Cutting device special for petroleum pipelines

A technology for cutting devices and oil pipelines, which is applied in the direction of pipe cutting devices, shearing devices, feeding devices, etc., and can solve the problem of affecting the cutting quality and scope of application of pipe cutting devices, affecting the connection of new pipe sections, sealing effect, and unable to ensure that the cuts are even. and other problems, to achieve the effect of sealing effect, neat cutting and reducing the use of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

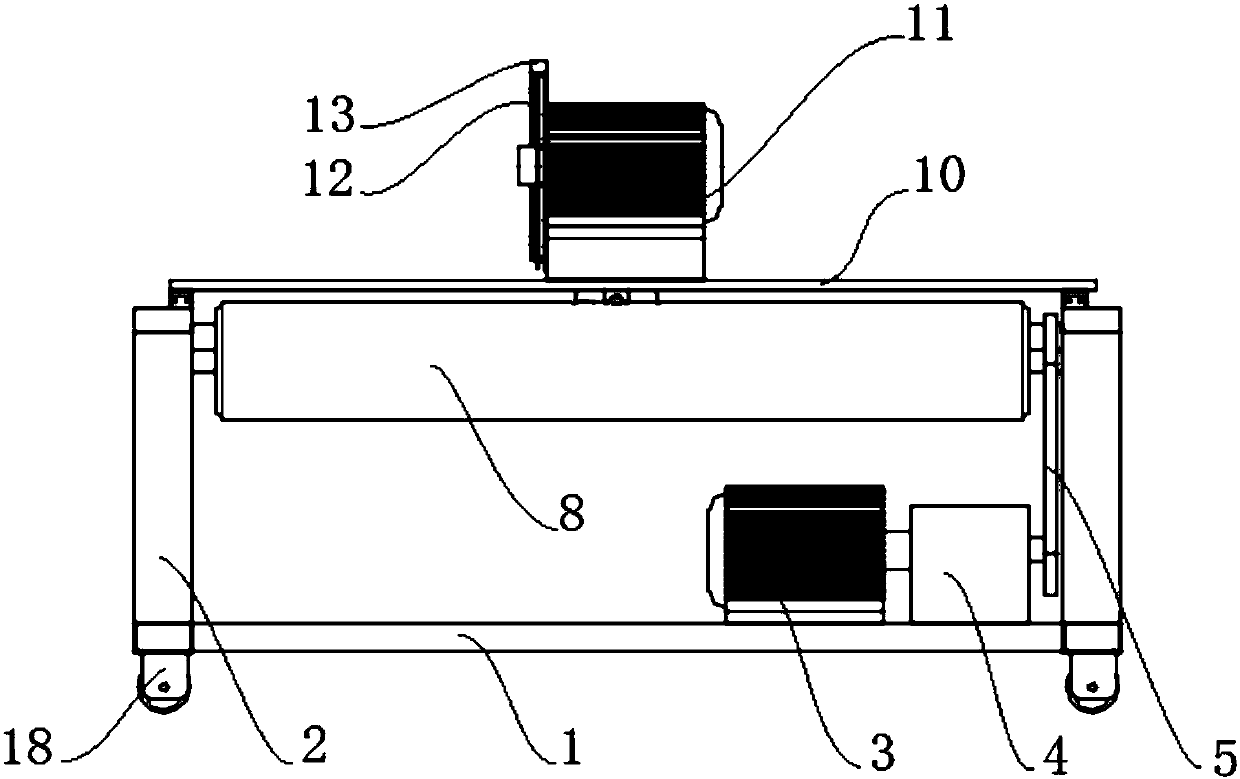

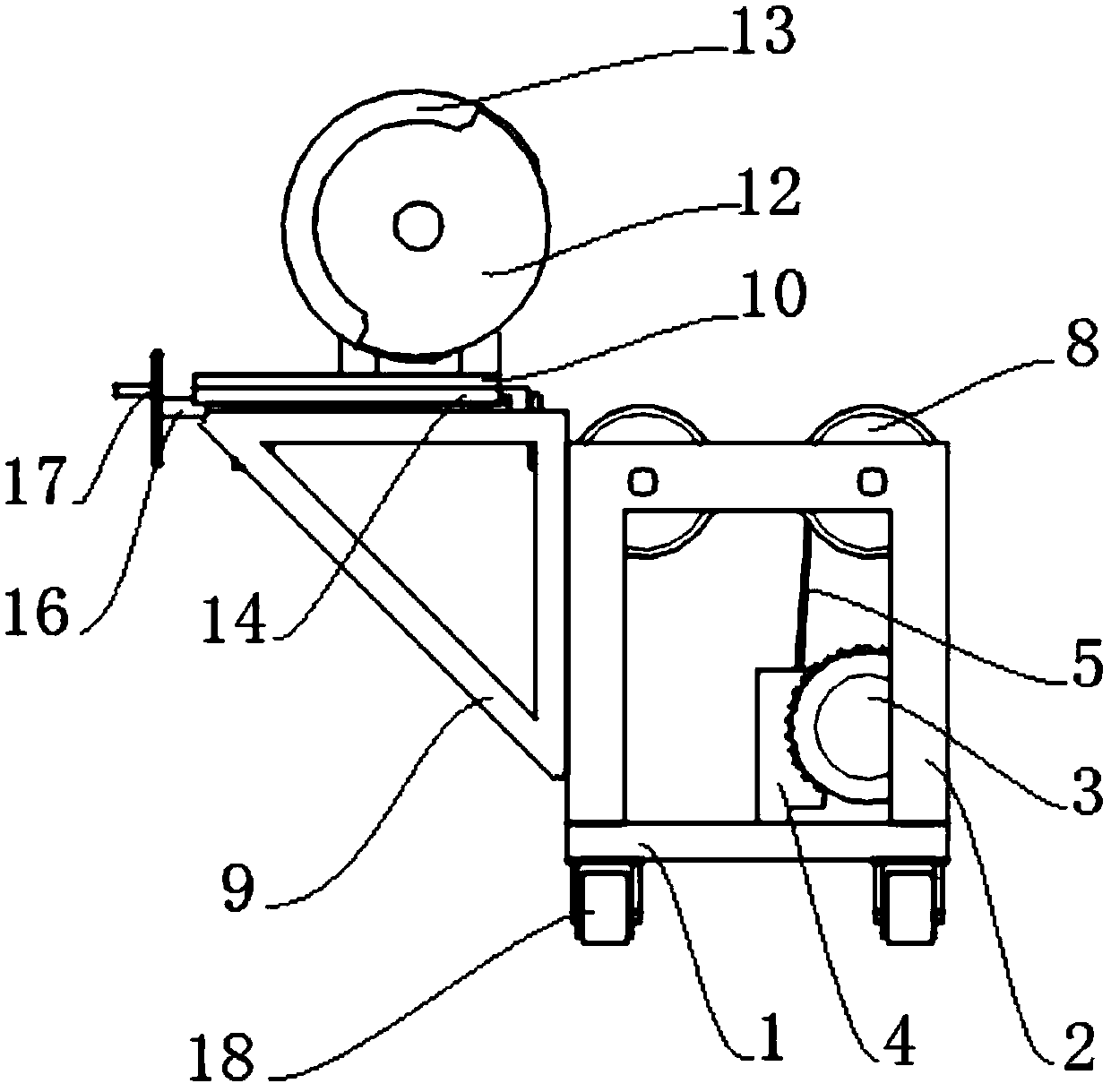

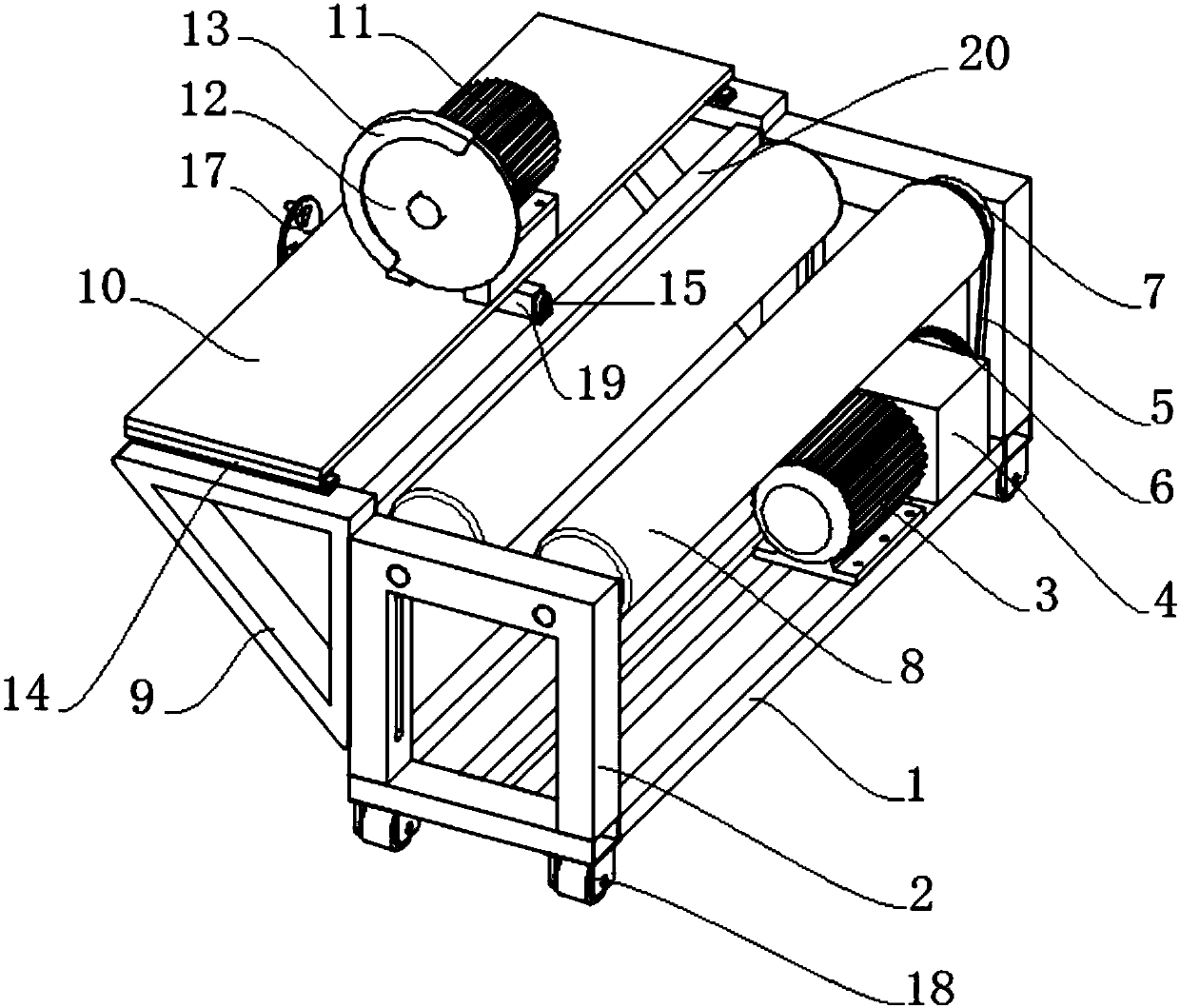

[0019] Such as Figure 1 to Figure 3 As shown, a cutting device dedicated to oil pipelines of the present invention includes a cutting device and a transmission unit, and the transmission unit includes a base 1, a bracket 2, a first motor 3, a reduction box 4, a transmission belt 5, and a first transmission pulley 6 , the second drive pulley 7, drive roller 8, two supports 2 are fixedly installed at the left and right ends of the base 1 respectively, and two drive rollers 8 are respectively installed at the top ends of the support 2, and the two drive rollers 8 are positioned at the same height and mutually Parallel, a second drive pulley 7 is fixedly installed on the shaft of any drive roller 8, the first motor 3 is connected with the reduction box 4 through a coupling, and the output shaft of the reduction box 4 is fixedly connected with the first drive pulley 6 , the first transmission pulley 6 and the second transmission pulley 7 are connected by a transmission belt 5, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com