An automatic control multifunctional engraving machine

An automatic control and multi-functional technology, applied in decorative arts, processing models, painting tools, etc., can solve the problems of low degree of automation of the engraving machine, affecting the machining accuracy of the workpiece, time-consuming and laborious carving of the workpiece, etc., to achieve simple structure, improve quality, The effect of easy chip evacuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

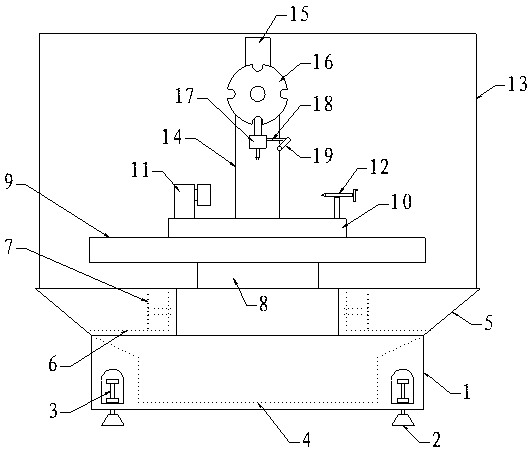

[0018] Such as figure 1 and figure 2 As shown, an automatic control multi-function engraving machine, it includes a base 1, the lower end of the base 1 is provided with a support bolt 3, the bottom of the base 1 is provided with an anchor 2, and the support bolt 3 Connected with the foundation 2, the inside of the machine base 1 is provided with a water tank 4, the upper side of the machine base 1 is provided with a dust collection box 5, and the upper side of the described dust collection box 5 is provided with a protective plate 13. A filter screen 6 is provided inside the dust collection box 5, an electric chip removal plate 7 is provided inside the dust collection box 5, an X-axis arm 8 is provided on the upper side of the machine base 1, and the X-axis arm 8, a Y-axis arm 9 is arranged on the upper side, and a working platform 10 is arranged on the upper side of the Y-axis arm 9. An electric dividing head 11 and a thimble 12 are arranged on the upper side of the working...

Embodiment 2

[0021] Such as figure 1 and figure 2 As shown, an automatic control multi-function engraving machine, it includes a base 1, the lower end of the base 1 is provided with a support bolt 3, the bottom of the base 1 is provided with an anchor 2, and the support bolt 3 Connected with the foundation 2, the inside of the machine base 1 is provided with a water tank 4, the upper side of the machine base 1 is provided with a dust collection box 5, and the upper side of the described dust collection box 5 is provided with a protective plate 13. A filter screen 6 is provided inside the dust collection box 5, an electric chip removal plate 7 is provided inside the dust collection box 5, an X-axis arm 8 is provided on the upper side of the machine base 1, and the X-axis arm 8, a Y-axis arm 9 is arranged on the upper side, and a working platform 10 is arranged on the upper side of the Y-axis arm 9. An electric dividing head 11 and a thimble 12 are arranged on the upper side of the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com