroleum pipe threads

InactiveCN107096967AReduce failureExtended service lifeThread cutting toolsTool holdersEconomic benefitsMechanical engineering

The invention relates to a full-station composite cutter bar for processing petroleum pipe threads. The full-station composite cutter bar comprises a cutter bar body, and a blade connecting part is arranged at the front end of the cutter bar body; a boring blade is arranged on the upper side of the front end of the blade connecting part; a chamfering blade is arranged on the front side of the front end of the blade connecting part; a threading blade is arranged on the lower side of the front end of the blade connecting part; a mounting plane matched with the boring blade, the chamfering blade and the threading blade is arranged on the blade connecting part; a boring chip removal guide surface is arranged in the position, between the boring blade and the cutter bar body, on the blade connecting part; a chamfering chip removal guide surface is arranged in the position, between the chamfering blade and the cutter bar body, on the blade connecting part; and a threading chip removal guide surface is arranged in the position, between the threading blade and the cutter bar body, on the blade connecting part. According to the full-station composite cutter bar for processing the petroleum pipe threads, end face chamfer turning, excircle turning, bored hole burr removal and thread turning procedures can be carried out at the same time, the blade does not need to be changed halfway, chips can be quickly discharged, processing efficiency can be improved, the risk that a rotating knife rest breaks down is reduced, service life of a cutter is prolonged, utilization cost of the cutter is reduced, and economic benefits are increased.

Owner:KUNSHAN HIECISE PRECISION TOOL

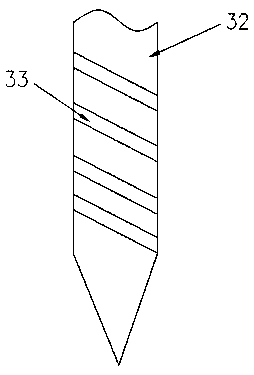

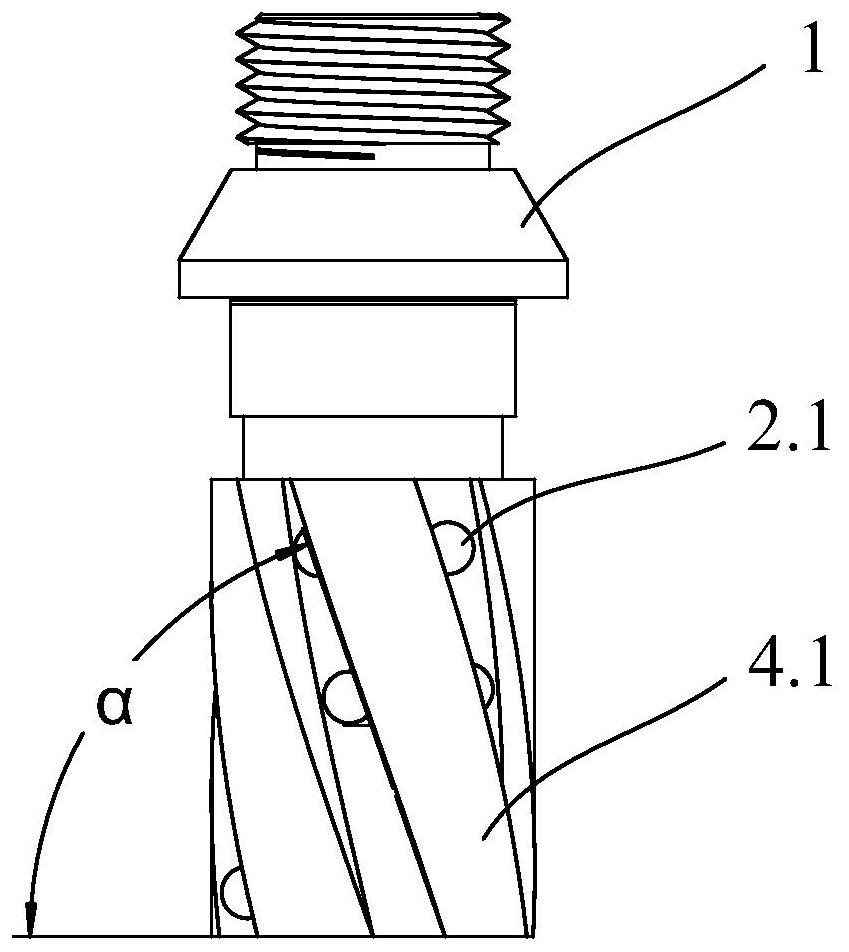

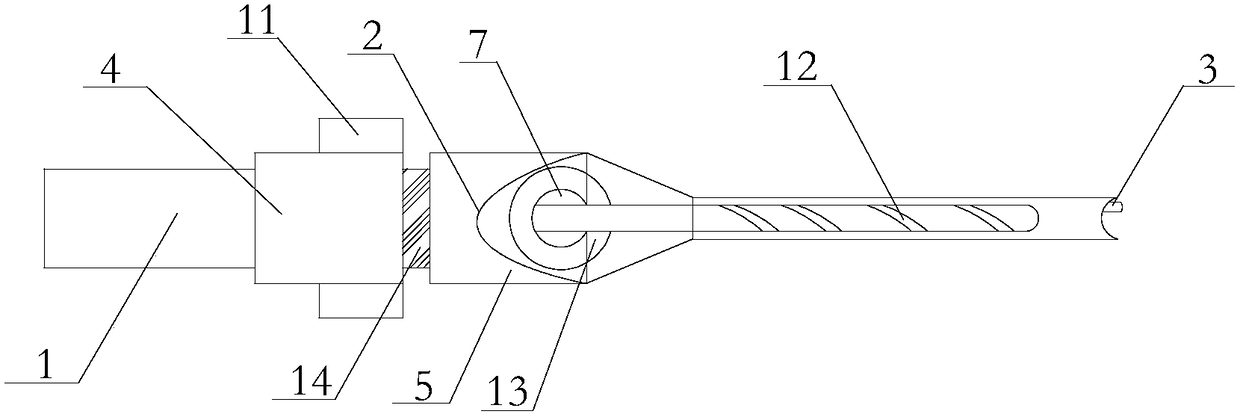

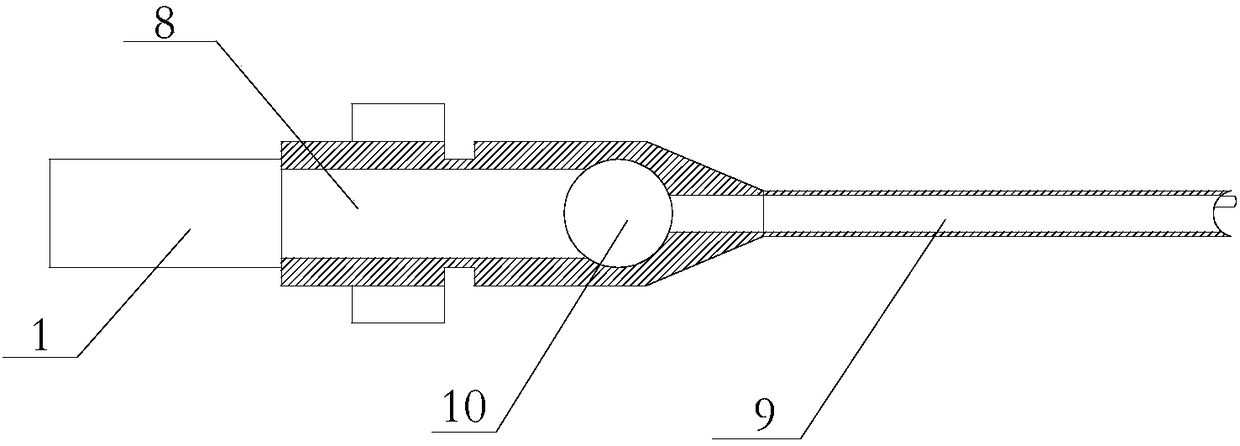

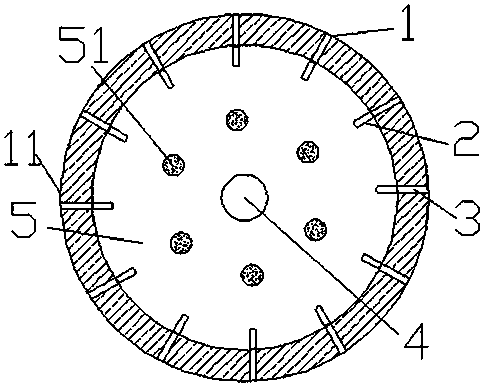

Woodworking square hole drill

InactiveCN108068174AFast Chip EvacuationReduce shakingDrilling machinesWood mortising machinesDrill bitPetroleum engineering

The invention provides a woodworking square hole drill, wherein a drill sleeve is arranged on the outer portion of a drill core in a sleeved manner, the front end of the drill core is provided with adrill tip, the drill sleeve comprises a clamping part, a guide part, a sawdust discharge groove, a sawdust discharge hole I, a drill bit installation groove I, a drill bit installation groove II and asawdust discharge hole II, wherein the guide part is arranged on one side of the clamping part, both sides of the clamping part are provided with wind suction devices, the sawdust discharge hole I isarranged on the outer wall of the guide part, the sawdust discharge groove penetrates through the guide part and the sawdust discharge hole I, the center of the clamping part is provided with the drill bit installation groove I, the center of the guide part is provided with the drill bit installation groove II, the outer side of the guide part is provided with the sawdust discharge hole II penetrating through the guide part, the drill core is provided with a spiral sawdust outlet groove, the sawdust discharge hole I is provided with an elastic position limiting member matched with the drill core, and the outer side of the clamping part is provided with a snapping groove. According to the present invention, under the co-action of the sawdust discharge groove and the sawdust discharge holes, the wind suction devices rapidly apply the adsorption force on the sawdust, the broken sawdust generated by the drilling is rapidly discharged, and the elastic position limiting member is arranged on the periphery of the drill core so as to stabilize the drill core and reduce the shaking degree.

Owner:天津千艺达建筑工程有限公司

Abrasion-resistant cutting blade special for motor

InactiveCN107671755ASimple structureEffective absorptionBonded abrasive wheelsWear resistantRapid processing

The invention discloses a special wear-resistant cutting disc for electric motors, which comprises a circular base plate, an annular cutting belt is arranged on the circumference of the base plate, a bearing hole for installing a bearing is arranged at the center of the base plate, the bearing hole is connected with the cutting There are several evenly distributed strip-shaped holes between the belts, wedge-shaped grooves are also arranged on the base plate, and several muffler holes are fixed on the outer end of the bearing hole, and the muffler holes are set on the base plate, and the base plate A wear-resistant layer is also fixedly installed on the outer surface, and the thickness of the wear-resistant layer is 1-3mm. The invention adopts an annular cutting belt, which has a simple structure and can effectively cut hard and brittle objects such as ceramics and vitrified bricks. The effective cooperation of wedge-shaped grooves and strip-shaped holes is helpful for rapid chip removal and The heat dissipation further improves the service life of the cutting disc. At the same time, the sound-absorbing holes are set on the upper surface of the base plate, which can effectively absorb the sound generated during the cutting process.

Owner:QIDONG TIANSHAN TOOLS CO LTD

A kind of lock body steel with easy drilling and fast chip removal and preparation method thereof

The invention discloses a lock body steel which is easy to drill and has fast chip removal and a preparation method thereof, belonging to the technical field of locks. Its chemical composition is calculated by mass percentage: C: 0.01-0.03%, Si: 0-0.04%, Mn: 1.6%-2.0%, P: 0.010%-0.030%, S: 0.40%-0.55%, Bi: 0.15 %~0.22%, Se: 0.005%~0.01%, T[O]: 0.003%~0.006%, B: 0.004%~0.006%, and the rest are Fe and unavoidable impurities. The invention effectively controls the size and shape of Mn(S, Se), ferrite and pearlite of the lock body steel by compounding a certain amount of Bi and Se and optimizing the content of Mn and S in the steel, further reducing the hardness of the steel, Improve the chip removal, chip breaking ability and drill bit life during the drilling process; and through forging, hot rolling, staged cooling and shot blasting processes in the preparation process, the matrix ferrite structure and a small amount of pearlite structure are finally obtained, and the drilling performance is excellent The lock body steel product is low in hardness, easy to drill, fast in chip removal, fast in heat dissipation, and has little wear on high-speed drill bits. It can be widely used in the manufacture of padlocks and gourd locks.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

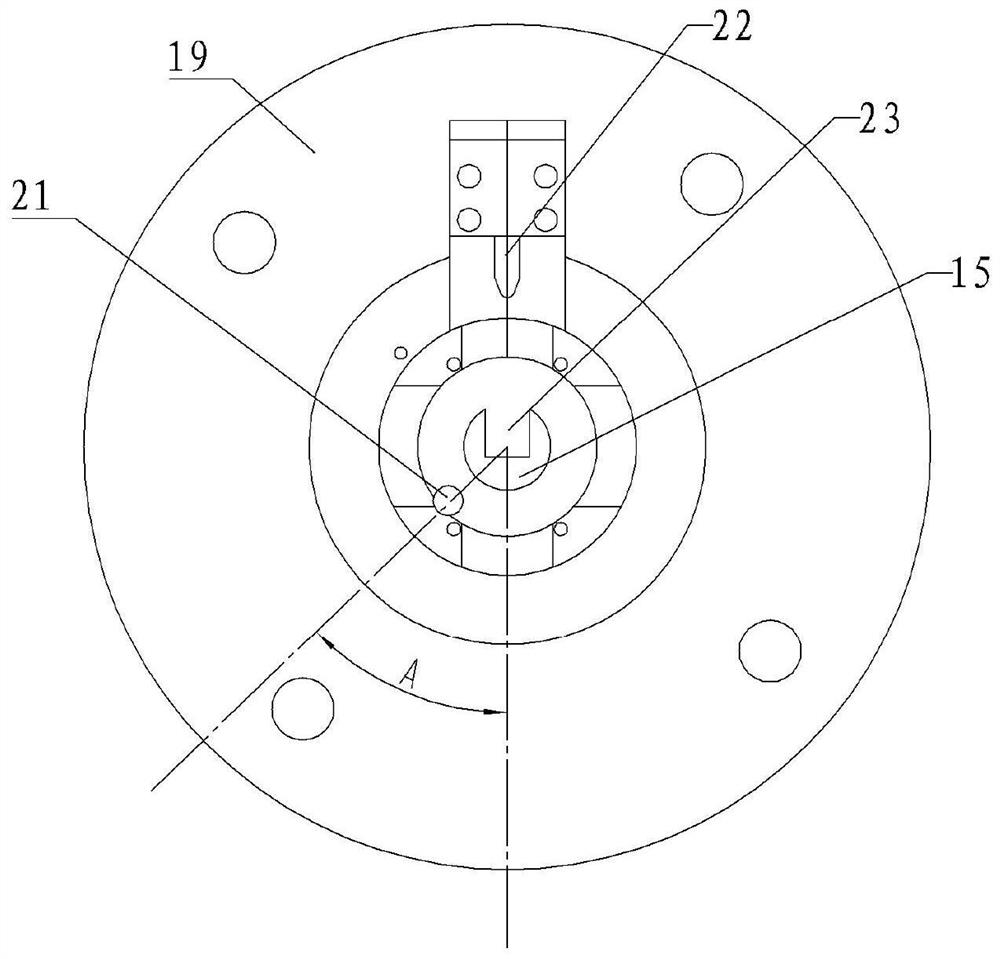

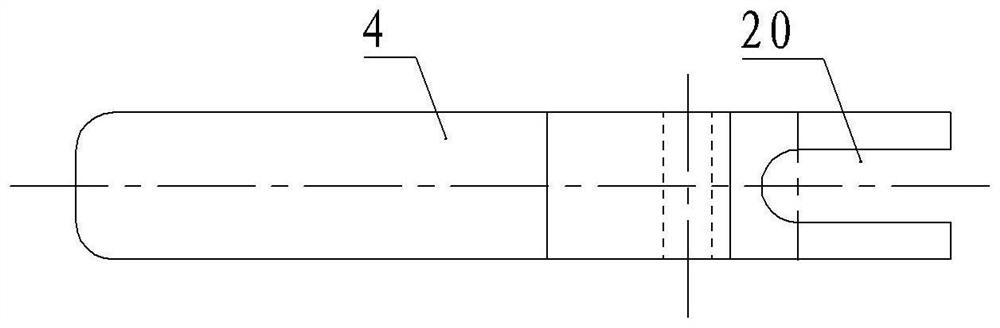

Gear slotting and trepanning process

The invention relates to the technical field of gear machining, in particular to a gear slotting and trepanning process which comprises the following steps that firstly, at least one lightening hole is forged in a workpiece at a time, and the lightening holes are evenly distributed in the workpiece; step 2, making teeth; thirdly, a key groove is pulled out through a groove pulling tool; fourthly, threaded holes are machined; the groove broaching tool comprises a capstan, a guide sleeve and a positioning mechanism, the guide sleeve and the positioning mechanism are both fixed to the capstan, a broach groove axially penetrates through the guide sleeve, the positioning mechanism is located on one side of the guide sleeve, and a limiting pin is fixed to the capstan and used for being inserted into the lightening hole. An included angle A formed between the limiting pin and the broach groove is used for avoiding overlapping of the lightening hole and the threaded hole. According to the scheme, an existing machining sequence is changed, the positions of the lightening holes are combined, the positions of the key grooves are determined through the groove broaching tool, overlapping of the threaded holes and the lightening holes can be effectively avoided, workpiece scrapping is avoided, and the problem that in the prior art, the lightening holes and the threaded holes are prone to overlapping is solved.

Owner:CHONGQING XINGJI GEAR

CBN cutting tool bit for sintered steels

Owner:MAANSHAN GOLDEN EAGLE SUPER HARD MATERIAL

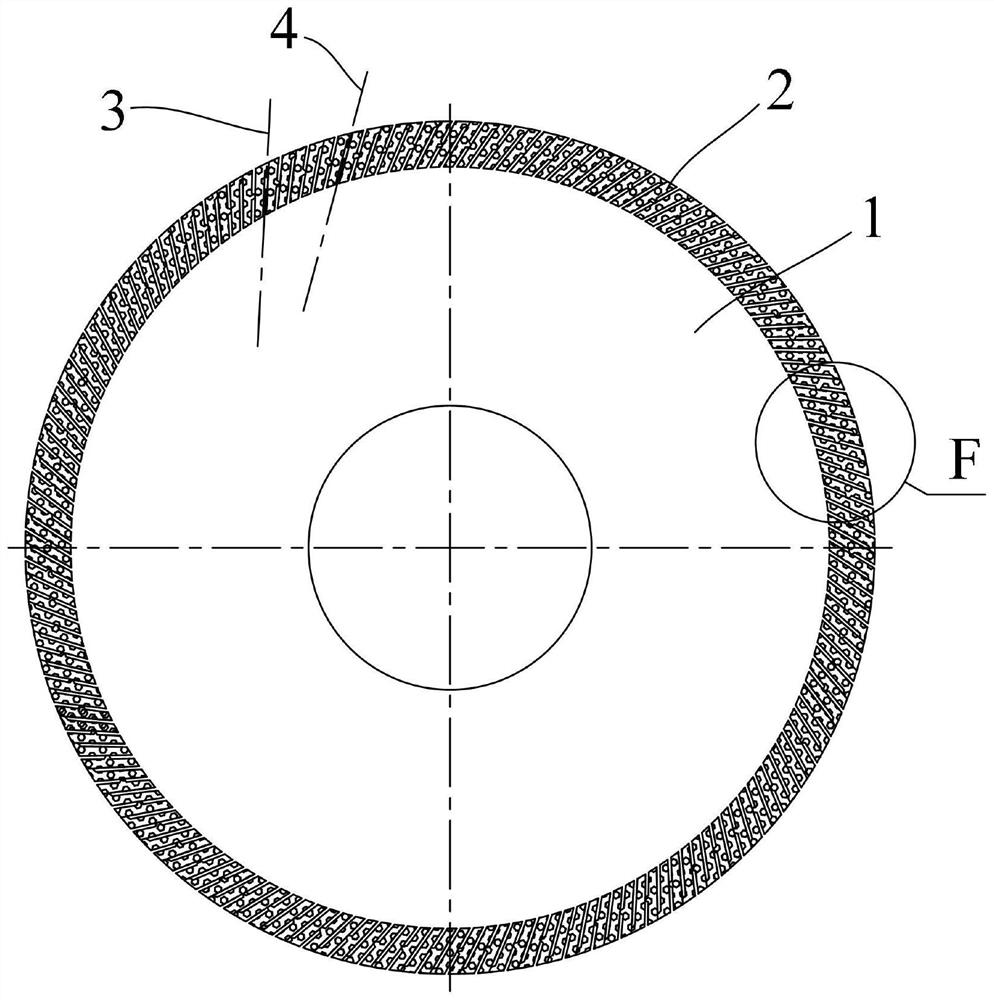

Composite structure cup-shaped grinding wheel

PendingCN112936119AFunction increaseGood cooling functionBonded abrasive wheelsCooling effectStructural engineering

The invention relates to a composite structure cup-shaped grinding wheel which comprises a grinding wheel base body and a diamond working ring fixedly connected to the grinding wheel base body. The diamond working ring comprises a plurality of tooth sets, and the tooth sets are sequentially and fixedly arranged along the edge of the grinding wheel base body. A first composite tooth groove is formed between each tooth set and the adjacent tooth set. Compared with the prior art, the chip removal function and the cooling function of the diamond working ring can be improved, the utilization rate of cooling water is increased, the cooling effect of the cooling water on an inner ring part is enhanced, the intermittent grinding function is improved, the negative effect of through tooth vibration is weakened, and the quality can be guaranteed while the grinding efficiency is improved.

Owner:宋京新 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com