A screw nail

A screw and thread technology, applied in the field of screw-fixing products, can solve the problems of outward expansion of objects, damage to the appearance of objects, and difficulty in screwing operations, and achieve the effect of improving use efficiency and cutting labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Regarding the screw of the present invention, the technical means adopted and the effect of achieving the above-mentioned purpose are easy to understand. Hereby, a detailed description is made with the best embodiment in conjunction with the simple description of the drawings and the symbols of each component as follows:

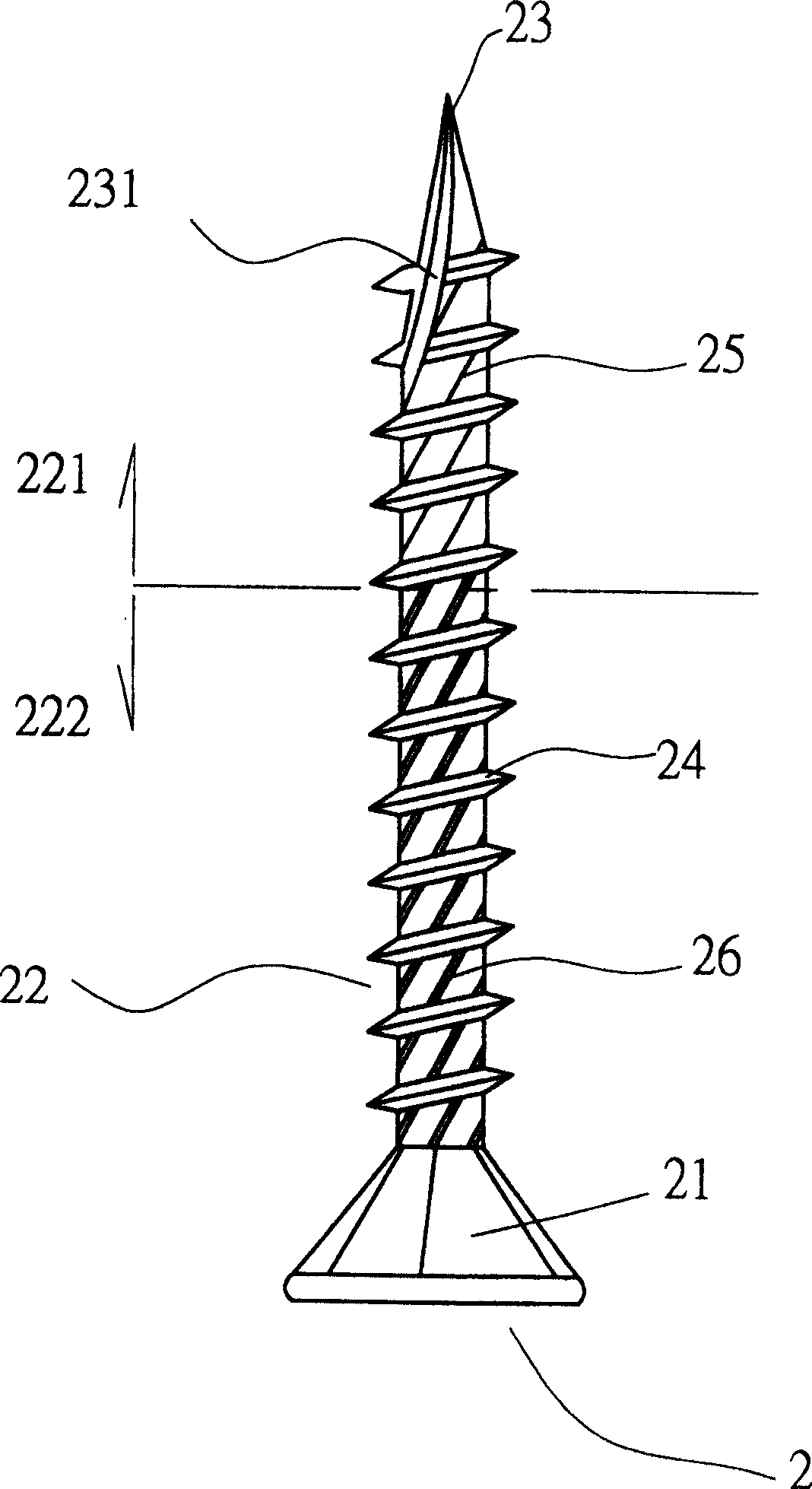

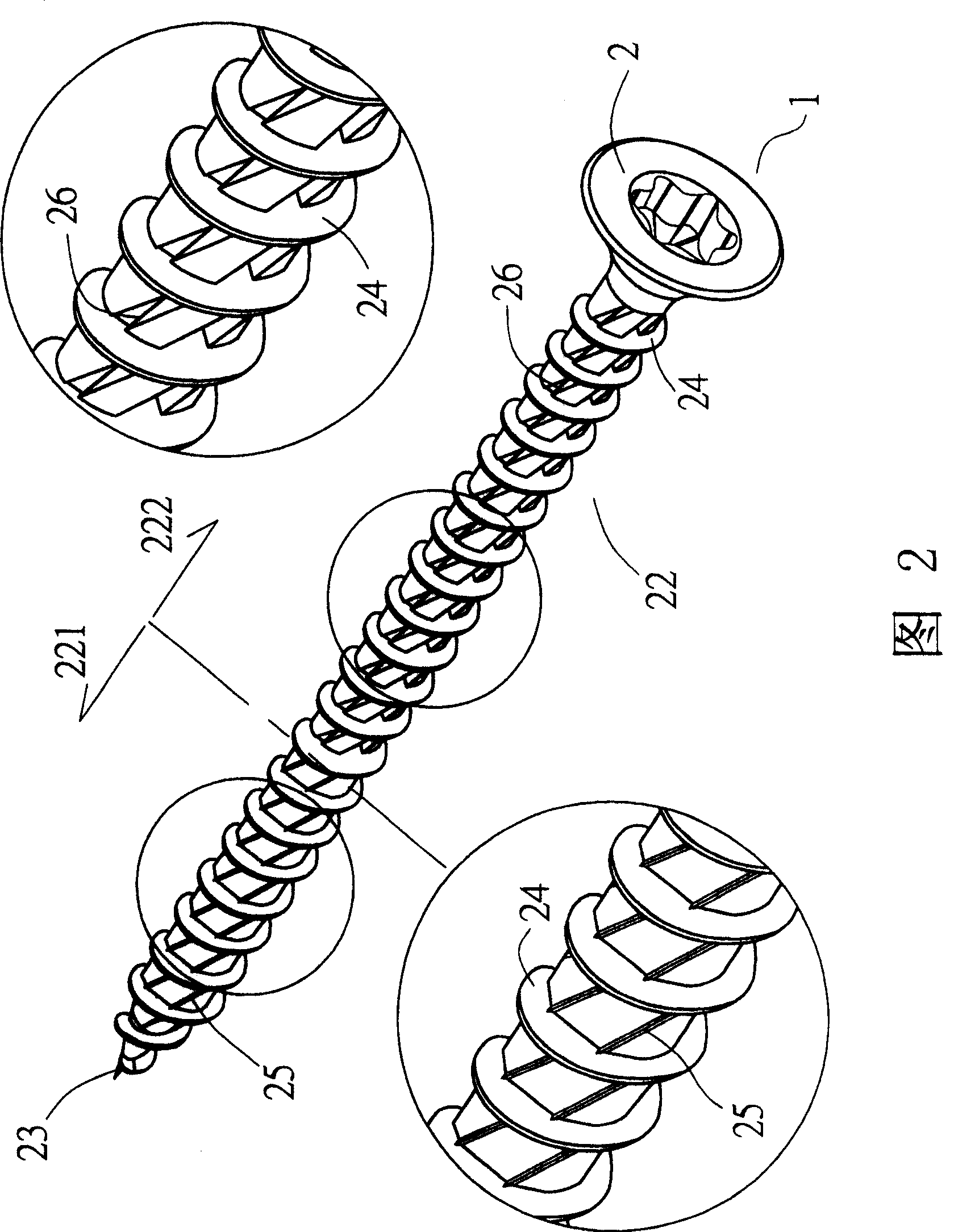

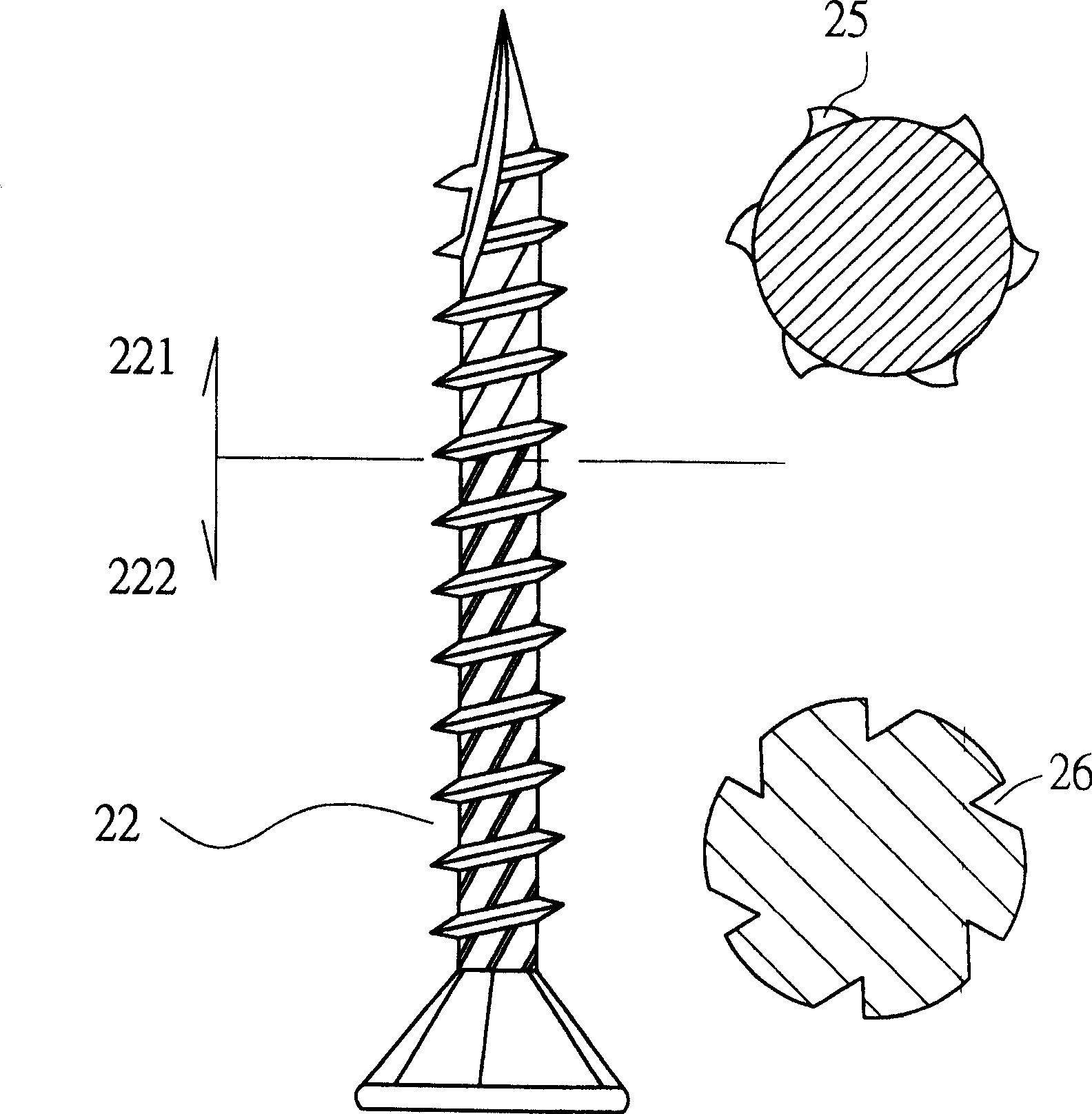

[0026] First, please also see Figure 1 to Figure 3 As shown, the screw 2 designed by the present invention includes a head 21, a shank 22, a tip 23, and a plurality of threads 24 integrally formed on the shank 21 and coiled continuously in a helical shape; wherein:

[0027] The shank 22 of the screw 2 is provided with several outer convex cutting parts 25 at the front section 221 having the thread 24 in the direction of the tip 23, so that the front section 221 can be screwed into the object 3 to smoothly complete the cutting and quick discharge. The first stage of crumb work is shown in Figure 2 and Figure 4 shown; in addition, the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com