Razor blade

A technology of blades and razors, applied in the field of razor blades, which can solve problems such as limitations, inability to shave beard or hair smoothly, and difficulty in obtaining the radius of the blade tip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

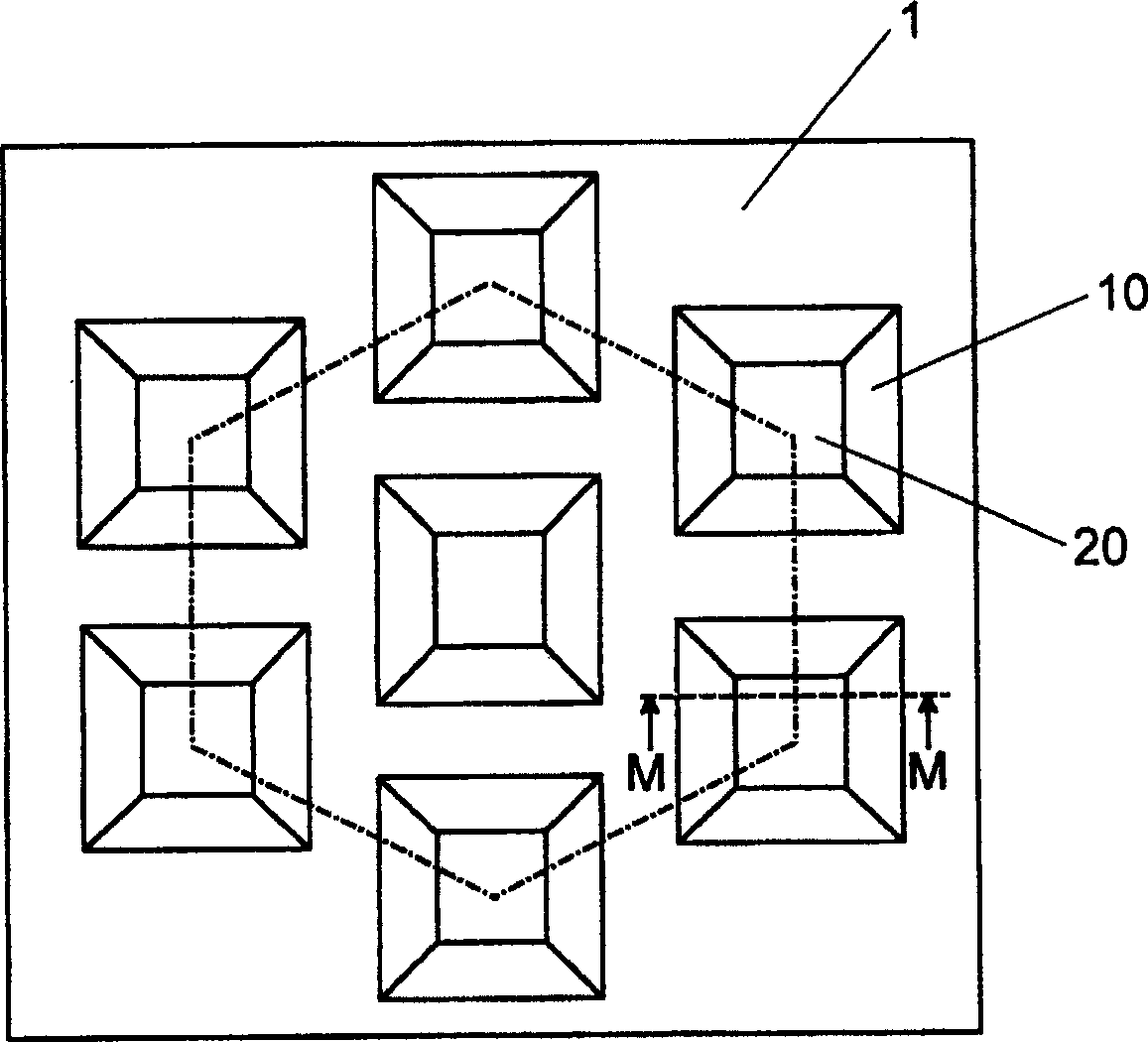

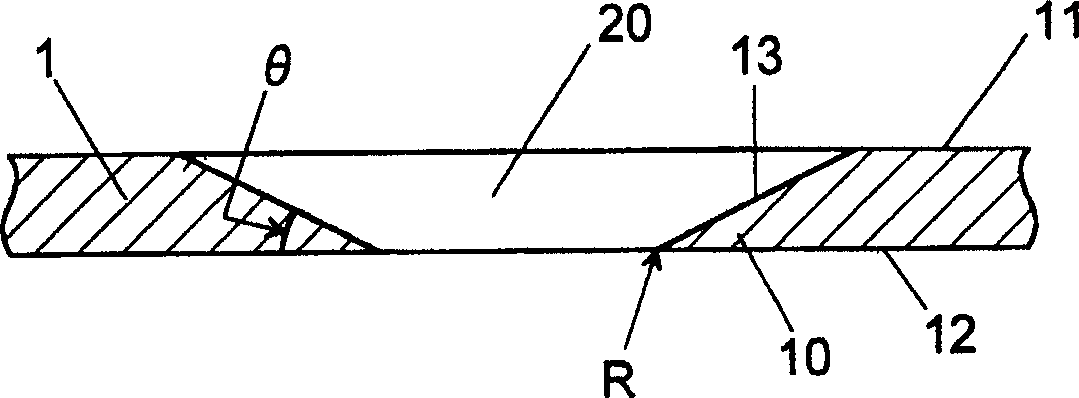

[0035] A polycrystalline silicon block with a grain size of about 10mm is cut into a 0.3mm thick 7mm×7mm square sheet-like monocrystalline silicon. Then, by chemical etching, follow Figure 1A The pattern shown forms a plurality of square openings (blade openings) measuring 1.5mm x 1.5mm. Next, a blade 10 is formed in each opening 20 by using an argon ion beam etching technique, the blade angle is 20°, and the blade protrudes into the opening 20 . In this embodiment, the blades 10 are formed on all four sides of the square opening 20 . The center-to-center distance of adjacent blade openings is 2.0 mm. The blade openings are arranged in the same plane for the closest packing. Such as Figure 1A As shown by the dotted lines, the centers of the three adjacent openings are set at the vertices of an equilateral triangle with a side length of 0.7 mm.

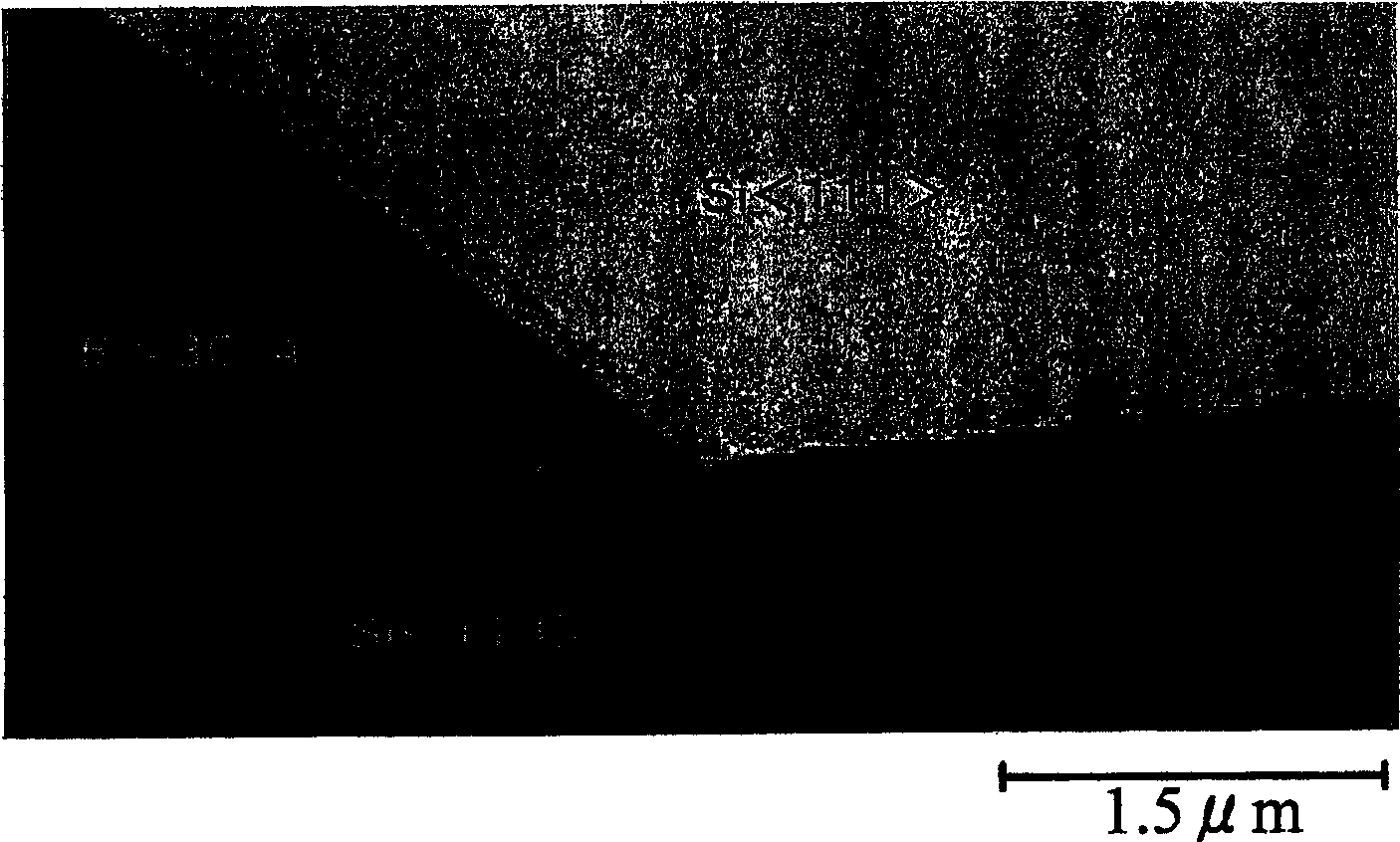

[0036] Observing the cutting edge 10 of the obtained razor blade 1 through a scanning electron microscope, it can be confirmed t...

Embodiment 2

[0038] A polycrystalline silicon block with a grain size of about 10mm is cut into a 0.3mm thick 7mm×7mm square sheet-like monocrystalline silicon. Then, by chemical etching, follow figure 2 The pattern shown forms a plurality of rectangular openings (blade openings) measuring 1.5mm x 5mm. Next, by using an argon ion beam etching technique, a blade 10 is formed in each rectangular opening, the blade angle is 20°, and the blade protrudes into the rectangular opening 20 . In this embodiment, the blades 10 are formed on all four sides of the rectangular opening. The center-to-center distance between adjacent openings is 2.0 mm.

[0039] Observing the obtained edge 10 of the razor blade through a scanning electron microscope, it can be confirmed that the edge radius (R) of the edge is less than 10 nm. As in the case of Example 1, in the case of cutting one hair, the cutting resistance of the razor blade in Example 2 was compared with that of a commercially available razor blad...

Embodiment 3

[0041] A silicon wafer with a thickness of 0.3 mm was obtained by cutting a (110) monocrystalline silicon block into a thin slice. then press Figure 1A In the pattern shown, a square opening (blade opening) with a size of 1.5 mm x 1.5 mm was formed by chemically etching (selective etching) the (111) plane. In this embodiment, through the intersection of (110) plane and (111) plane ( Figure 1C ) obtained a cutting edge 10 with a cutting edge angle of 35.4°. Observing the obtained edge 10 of the razor blade through a scanning electron microscope, it can be confirmed that the edge radius (R) of the edge is less than 10 nm. In the case where the razor blade cuts a single hair, the cutting resistance is 3 grams force. And use the razor blade that has the blade angle of about 20 ° on the market now, the cutting resistance of cutting a hair is 10 grams force. Therefore, the cutting resistance of the razor blade shown in Example 3 is lower than that of the razor blades on the mar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com