Production method of dialysis base paper

A production method and technology for base paper, applied in the field of papermaking, can solve the problems of less than 30% of the overall utilization rate, unsatisfactory popularity of dialysis sterilization packaging, etc., and achieve the advantages of improving surface film-forming performance, reducing dosage and reducing pulp cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

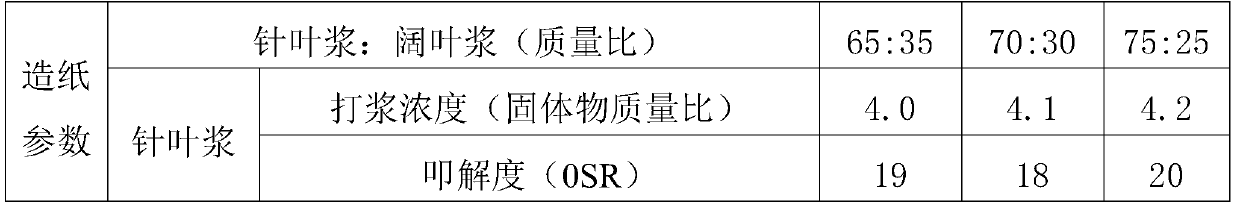

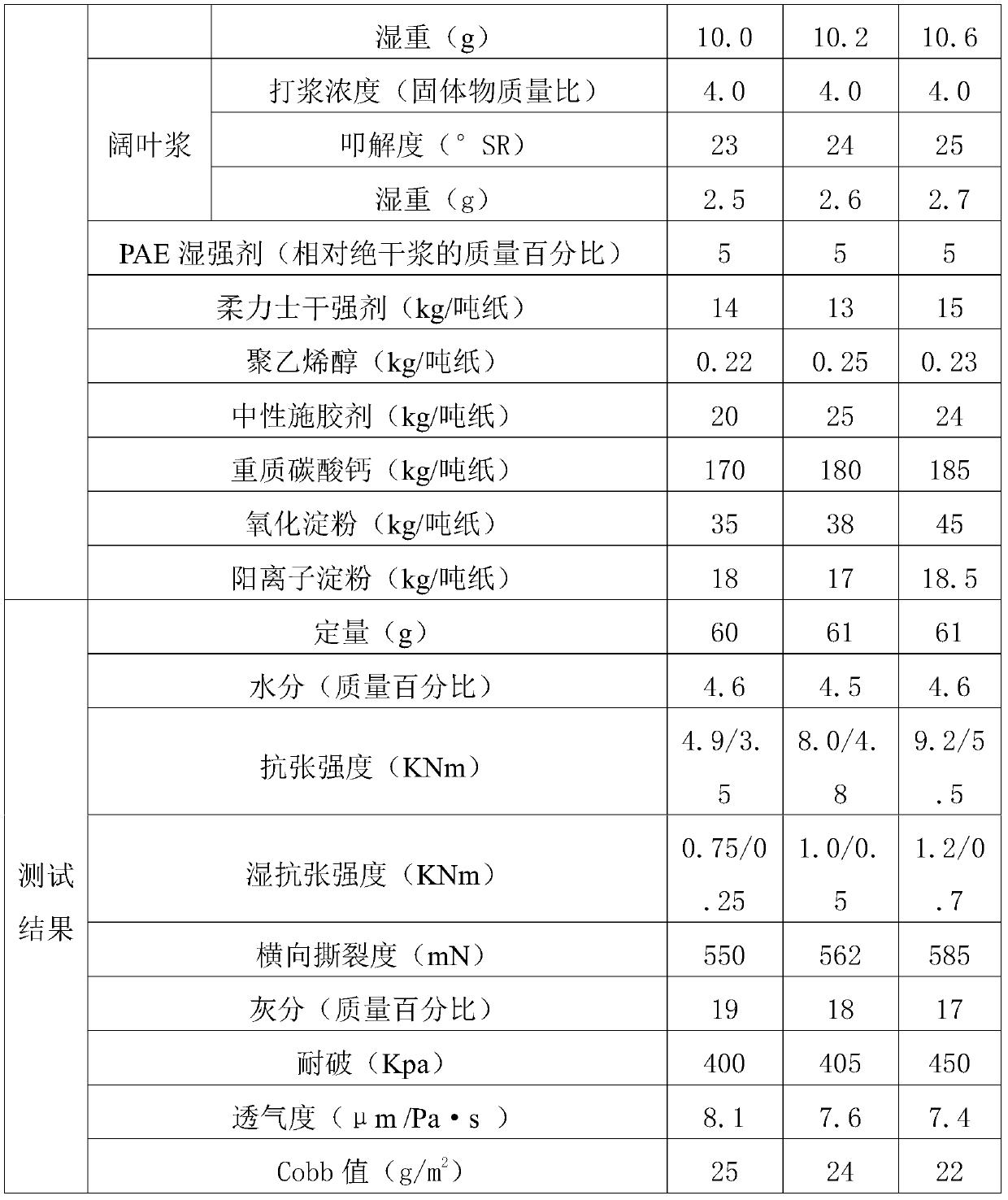

[0028] In order to clearly illustrate the technical features of the present solution, the present invention will be described in detail below through specific embodiments.

[0029] We use three different papermaking parameters for production, and then test physical indicators such as moisture, tensile strength, wet tensile strength, ash content, burst resistance, and Cobb value.

[0030] The specific form is as follows:

[0031]

[0032]

[0033] The test results fully meet the standards.

[0034] The above-mentioned embodiment is a preferred embodiment of the present invention, but the embodiment of the present invention is not limited by the above-mentioned embodiment, and any other changes, modifications, substitutions, combinations, Simplifications should be equivalent replacement methods, and all are included in the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com