Straw fiber dividing machine

A technology of straw fiber and splitting machine, which is applied in fiber raw materials, fiber raw material processing, raw material separation, etc. It can solve the problems of unqualified fiber grinding, unreasonable power matching, manual feeding, etc., to ensure accuracy and uniformity , high degree of automation, and the effect of improving softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

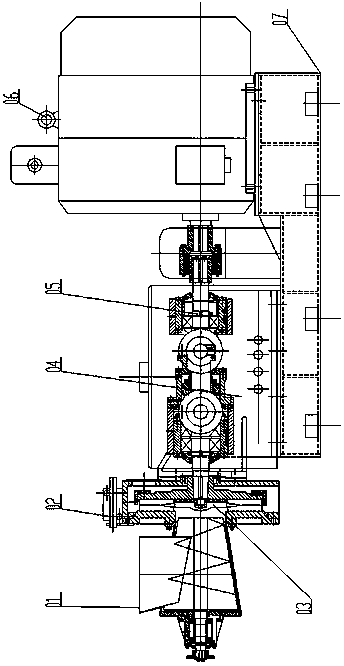

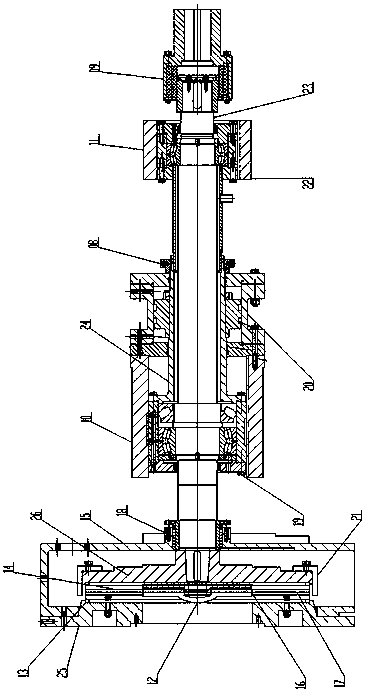

[0040] The invention provides a straw fiber splitting machine, such as figure 1 with 2 As shown, the straw fiber splitting machine is composed of a forced screw feeding device 01, a grinding disc decomposition area, a sliding bearing device, a hydraulic device 20, a thin oil lubrication device, a manual fine-tuning device 08, a telescopic coupling 09, and a main motor 06 , base 07, electric control system and other components.

[0041] In the present invention, the forced screw feeding device 01 is driven by a separate reduction motor, which is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com