Work station for joining body parts of a motor vehicle, assembly line comprising such a work station, and method for delivering/replacing clamping frames in a work station

A technology for clamping frames, workstations, applied to workstations for connecting body parts of automobiles, production lines with such workstations, and for feeding/replacing clamping frames in the workstations, which can solve the problem of expensive conveying, Time-consuming and other problems, to achieve the effect of small production area and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

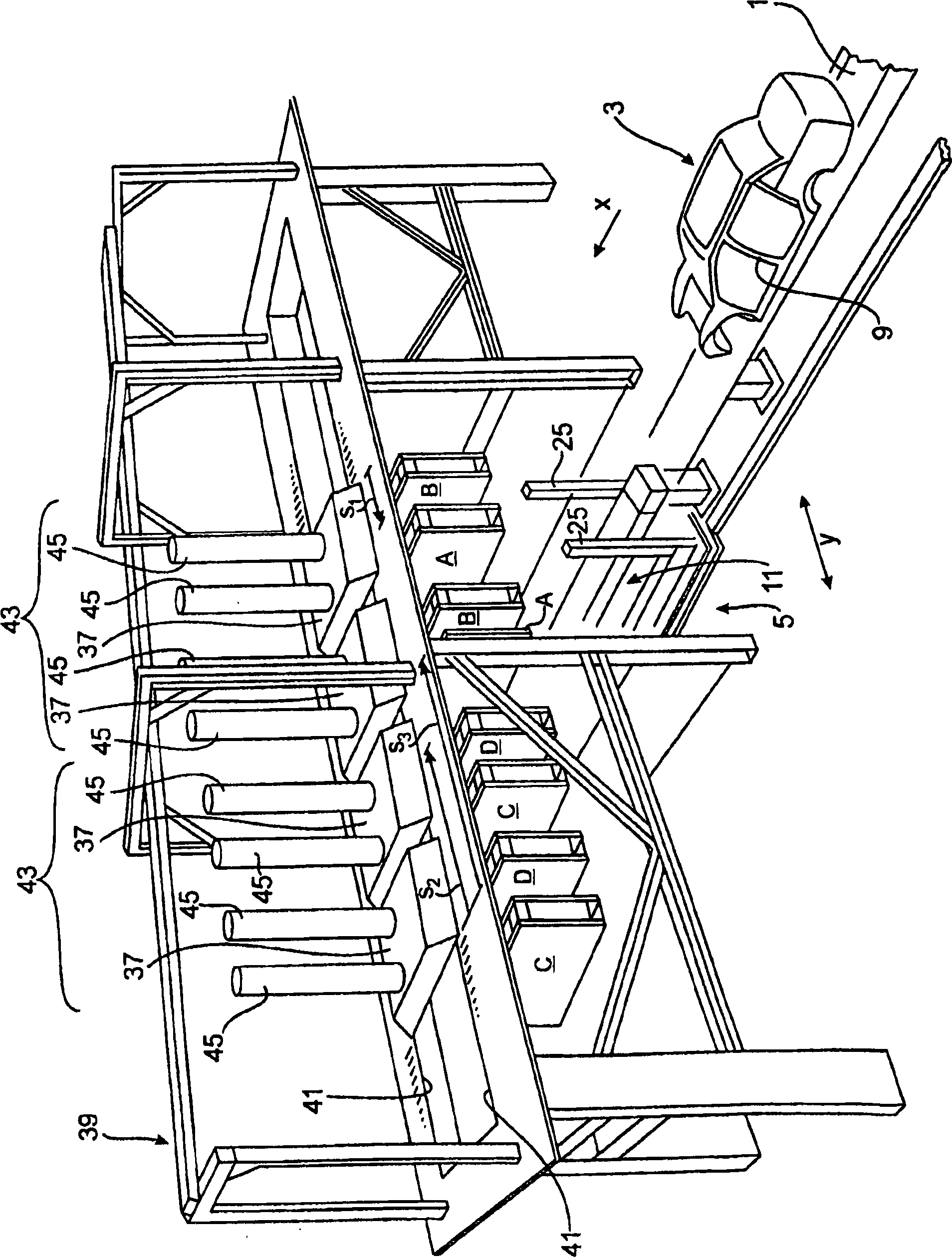

[0031] exist figure 1 shows a part of a production line 1 on which a car body 3 of a first model is conveyed to successive workstations, wherein figure 1A welding station 5 is shown by way of example. A fitting station (not shown) is arranged upstream of the welding station 5 , in which body parts 9 of the first vehicle type are held or prepositioned loosely on both sides of the body structure 3 . Workstation 5 is a welding station with a corresponding robotic application for processing vehicle body 3 . Workstation 5 has some welding manipulators 7 in a known manner for this reason, and they only Figure 5 and 6 shown schematically.

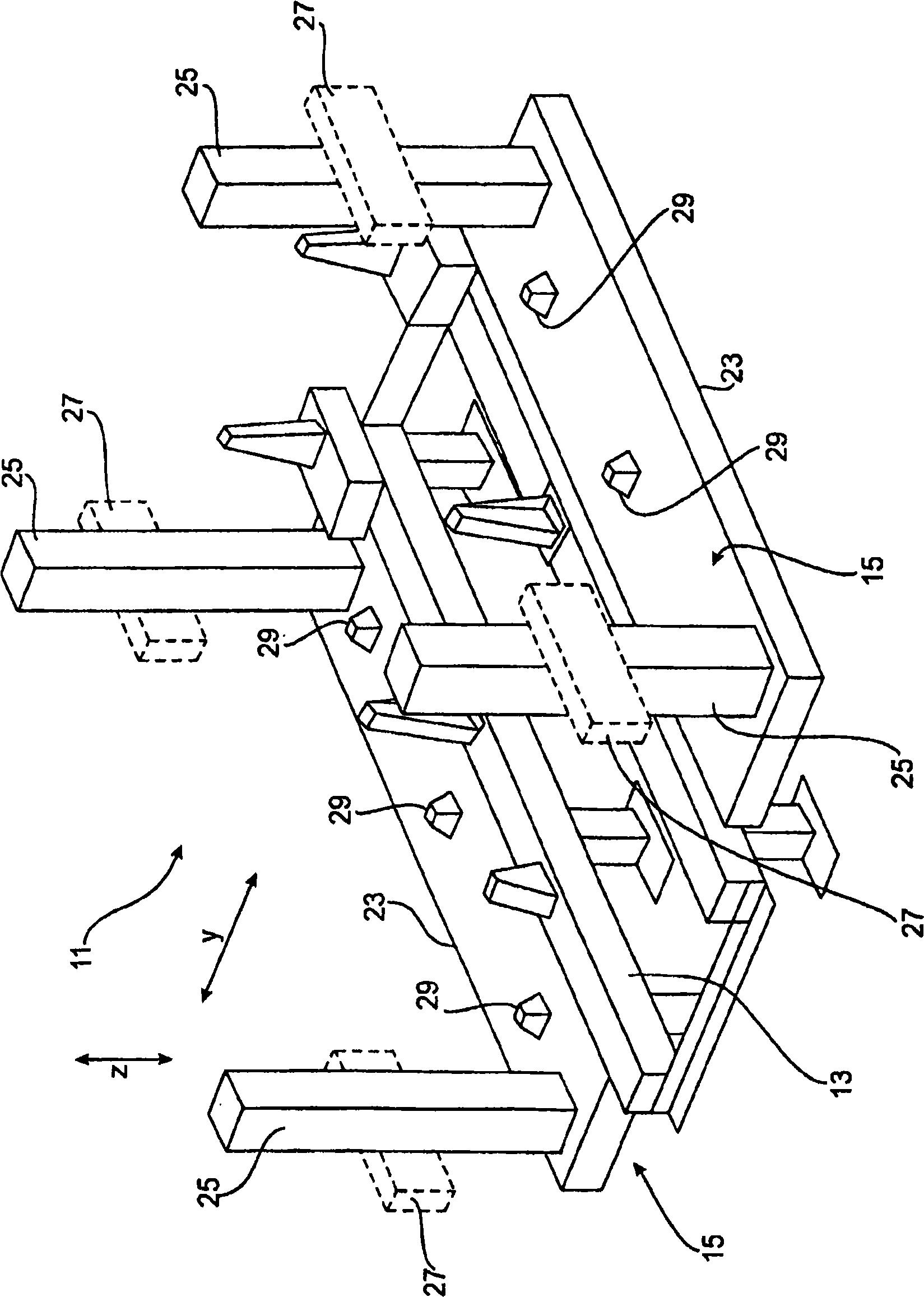

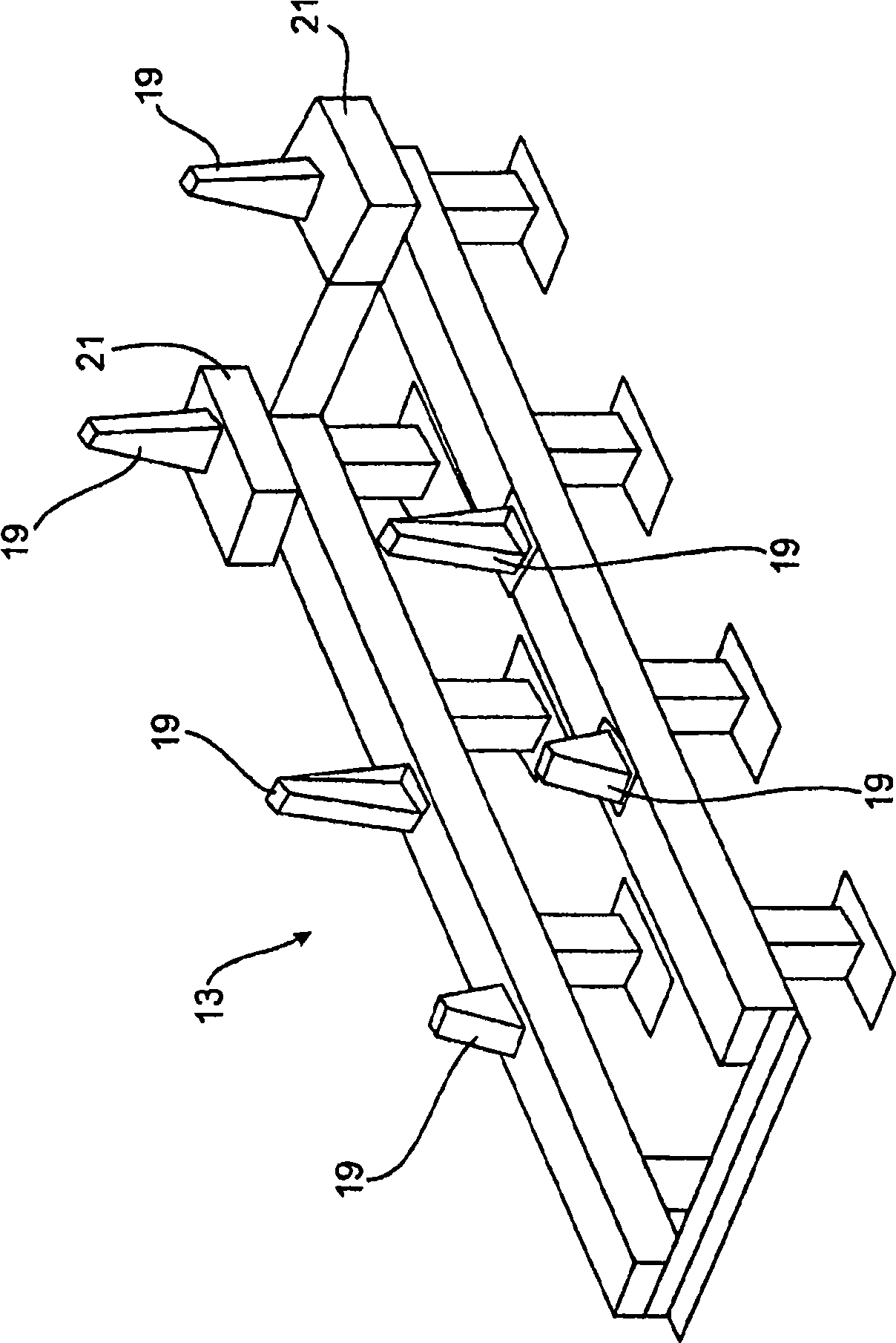

[0032] according to figure 1 , the workstation 5 has a fixed standard assembly 11, which is shown separately in figure 2 middle. The fixed standard assembly 11 is essentially two-piece consisting of the image 3 The basic frame 13 shown in and a positioning and locking unit 15 for the clamping frames A, B, C, D described later are formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com