Screw with low spin lock torque

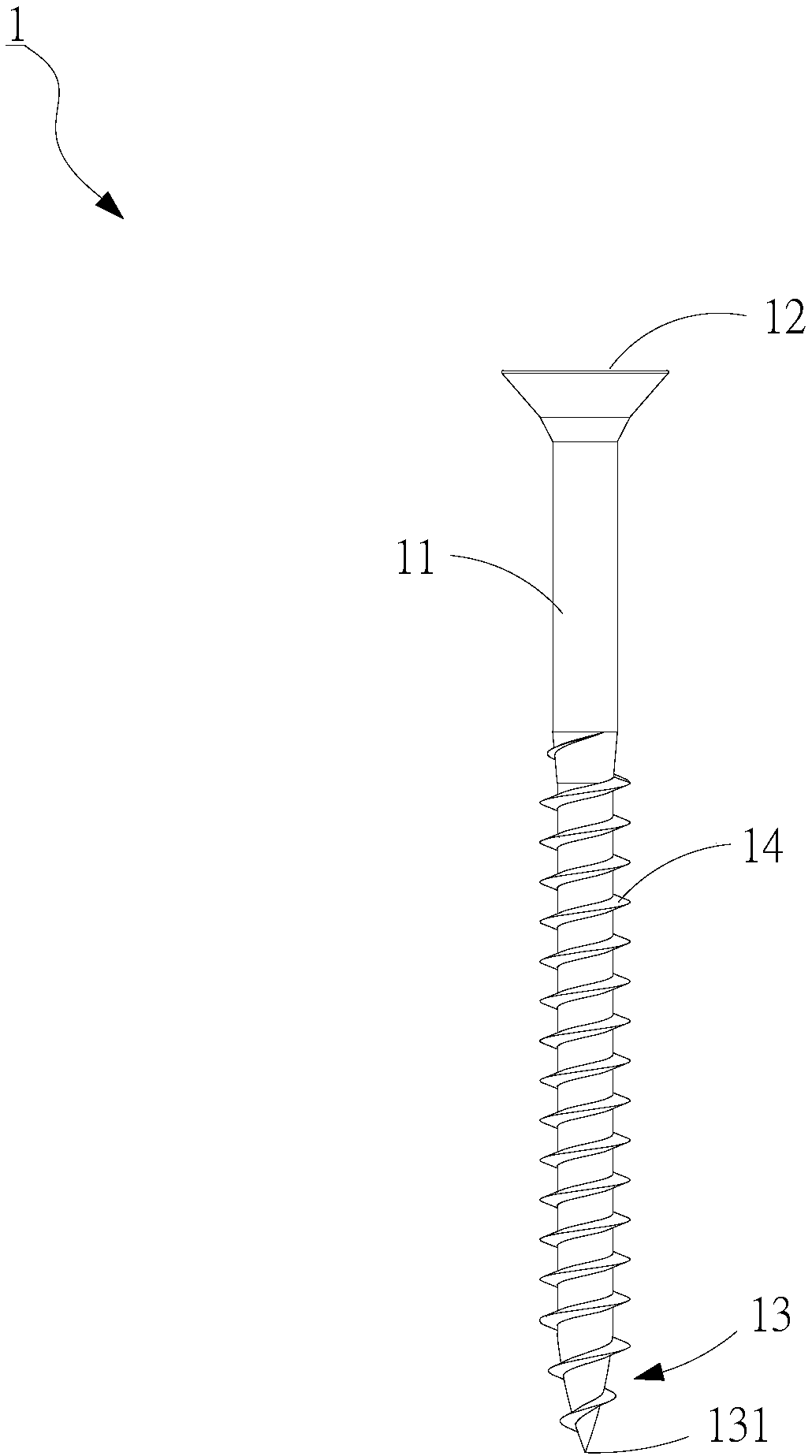

A technology of locking twist and screws, applied in the direction of screws, bolts, threaded fasteners, etc., can solve the problems of increased twist lock torque, increased difficulty of locking, loosening, shaking or falling off of screw 1

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The above and other technical content, features and effects of the present invention will be clearly understood in the following detailed description of preferred embodiments with reference to the accompanying drawings.

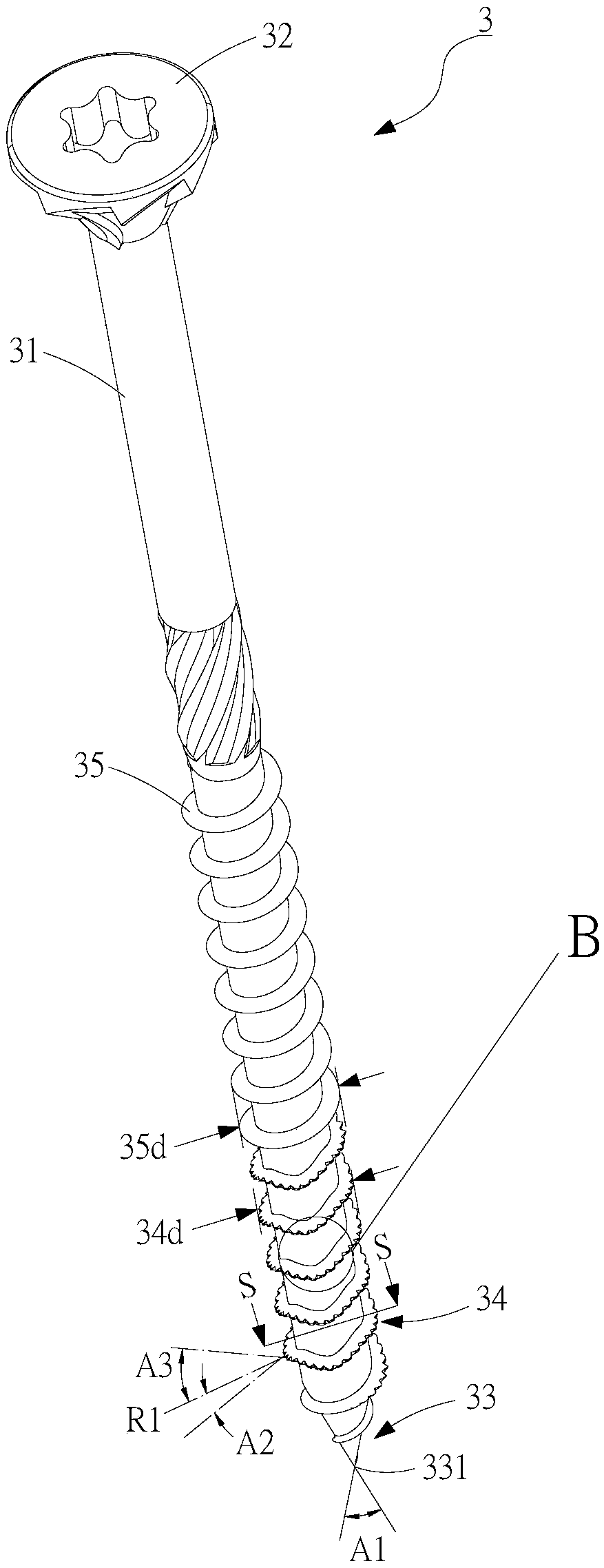

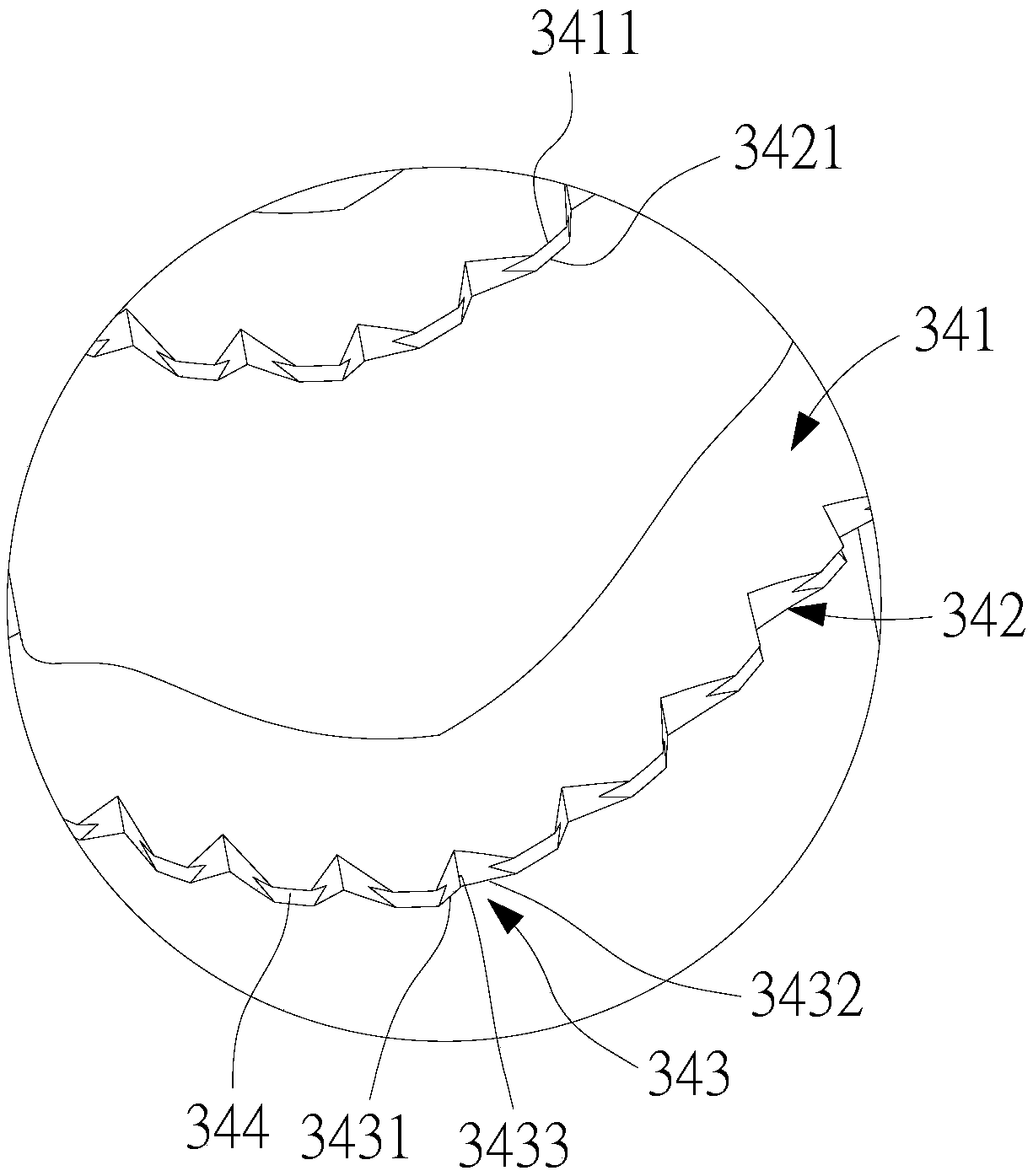

[0044] refer to figure 2 As shown, in a preferred embodiment of the present invention, the screw 3 with low twist-lock torque includes a rod body 31, a screw head 32 arranged at one end of the rod body 31, and a screw head 32 arranged at the other end of the rod body 31 and opposite to the rod body 31. The locking part 33 of the screw head 32, and a plurality of cutting threads 34 which are arranged on the rod body 31 and extend toward the locking part 33; wherein, the locking part 33 tapers to form a drill point 331, and the lock The angle A1 formed by the converging portion 33 converging and extending outward after the drill tip 331 is preferably 22-26 degrees. The auxiliary screw teeth 35 are provided in a complete tooth type. The above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com