Patents

Literature

51results about How to "Guaranteed evenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spinning process of covering yarn with high hollowness degree, prepared covering yarn and process for weaving towel by utilizing covering yarn

ActiveCN102888686AIncrease warmthHigh hollownessBiochemical fibre treatmentBleaching apparatusCotton fibreEngineering

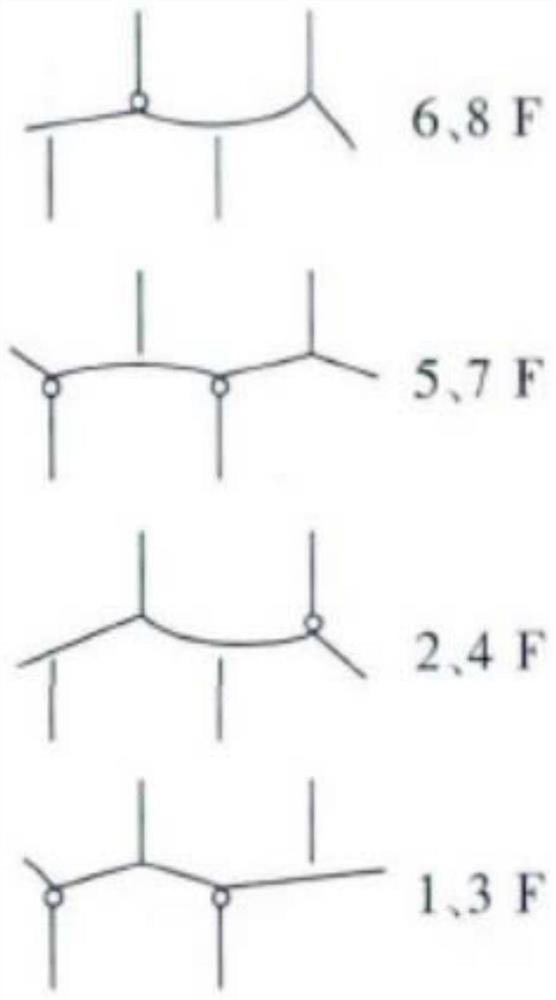

The invention provides a spinning process of covering yarn with high hollowness degree, a prepared covering yarn and a process for weaving towel by utilizing the covering yarn. The spinning process comprises the following steps of: compositing and twisting two crude cotton yarns and water-soluble vinylon filament with number of 4.1-7.3 tex to prepare a spun yarn with cotton fiber covering the water-soluble vinylon filament; and hydrolyzing the water-soluble vinylon filament to obtain the covering yarn with the high hollowness degree. The strength and the hollowness degree of the covering yarn with the high hollowness degree, prepared by the spinning process disclosed by the invention, are higher than the strength and the hollowness degree of a common hollow covering yarn with the same yarn count, the overing yarn with the high hollowness degree is soft and fluffy and has strong water absorbability and improved heat insulation performance; and the woven towel prepared by the process of the invention is light and fluffy, and has good heat insulation performance and resilience, high water absorption speed, large unit-area water absorption amount and high drying speed.

Owner:SUNVIM GROUP

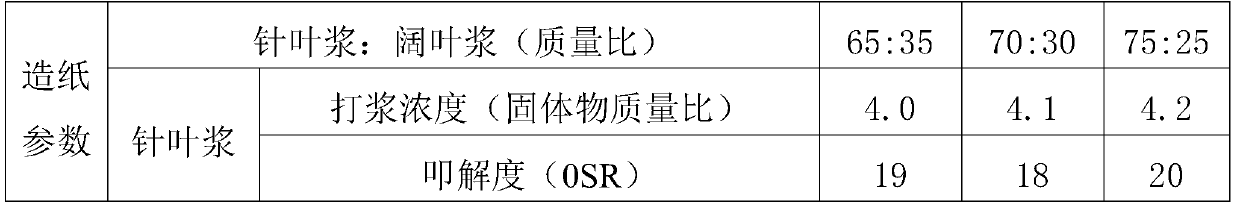

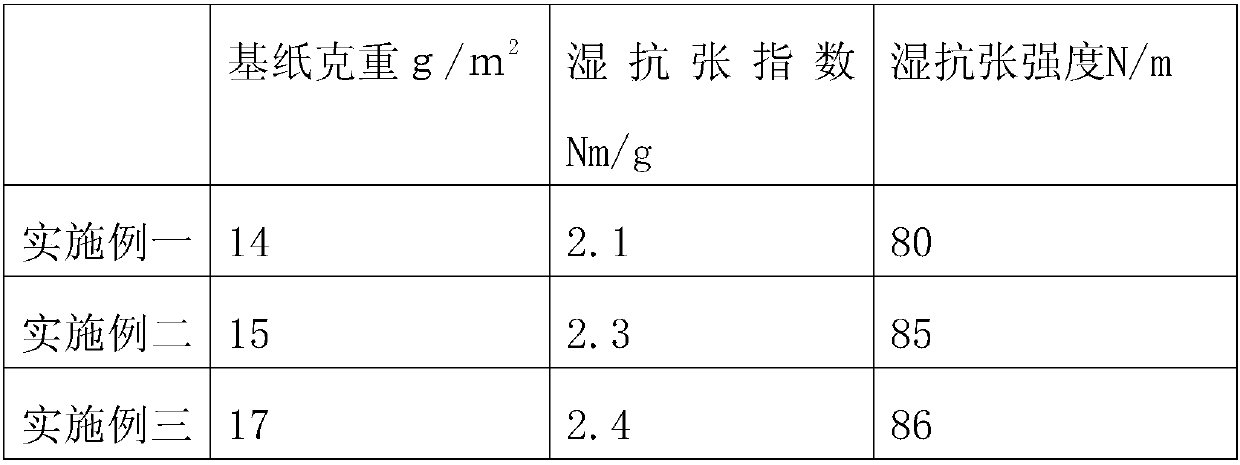

Production method of base paper of tipping paper used by cigarettes with high natural air permeability

InactiveCN103103859AGood operating strengthGood flexibilityPulp beating methodsReinforcing agents additionWet strengthRaw material

The invention relates to a production method of tipping paper of base paper used by cigarettes with high natural air permeability and aims to provide the production method of the tipping paper of the base paper used by the cigarettes with the high natural air permeability of 80-300CU. The production method of the tipping paper of the base paper used by the cigarettes with the high natural air permeability is characterized by comprising the following steps: a, beating section, beating is conducted on needle pulp and eucalyptus pulp through fibrillation and cut of a millstone mill to reach the effects that the beating degree of the needle pulp is 20-300SR, the wet weight of the needle pulp is 9-10g, the beating degree of the eucalyptus pulp is 20-220SR, and the wet weight of the eucalyptus pulp is 1-2g, b, preparation of pulp. Raw material components of pulp material comprises, by weight, 20-30 of needle pulp, 70-80 of eucalyptus pulp, 50-80 calcium carbonate and 0.2-0.4 wet strength agent. The produced tipping paper of the base paper used by the cigarettes with the high natural air permeability of 80-300CU uses high natural holes to bring a large quantity of are into the main stream smoke of the cigarettes and enables injurious ingredients in the main stream smoke to be greatly reduced.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

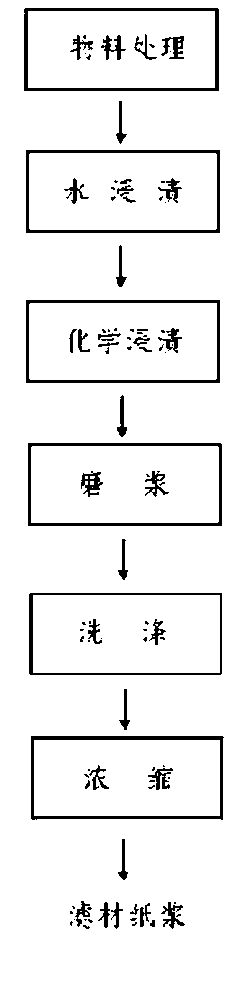

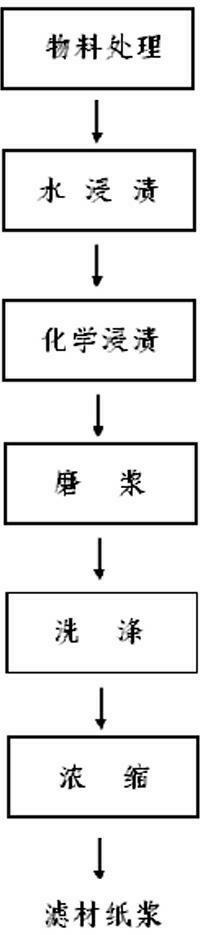

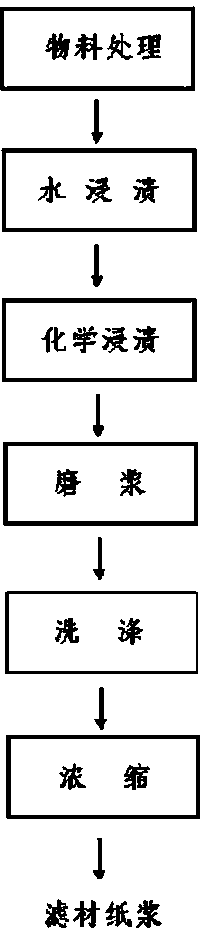

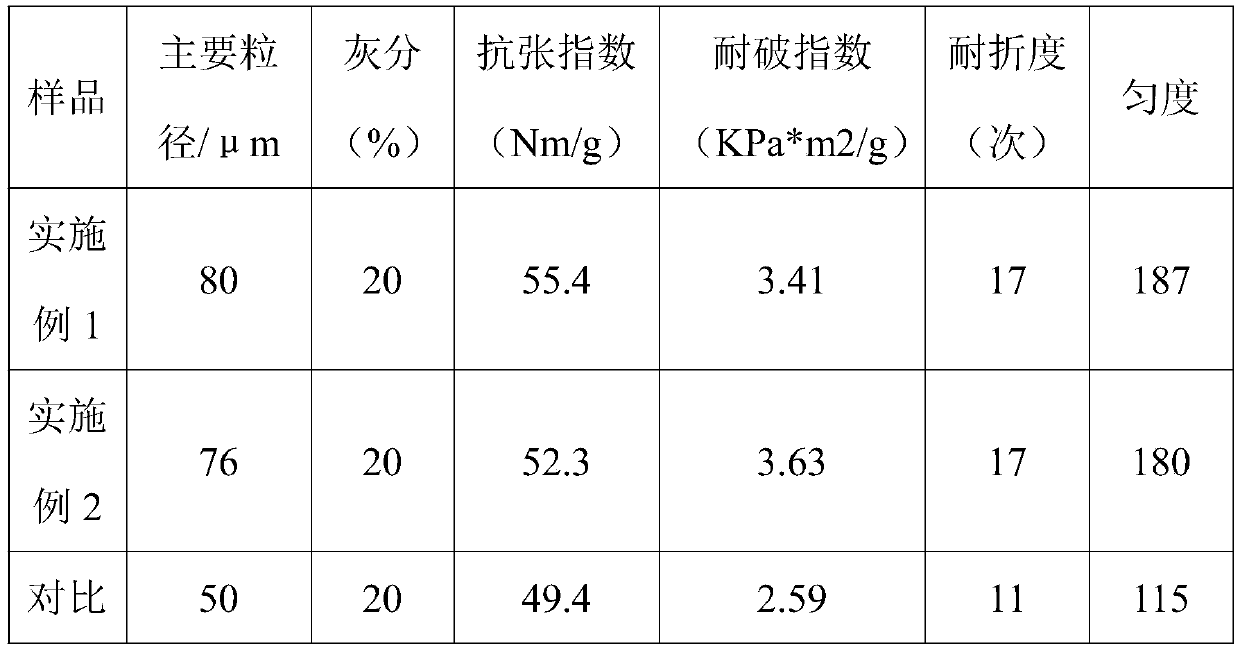

Method for reproducing paper pulp used for filter stick core paper by utilizing filter stick waste

ActiveCN102704300AIncrease profitImprove overall utilizationWashing/displacing pulp-treating liquorsContinuous pulping processFiberWaste material

The invention discloses a method for reproducing paper pulp used for filter stick core paper by utilizing filter stick waste, which includes procedures of material treatment, impregnation, defibrination, washing and concentration. Impurities in the filter stick waste are eliminated, and the filter stick waste is cut off into particles of 1-150 mm; the particles are impregnated by 4-10 times of water for 5-30 minutes under 70-100 degree C; inorganic base with weight being 0.5%-6% of dry weight of the particles is added into the impregnation liquid, so that the chemical concentration of the impregnation liquid is 0.25g-3g / L; the pulp liquid is concentrated to 10%-30%, and then pan-grinding defibrination is performed; and finally, the pulp liquid is washed and concentrated to 20-30%, so that the paper pulp used for wet process papermaking cigarette filter stick filter material can be obtained. The method disclosed by the invention has low treatment requirement for the impurities in the raw material, dispenses with molding paper stripping procedure, uses no toxic solvent, has high paper pulp yield, is excellent in fiber evenness, has centralized length distribution and uniform pulp, has no paper fragments and fiber beams, has excellent dispersion property, and is very suitable for making the filter stick core paper.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

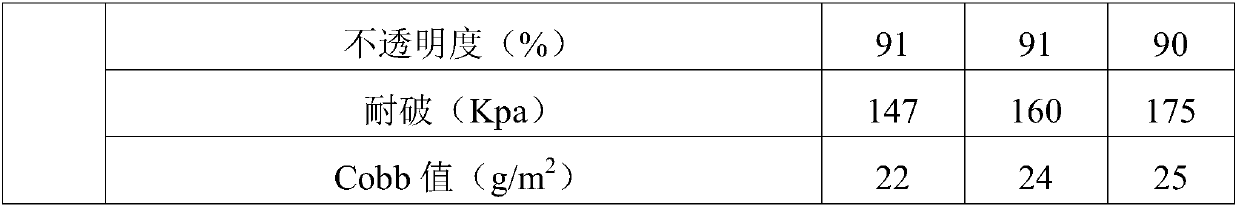

Water-resistant abrasive base paper and production method thereof

ActiveCN105297526AGood waterproof and oil-proof performanceImprove toughnessWater-repelling agents additionPaper coatingSolventPaper sheet

The invention discloses water-resistant abrasive base paper and a production method thereof. The water-resistant abrasive base paper is prepared from the following raw materials in parts by weight: 32-35 parts of softwood pulp fibers, 32-35 parts of hardwood pulp fibers, 5-10 parts of polyester fibers, 10-15 parts of modified thermoplastic resin, 3-5 parts of a water-proofing agent and 3-5 parts of an oil-proofing agent. The preparation method comprises the following steps: (1) mixing, crushing, pulping and repulping the softwood pulp fibers, the hardwood pulp fibers and the polyester fibers in parts by weight; (2) starching by a fourdrinier machine; (3) molding and drying a paper sheet on the fourdrinier machine, and carrying out gumming treatment once online, wherein the glue quantity is 10%-15%; (4) after drying the glue obtained in the step (3), carrying out secondary gumming on the front surface of the paper sheet, wherein the glue quantity is 6%-10%; and (5) calendaring the paper sheet which is gummed for the second time in the step (4) by a soft calendar. The Water-resistant abrasive paper prepared from the water-resistant abrasive base paper has the advantages of good waterproofness, softness, solvent resistance, dimension stability, high dry strength, good high temperature resistance and good weathering resistance.

Owner:SHANDONG LUNAN NEW MATERIALS

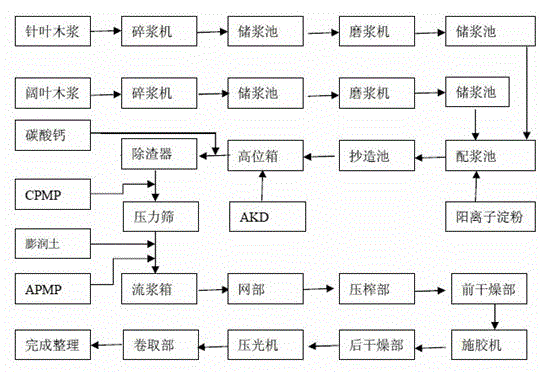

Production method of PS plate interleaving paper

InactiveCN106049164AGuaranteed evennessGuaranteed finenessSurface covering paperPulp beating methodsSizingHardwood

The invention discloses a production method of PS plate interleaving paper. The production method comprises the process steps as follows: respective beating of softwood pulp and hardwood pulp, pulp blending and addition of auxiliary materials, wet paper sheet making, pre-drying, surface sizing, after-drying, calendaring and finishing. Through research of pulp selection, pulp proportioning, a beating process and addition of functional chemical assistants to the pulp, adoption of film transfer surface sizing treatment as well as integration of finishing measures such as a soft calendaring equipment and the like, production of qualified PS plate interleaving paper is executed according to related paper machine parameters, and the method has great significance in optimization of product structure for a company and improvement of profitability of the company.

Owner:YUEYANG FOREST & PAPER CO LTD

Yellow card paper and manufacturing method thereof

InactiveCN104195877AGuaranteed evennessAvoid strong dryingWater-repelling agents additionLuminescent/fluorescent substance additionSulfateHue

The invention relates to a yellow card paper and a manufacturing method thereof. The manufacturing method is mainly characterized by comprising the following steps: respectively preparing bleached sulfate softwood pulp, bleached sulfate reed pulp and poplar PRC-APMP pulp; making paper from the bleached sulfate softwood pulp, the bleached sulfate reed pulp and the poplar PRC-APMP pulp according to the weight ratio of (15%-25%) to (35%-45%) to (35%-40%); optimizing dye types and different dye ratios; and with a CPAM and cationic starch retention system, carrying out soft roll calendaring treatment. The prepared yellow card paper has the characteristics that the fixed amount is 103-106g / m<2>, the thickness is greater than or equal to 140 microns, the moisture content is 4%-6%, the hygroscopic property is smaller than or equal to 30g / m<2>, the transverse folding strength is greater than or equal to 6 times, the transverse expansion rate is smaller than or equal to 3.2%, the longitudinal fracture length is greater than or equal to 3500m, the smoothness is greater than or equal to 20s, the two side difference is smaller than or equal to 30%, the b value is 26, and the content of dust of 0.2mm<2> to 1.5mm<2> is smaller than or equal to 60 / m<2>. The yellow card paper disclosed by the method is stable in hue and low in cost.

Owner:YUEYANG FOREST & PAPER CO LTD

Method for producing highly quantitative two-side offset paper

ActiveCN103603225AImprove water filtration performanceReduce poor qualityChemical/chemomechanical pulpPaper-making machinesSulfatePulp and paper industry

The invention belongs to papermaking technologies and relates to a method for producing highly quantitative two-side offset paper. The method comprises the following steps: sequentially performing pulping, size mixing, sizing, manufacturing paper with pulp, pre-drying, surface sizing, after-drying, press polish and rolling on basic raw materials such as bleached sulfate needlebush pulp and bleached sulfate broadleaf wood pulp, and finally finishing into paper; and allowing the materials in the pulping process to sequentially pass through a pulper, a pulp storage pool, a pulp grinder and the pulp storage pool according to a material transfer sequence, wherein in the pulping process, the pulping beating degree of the bleached sulfate needlebush pulp in the basic raw materials is required to be 25-320SR, and the pulping beating degree of the bleached sulfate broadleaf wood pulp is required to be 24-330SR. According to the method, the highly quantitative two-side offset paper can be manufactured with pulp, and the manufactured paper is high in surface strength, high in internal binding force, high in smoothness and small in two-side difference.

Owner:ZHENJIANG DADONG PULP & PAPER

Production method of lightweight paper

InactiveCN109680536AHigh yieldHigh opacityWater-repelling agents additionChemical and mechanical pulp mixtureSulfatePaper manufacturing

The invention discloses a production method of lightweight paper. The production method comprises a wood pulp proportioning step and a mixing step. Needle BCMTP chemimechanical pulp and needle bleached chemical wood pulp are proportioned and pulped; a neutral sizing agent, cationic starch, cationic polyacrylamide and talcum powder are used; then a paper manufacturing process is performed. Importedneedle wood pulp and broadleaf wood bleached sulfate pulp are respectively pulped and blended, and various additives are added; the blend is conveyed into an approaching system for dehydration forming through a wet part and then is further dehydrated through a squeezing part; after pre-drying, semi-dry calendaring and surface sizing are performed, the product is dried through a drying part; the product is baked at low temperature, subjected to soft calendaring finishing and wound. First of all, high bulkiness is achieved, and the flatness and the tensile strength of paper are not affected, sothe production method is suitable for high-speed printing; secondly, no flourescent brightener is contained; compared with common coated paper, offset paper and lightweight paper, the lightweight paper produced according to the method is relatively dark and has a color close to the primary color of wood pulp, so that visual fatigue cannot be caused by long-time reading.

Owner:SHANDONG TIANYANG PAPER

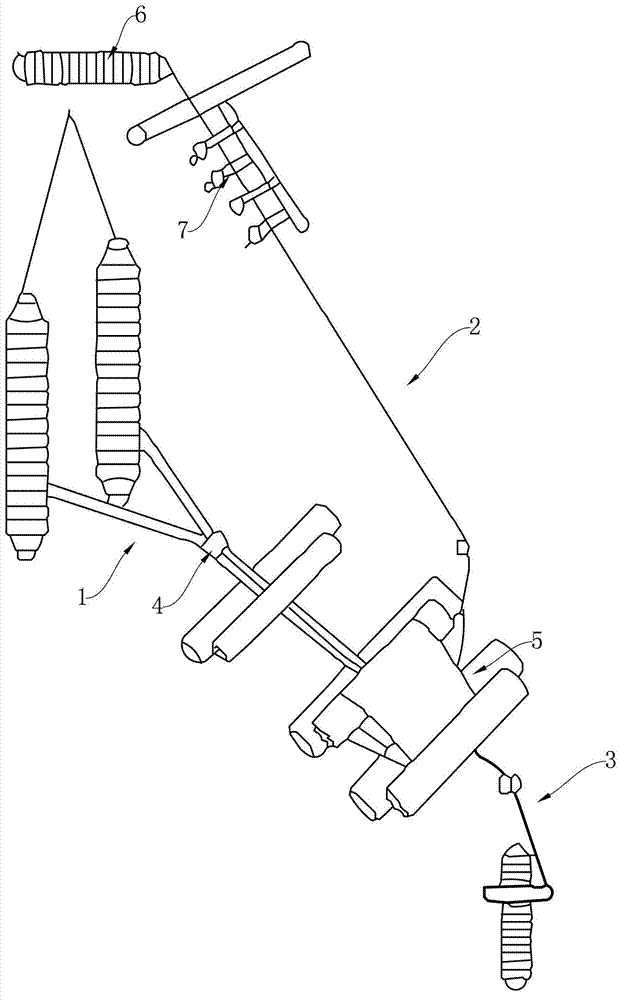

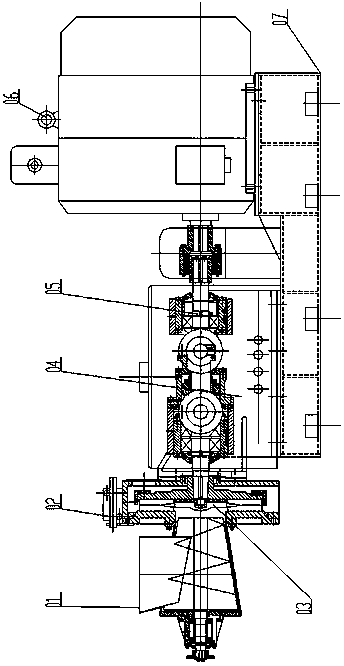

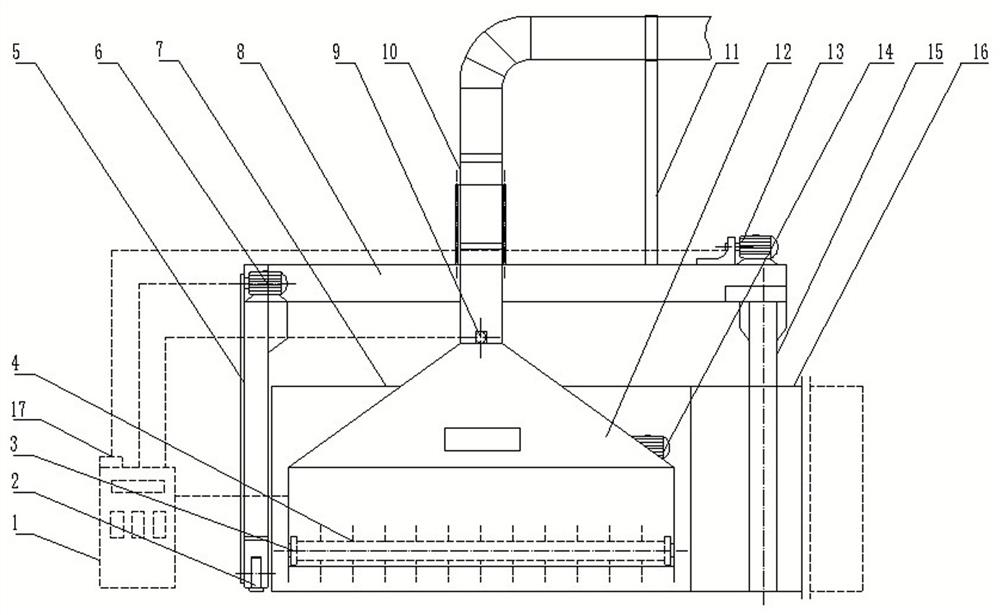

Straw fiber dividing machine

The invention discloses a straw fiber dividing machine. The straw fiber dividing machine comprises a forced screw feeding device, an abrasive disc decomposition zone, a sliding bearing device, a hydraulic device, a thin oil lubricating device, a telescopic shaft coupling and a main motor, wherein the forced screw feeding device comprises a spiral cylinder, a spiral auger and a non-slip strip; theabrasive disc decomposition zone comprises a shell, a shell end cap, an end cap exiting mechanism, a dividing disc, a moving disc and a material shifting wheel; the sliding bearing device comprises abearing body, a sliding bearing chamber and a sliding bearing shell; the thin oil lubricating device comprises a thin oil station; and the hydraulic device comprises a hydraulic rod, a hydraulic station and a hydraulic engage and retract mechanism. The straw fiber dividing machine has the advantages of small damages to the length of straw fibers, excellent fibrillation effect on the fibers, and adaptation to various plant fiber raw materials.

Owner:李克明

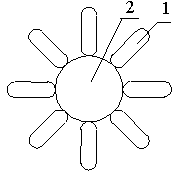

Matt eight-leaf polyester fibers and production method thereof

ActiveCN103233293AWith mattingMoisture absorption and quick dryingFilament forming substance formingArtificial thread manufacturing machinesFiberPolyester

The invention relates to the technical field of differential fibers and productions thereof. In order to solve problems of surface reflection and shining of polyester, the present invention provides matte eight-leaf polyester fibers and a production method thereof, wherein a crystallization accelerator is added during polyester condensation polymerization production, and a spinning plate with a eight-leaf-shaped spinning hole cross section is adopted to spin to obtain the matte eight-leaf polyester fibers. According to the present invention, the produced fibers have good matt property without addition of titanium dioxide, and further have characteristics of good moisture absorption and sweat discharging, good dyeability, good bionic property, wide application range, and high product added value.

Owner:ZHEJIANG HENGYI HIGH TECH MATERIAL

Production method of dialysis base paper

InactiveCN109778587AFully swollenGuaranteed StrengthWater-repelling agents additionReinforcing agents additionSulfatePapermaking

The invention discloses a production method of dialysis base paper. The production method comprises the steps of selecting pulp, ingredients and a papermaking process, controlling the proportion of bleached sulfate hardwood pulp to bleached sulfate softwood pulp, separately pulping the two kinds of wood pulp, and controlling the corresponding pulping concentration, beating degree and wet weight; then, conducting processes such as pulping, pulp preparation and papermaking. In a formula, PVA is a good surface sizing agent which is prepared by mixing with surface sizing starch and can improve thesurface film forming performance and water resistance of paper; when paper sheets with the same water absorption performance is about to be subjected to surface sizing before sizing, glue can be effectively prevented from excessively permeating inwards when the paper sheets are subjected to surface sizing as long as there is a certain amount of the PVA in the glue; only the surface of each papersheet is covered with a thin film formed by the glue, and the absorption amount of the glue on the paper sheets is basically unchanged. The base paper has good ink absorption and opacity and can meetthe printing requirements of a high-speed rotary printing machine in the aspect of strength, and a soft calender is adopted for finishing of the paper sheets.

Owner:SHANDONG TIANYANG PAPER

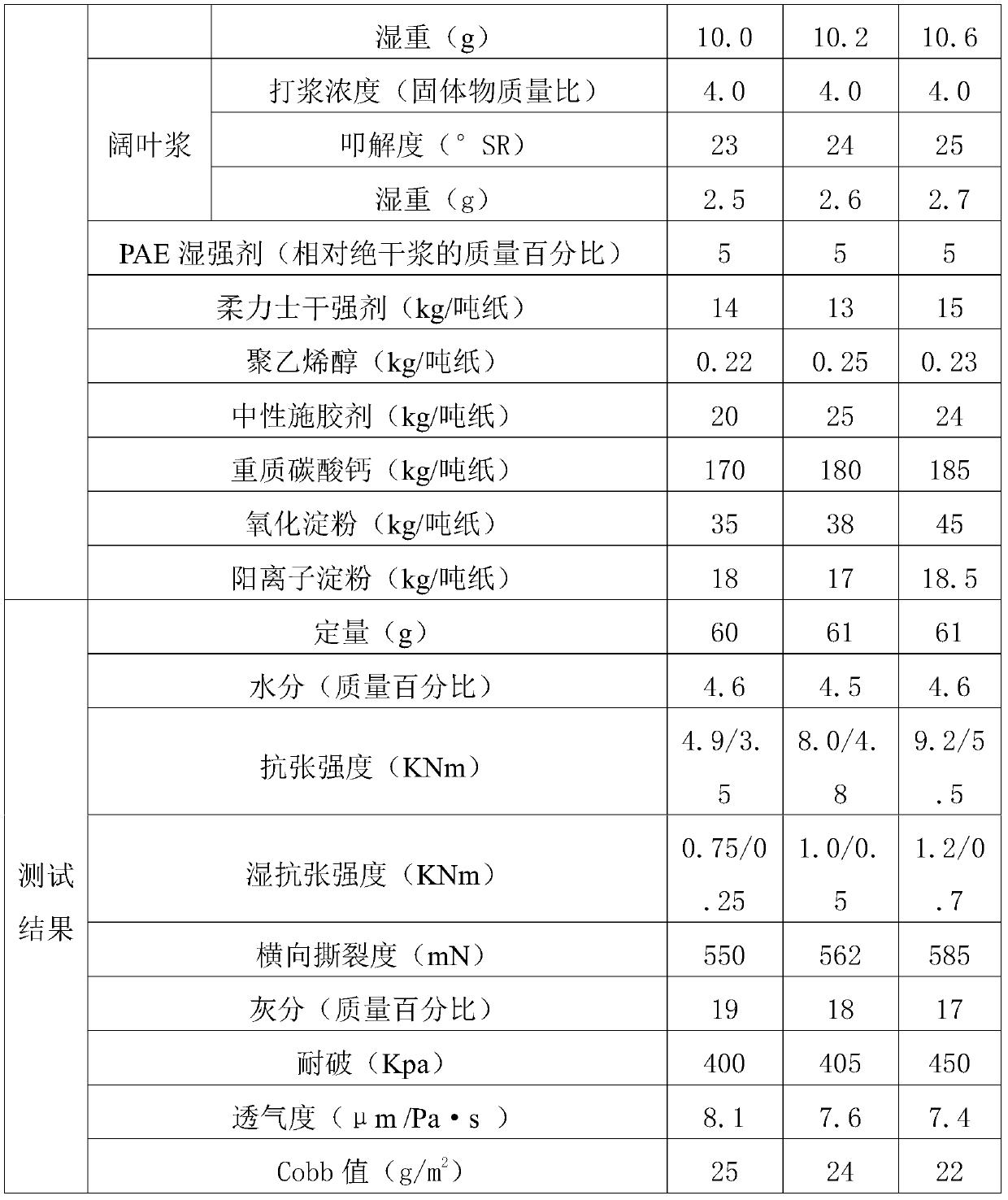

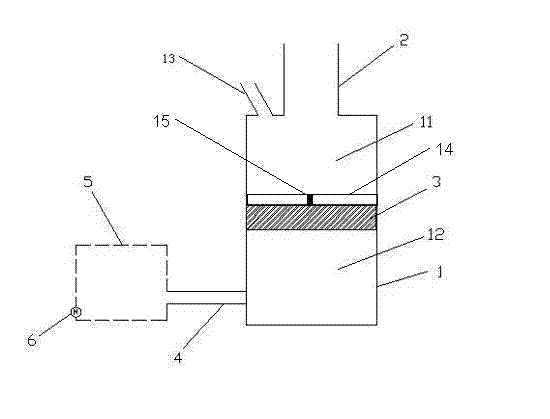

Overflow device of pulp molding machine

InactiveCN102242534AHigh control precisionImprove evennessTextiles and paperMolding machineElectrical control

The invention provides an overflow device of a pulp molding machine. The overflow device comprises a cylinder, an overflow pipeline, a piston, a slushing pipe, a dispersion stabilization unit, a pneumatic control valve and a synchronous electrical control unit (ECU), wherein, one end of the overflow pipeline is communicated with the cylinder; the piston is arranged in the cylinder and divides the cylinder into a first space and a second space which are hermetically connected together, and the first space is communicated with the overflow pipeline; the slushing pipe is arranged at one side of the overflow pipe and is communicated with the cylinder; the dispersion stabilization unit is arranged in the first space of the cylinder and is connected with the piston, and the dispersion stabilization unit is equipped with a motor for providing power for rotation of the dispersion stabilization unit; the pneumatic control valve is communicated with the second space of the cylinder through a pneumatic control pipeline; and the synchronous ECU is used for controlling on / off of the pneumatic control valve in different directions. The overflow device provided by the invention has the advantages that the residual pulp raw material can be uniformly reused, thus saving raw materials and lowering cost.

Owner:佛山市昆保达模塑科技有限公司

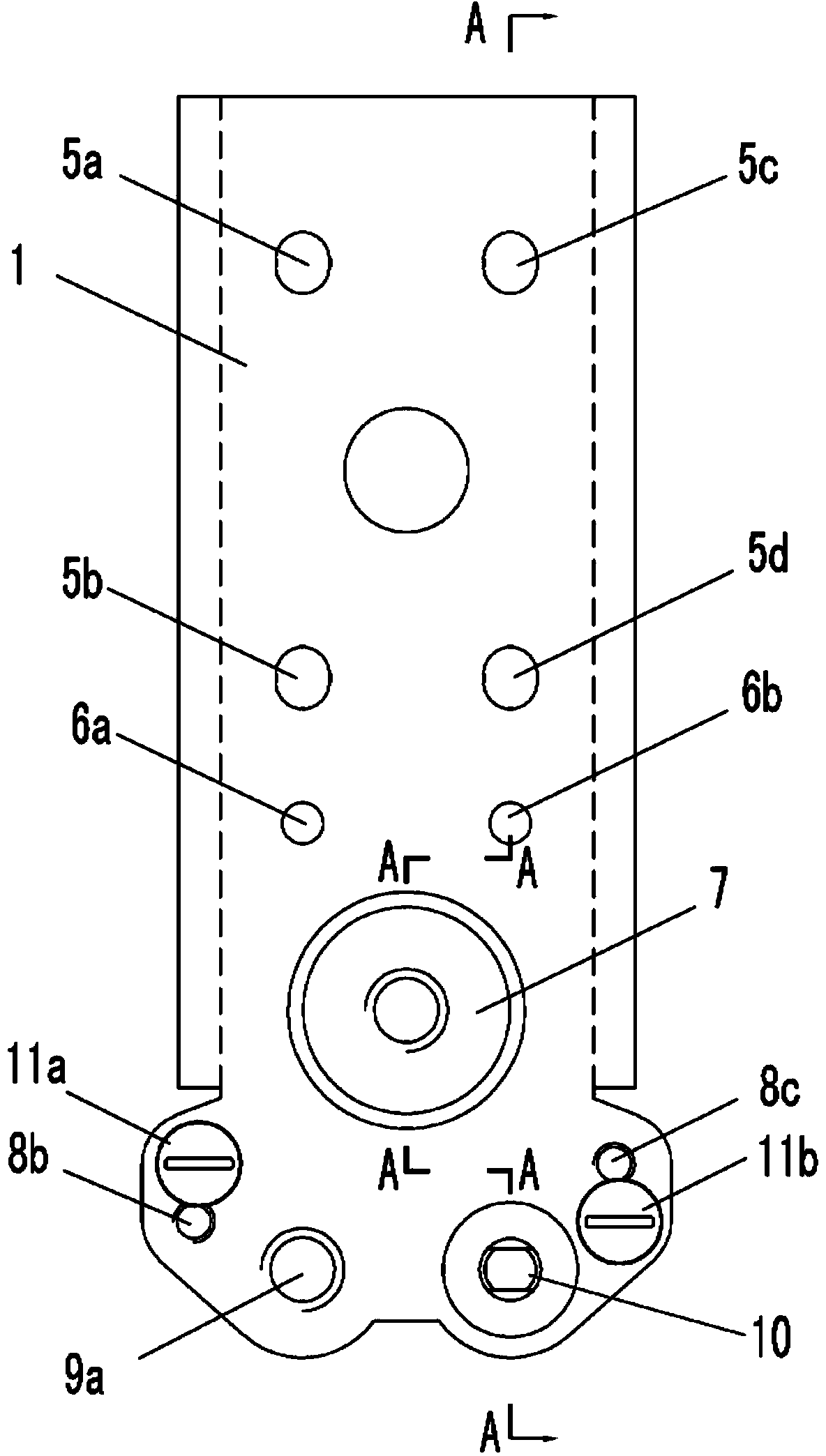

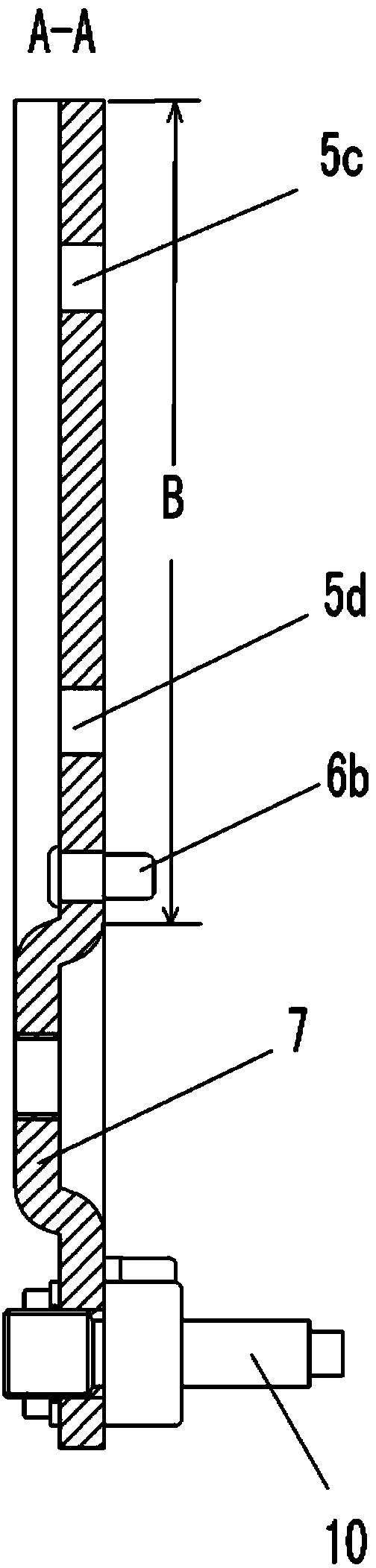

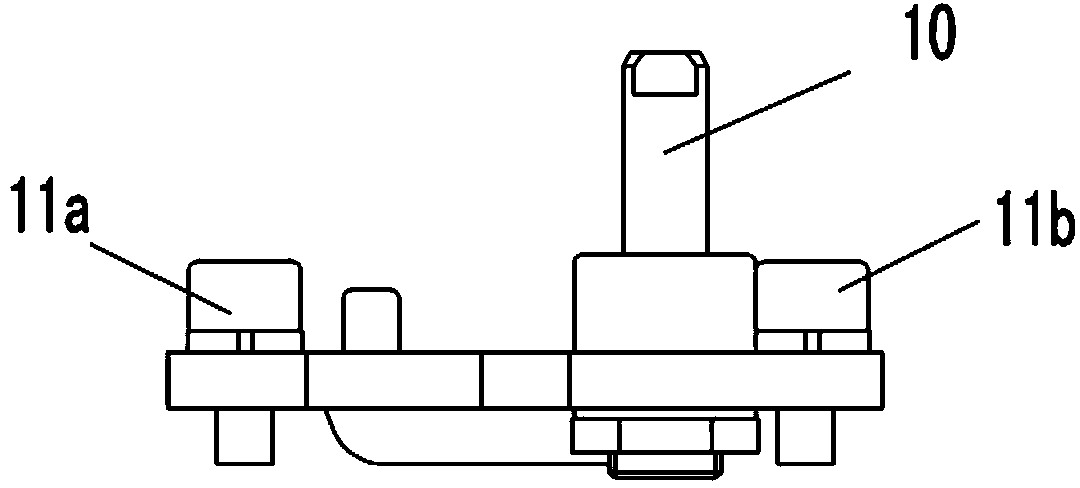

Multifunctional refrigerator lower hinge device

The invention discloses a multifunctional refrigerator lower hinge device. The multifunctional refrigerator lower hinge device comprises a lower hinge body, a limiting block and a locking block. The lower hinge body is composed of a rectangular body and an extension part connected with the tail part of the rectangular body, and the limiting block and the locking block are fixedly connected and can be fixed in a left door spindle fixing hole or a right door spindle fixing hole through a door spindle stud. Two limiting self-locking studs can be arranged in an upper set of stud fixing holes and a lower set of stud fixing holes. The limiting block, the locking block, the door spindle stud and the two limiting studs form a matched structure for opening and closing a refrigerator door for a refrigerator body. The multifunctional refrigerator lower hinge device integrates the positioning function, the limiting function and the self-locking function and is of a structure in bilateral symmetry or longitudinal symmetry or central symmetry, and thus the door can be directly replaced and installed without replacing the lower hinge body when changing between a left opening door and a right opening door, time and labor are saved, and cost is reduced.

Owner:CHANGHONG MEILING CO LTD

Vortex spinning anti-pilling knitted fabric

PendingCN111793884AGuaranteed electrical conductivityHigh strengthWeft knittingYarnYarnPolymer science

The invention discloses a vortex spinning anti-pilling knitted fabric. The vortex spinning anti-pilling knitted fabric comprises a fabric body; the fabric body adopts a rib stitch knitted structure; the odd-numbered paths and the even-numbered paths of the fabric body are formed by penetrating and knitting an antistatic core-spun yarn; the antistatic covering yarn comprises a core yarn and a wrapping fiber, the wrapping fiber is organic cotton fiber; the wrapping fiber is spirally wrapped outside the core yarn; the core yarn comprises a core yarn layer and a skin layer; the core yarn layer ismade of untwisted and stranded flax fiber yarns; and the skin layer is formed by spirally winding carbon fiber filaments outside the core yarn layer. According to the vortex spinning anti-pilling knitted fabric, the antistatic core-spun yarn which is excellent in antistatic performance, less in surface hairiness and uniform in evenness is adopted as the knitting yarn, so that the vortex spinning anti-pilling knitted fabric is soft and comfortable in touch, good in wet permeability and air permeability, antistatic and free of pilling, and has excellent wearability.

Owner:SUZHOU CITY XINGJINGZE FIBER TECH CO LTD

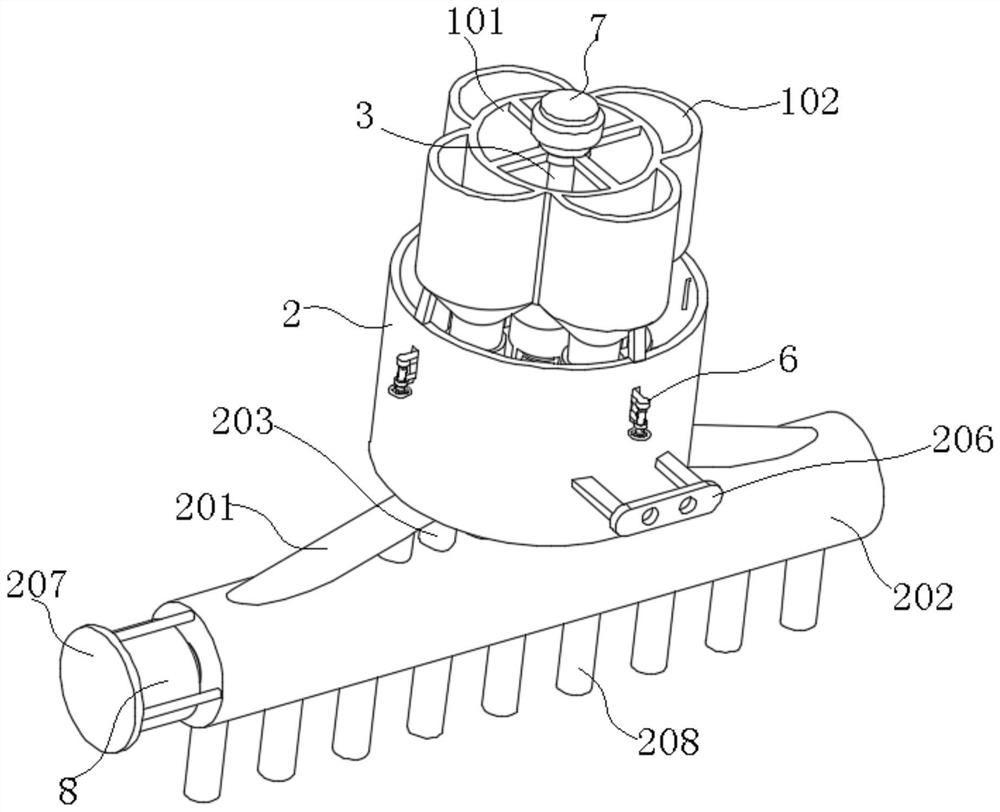

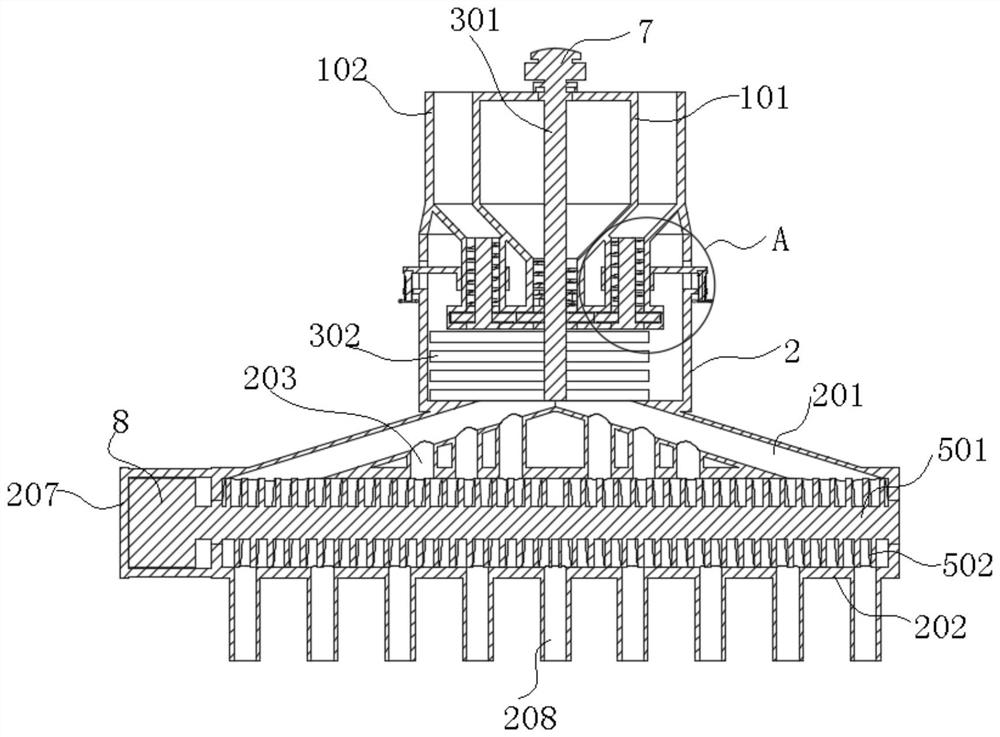

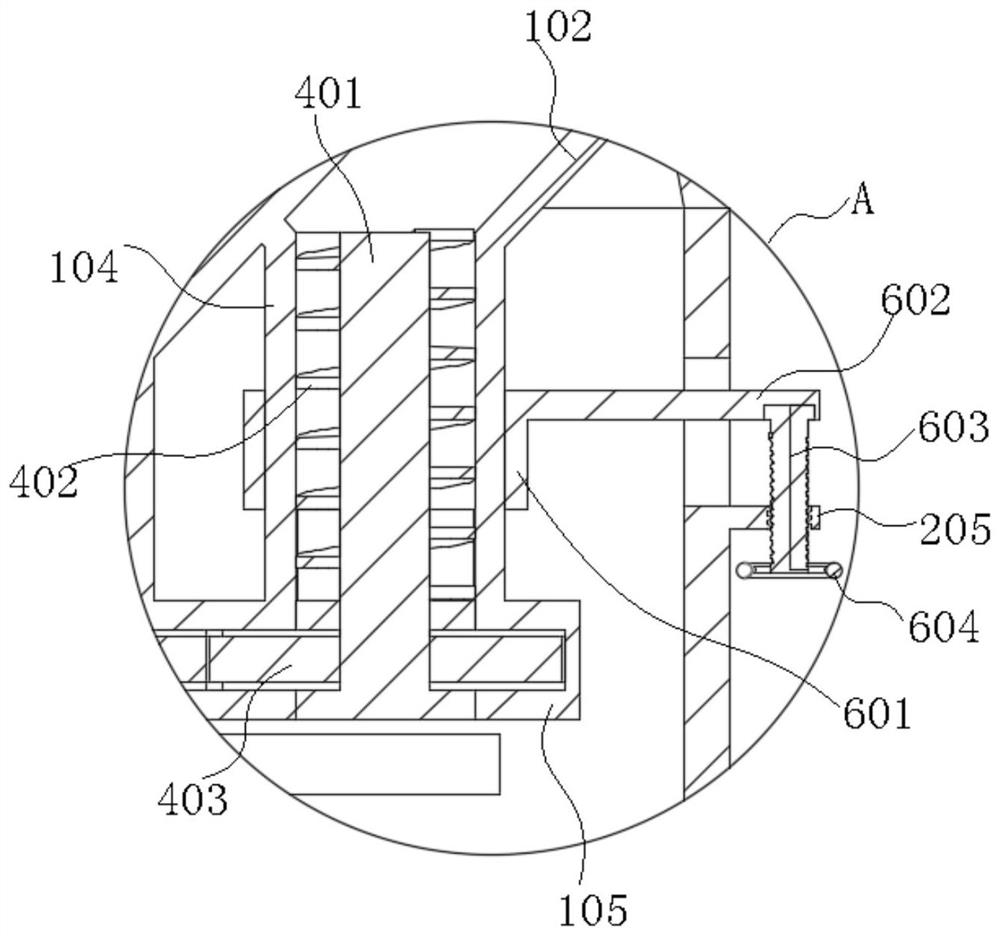

Agricultural sowing and fertilizing all-in-one machine

PendingCN112772061AWrappedIncrease profitRotary stirring mixersTransportation and packagingAgricultural scienceAgricultural engineering

The invention discloses an agricultural sowing and fertilizing all-in-one machine, and relates to the technical field of agricultural planting. The agricultural sowing and fertilizing all-in-one machine comprises a material storage cylinder, wherein the material storage cylinder comprises a seed storage cylinder; fertilizer storage cylinders are arranged on the circumferential side face of the seed storage cylinder in an annular array manner; mixing barrels are fixedly connected between the peripheral side surfaces of the bottom ends of the fertilizer storage cylinders; the bottom end of the seed storage cylinder is communicated with a seed discharging pipe; the bottom end of each fertilizer storage cylinder is communicated with a fertilizer discharging pipe; sealing boxes are fixed between the bottom ends of the seed discharging pipe and the fertilizer discharging pipes; and a center rotating frame and driven rotating frames are rotationally connected to the inner bottom end of each sealing box. According to the agricultural sowing and fertilizing all-in-one machine, when each center rotating frame rotates, the center rotating frame is in meshing transmission with the multiple corresponding driven rotating frames, so that first spiral blades and second spiral blades guide out seeds and fertilizer respectively, the seeds and the fertilizer are mixed under the action of stirring blades, the fertilizer and the seeds are completely mixed, the seeds are well coated by the fertilizer during sowing, and the utilization rate of the fertilizer is increased.

Owner:JILIN AGRICULTURAL UNIV

Method for preparing high-transparency copying paper by applying waste-paper deinked pulp

InactiveCN107641994AHigh transparencyLow costPaper recyclingWaste paper working-upPulp treatmentPapermaking

The invention relates to the field of paper making and provides a method for preparing high-transparency copying paper by applying waste-paper deinked pulp. By adoption of the high-transparency copying paper, the defects of bad transparency, poor deinking effect and poor mechanical property in the copying paper prepared by the waste paper pulp in the prior art are solved. The high-transparency copying paper comprises the following steps of: (1) collecting the waste paper pulp and adding a modified deinking agent to carry out deinking on the waste paper pulp; (2) adding sodium borohydride and diethylene triamine penlaacetic acid into deinking pulp obtained by treatment of the step (1), and washing; (3) carrying out beating and pulping treatment on the deinking pulp subjected to washing, wherein the beating degree is 30-35 degree SR; (4) carrying out beating and pulping treatment on chemical pulp of needlebush, wherein the beating degree is 70-80 degree SR; (5) mixing the pulp in the step (3) and the pulp in the step (4), and carrying out papermaking, wherein a dispersing agent is added in the papermaking process.

Owner:福建省晋江优兰发纸业有限公司

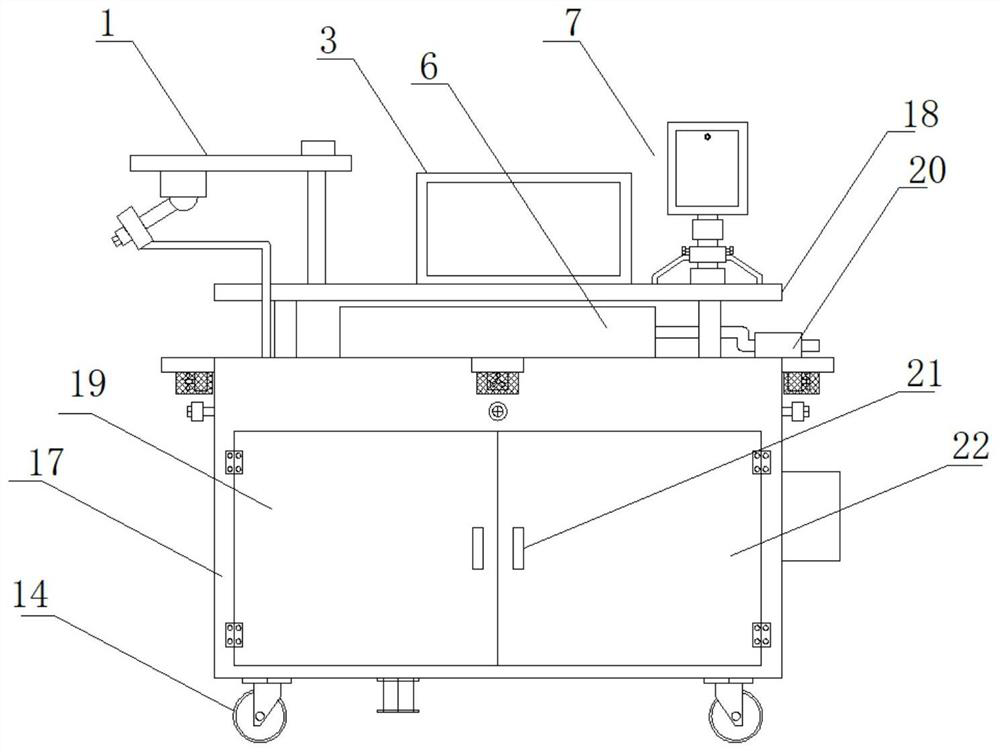

An all-in-one intelligent terminal with functions of space disinfection and hand disinfection temperature measurement

ActiveCN113040727BRealize Orientation AdjustmentMeet the needs of different orientationsLavatory sanitoryMedical applicatorsElectric machineryProcess engineering

The invention discloses an integrated intelligent terminal with the functions of space disinfection and hand disinfection temperature measurement, which includes a box body, an ozone generator, a motor and a liquid storage tank. When the temperature of a person needs to be measured, the person only needs to face the The integrated temperature measurement machine can realize the rapid measurement of personnel body temperature, and the measurement is fast and convenient. When the personnel's hands need to be disinfected, the water pump is used to make the disinfectant in the liquid storage tank pass through the liquid guide tube and then enter the liquid storage box. And it is sprayed out through the spray head, so as to realize the spray disinfection of the personnel's hands. When the space needs to be disinfected, the ozone generator is used to generate ozone, and the ozone enters the second air guide tube and further enters the air guide In the box, the ozone in the air guide box passes through the third air guide pipe and sprays out through the nozzle, so as to realize the disinfection of indoor and other spaces, and use the fan to blow the air, thus speeding up the speed of ozone emission into the air and improving the efficiency of space disinfection and effects.

Owner:NINGXIA YOUAN MEDICAL INSTR CO LTD

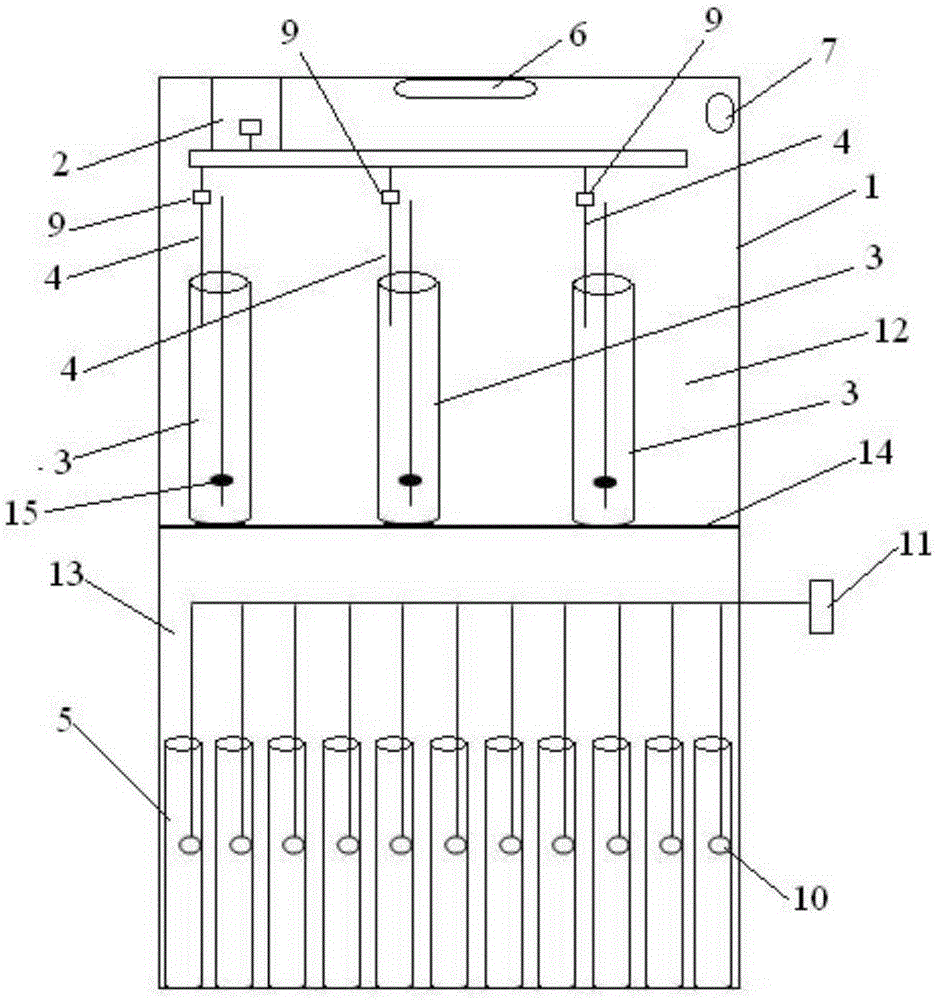

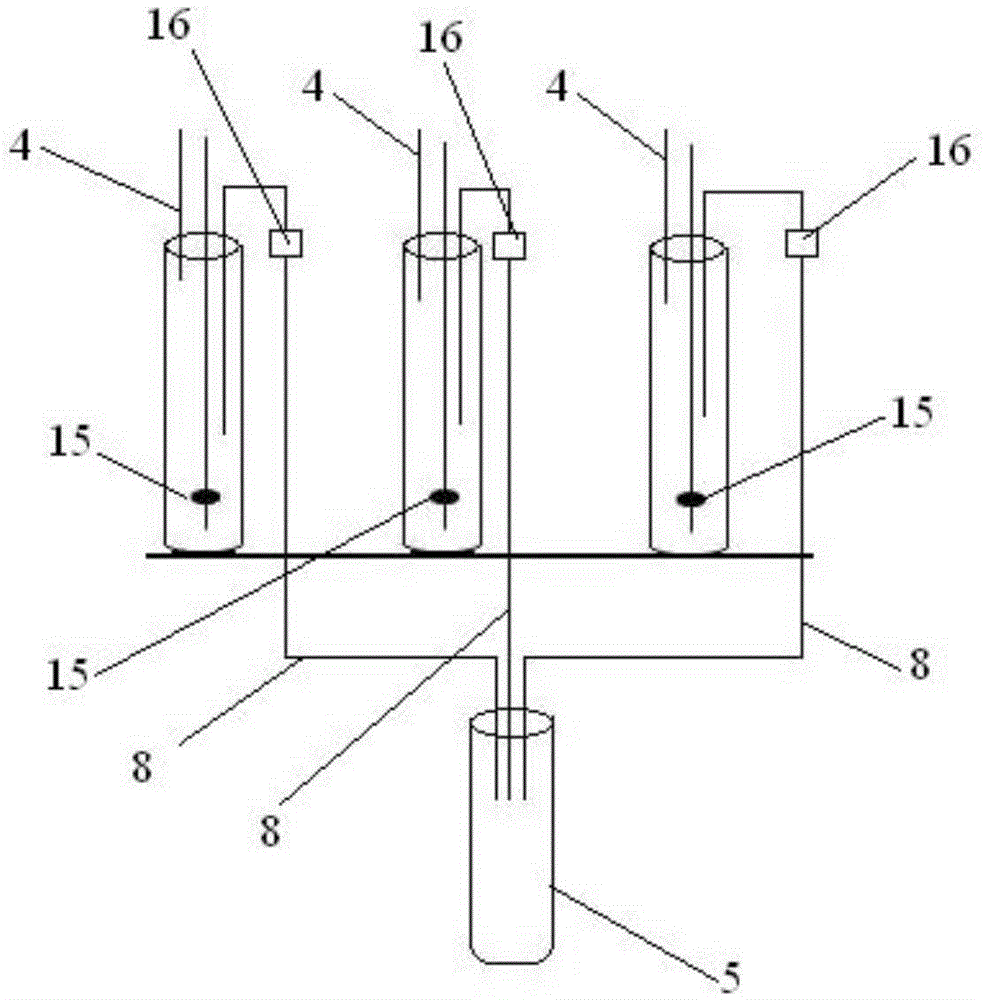

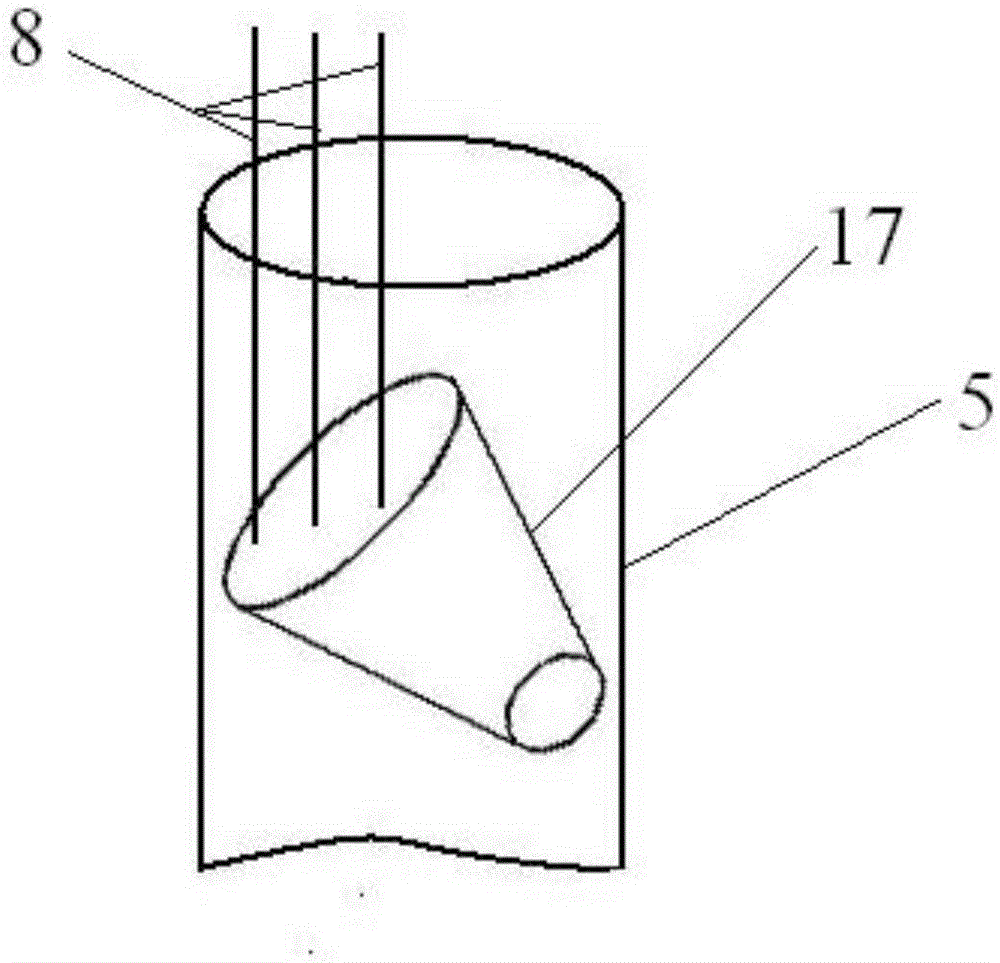

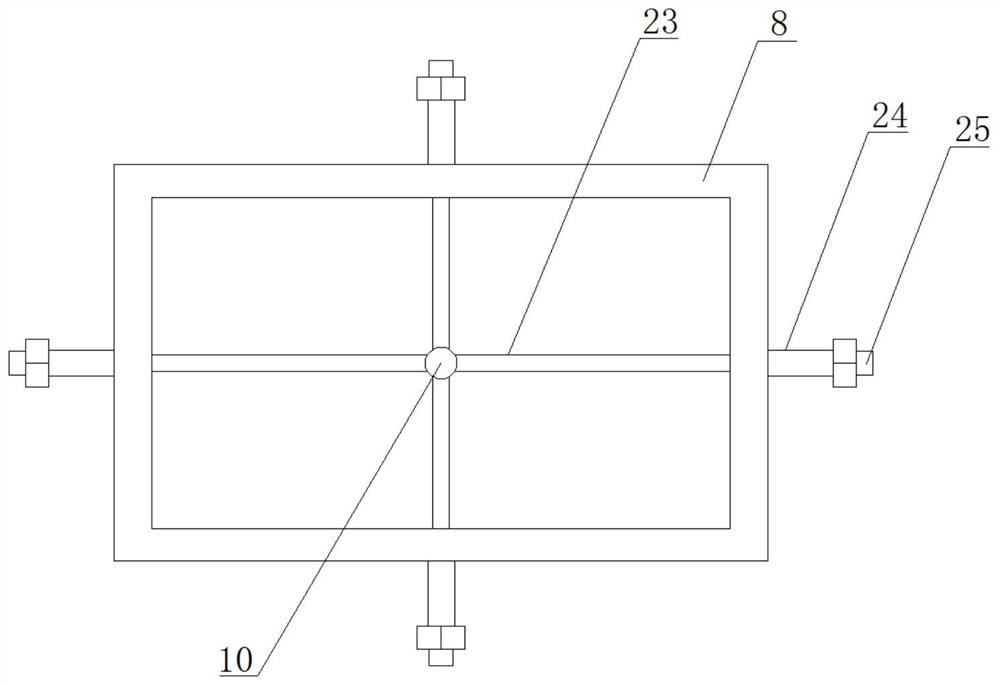

Indoor simulation device used for research of organic phosphorus enzyme hydrolysis process in water environment

ActiveCN105255728AThere will be no concentration fluctuationsMix well and evenlyBioreactor/fermenter combinationsBiological substance pretreatmentsPh controlInterference factor

The invention relates to a laboratory control simulation device used for research of organic phosphorus hydrolysis influencing process of enzymes in water environment. An enzyme dissolving reagent storage tank, enzyme solution preparation containers and test tubes arranged in a device cabinet body, the enzyme solution preparation containers are located under the enzyme dissolving reagent storage tank and are communicated with the enzyme dissolving reagent storage tank through enzyme dissolving reagent drawing pipes, and the test tubes are communicated with the enzyme solution preparation containers through enzyme solution reagent drawing pipes. The indoor simulation device is equipped with an ultraviolet disinfection device, an upper part temperature control device, enzyme dissolving reagent quantificational drawing devices which are connected with the enzyme dissolving reagent drawing pipes and used for quantificational drawing of the enzyme dissolving reagent in the enzyme dissolving reagent storage tank to the enzyme solution preparation containers, enzyme solution quantificational drawing devices which are connected with the enzyme solution drawing pipes and used for quantificational drawing of the solution in the enzyme solution preparation containers to the test tubes, and a pH control system monitoring and adjusting the pH values of the solutions in the test tubes. The indoor simulation device can reduce interference factors in the reaction process effectively and raises the reaction controllability.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

High-sealing pipeline laying device for styrene pipe transportation

The invention relates to the related technical field of styrene pipe transportation, in particular to a high-sealing pipeline laying device for styrene pipe transportation, which comprises a base, a fixed clamping assembly and an adjustable clamping assembly, a movable mounting seat is driven by a hydraulic assembly, and the base is of a rectangular seat body structure; a fixed mounting seat is arranged on the upper surface of the base close to the left side end, a first linear guide rail is mounted on the right side of the base, and a movable mounting seat is movably mounted on the first linear guide rail; according to the welding positioning device for pipeline laying, the base, the fixed clamping assembly and the adjustable clamping assembly are combined to form the welding positioning device for pipeline laying, so that the fixed clamping assembly and the adjustable clamping assembly are correspondingly aligned with two to-be-welded pipeline structures, and the two to-be-welded pipeline structures are prevented from deviating; therefore, the levelness of the butt joint port is effectively ensured.

Owner:青岛海湾化学股份有限公司

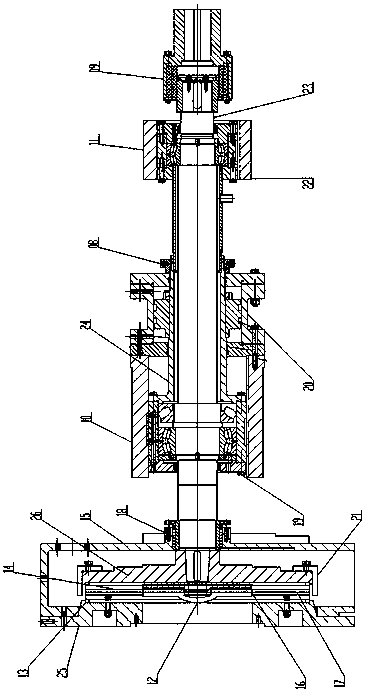

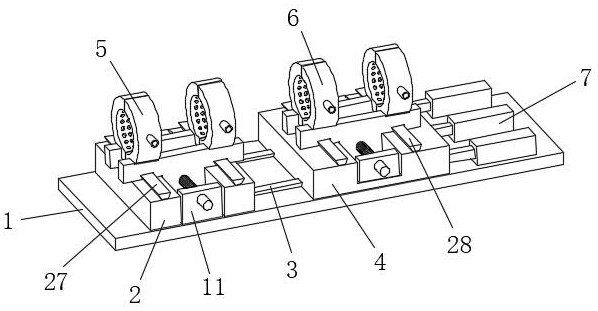

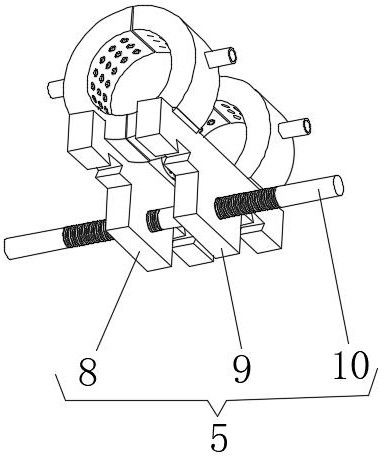

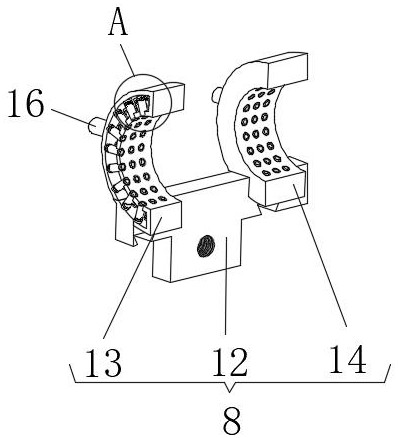

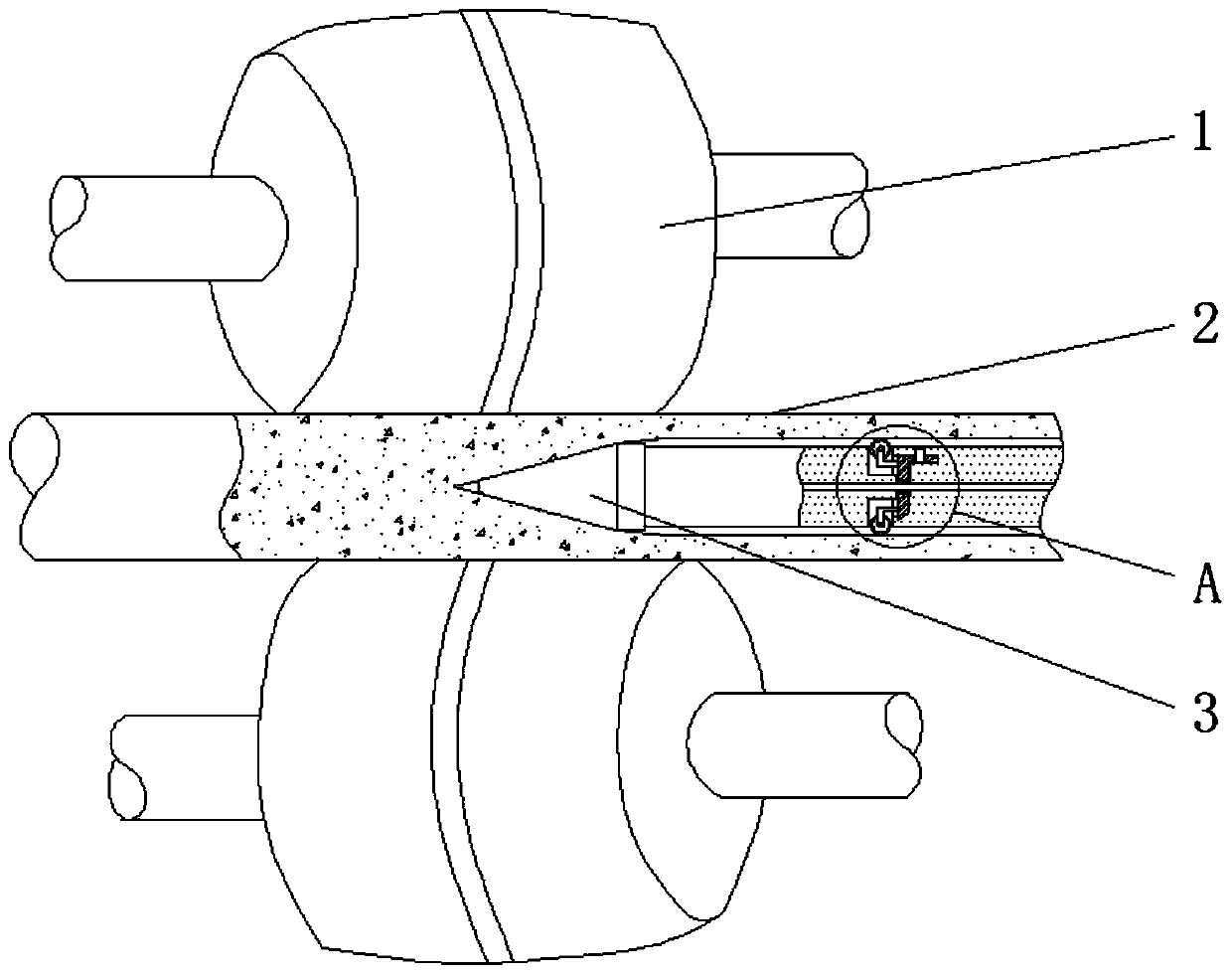

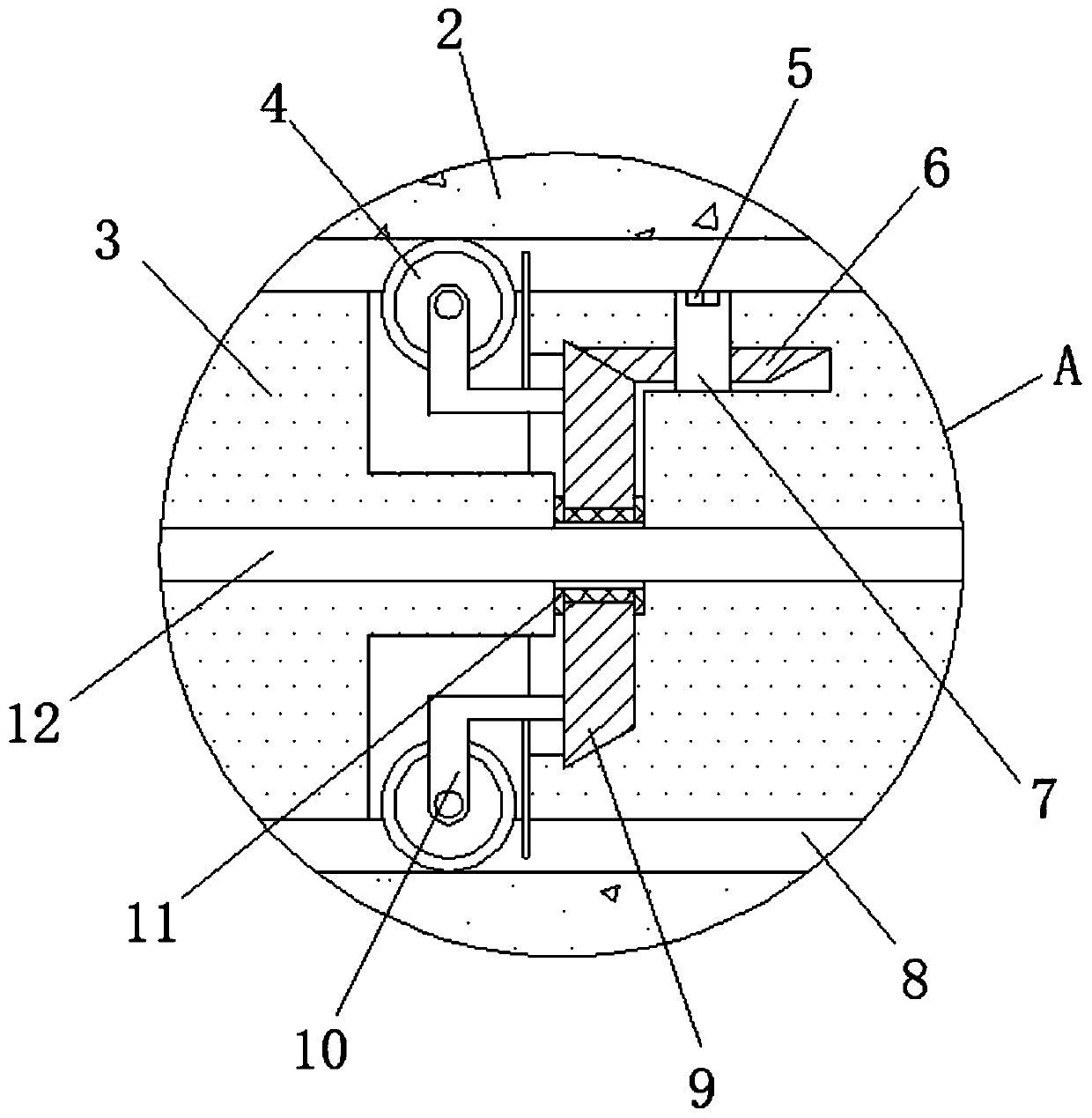

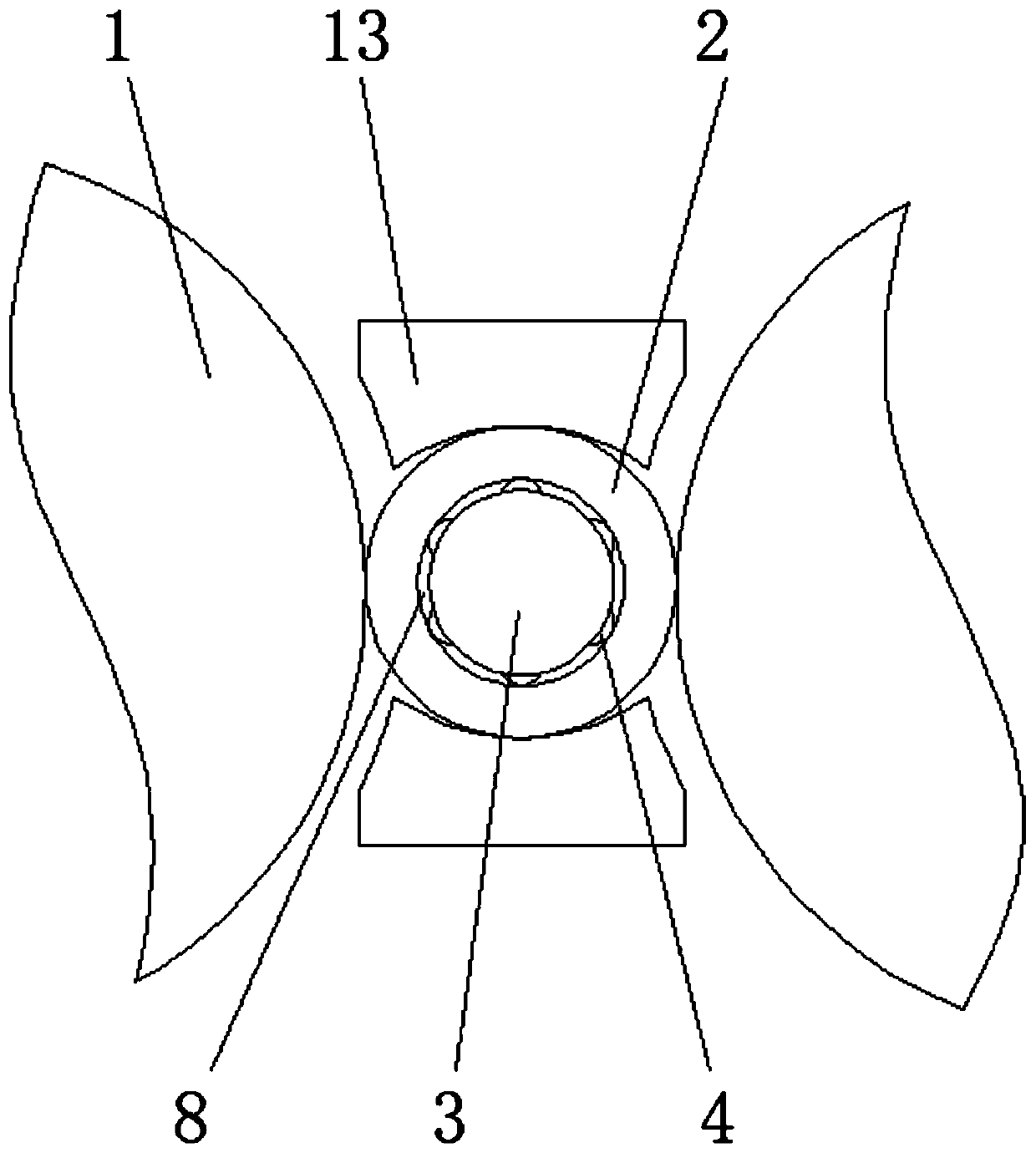

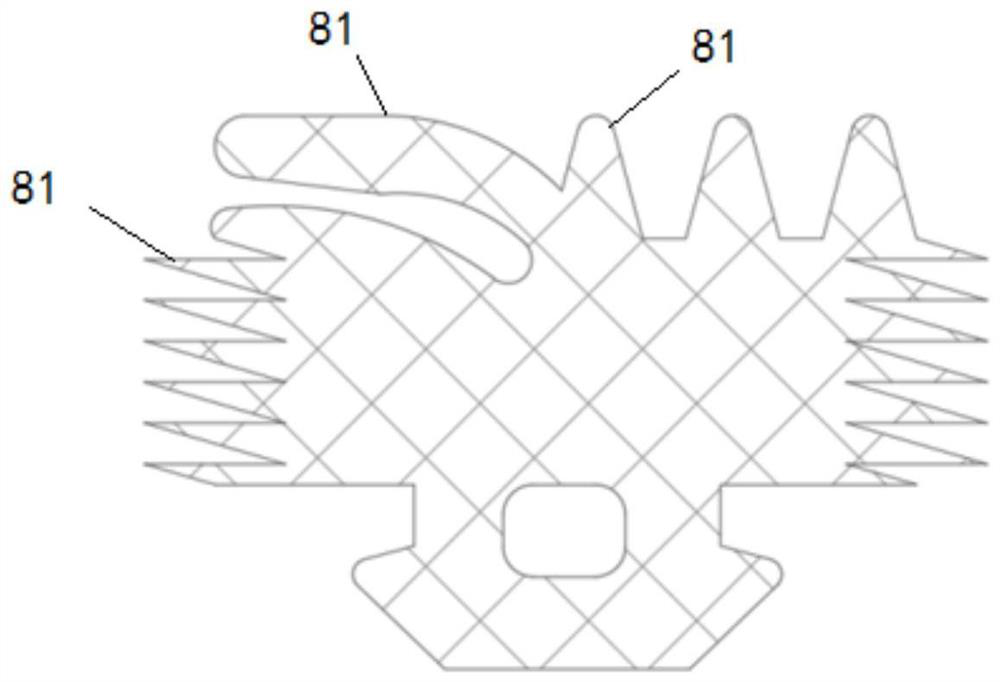

Expanding device for perforation of seamless steel pipes

ActiveCN111515251AGuaranteed evennessImprove pass rateMandrelsMetal rolling arrangementsSteel tubePipe

The invention discloses an expanding device for perforation of seamless steel pipes. The expanding device is applied to a perforator, and comprises a pair of rollers, a steel pipe, an ejector rod, a pair of guide plates and a correction mechanism; the correction mechanism is connected to the inside of the ejector rod, the ejector rod is placed right in the middle of the pair of rollers and the pair of guide plates, the steel pipe is placed between the pair of rollers and the pair of guide plates and attached to the rollers and the guide plates, and the ejector rod penetrates into the steel pipe; and the correction mechanism comprises correction wheels, a trapezoidal gear, an adjustment shaft and a trapezoidal fluted disc. The expanding device can effectively perform roundness shaping on asteel pipe through hole formed after perforation, the generation of an ellipse shape after perforation of the steel pipe is avoided, the uniformity of the wall thickness after perforation of the steelpipe is ensured, and the qualified rate of the finished steel pipe is increased; and the height of the correction wheels extending into a correction gap can be adjusted according to the required perforation aperture of the to-be-machined steel pipe, so that the correct mechanism meets perforation shaping of different steel pipes with different apertures, the applicability of the device is improved, and the device is suitable for popularization.

Owner:LIAOCHENG ANTAI PETROLEUM MACHINERY

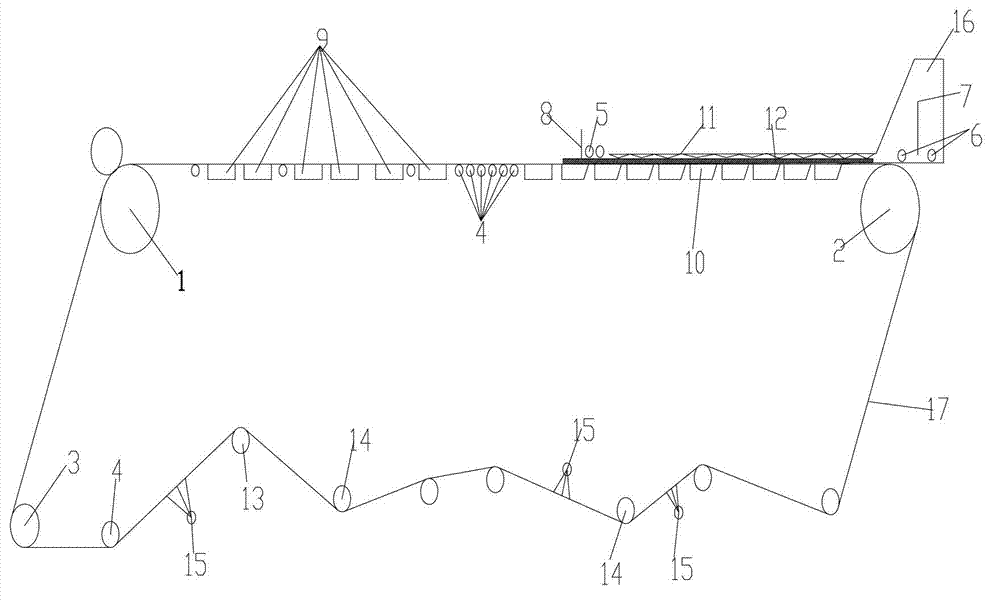

Raw paper of abrasive paper and preparation method thereof

InactiveCN108755258AImprove water and oil releaseImprove stretch resistanceSpecial paperWater-repelling agents additionDigestionOxygen

The invention discloses a raw paper of an abrasive paper and a preparation method thereof. The preparation method comprises the following steps of selecting 60 to 80 parts of coniferous wood pulp, 10to 25 parts of chemical fiber and / or 5 to 10 parts of bamboo charcoal fiber, fully cutting, grinding and pulping; adding 1 to 10% of wet strength agent, 1 to 5 parts of chitosan, 1 to 5 parts of modified thermoplastic resin, and 1 to 4 parts of waterproof agent, and diluting by water until the mass concentration of the material of the raw pulp is 10% to 20%; adjusting the pH (potential of hydrogen) value to 5.5 to 8.5, performing DDS (displacement digester system) displacement digestion, washing and screening, removing lignin by oxygen and alkaline, bleaching by hydrogen peroxide, and fully pulping and crushing, so as to obtain sulfate slightly-bleached wood pulp; performing inclined net forming, dewatering, large-cylinder pre-baking, two-cylinder drying and calendering, group-cylinder drying, coiling, recoiling and splitting on the material of the raw pulp, so as to obtain the pretreated raw paper; after the inclined net forming procedure is performed, impregnating the formed paper, and applying latex; coating anti-solvent latex to the front side and back side of the pretreated raw paper, drying, coiling, recoiling and splitting, so as to obtain the raw paper of the abrasive paper. The raw paper has the advantages that the water-resistant property is good, the solvent-resistant property is good, the high temperature-resistant property is realized, the abrasion-resistant property is good, and the tension property is good.

Owner:台州市玫瑰纸业有限公司

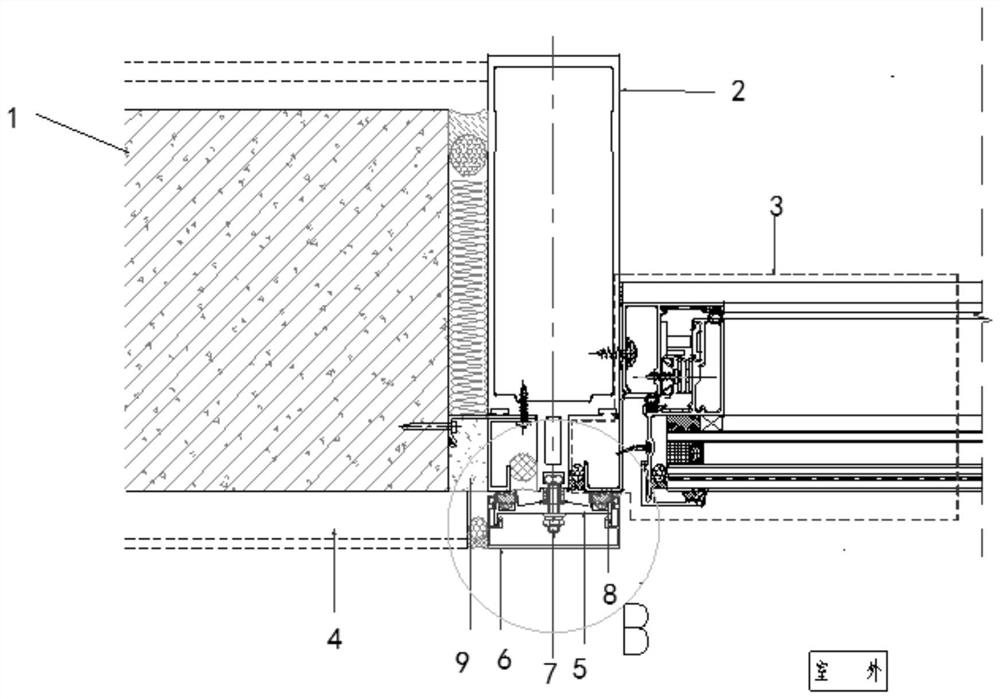

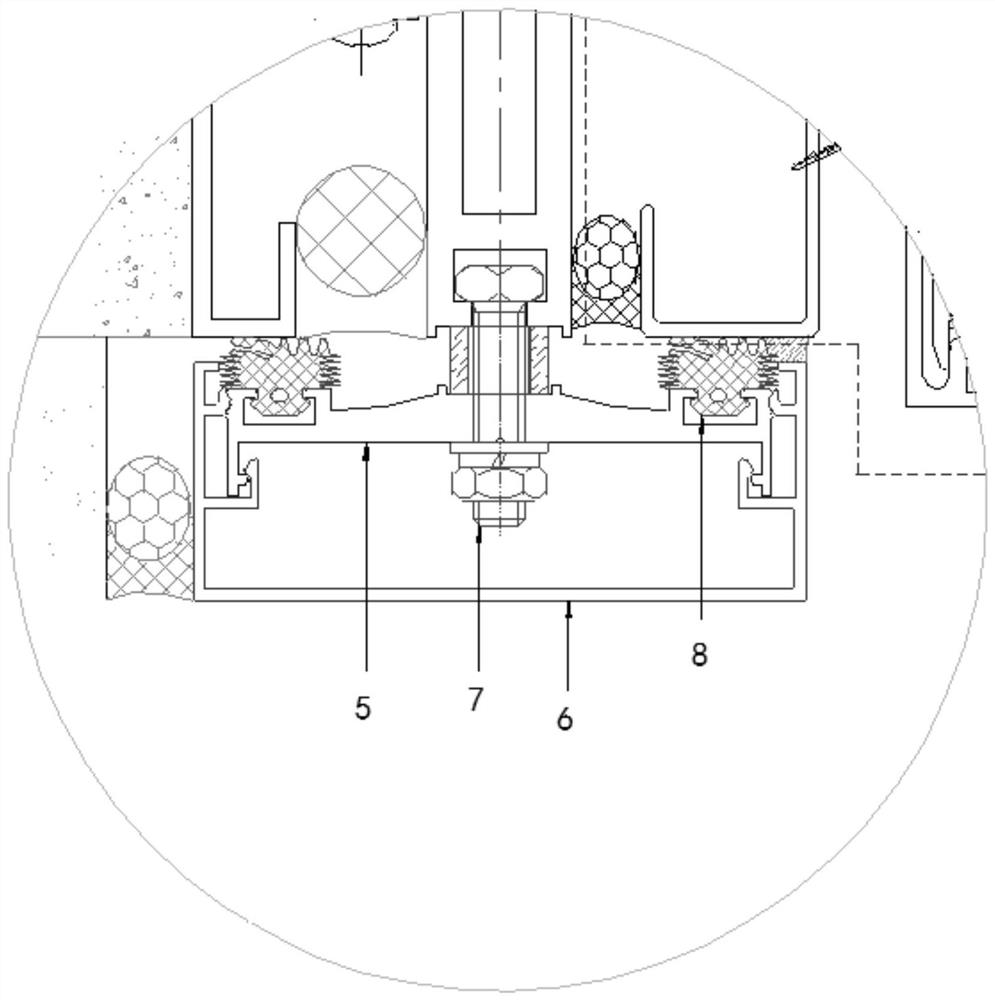

Glass curtain wall frame node and installation method thereof

ActiveCN114277983ARealize in and out position adjustmentGuaranteed evennessWallsClimate change adaptationEngineeringMechanical engineering

According to the glass curtain wall frame node and the installation method thereof, the telescopic sealing rubber strip is arranged behind the aluminum alloy pressing plate of the glass curtain wall frame, in-out position adjustment of the aluminum alloy pressing plate is achieved, and therefore adjustment of the position of an aluminum alloy decorative buckle cover of the glass curtain wall frame in the in-out position direction is achieved; and the effect that the finished surface of the glass curtain wall frame aluminum alloy decorative buckle cover is flush with the finished surface of the outer wall coating is ensured. The invention is suitable for the engineering condition that the outer side of the glass curtain wall frame is the exterior wall coating. The glass curtain wall frame node is adopted, the size of the in-out direction of an aluminum alloy decorative buckle cover of a glass curtain wall frame can be adjusted according to the site condition through matched adjustment of an aluminum alloy pressing plate and a telescopic sealing rubber strip, and extra work needed for ensuring that the aluminum alloy decorative buckle cover and an outer wall are located on the same plane after completion is avoided; project cost is saved, and on-site working efficiency is improved.

Owner:SHANGHAI NO 4 CONSTR

Anti-damage low-temperature-resistant cable material

InactiveCN110684304ADamage-resistantWear-resistantPlastic/resin/waxes insulatorsGlass fiberPlasticizer

The invention discloses an anti-damage low-temperature-resistant cable material, which is prepared from the following raw materials by weight: 90-110 parts of a PVC resin, 0.1-0.3 part of nanometer aluminum oxide, 15-20 parts of glass fiber, 0.5-1 part of stearic acid, 2-6 parts of white carbon black, 2-3 parts of a plasticizer, 10-12 parts of a compatilizer and 3-4 parts of a stabilizer. According to the invention, the PVC resin is used as the base material, the proper functional raw material addition ingredients are added, and in the processing process, the proper compounding is generated through cross-linking and filling effects, so that the advantages can be made up, the whole material has excellent properties of damage resistance, wear resistance, oil resistance, low temperature resistance, high tensile strength, tear resistance and the like; and the preparation process is simple, can be adjusted on existing processing equipment, is easy to operate, and can meet the requirements of large-scale production of factories.

Owner:安徽中青欣意铝合金电缆有限公司

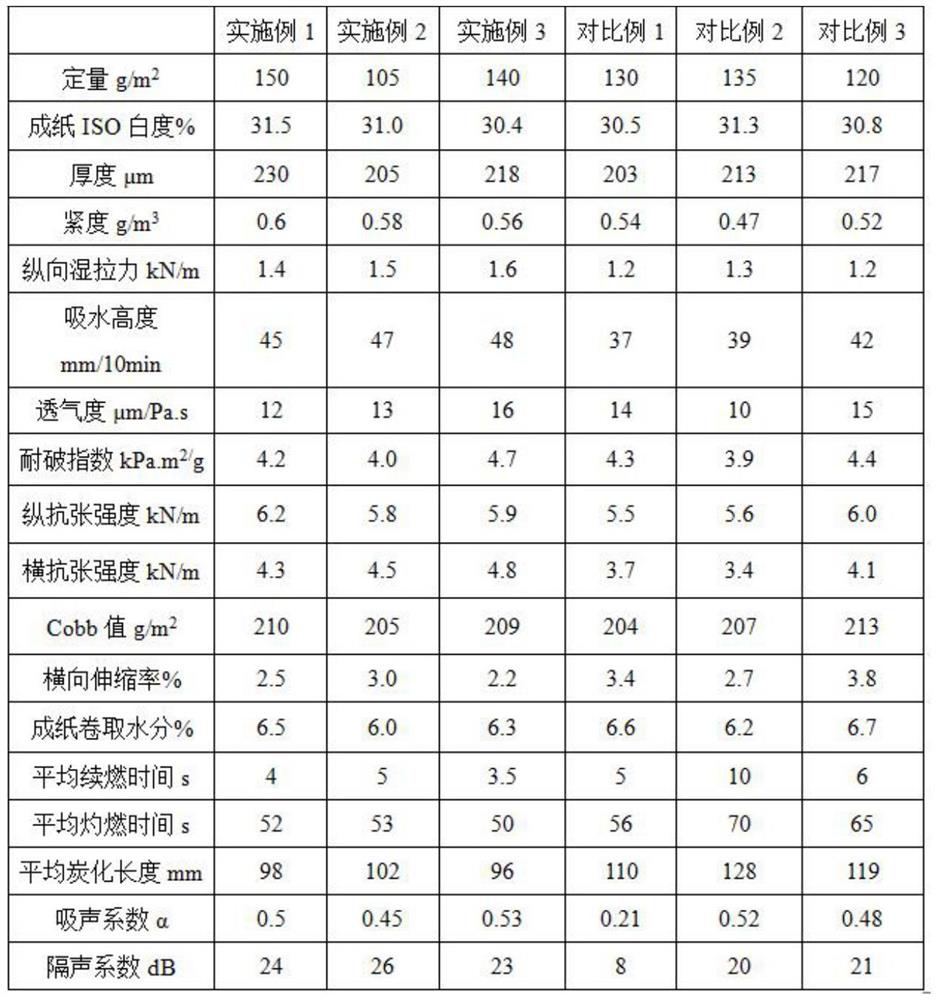

Manufacturing method of fireproof board core paper

InactiveCN111962332AImprove uniformityQuantitatively stableDefoamers additionSpecial paperFiberPapermaking

The invention discloses a manufacturing method of a fireproof board core paper. The invention belongs to the technical field of papermaking, needle-leaved wood, broad-leaved wood and camphorwood are used as fiber raw materials, the preparation method comprises the following steps: cooking, extracting, performing oxygen delignification, performing hydrogen peroxide micro-bleaching, washing, pulping, preparing pulp, slushing, screening and purifying, sizing, dehydrating and forming a net part, squeezing, performing pre-drying, performing surface sizing, performing post-drying, coiling, rewindingand packaging, wherein the ratio of the needle-leaved wood to the broad-leaved wood to the camphorwood is (4.5-5): (3-4): 1. The fireproof board core paper manufactured through the method is good inuniformity, stable in quantification, consistent in tightness, smooth in paper surface, good in laminating performance, free of impurities on the appearance of the paper surface and free of lint on the end face, and the flame retardant property and the sound insulation property of the core paper are improved simultaneously.

Owner:YUEYANG FOREST & PAPER CO LTD

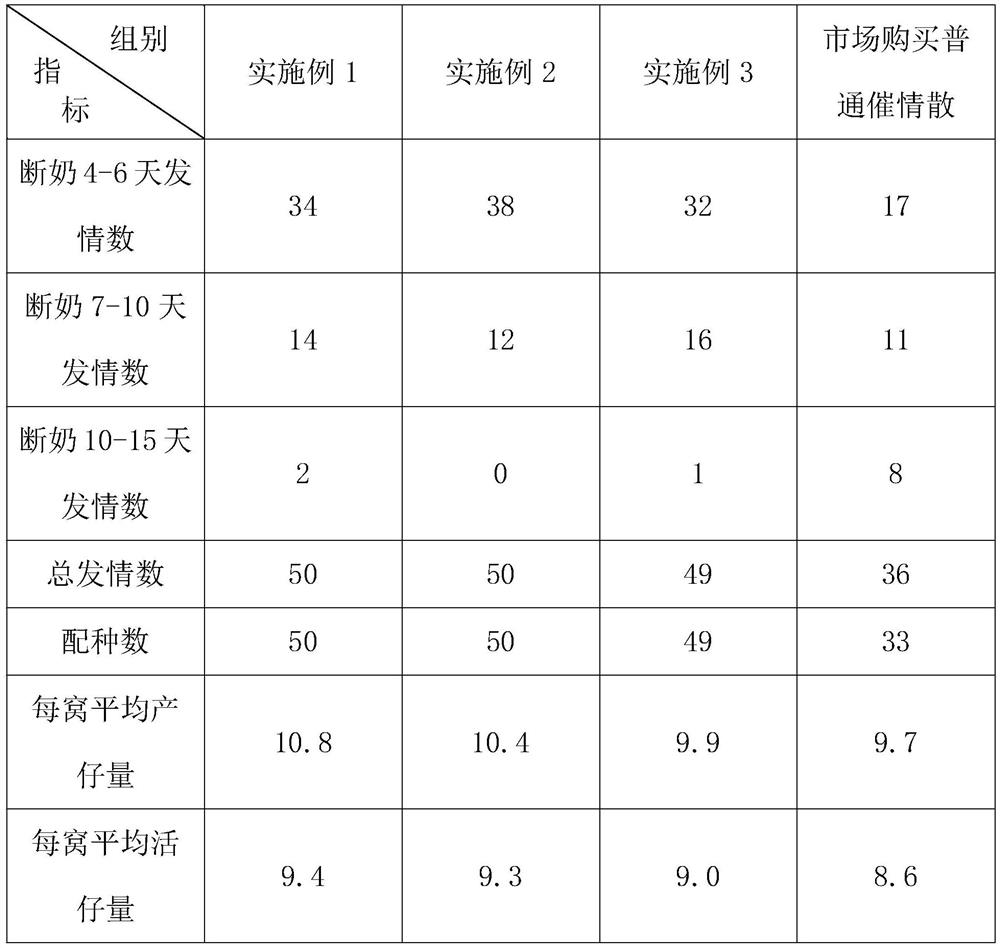

A kind of mother animal aphrodisiac powder superfine powder and preparation method thereof

ActiveCN109394967BGood secretion effectCure waist and knee painHeavy metal active ingredientsPowder deliveryBiotechnologyAnimal science

The invention discloses a mother animal aphrodisiac powder superfine powder and a preparation method thereof. The preparation raw materials include epimedium, actinolite (wine quenching), angelica, Cyperus cyperi, motherwort, cornus, ryepogon, and pearl ginseng , Polygonatum. The invention has the advantages that it can effectively solve the problems of low estrus rate, long-term infertility, low litter rate and high abortion probability of female animals; meanwhile, it can also promote the growth and development of female animals. Adopting a specific preparation method can effectively remove impurities in each raw material without causing secondary pollution to the raw materials; ensure the quality and uniformity of the coarse powder; it is easier to exert the drug effect and be absorbed; it is convenient for the later preparation of aphrodisiac powder Preservation and use; it is more convenient whether it is mixed into feed or mixed into drinking water during later administration, and effectively reduces the sensitivity of female animals to drugs.

Owner:合肥中龙神力动物药业有限公司

Method for dewatering double sides of asbestos-free papermaking plate

ActiveCN102828433AImprove water filtration performanceDehydration fastMachine wet endPapermakingPolyacrylamide

The invention discloses a method for dewatering double sides of an asbestos-free papermaking plate. The method includes the steps of (1) adding polyacrylamide (PAM) and bentonite into slurry after the slurry leaves a pressurized screen; (2) subjecting the slurry flowing into a slurry box to slurry distribution and rectification; (3) the slurry flows onto a papermaking screen with two sides sealed at a slurry outlet of the slurry box to form two an upper layer and a lower layer, wherein the lower layer is a slurry layer and the upper layer is a water layer, in the flowing process of the slurry, the water layer enters a slurry and water separation box suspended above the papermaking screen and is absorbed and discharged by vacuum water suction tubes in the slurry and water separation box, and the slurry layer penetrates the bottom of the slurry and water separation box and is dewatered by water scraping plates arranged at the bottom of the papermaking screen. By the aid of the method, double sides of the slurry can be dewatered on a screen portion of a paper making machine, the problem about dewatering difficulty of the slurry on the screen portion of the papermaking machine is solved, and continuous production of the asbestos-free papermaking plate is realized.

Owner:南阳国宇实业有限公司

Integrated intelligent terminal with space disinfection, hand disinfection and temperature measurement functions

ActiveCN113040727ARealize orientation adjustmentMeet the needs of different orientationsLavatory sanitoryMedical applicatorsHand partsLiquid storage tank

The invention discloses an integrated intelligent terminal with space disinfection, hand disinfection and temperature measurement functions. The integrated intelligent terminal comprises a box body, an ozone generator, a motor and a liquid storage tank. When the temperature of a person needs to be measured, the person only needs to face a temperature measurement all-in-one machine, so that the body temperature of the person can be rapidly measured, and the measurement is rapid and convenient; when the hands of the person need to be disinfected, a disinfectant in the liquid storage tank enters a liquid storage box through a liquid guide hose by utilizing a water pump and is sprayed out through a spray head, and therefore, spray disinfection of the hands of the person is realized; and when the space needs to be disinfected, ozone is generated by utilizing the ozone generator, the ozone further passes through a first gas guide tube, then enters a second gas guide tube and further enters a gas guide box, the ozone in the gas guide box passes through a third gas guide tube and is sprayed out through the spray head, so that disinfection of indoor space and other spaces is achieved, a fan is used for blowing, the speed of the ozone diffusing into the air is increased, and the space disinfection efficiency and effect are improved.

Owner:NINGXIA YOUAN MEDICAL INSTR CO LTD

Disc bale plucker having bale plucking beater with multi-gear adjustable reduction speed

PendingCN112127018ANot easy to tangleAvoid the phenomenon of pinching the cotton and thugsFibre breaking by beater armsCircular discElectric machinery

The invention relates to a disc bale plucker having a bale plucking beater with multi-gear adjustable reduction speed. A cotton discharging hopper is provided with a first transmission motor, a secondtransmission motor is arranged at the left end of a cross arm, and a third transmission motor is arranged at the right end of the cross arm; a main control machine box is arranged on one side of theouter disc; the first transmission motor, the second transmission motor and the third transmission motor respectively communicate with the main control machine box; a discharging pipe is provided witha pressure controller, and the pressure controller is connected with the main control machine box; the pressure controller is arranged at the inlet end of the discharging pipe; the two ends of the bale plucking beater penetrate through flange plates respectively, and the flange plates are fixed to the bale plucking beater through screws; and a positioning rod is arranged at the bent part of the cross arm and the discharging pipe. The disc bale plucker is simple in structure, can be manufactured by slightly modifying existing equipment, is low in cost and efficient and stable in operation, andis suitable for large-scale popularization and application.

Owner:ANHUI HUAMAO TEXTILE

Method for reproducing paper pulp used for filter stick core paper by utilizing filter stick waste

ActiveCN102704300BIncrease profitImprove overall utilizationWashing/displacing pulp-treating liquorsContinuous pulping processFiberWaste material

The invention discloses a method for reproducing paper pulp used for filter stick core paper by utilizing filter stick waste, which includes procedures of material treatment, impregnation, defibrination, washing and concentration. Impurities in the filter stick waste are eliminated, and the filter stick waste is cut off into particles of 1-150 mm; the particles are impregnated by 4-10 times of water for 5-30 minutes under 70-100 degree C; inorganic base with weight being 0.5%-6% of dry weight of the particles is added into the impregnation liquid, so that the chemical concentration of the impregnation liquid is 0.25g-3g / L; the pulp liquid is concentrated to 10%-30%, and then pan-grinding defibrination is performed; and finally, the pulp liquid is washed and concentrated to 20-30%, so that the paper pulp used for wet process papermaking cigarette filter stick filter material can be obtained. The method disclosed by the invention has low treatment requirement for the impurities in the raw material, dispenses with molding paper stripping procedure, uses no toxic solvent, has high paper pulp yield, is excellent in fiber evenness, has centralized length distribution and uniform pulp, has no paper fragments and fiber beams, has excellent dispersion property, and is very suitable for making the filter stick core paper.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

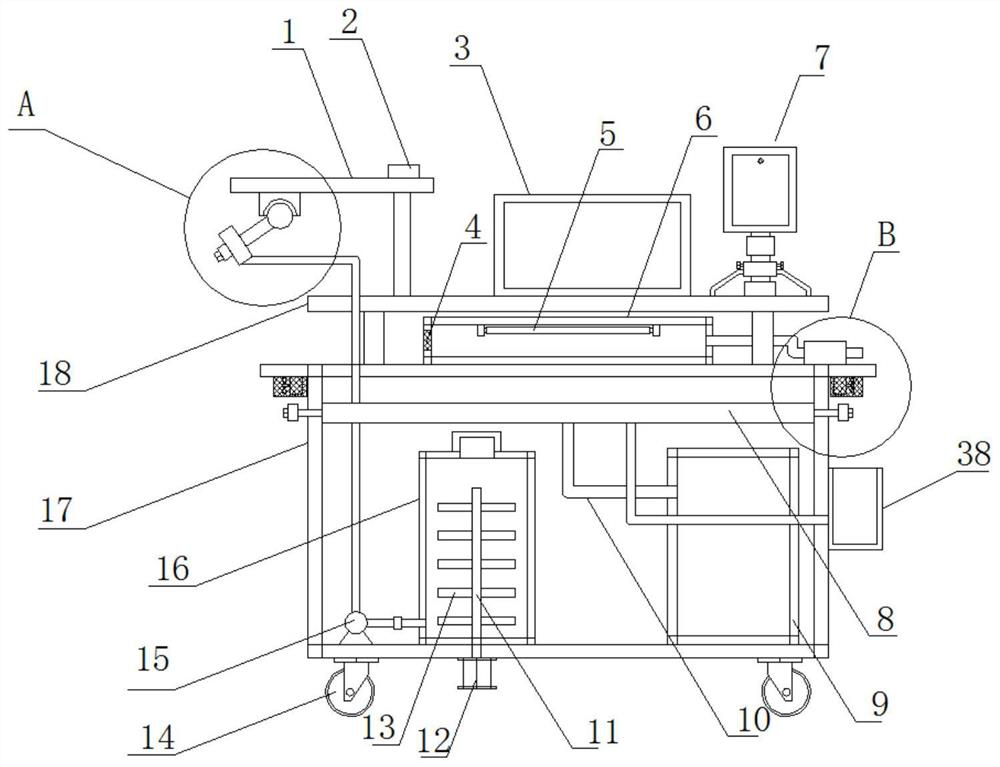

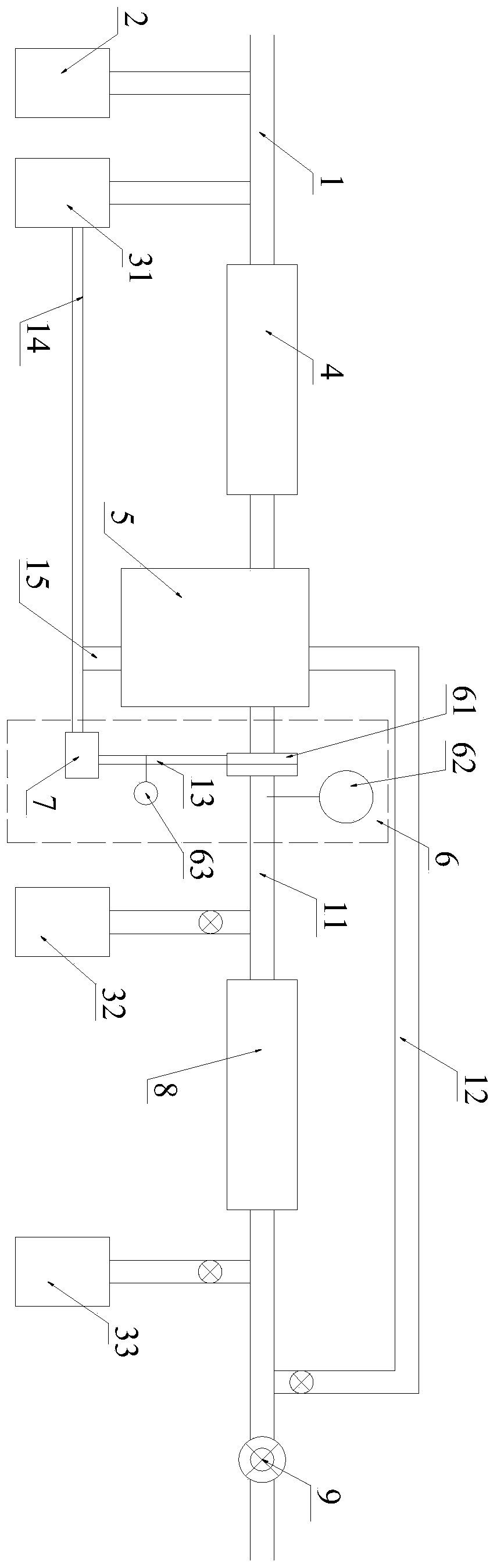

Papermaking filler pretreatment device and treatment method

ActiveCN110105790AImprove the wrapping effectIncrease contact areaPaper/cardboardMaterial mixture additionPapermakingEngineering

Belonging to the technical field of papermaking, the invention in particular relates to a papermaking filler pretreatment device and a treatment method. The device includes a first static mixer, a reactor and a second static mixer that are communicated in order by a charge pipe, the outlet of the reactor is equipped with a filler classification apparatus, which consists of a multi-stage vibrationscreen, a particle size detection apparatus and an ash content determinator. The treatment method adopting the device includes: filler dilution, filler coating, small particle size filler re-coating,pretreated filler pump-out, filler particle size correction and oversized filler recycling. The device has a simple structure and is convenient to use, the filler particles are fully coated with a flocculant, and the filler particle size is effectively adjusted. The filler treated by the device provided by the invention has good particle fineness and uniformity, thus enhancing the combination strength of the flocculant and particles, improving the retention rate of the papermaking filler on paper stock, increasing the ash content of base paper and lowering the production cost.

Owner:苏州赛维科环保技术服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com