Shaft side drilling clamp

A drilling fixture and drilling mechanism technology, applied in clamping, manufacturing tools, supports, etc., can solve problems such as difficult chip removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below through specific implementations:

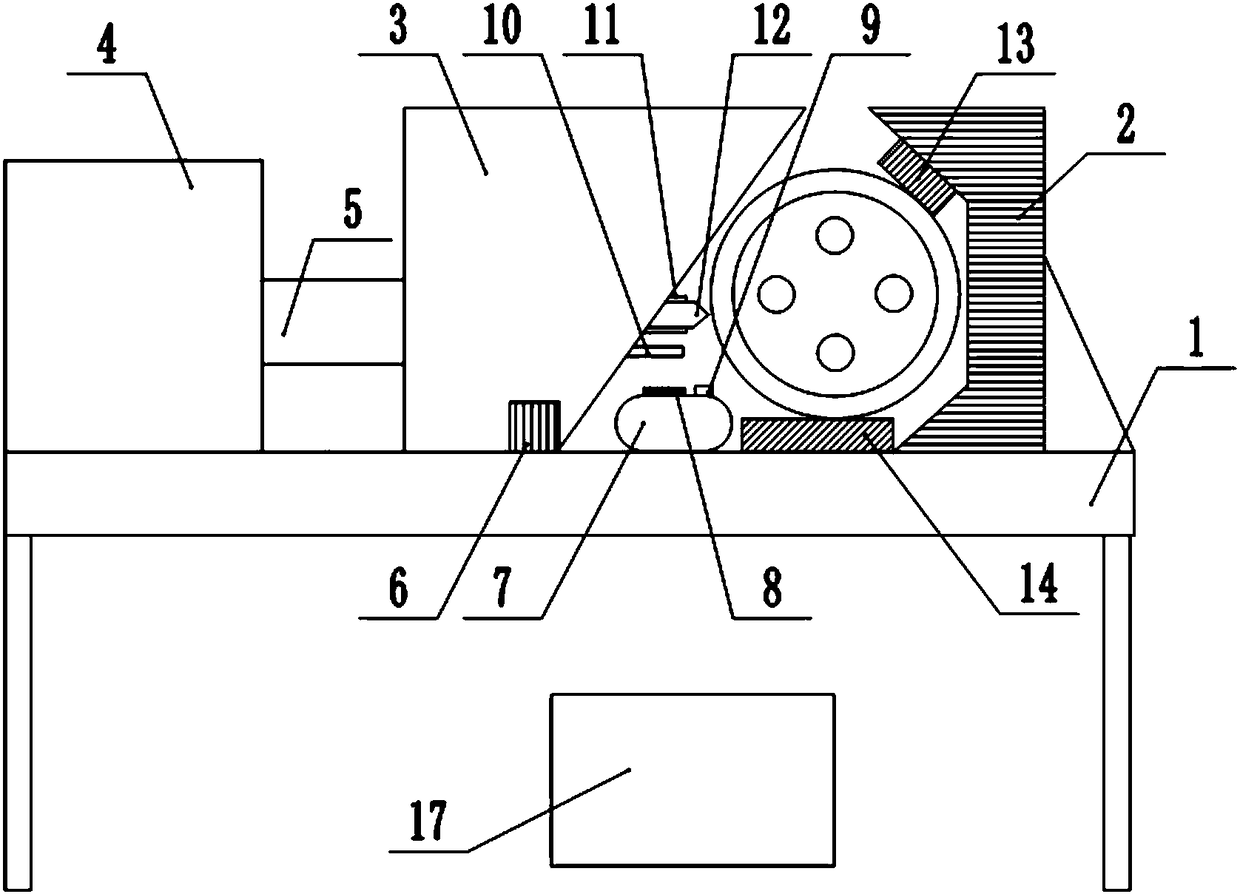

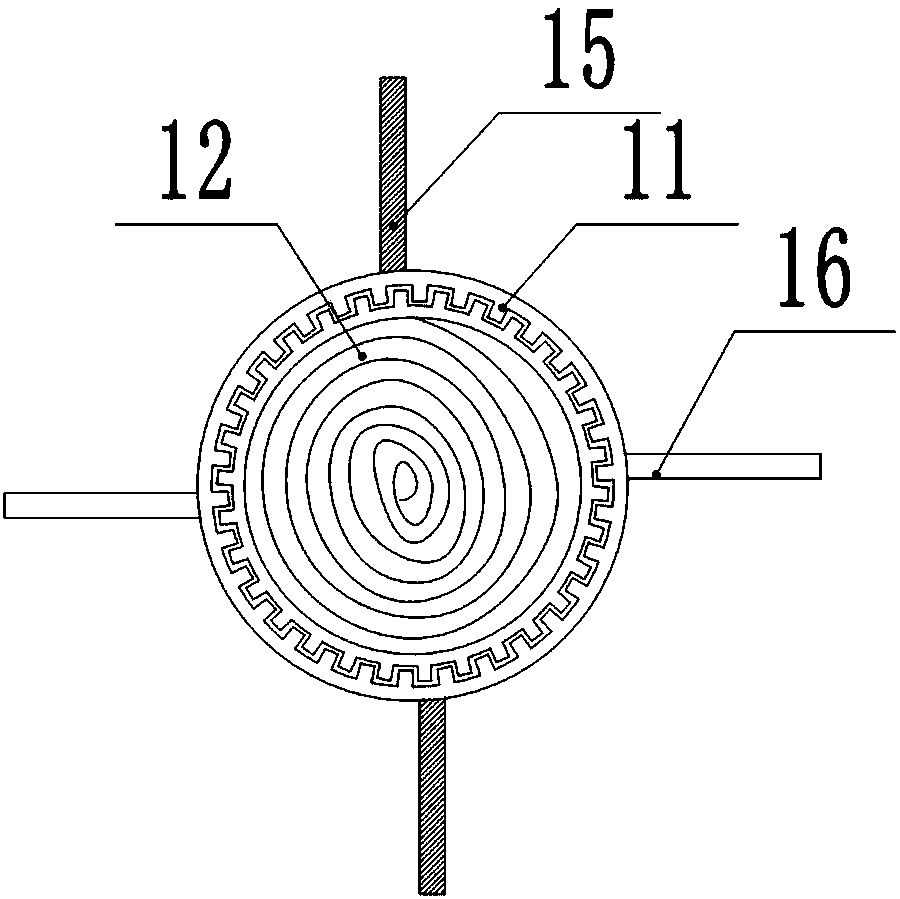

[0016] The reference signs in the drawings of the specification include: base 1, V-shaped block 2, compression slider 3, cylinder 4, piston rod 5, check valve 6, water bladder 7, second magnet 8, nozzle 9, chip stopper The block 10, the hoop 11, the drill bit 12, the wear-resistant pad 13, the support plate 14, the iron chip blade 15, the chip discharge blade 16, and the collection groove 17.

[0017] Such as figure 1 , figure 2 As shown, a shaft side drilling fixture includes a base 1, a V-shaped block 2 is fixed on the base 1, a wear-resistant pad 13 is fixed on the V-shaped block 2, and the opening direction of the V-shaped block 2 is provided with a pressing slide Block 3, the position on the pressing slider 3 that is directly opposite to the opening direction of the V-shaped block 2 is provided with an inclined surface, the lower part of the inclined surface is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com