Electroplating coating slotting grinding tool

A technology for coating and grinding tools, which is applied in the direction of grinding machines, manufacturing tools, grinding/polishing equipment, etc., and can solve the problems of reduced shape retention function, reduced pressure, increased area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The principles and features of the present invention will be described below with reference to the accompanying drawings, and the exemplary examples are intended to be construed as they are intended to limit the scope of the invention.

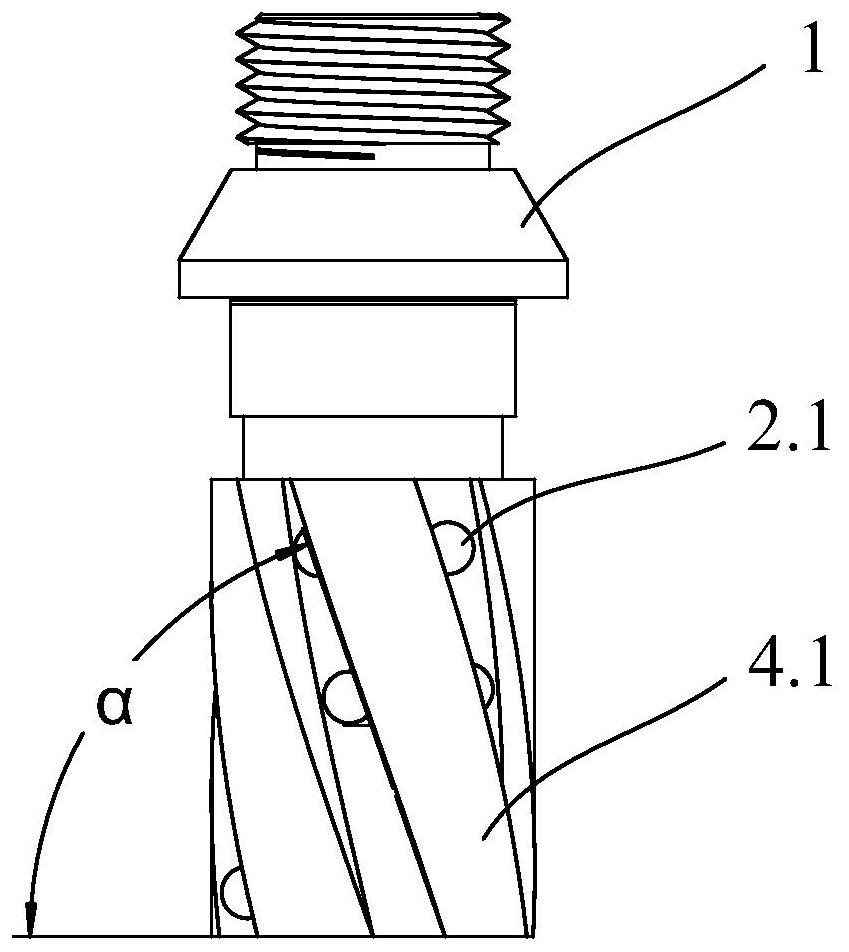

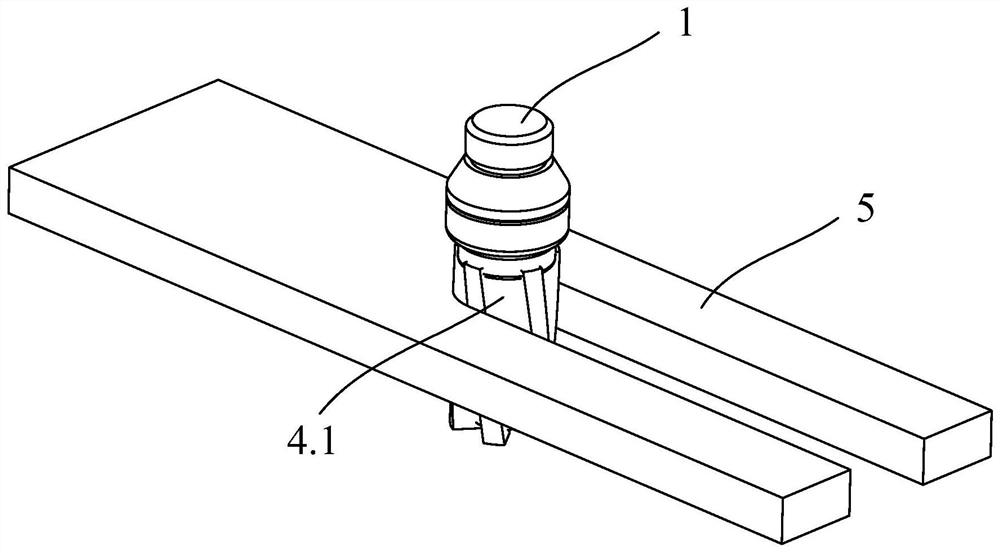

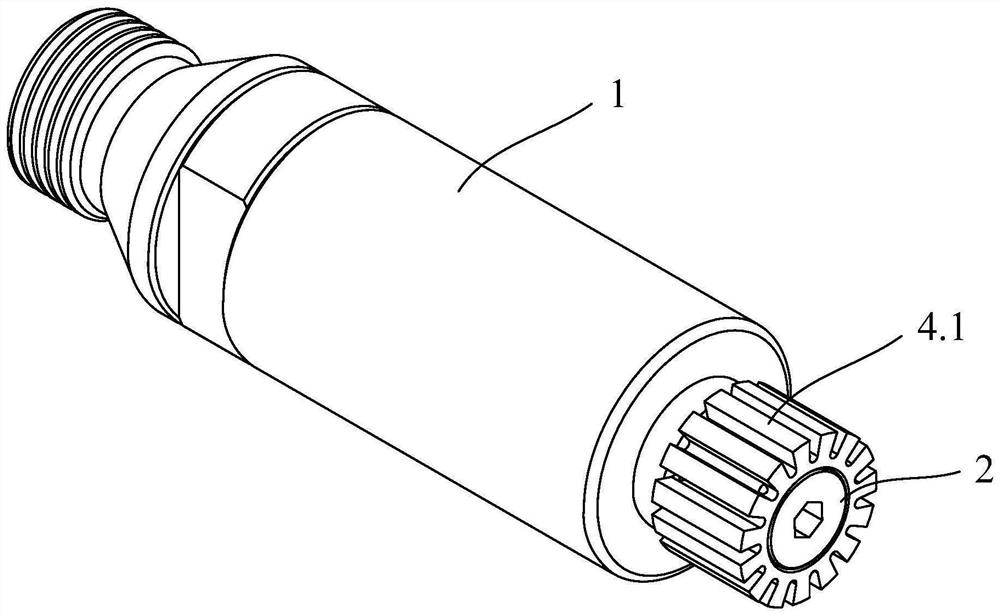

[0043] Such as Figure 4 to 8 As shown, a plating coated slotted abrasive, including a substrate 1, a grinding end portion 2 that is fixedly coupled to the base body 1, and a water flow passage 3 through the base 1 and the grinding end 2; The grinding end 2 is fixed to a grinding teeth 4 axially arranged axially along the grinding end portion 2, and the plurality of the grinding cladding group 4 follow the circumferential direction of the grinding end portion 2. Interval arrangement;

[0044] A plurality of outlet holes 2.1 are disposed between the adjacent two of the grinding cladding groups, and the plurality of the hydrophilic holes 2.1 are arranged in an axial direction of the grinding end portion 2. 2.1 is in communication with the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com