Improved diamond saw blade

A technology of diamond saw blades and diamond blades, applied in the field of improved diamond saw blades, which can solve the problems of easy falling off of diamond blades, insufficient cutting sharpness, and low cutting efficiency, so as to improve the heat dissipation effect, prevent tooth loss, and relieve expansion pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following specific examples illustrate the implementation of the present invention. Those familiar with the technology can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

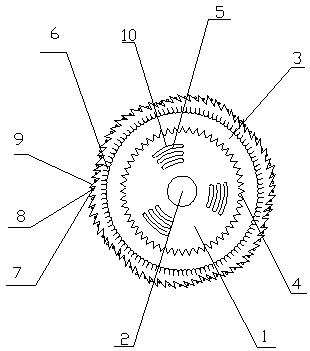

[0017] Such as figure 1 As shown, an improved diamond saw blade includes a base 1 and a diamond cutter head 3. A mounting hole 2 is opened at the center of the base body 1, a diamond cutter head 3 is ring-fixed on the outer circumferential wall of the base body 1, and a plurality of In the fan-shaped area 5, the diamond cutter head 3 is provided with a plurality of chip flutes 6.

[0018] The outer ring of the diamond cutter head 3 is a sawtooth structure 7. The sawtooth structure 7 is glued with diamonds 8. The surface of the sawtooth 7 has a working bevel 9. The sawtooth structure has a working bevel, which can reduce the cutting resistance and effectively solve the traditional diamond saw The problem of high friction when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com