Wax block core penetrating equipment

A technology of wax blocks and equipment, which is applied in candle preparation devices, candles, fatty acid production, etc., and can solve problems such as time-consuming and labor-intensive operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

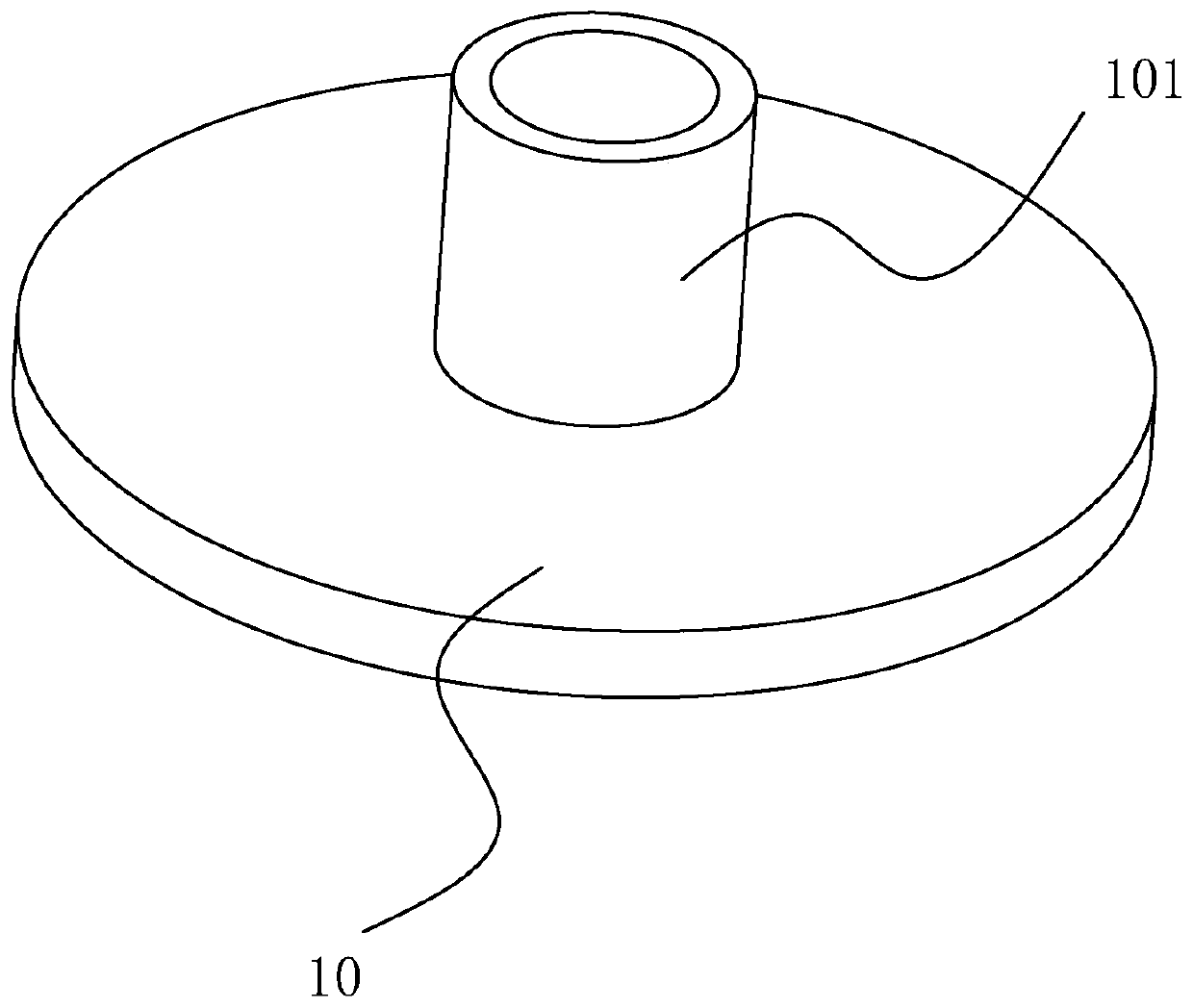

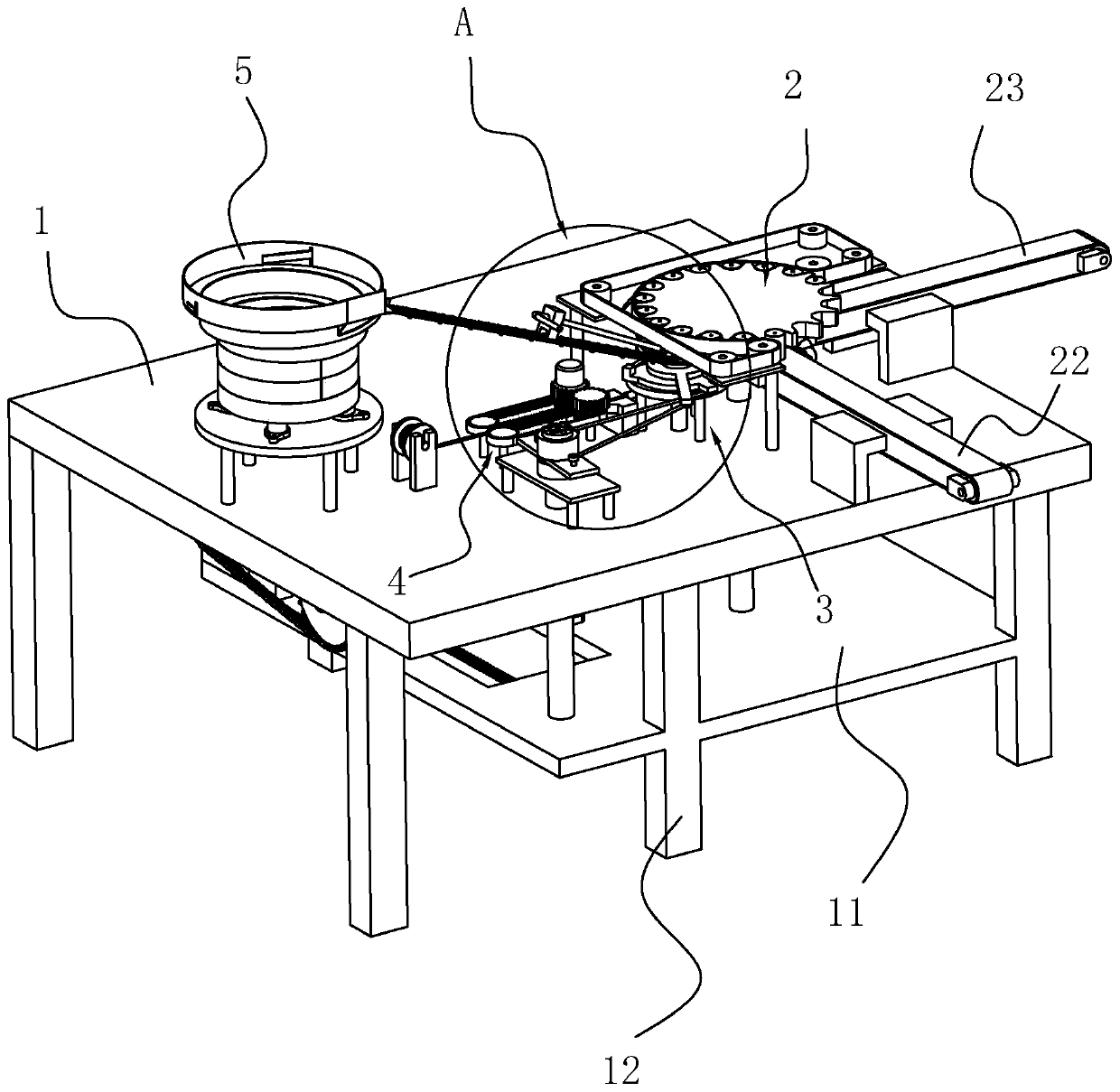

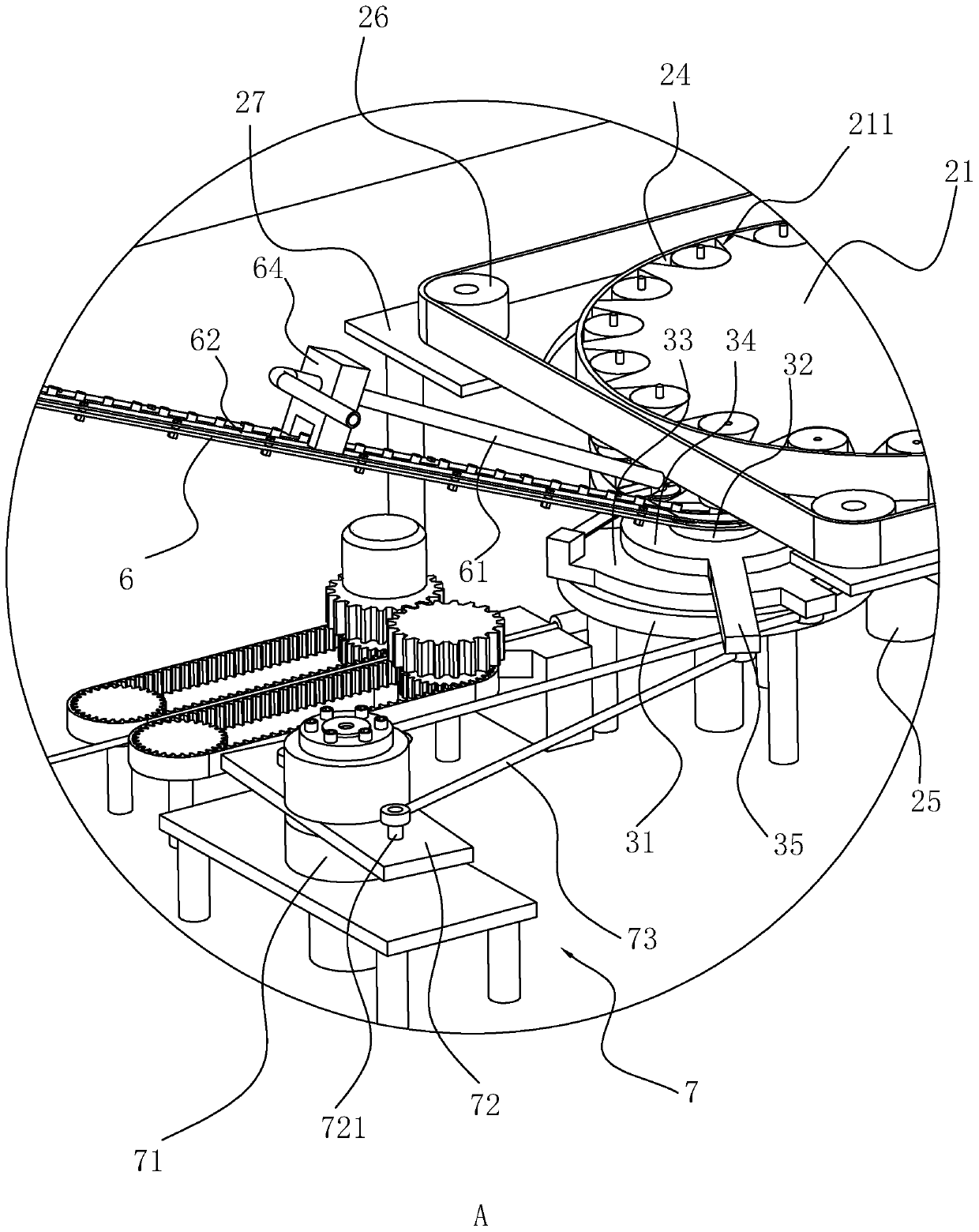

[0061] Embodiment: a kind of wax block core piercing equipment, see attached figure 2 and attached image 3 , comprising a workbench 1, a mounting plate 11 arranged below the workbench 1, a number of vertical support rods 12 fixedly connected around the mounting plate 11, and a set on the top of the workbench 1 for inserting the wax core into the wax block The core threading mechanism 3 among the base and the wax block, the wax block feeding mechanism 2 arranged on the top of the workbench 1 for conveying the wax block, the feeder arranged on the top of the workbench 1 for feeding the wax core The wire mechanism 4, the vibrating plate 5 arranged on the top of the workbench 1, and the guide plate 6 fixedly connected to the discharge side of the vibrating plate 5 for transporting the base of the wax block to the core threading mechanism 3. The support rod 12 is fixedly connected with the workbench 1, and the bottom of the support rod 12 is lower than the bottom of the mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com