Preparation method of wet and dry dual-purpose diamond saw blade

A diamond saw blade, dry and wet dual-use technology, applied in the direction of metal sawing equipment, sawing machine tool manufacturing, metal processing equipment, etc., can solve problems such as harsh environments, and achieve not easy to fall off, stable cutting performance, and good safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

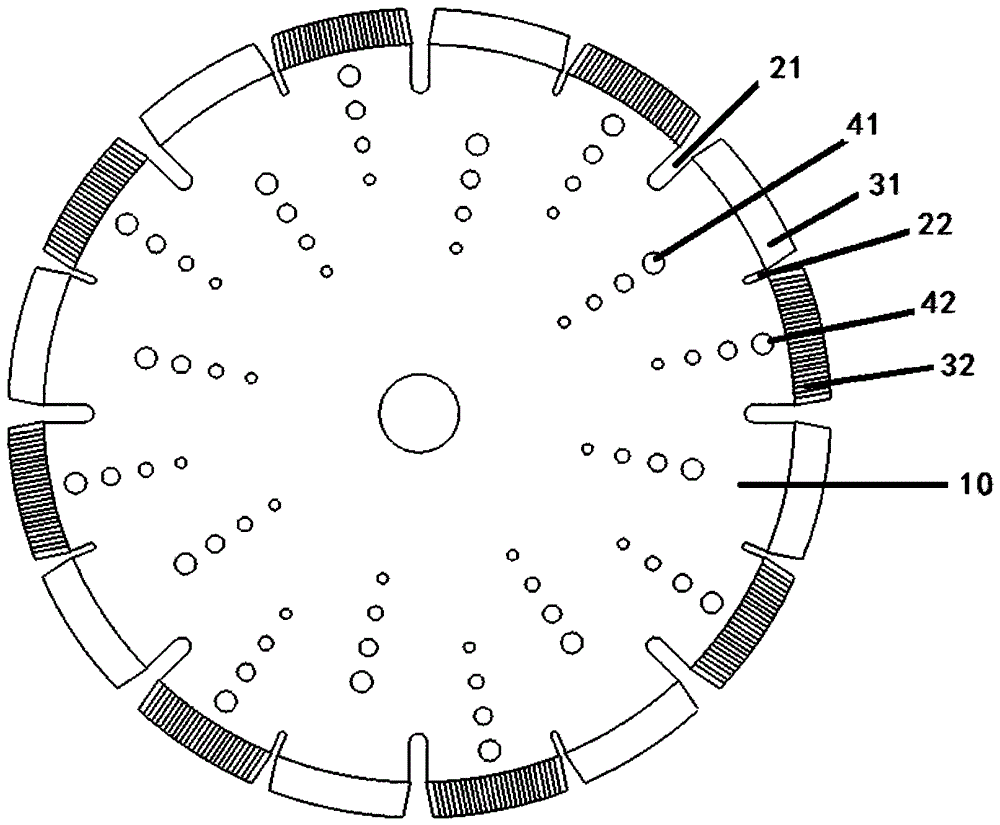

[0025] The preparation method of the wet and dry dual-purpose diamond saw blade of the present invention is as follows: a circular substrate is provided, and the circular substrate includes a side circumferential surface positioned at the edge of the substrate; Machining along the direction of the center of the circle forms a plurality of flutes arranged at intervals; the flutes include first flutes and second flutes arranged at intervals, and the cross section of the first flutes is larger than that of the second flutes Groove; diamond cutter head is set between the flutes of the circular substrate, and the diamond cutter head includes a first diamond cutter head and a second diamond cutter head arranged at intervals; the surface of the first diamond cutter head is a plane , the surface of the second diamond segment is provided with a plurality of mutually parallel protruding strips, and grooves are formed between the protruding strips.

[0026] Specifically, the preparation ...

Embodiment 1

[0029] Take 2.7kg of copper powder, 4.16kg of iron powder, 0.5kg of nickel powder, 1.5kg of cobalt powder, 0.7kg of tin powder, and 0.15kg of cerium powder. kg (compressive strength is 25Kg, particle size is 35 / 40), and after 3 hours of continuous mixing, the powder is poured into the mold for cold pressing and sintering by hot pressing (the sintering temperature is 800°C and the pressure is 320kg / cm 2 ), grind the cutter head with the grinding wheel and the abrasive belt, put the cutter head and the substrate together on the corresponding substrate position according to the drawing requirements, adjust the light spot of the machine to the appropriate position between the cutter head and the substrate, start the machine welding, and make the cutter head and the substrate Weld together at the moment of laser penetration, and then at 600N / mm 2 Intensity Standards Welding strength testing is carried out for each diamond segment, and the wet and dry diamond saw blade after welding...

Embodiment 2

[0031] Take 3.1kg of copper powder, 4.15kg of iron powder, 0.8kg of nickel powder, 1.1kg of cobalt powder, 0.4kg of tin powder, and 0.15kg of cerium powder. kg (compressive strength is 25Kg, particle size is 35 / 40), and after 3 hours of continuous mixing, the powder is poured into the mold for cold pressing and sintering by hot pressing (the sintering temperature is 800°C and the pressure is 320kg / cm 2), grind the cutter head with the grinding wheel and the abrasive belt, put the cutter head and the substrate together on the corresponding substrate position according to the drawing requirements, adjust the light spot of the machine to the appropriate position between the cutter head and the substrate, start the machine welding, and make the cutter head and the substrate Weld together at the moment of laser penetration, and then at 600N / mm 2 Intensity Standards Welding strength testing is carried out for each diamond segment, and the wet and dry diamond saw blade after welding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com