Use of N-(2-hydroxy-3-trimethyl) propyl ammonium chloride chitosan and nano silicon dioxide

A technology of nano-silica and propylammonium chloride, which is applied in textiles and papermaking, inorganic compound addition, papermaking, etc., can solve the problems of heavy environmental load, poor paper evenness, and difficult degradation, and reduce the The concentration of white water, the reduction of sewage pollution, and the effect of small amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

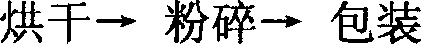

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: Adding relative dry pulp 20% CaCO in beating degree is 38 ° SR, concentration is the reed slurry of 0.1wt% 3 (average particle size: 2.69μm, specific surface area: 41684cm 2 / g) solid powder, the molecular weight is 19×10 after stirring 4 , degree of substitution is 93%, concentration of 0.1wt% N-(2-hydroxyl 3-trimethyl) propyl ammonium chloride chitosan aqueous solution, N-(2-hydroxyl-3-trimethyl) propyl chloride The add-on of ammonium chitosan aqueous solution is 0.32wt% relative to the dry pulp in terms of N-(2-hydroxyl-3-trimethyl) propyl ammonium chloride chitosan; stir for 10 seconds, then add concentration 0.04 wt% SiO2 (specific surface area is 350--450m 2 / g, average particle size 14nm) colloidal solution (addition amount is 0.07 mg silica / per gram dry pulp), CaCO 3 The retention rate is 85%. The retention rate of fine fibers and soluble colloidal carbohydrates is 37%.

Embodiment 2

[0016] Embodiment 2: molecular weight is 7 * 10 4 , a degree of substitution of 53%, a concentration of 0.02wt% N-(2 hydroxyl 3-trimethyl) propylammonium chloride chitosan aqueous solution, adding to the degree of beating 38-42 ° SR, a concentration of 0.5wt% In the reed slurry, stir for about 10 seconds, then add a concentration of 0.01wt% silicon dioxide (specific surface area is 350--450m 2 / g, average particle size 25nm) colloidal solution, in N-(2 hydroxyl 3-trimethyl) propyl ammonium chloride chitosan dosage is 2.5mg / g absolute dry pulp, silicon dioxide is 0.14mg / g absolute When the pulp is dry, its drainage performance is improved by 20-26%.

Embodiment 3

[0017] Embodiment 3: the molecular weight is 10 * 10 4 , the N-(2 hydroxyl 3-trimethyl) propyl ammonium chloride chitosan that substitution degree is 60% is mixed with 0.2wt% solution, joins beating degree and is 38-42 ° SR, pH is 7-8, Concentration is in the reed slurry of 0.3wt%, stir about 10 seconds, then add concentration and be 0.4wt% silicon dioxide (specific surface area is 350--450m 2 / g, average particle size 13-27nm) colloidal solution, when N-(2 hydroxyl 3-trimethyl) propyl ammonium chloride chitosan consumption is 3.2mg / g dry pulp, silicon dioxide consumption is 0.14mg / g dry pulp, the drainage performance of the pulp is increased by 22-25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com