Coated kraft paper and production technology thereof

A technology for coating kraft paperboard and production process, applied in the field of papermaking, can solve problems such as lack of characteristics, and achieve the effects of reasonable proportion, high degree of automation and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

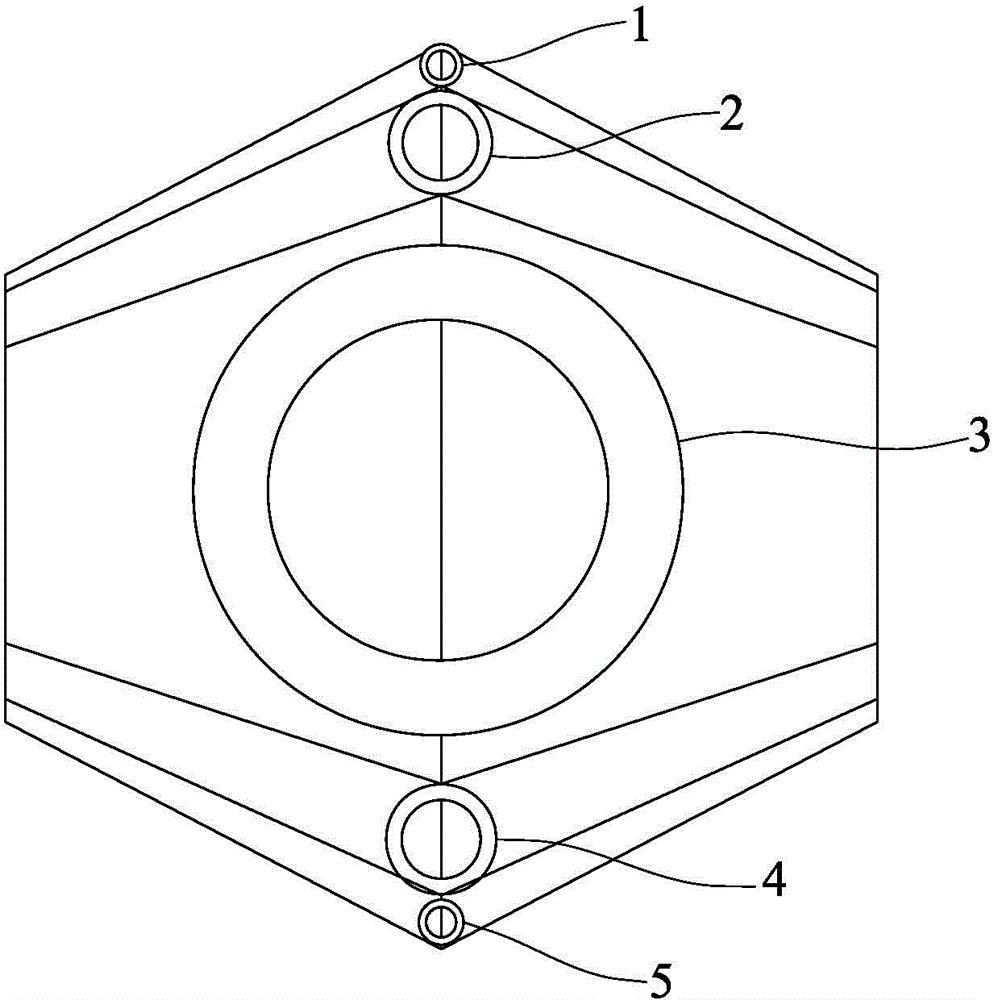

[0043] Such as figure 1 As shown, the present invention is a coated kraft cardboard, which consists of a coating layer 1, a surface layer 2, a core layer 3, a bottom layer 4 and a starch sizing layer 5.

[0044] The coating layer 1, the surface layer 2, the core layer 3, the bottom layer 4 and the starch sizing layer 5 are sequentially stacked together. The surface layer 2 is bleached chemical wood pulp, wherein bleached chemical hardwood pulp accounts for 20%-80%, and bleached chemical softwood pulp accounts for 20%-80%; the core layer 3 is mixed pulp, wherein natural color wood pulp Pulp accounts for 30%-70%, and mechanical wood pulp accounts for 30%-70%. The bottom layer 4 is 100% natural color wood pulp.

[0045]The main components of the coating layer 1 are calcium carbonate, china clay and latex, and the mass proportions of each component are 40-60%, 30-50%, 5-20%, and the remaining components are 5-10%. The remaining components are one or more of water-retaining agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com