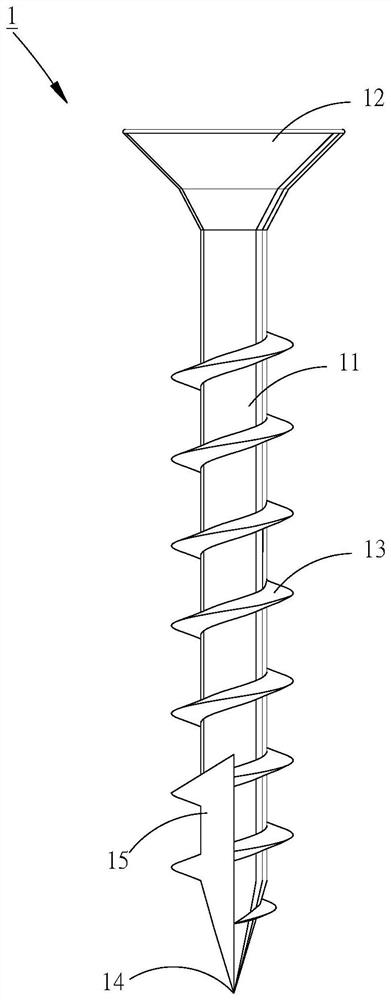

Slotted point-tail screws

A technology for cutting grooves and screws, which is applied in the direction of screws, threaded fasteners, connecting components, etc., and can solve problems such as chip extrusion, deflection, and large locking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The above and other technical contents, features and effects of the present invention will be clearly and clearly shown in the following detailed description of the preferred embodiments with reference to the drawings.

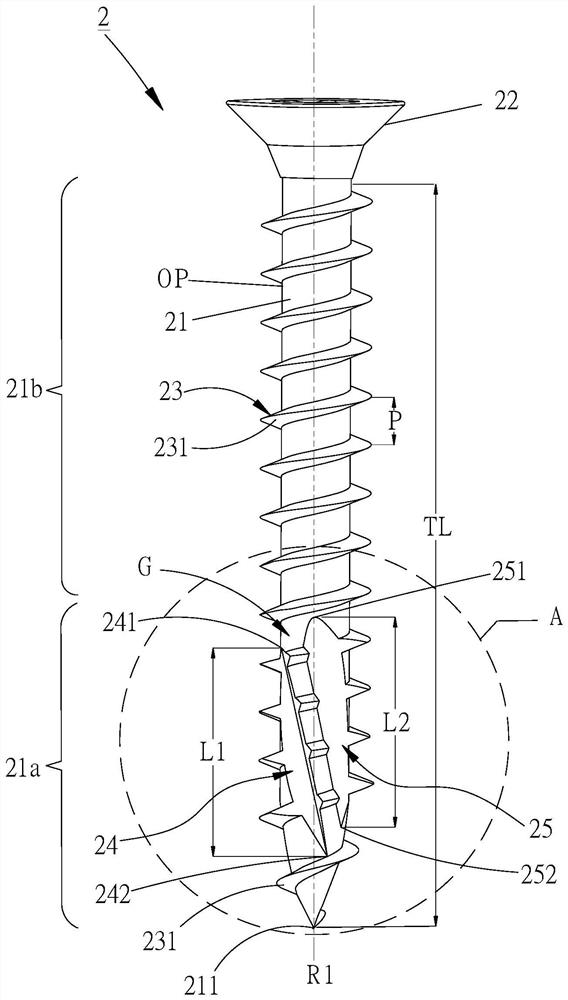

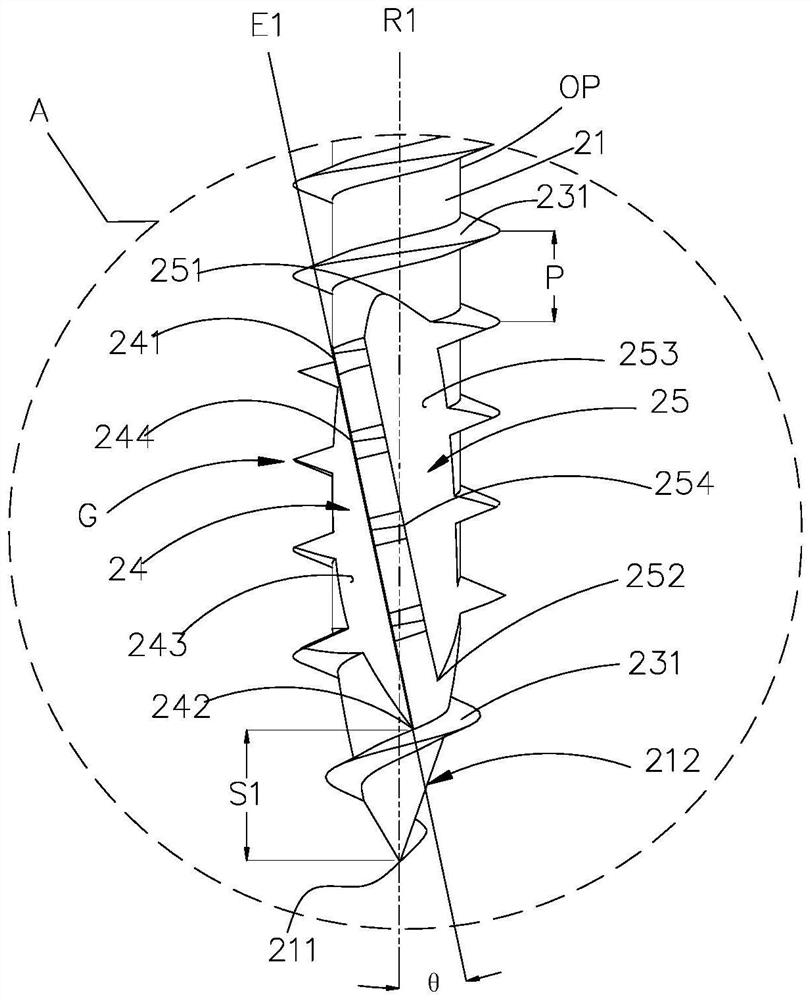

[0087] see figure 2 , the first preferred embodiment of the present invention, the pointed end screw 2 with the slot includes a rod body 21, a screw head 22 provided at one end of the rod body 21, and a screw thread portion provided on the rod body 21 by a helical ring 23; wherein, the screw portion 23 has a plurality of screw teeth 231 (as shown in the figure, right-handed screw teeth 231), any two adjacent screw teeth 231 are spaced apart to form a pitch P, and the rod body 21 can be The rod body 21 is round rod-shaped and has an outer peripheral surface OP. The other end of the rod body 21 is tapered to form a tip 211 opposite to the screw head 22. The rod body 21 defines a longitudinal axis R1 passing through the tip 211 and also defines a A lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com