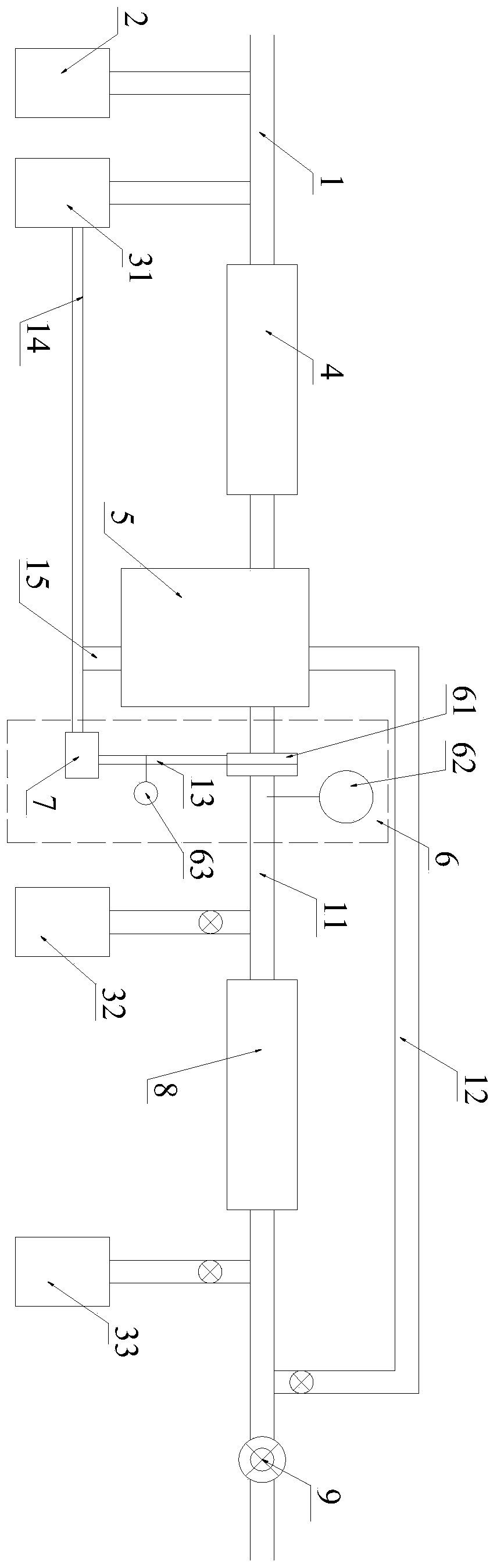

Papermaking filler pretreatment device and treatment method

A pretreatment device and paper-making filler technology, which is applied in the field of papermaking, can solve the problems of reducing paper strength performance, poor paper evenness, weak bonding, etc., and achieve the effect of improving uniformity, tensile strength, and contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

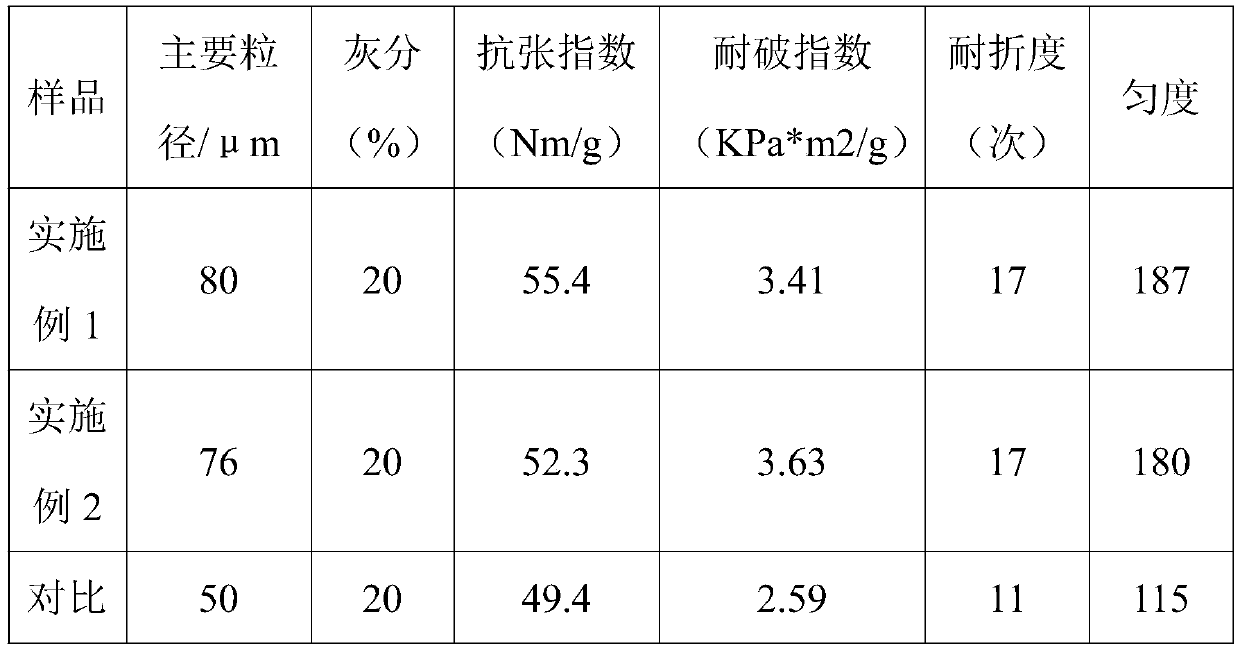

Embodiment 1

[0028] Embodiment 1: papermaking filler pretreatment method, adopts the processing method described in above-mentioned equipment to comprise the following steps:

[0029] Step a, the filler is diluted, light calcium carbonate is filled in the first static mixer 4, water is pumped into the first static mixer 4 from the water tank 2, pre-diluted in the first static mixer 4, and passed through the first The static mixer 4 is delivered to the reactor 5, fully diluted in the reactor, and the dilution concentration of the filler is 30%;

[0030]Step b, filler coating, the chelating titanate coupling agent is pumped into the first static mixer 4 from the first drug box 31 and enters the reactor 5, and the light calcium carbonate and chelating titanium The ester coupling agent is fully mixed, and the light calcium carbonate is coated by the chelating titanate coupling agent. The amount of the chelating titanate coupling agent is 0.2% of the mass of the filler. Shear reaction for 3 mi...

Embodiment 2

[0035] Embodiment 2: papermaking filler pretreatment method, adopt the processing method described in above-mentioned equipment to comprise the following steps:

[0036] Step a, the filler is diluted, titanium dioxide is filled in the first static mixer 4, water is pumped into the first static mixer 4 from the water tank 2, pre-diluted in the first static mixer 4, and passed through the first static mixer 4 is transported to the reactor 5, fully diluted in the reactor, and the dilution concentration of the filler is 25%;

[0037] Step b, filler coating, the chelating titanate coupling agent is pumped into the first static mixer 4 from the first medicine box 31 and enters the reactor 5, and the titanium dioxide is coupled with the chelating titanate The coupling agent is fully mixed, and the titanium dioxide is coated with a chelating titanate coupling agent. The amount of the chelating titanate coupling agent is 0.25% of the mass of the filler, and the shear reaction is perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com