Method for dewatering double sides of asbestos-free papermaking plate

A technology of latex copy board and double-sided dehydration, which is applied in textiles and papermaking, papermaking, paper machine wet end, etc., can solve problems such as difficulty in dehydration, achieve high water filtration performance and ensure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

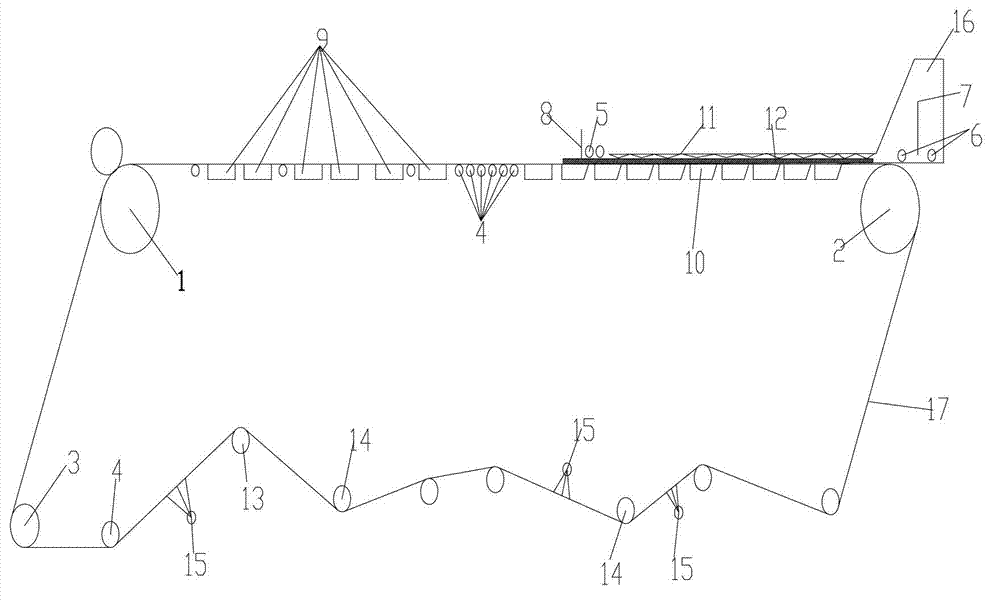

[0021] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

[0022] refer to figure 1 , the double-sided dehydration method of a kind of non-asbestos latex sheet of the present invention, at first put non-asbestos fiber into water to disperse, after adding filler and beating, add coloring agent, latex, vulcanizing agent, anti-aging agent according to formula requirement, mix uniform; then send the uniformly mixed slurry into the paper machine wire flow delivery system, and the slurry passes through the pulp pump and pressure screen;

[0023] The method also includes the steps of:

[0024] 1) After the slurry leaves the pressure screen, add polyacrylamide (PAM) and bentonite to the slurry; the amount of polyacrylamide added is 0.05% of the mass of asbestos-free fiber, and the amount of bentonite added is asbestos-free 0.25% of fiber mass;

[0025] 2) The slurry enters the headbox for slurry distribution and rec...

specific Embodiment 2

[0032] The characteristics of this embodiment are: in step 1), the addition amount of the polyacrylamide is 0.04% of the mass of the asbestos-free fiber, and the addition amount of the bentonite is 0.2% of the mass of the asbestos-free fiber; other and specific examples 1 is the same.

specific Embodiment 3

[0033] The characteristics of this embodiment are: in step 1), the addition amount of the polyacrylamide is 0.06% of the mass of the asbestos-free fiber, and the addition amount of the bentonite is 0.3% of the mass of the asbestos-free fiber; other and specific examples 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com