Hand-operated drug mill

A hand-cranked and roller technology, which is applied in the direction of grain processing, etc., can solve the problems of laborious operation, limited bending and stretching distance, and affecting the fine crushing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

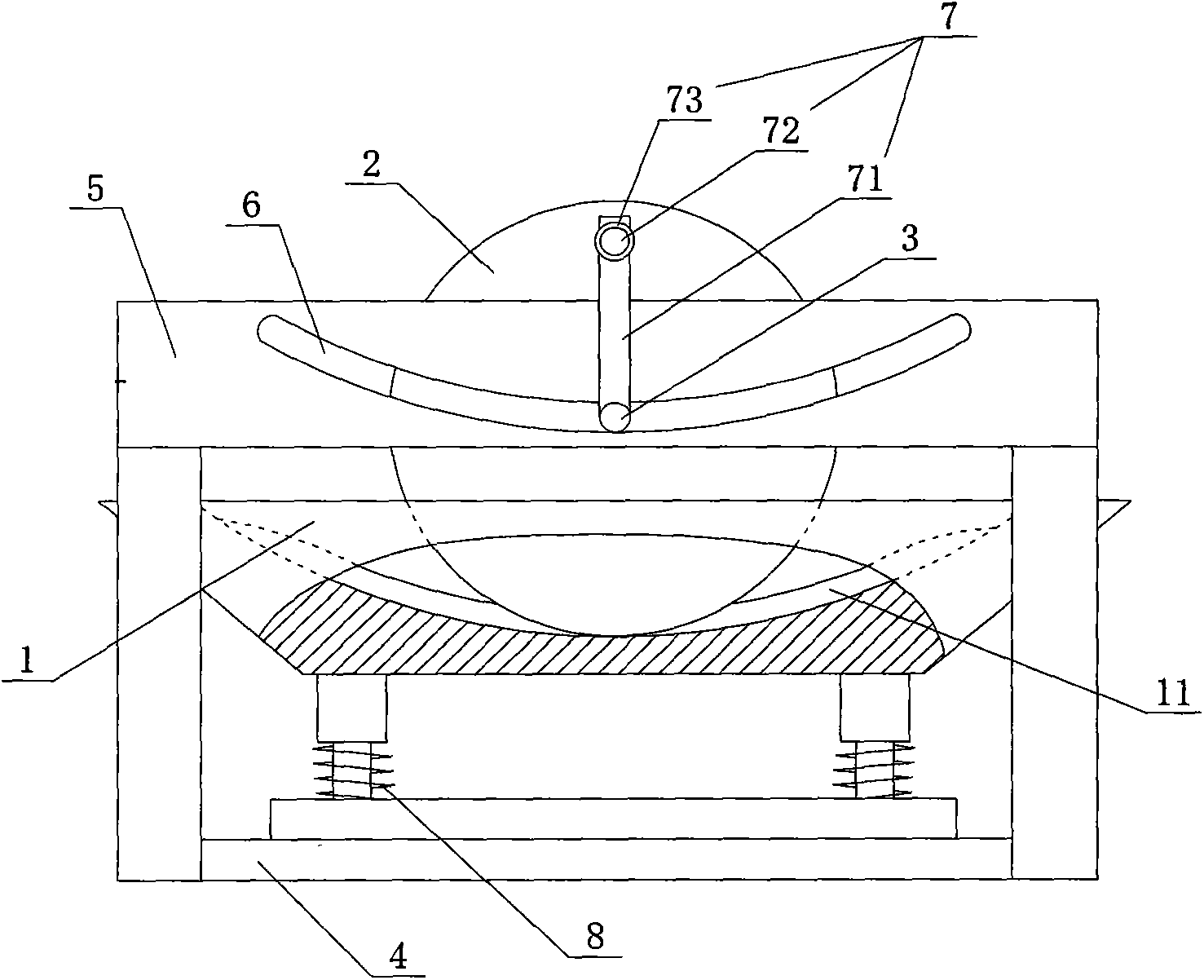

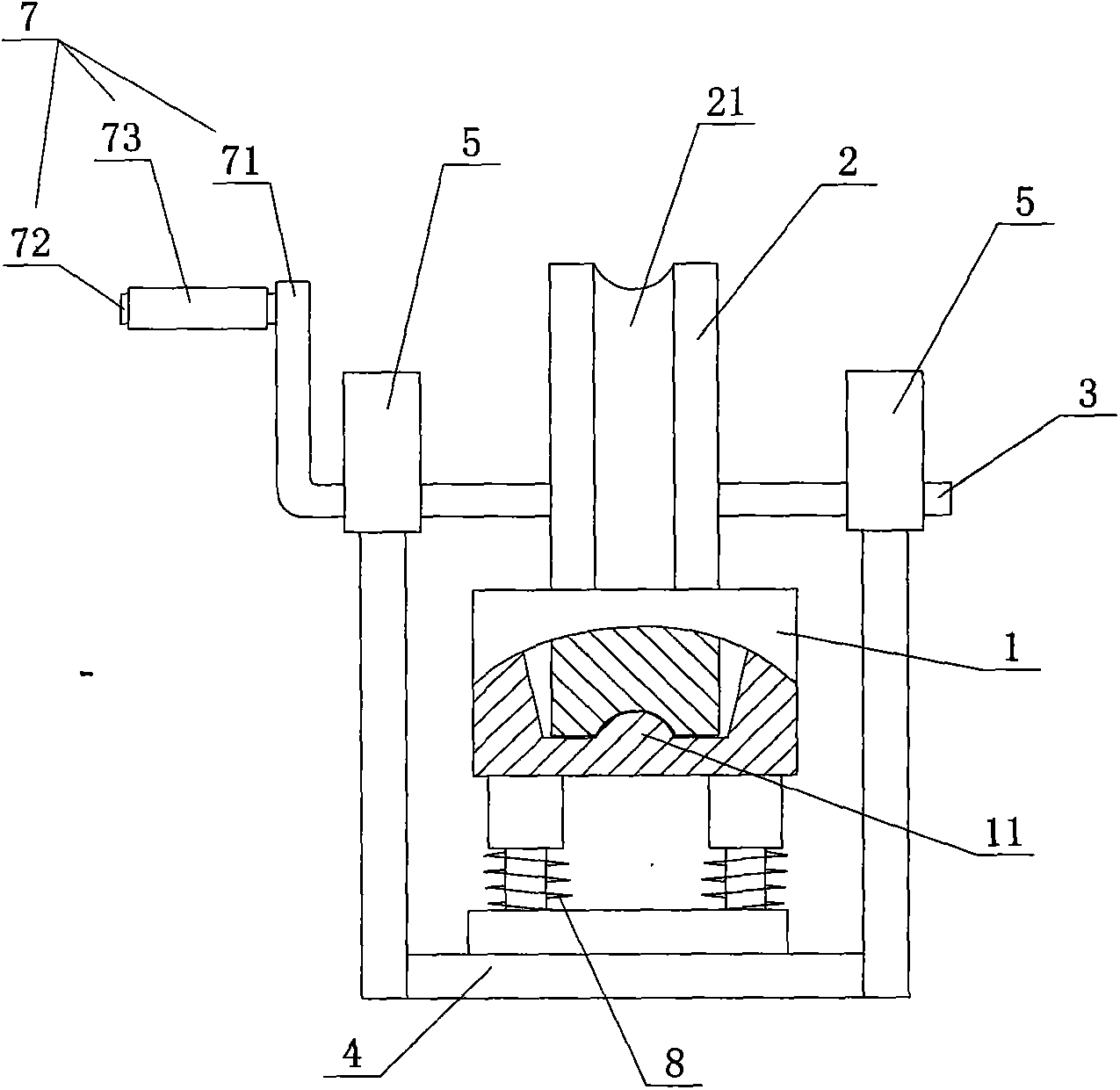

[0012] With reference to the accompanying drawings, the hand-operated medicine roller of the present invention includes a milling groove 1 and a milling plate 2, the milling groove 1 is an arc-shaped long groove, and the milling plate 2 is a disc with a hole in the center and a milling plate is installed in the opening of the milling plate 2 The shaft 3 and the milling groove 1 are installed on a base 4. On the base 4, a guide plate 5 is respectively provided on both sides of the milling plate 2. Each guide plate 5 is provided with an arc-shaped guide corresponding to the shape of the milling groove 1. Sliding hole 6, the two ends of disc shaft 3 are respectively worn in the arc-shaped guiding sliding hole 6 on both sides and a hand crank 7 is affixed to one of the ends. The disc 2 is limited between the two guide plates 5 by the disc shaft 3. At the same time, the disc shaft 3 is also limited in the arc-shaped guide slide hole 6, and the manual crank 7 is operated to make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com