Special machine tool for machining small-sized precise component of computer, communication and consumer electronic (3C) products

A technology for special machine tools and spare parts, applied in the field of special machine tools for the processing of small precision parts, can solve the problems of large area of machine tools, precision adjustment, poor installation and stability, and large demand, so as to improve the environment and performance. , The effect of improving machining accuracy and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

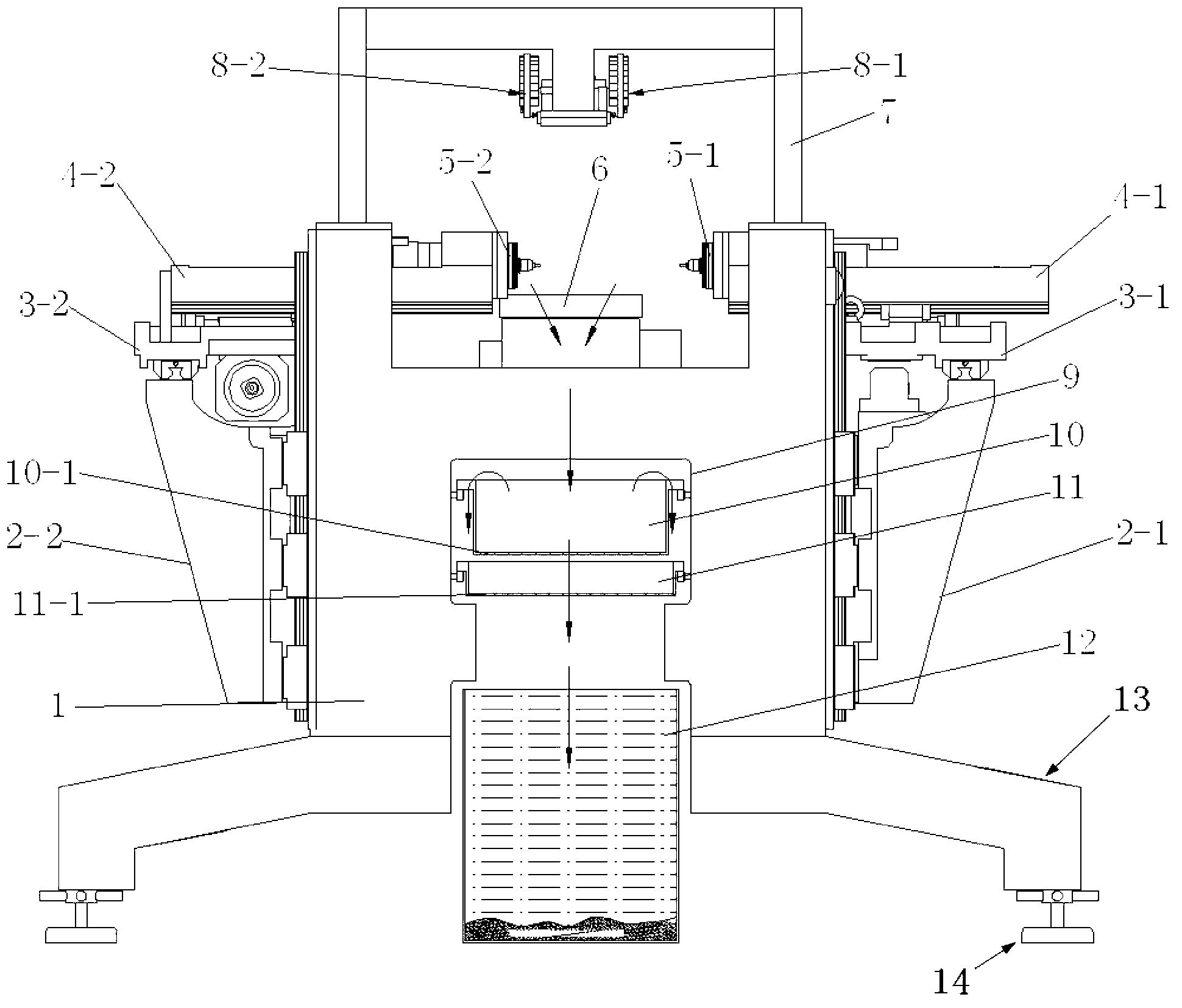

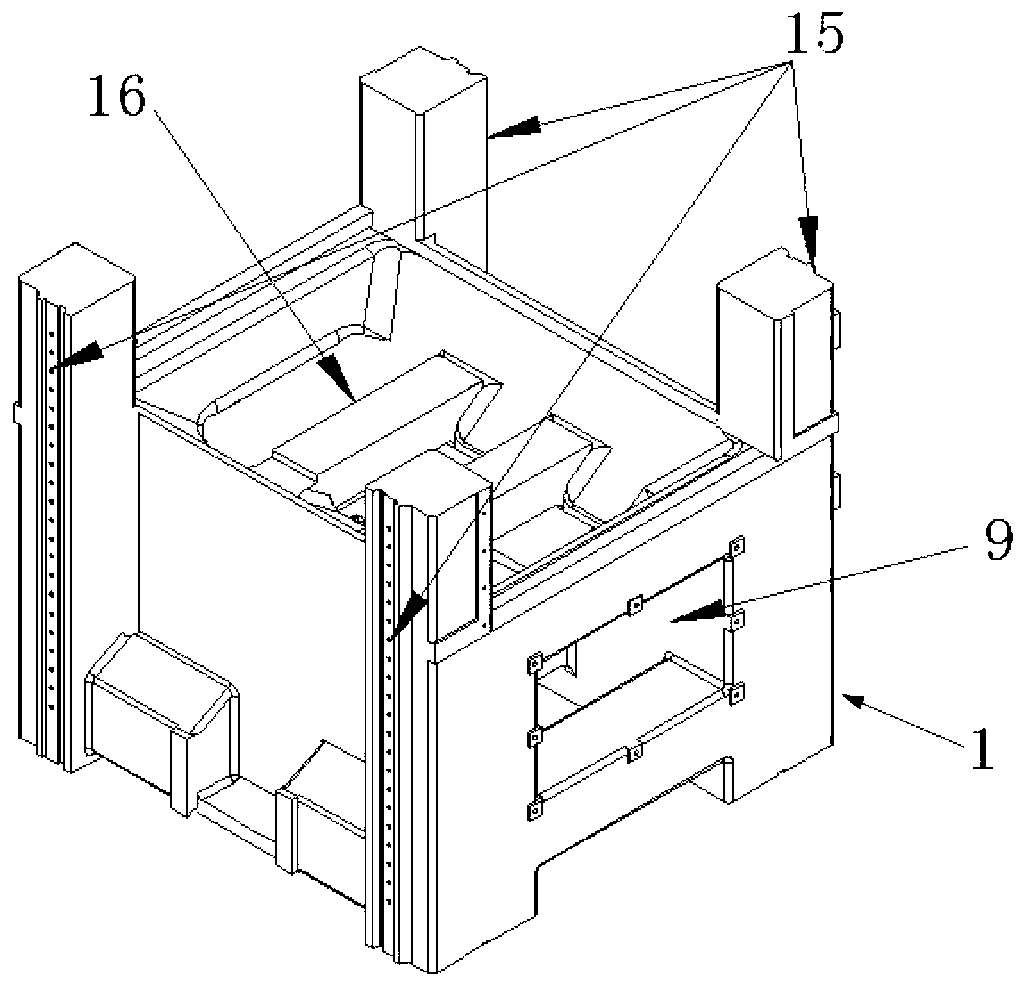

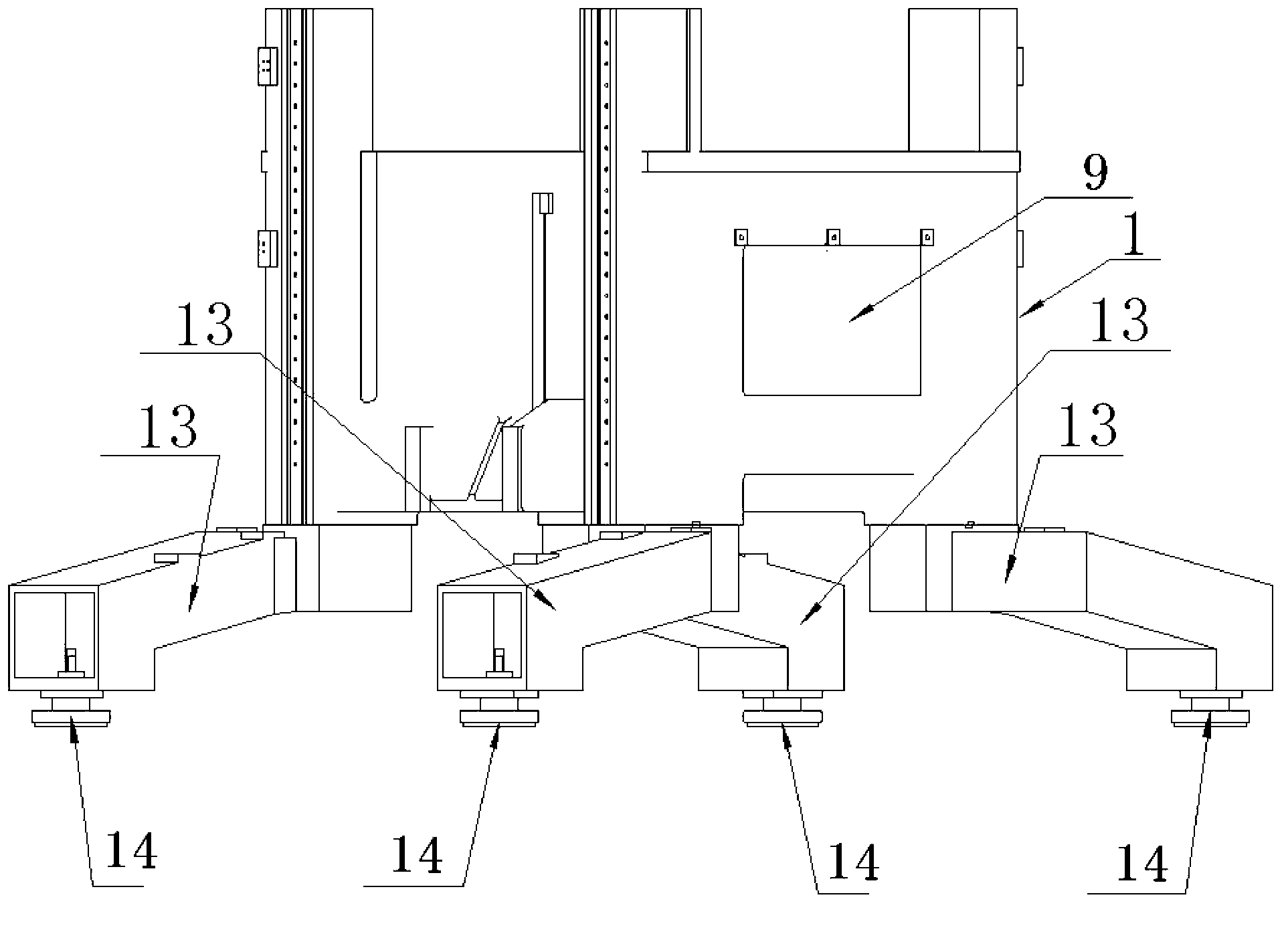

[0028] Such as figure 1Shown is a special machine tool for processing small precision parts of 3C products, which includes a base 1, and the two sides of the base 1 are respectively provided with a Y-axis 2-1 fixed to the side of the base 1 through guide rails, 2-2; the upper end of each Y axis fixes an X axis 3-1, 3-2 through a guide rail; the upper end of each X axis fixes a Z axis 4-1, 4-2 through a guide rail; forming two independent XYZ axis systems ;A main shaft 5-1, 5-2 is installed on each Z axis, a turntable 6 is installed in the middle of the upper top surface of the base, the two main shafts face the turntable sideways, and a tool magazine support 7 is installed on the base, Two sets of mutually independent tool magazines 8-1, 8-2 are respectively installed through the tool magazine bracket, and the two sets of tool magazines are installed above the turntable 6. Such as figure 2 As shown, the base is an integrated box-type structure with four bosses symmetrically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com