Composite structure cup-shaped grinding wheel

A cup-shaped grinding wheel and composite structure technology, applied in the field of grinding wheels, can solve the problems of poor cooling capacity, poor chip removal capacity, low water utilization rate, etc., to improve the chip removal function and cooling function, improve the circumferential chip removal ability, Enhanced cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

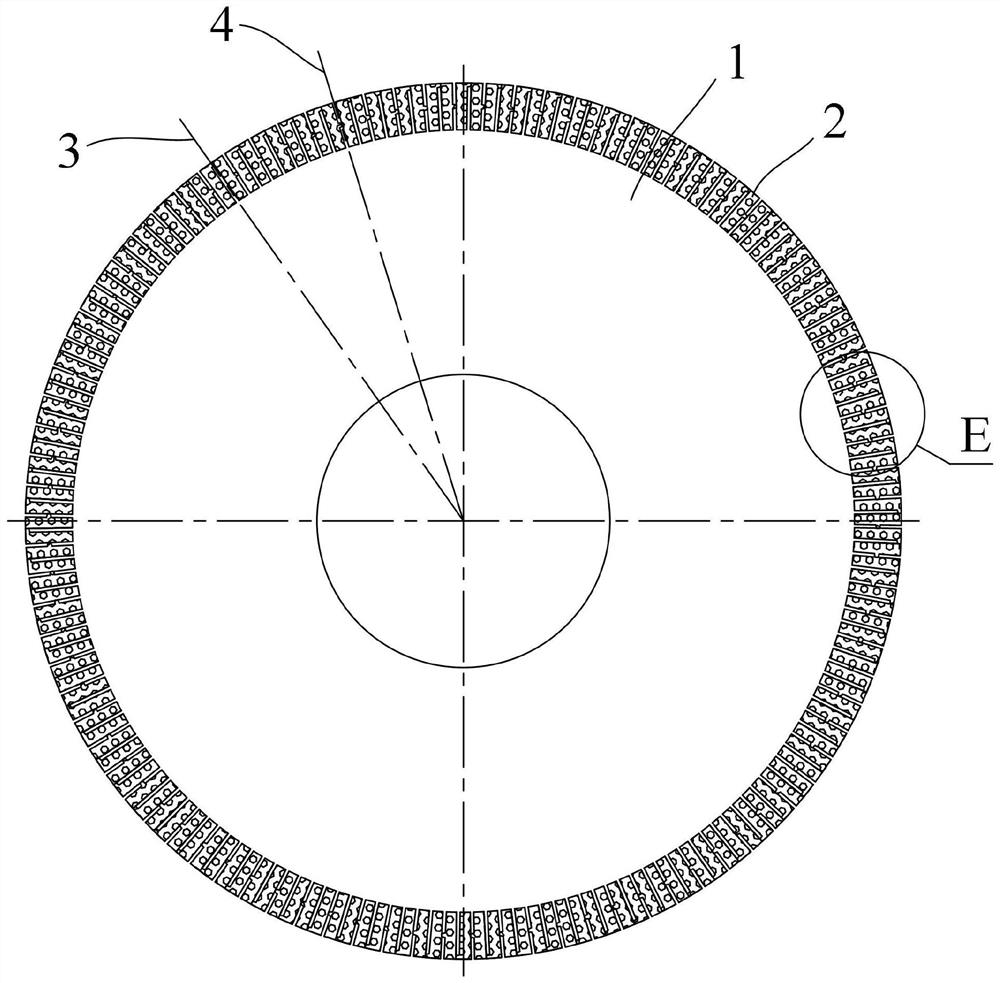

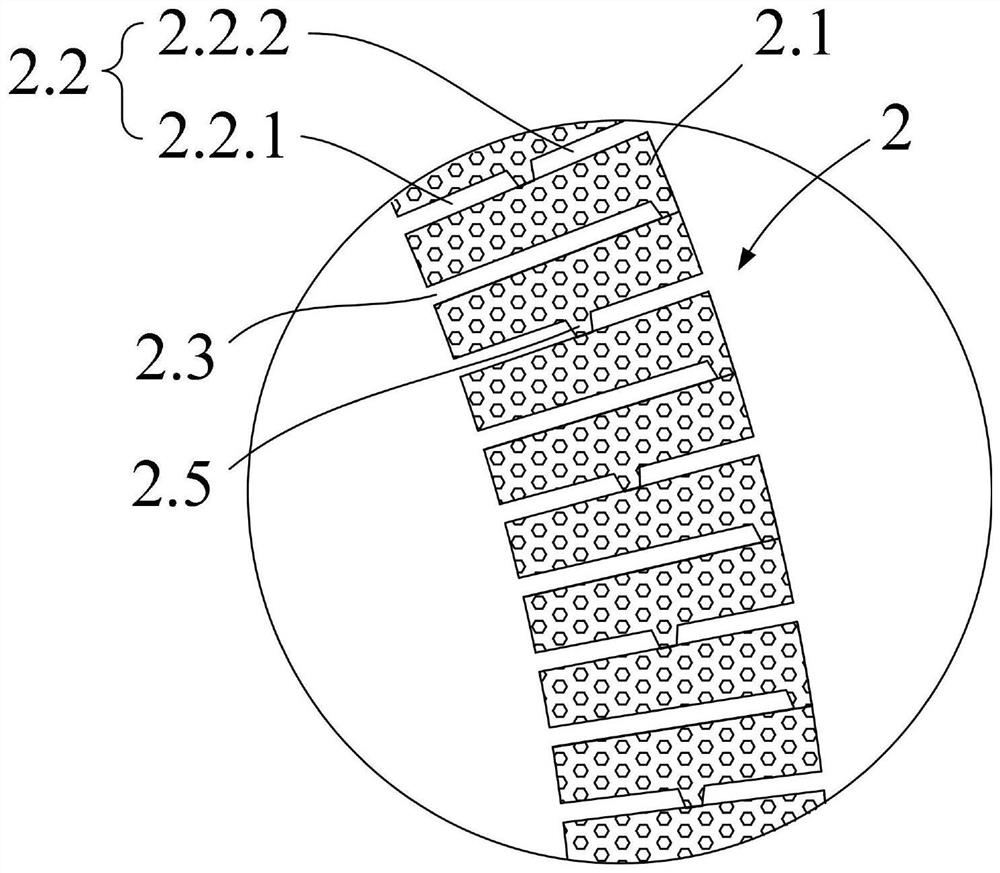

[0054] Such as figure 1 and figure 2As shown, the composite structure cup-shaped grinding wheel includes a grinding wheel base body 1 and a diamond working ring 2 consolidated on the grinding wheel base body 1. The diamond working ring 2 includes a plurality of tooth groups 2.1, and a plurality of the tooth groups 2.1 along the The edges of the grinding wheel base 1 are fixedly arranged in sequence; each tooth group 2.1 forms a first composite tooth space 2.2 between its adjacent tooth groups 2.1; each tooth group 2.1 is provided with a first internal tooth space 2.3.

[0055] The teeth group 2.1 integrates the advantages of the two structures of internal teeth and external teeth, and improves the chip removal function and cooling function of the diamond working ring 2 through the first internal tooth groove 2.3 and the first composite tooth groove 2.2, improves the utilization rate of cooling water, and strengthens the The cooling effect of the cooling water on the inner ri...

Embodiment 2

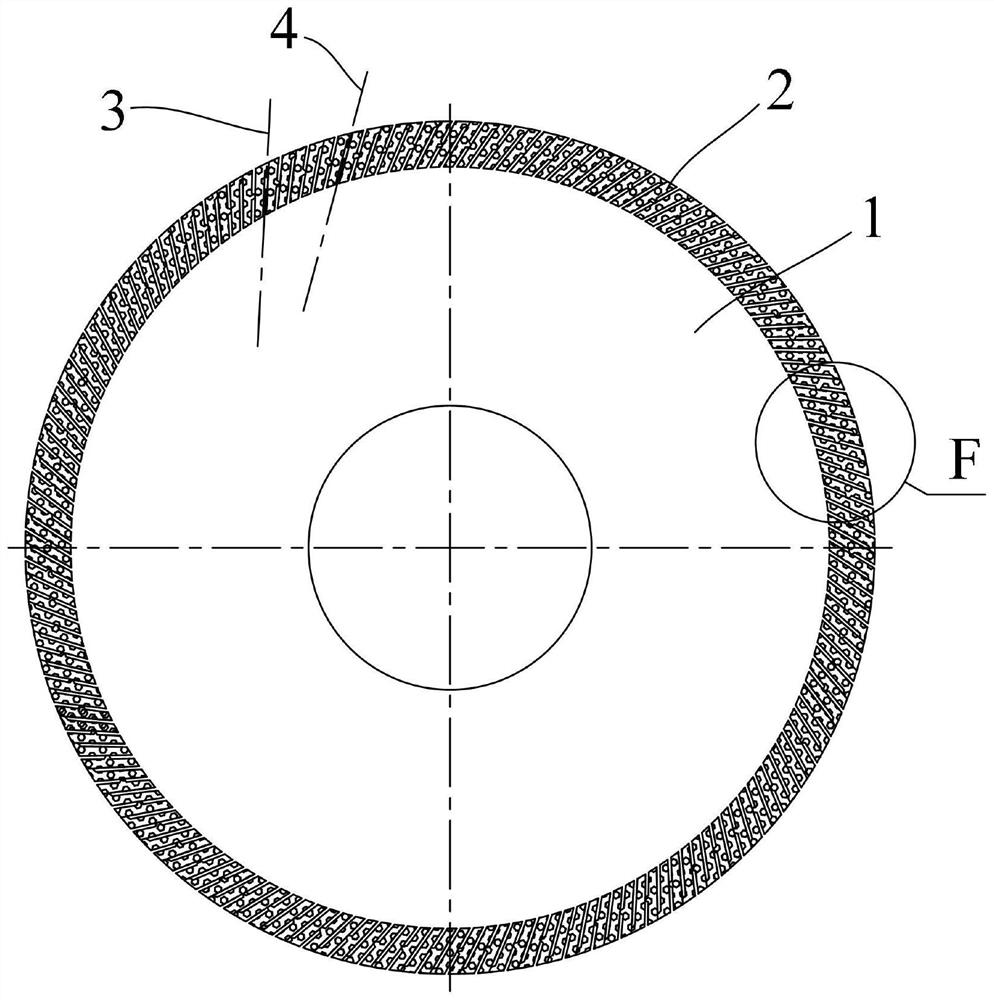

[0067] Such as image 3 and Figure 4 As shown, the composite structure cup-shaped grinding wheel includes a grinding wheel base body 1 and a diamond working ring 2 consolidated on the grinding wheel base body 1. The diamond working ring 2 includes a plurality of tooth groups 2.1, and a plurality of the tooth groups 2.1 along the The edges of the grinding wheel base 1 are fixedly arranged in sequence; each tooth group 2.1 forms a first composite tooth alveolar 2.2 between its adjacent tooth groups 2.1, and each tooth group 2.1 is provided with a first internal tooth alveolar 2.3.

[0068] The teeth group 2.1 integrates the advantages of the two structures of internal teeth and external teeth, and improves the chip removal function and cooling function of the diamond working ring 2 through the first internal tooth groove 2.3 and the first composite tooth groove 2.2, improves the utilization rate of cooling water, and strengthens the The cooling effect of the cooling water on t...

Embodiment 3

[0080] Such as Figure 5 to Figure 8 As shown, the composite structure cup-shaped grinding wheel includes a grinding wheel base body 1 and a diamond working ring 2 consolidated on the grinding wheel base body 1. The diamond working ring 2 includes a plurality of tooth groups 2.1, and a plurality of the tooth groups 2.1 along the The edges of the grinding wheel base 1 are fixedly arranged in sequence; each tooth set 2.1 forms a first composite tooth space 2.2 between its adjacent tooth sets 2.1.

[0081] In the above embodiment, each tooth set 2.1 is provided with a first internal tooth groove 2.3.

[0082] In the above embodiment, one end of each tooth set 2.1 is provided with a first tooth block 2.5, and each first tooth block 2.5 is integrally formed with the internal components of the tooth set 2.1 where it is located.

[0083] In the above embodiment, the first tooth block 2.5 connected to each tooth set 2.1 maintains a gap with its adjacent tooth set 2.1; each tooth set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com