Making method of UV (ultraviolet) reverse dull polish process

An offset printing ink and polymer technology, which is applied in the field of UV reverse sanding process, can solve the problems of low printing efficiency, poor adhesion, troublesome operation, etc., and achieve the effect of improving printing efficiency, reducing cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

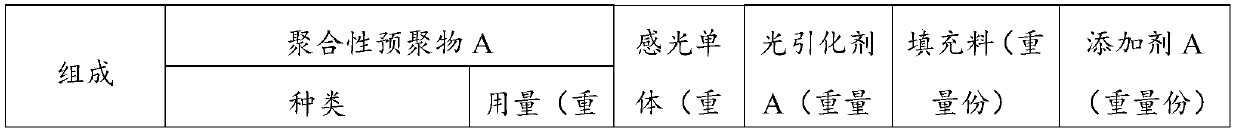

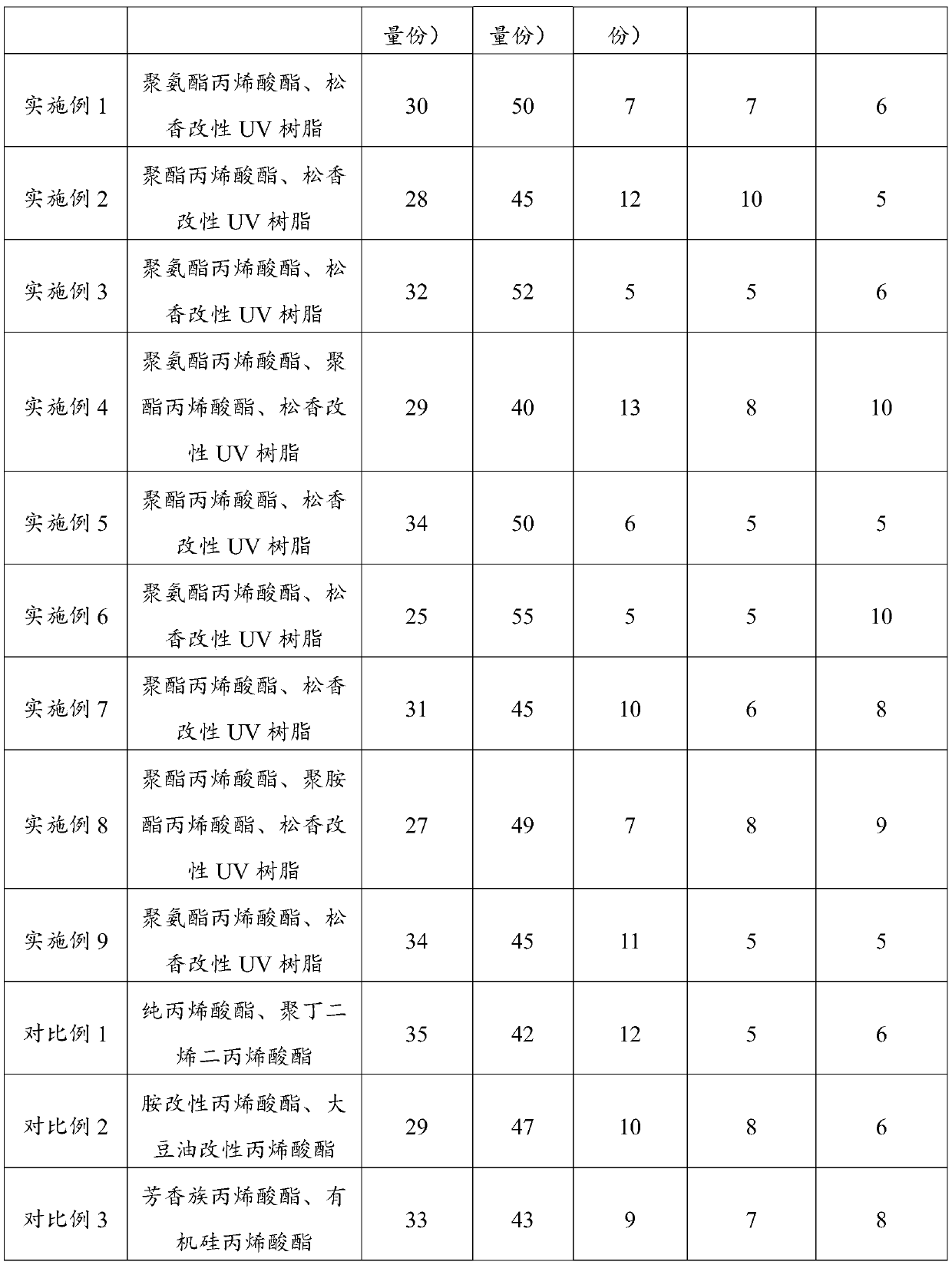

Examples

Embodiment 1

[0034] The preparation method of the UV offset printing ink of embodiment 1, comprises the following steps:

[0035] (1) Mix the polymerizable prepolymer A with the photosensitive monomer, and disperse it with a mixer at a speed of 1400r / min. After the polymerizable prepolymer A is completely dissolved and the fineness reaches below 5 μm, add photoinitiator A, After the filler and additive A, disperse and stir evenly at a speed of 600r / min, use a grinder to grind until the fineness reaches below 15 μm, and obtain the reverse base oil;

[0036] (2) Mix the polymeric prepolymer B with the reactive diluent, and disperse it with a mixer at a speed of 1400r / min. After the polymeric prepolymer B is completely dissolved and the fineness reaches below 5 μm, add photoinitiator B and Additive B is then dispersed at a speed of 1300r / min until the fineness reaches below 5 μm to obtain the reverse surface oil.

[0037] The preparation methods of the UV offset printing inks of Examples 2-9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com