Screws with low twist-lock torque

A technology of locking twist and screw, applied in the direction of screws, bolts, threaded fasteners, etc., can solve the problems of increasing the difficulty of locking, increasing the twisting torque, and cracking the lock compound, so as to improve the occlusal stability, The effect of reducing twist lock torque and increasing cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The above and other technical content, features and efficacy of the present invention will be apparent from the preferred embodiments of the preferred embodiments of the drawings.

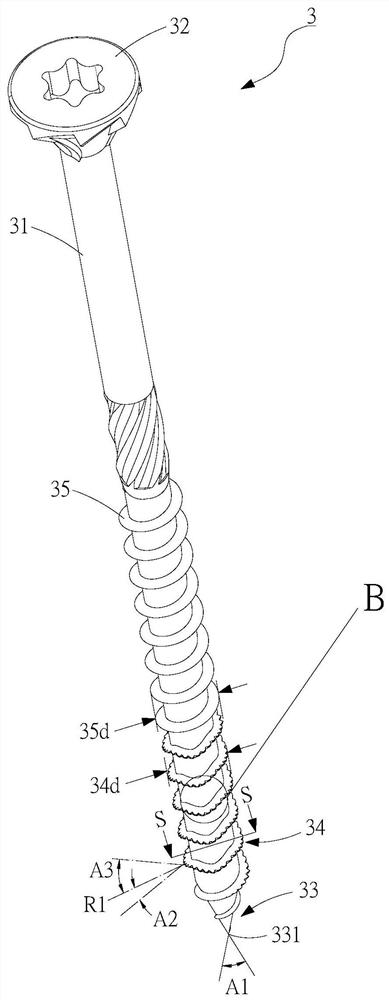

[0044] See figure 2 As shown, a preferred embodiment of the present invention, the screw 3 of the low rotary lock torque is includes a rod body 31, which is provided at the other end of the rod body 31 and the other end of the rod body 31 and opposite to screw head 32 of the locking portion 33, and a plurality of rods disposed on the body 31 and toward the cutting thread 33 of the locking portion 34 extends; wherein the locking portion 33 is formed a tapered drill point 331, and the lock engagement portion 33 meet at a tapered angle of the drill tip 331 extends outwardly formed A1 is preferably 22 to 26 degrees, while the present embodiment, the rod 35 further has a plurality of auxiliary thread 31, and the plurality The auxiliary screw 35 is provided with a complete dental state, and the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com