Full-station composite cutter bar for processing petroleum pipe threads

A full-station, compound knife technology, applied in the direction of thread cutting tools, metal processing equipment, tool holders, etc., can solve the problems of increased thread surface roughness, reduced service life of tool holders, and impact on processing efficiency, so as to reduce the use of cost, prolong service life, and improve economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

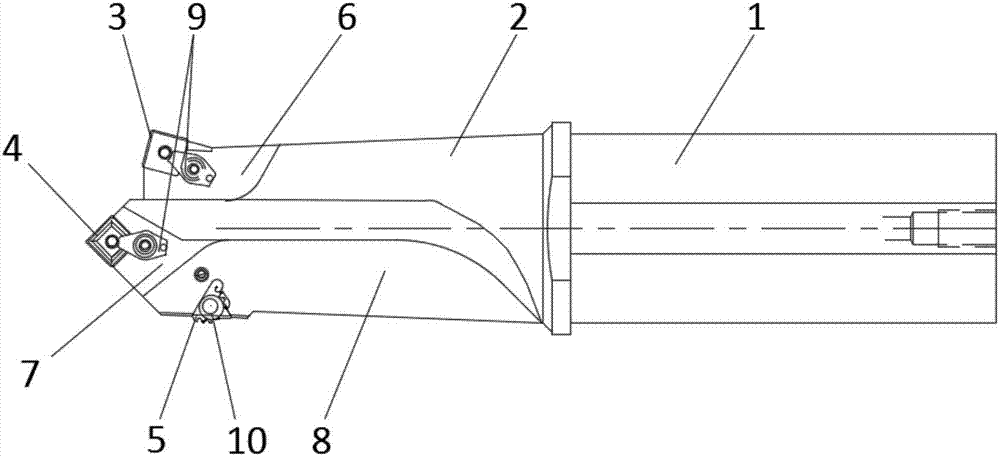

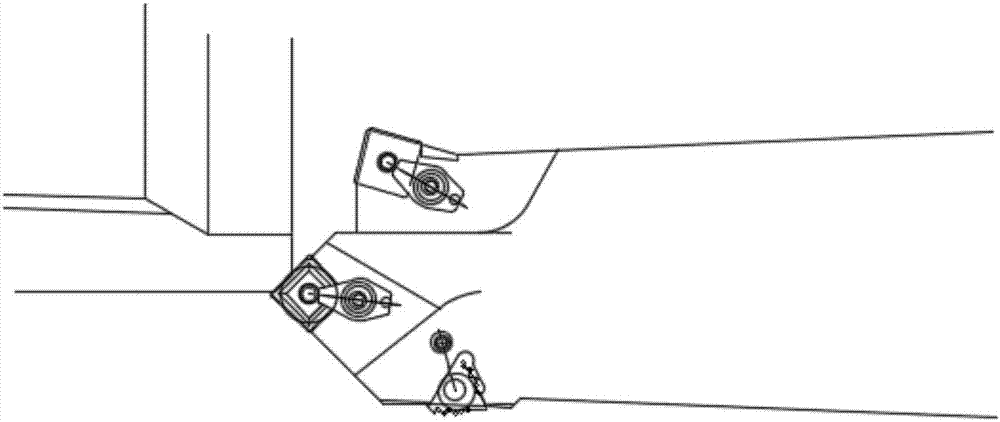

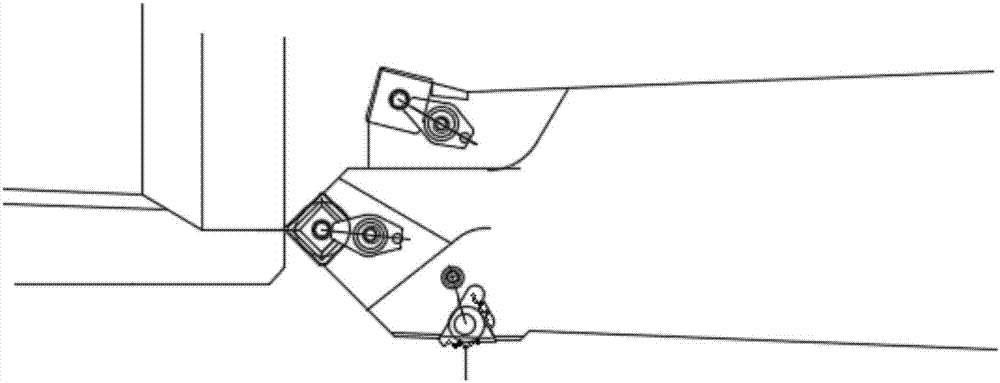

[0016] Such as figure 1 As shown, this embodiment provides a full-station composite tool holder for processing oil pipe threads, which includes a tool holder body 1; a blade connecting portion 2 is provided at the front end of the cutter rod body 1; The upper side of the upper side is provided with a boring blade 3, the front side is provided with a chamfering blade 4, and the lower side is provided with a threaded blade 5; Matching installation plane; the blade connecting portion 2 between the boring blade 3 and the tool holder body 1 is provided with a boring chip removal guide surface 6; the chamfering blade 4 and the blade between the tool holder body 1 The connecting part 2 is provided with a chamfering chip removal guide surface 7; the blade connection part 2 between the threaded insert 5 and the tool holder body 1 is provided with a threaded chip removal guide surface 6; the boring blade 3, chamfering The blades 4 and threaded blades 5 are distributed in a triangular s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com