Variable-speed manual pseudo-ginseng medicinal material slicing device

A slicing device and medicinal material technology, which is applied in metal processing and other directions, can solve problems such as poor stability of slicing, discontinuous slicing, difficult control of slicing size, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

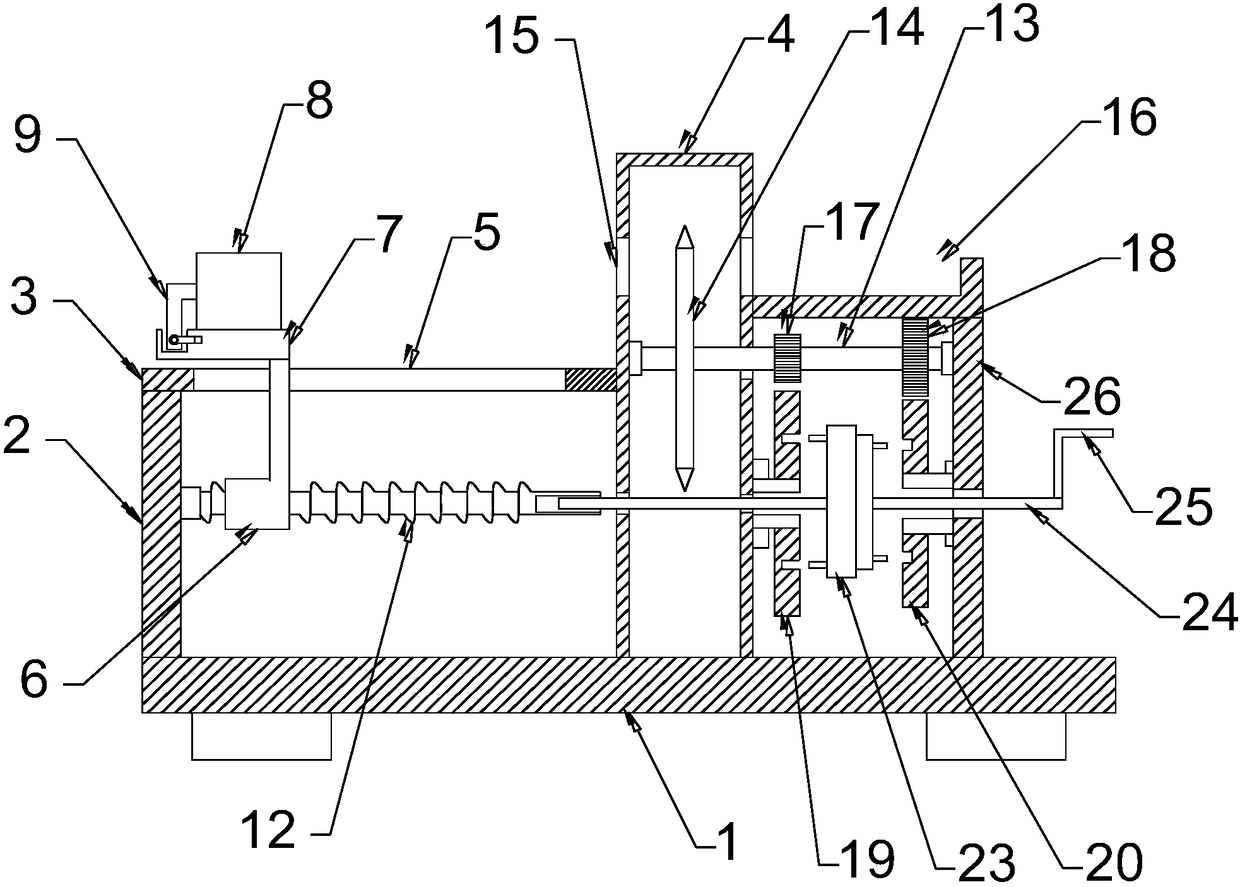

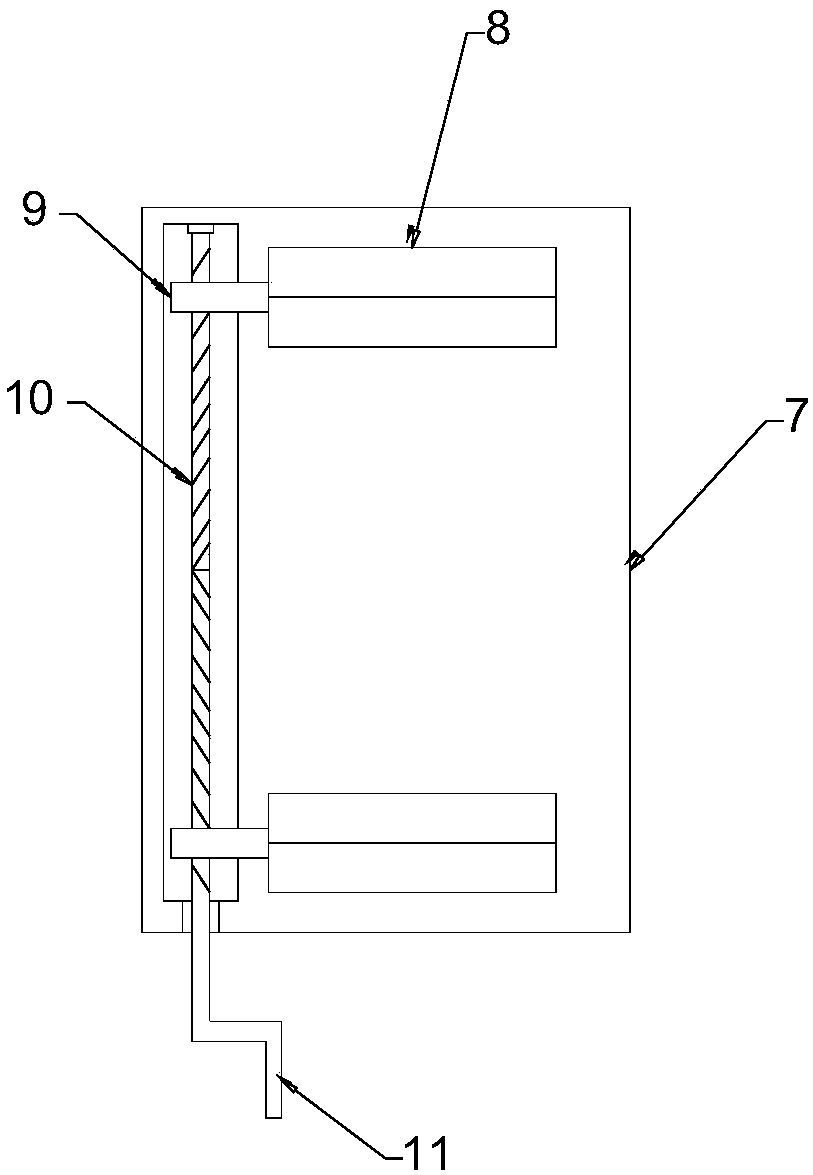

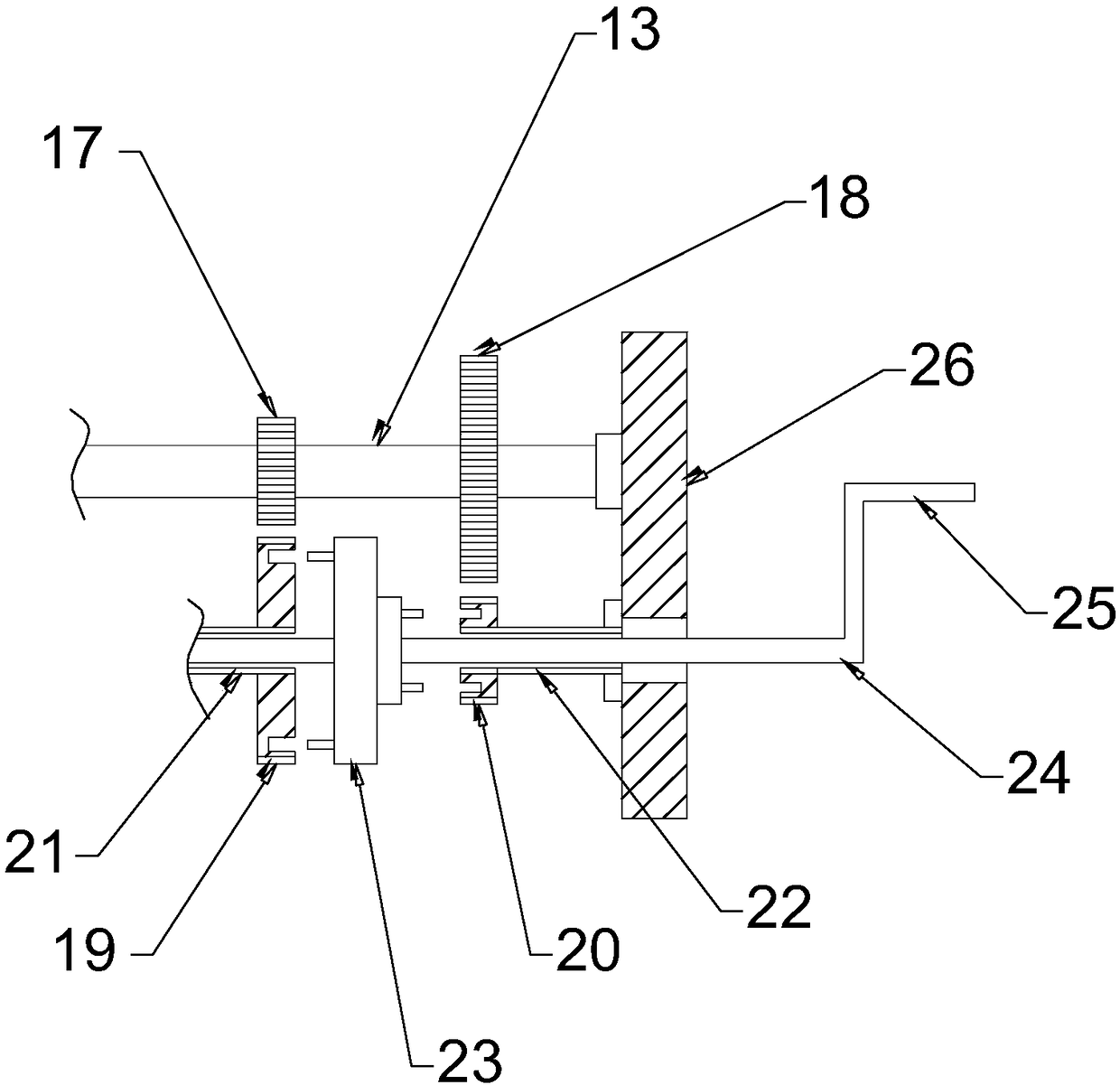

[0021] Example 1: See Figure 1~6 , in an embodiment of the present invention, a variable-speed manual panax notoginseng medicinal material slicing device includes a base plate 1 and a blade 14; the upper left side of the base plate 1 is fixedly connected with a left side plate 2, and the top of the left side plate 2 is fixedly connected with a horizontal plate 3 , the right side of the horizontal plate 3 is fixedly connected with a protective cover 4; the horizontal plate 3 is provided with a horizontal chute 5, and the chute 5 is a through groove; the chute 5 is nested with a moving block 6, and the moving block 6 The upper end is fixedly connected with a moving plate 7, and the surface of the moving plate 7 is slidably connected with a front and rear symmetrical clamping plate 8. The inner side of the clamping plate 8 is an arc surface, and the clamping plate 8 clamps the medicinal material; 8. The left side is fixedly connected with a moving rod 9, and the moving rod 9 is ...

Embodiment 2

[0024] Embodiment 2: the impact of different slicing methods on the thickness of Panax notoginseng slices

[0025] Experimental method: Take notoginseng tablets prepared in Example 1 and Comparative Example 1, randomly take 100 tablets, use a vernier truck to measure the thickness, and calculate the deviation.

[0026] group

[0027] Above-mentioned result shows, the Radix Notoginseng sheet prepared by the present invention is even in thickness, is better than manual sectioning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com