Method for producing highly quantitative two-side offset paper

A production method and technology of double-adhesive paper, applied in the field of papermaking, can solve the problems of high cost of three-layer net paper machine, large difference between the two sides of the paper, poor paper evenness, etc., so as to improve the ration of the Internet, reduce the difference between the two sides, and improve the retention of fillers. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

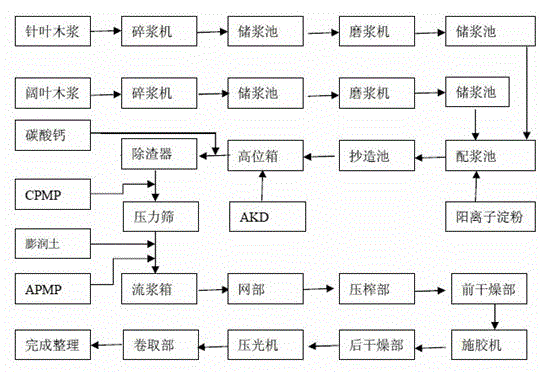

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: The production method of paper-making quantitative 230gsm, high quantitative offset paper is produced using a single-layer fourdrinier multi-cylinder paper machine with a top wire former, and the production process is beating, pulping, sizing, papermaking, drying, Surface sizing, calendering, coiling, and finally finishing into paper. High-quantitative double-adhesive paper uses bleached sulfate needles and hardwood pulp as the main raw materials, cationic starch, AKD (alkyl ketene dimer), calcium carbonate, CPAM (cation retention agent), bentonite, APMP (anion accelerator ) are auxiliary raw materials. The specific process parameters are as follows:

[0017] 1. Pulp ratio: 15% for bleached kraft softwood pulp, 85% for bleached kraft hardwood pulp;

[0018] 2. Beating degree: bleached kraft softwood pulp 32 0 SR, Bleached Kraft Hardwood Pulp 27 0 SR

[0019] 3. Auxiliary raw materials: cationic starch dosage 2.5%, AKD (alkyl ketene dimer) dosage 0.20%...

Embodiment 2

[0025] Embodiment 2: The production method of paper-making quantitative 300gsm, high quantitative double offset paper is produced using a single-layer fourdrinier multi-cylinder paper machine with a top wire former, and the production process is beating, pulping, sizing, papermaking, drying, Surface sizing, calendering, coiling, and finally finishing into paper. High-quantitative double-adhesive paper uses bleached sulfate needles and hardwood pulp as the main raw materials, cationic starch, AKD (alkyl ketene dimer), calcium carbonate, CPAM (cation retention agent), bentonite, APMP (anion accelerator ) are auxiliary raw materials. The specific process parameters are as follows:

[0026] 1. Pulp ratio: 11% for bleached kraft softwood pulp, 89% for bleached kraft hardwood pulp;

[0027] 2. Beating degree: bleached kraft softwood pulp 32 0 SR, Bleached Kraft Hardwood Pulp 26 0 SR

[0028] 3. Auxiliary raw materials: cationic starch dosage 2.9%, AKD (alkyl ketene dimer) dosag...

Embodiment 3

[0034] Embodiment 3: The production method of paper-making quantitative 350gsm, high quantitative offset paper is produced using a single-layer fourdrinier multi-cylinder paper machine with a top wire former, and the production process is beating, pulping, sizing, papermaking, drying, Surface sizing, calendering, coiling, and finally finishing into paper. High-quantitative double-adhesive paper uses bleached sulfate needles and hardwood pulp as the main raw materials, cationic starch, AKD (alkyl ketene dimer), calcium carbonate, CPAM (cation retention agent), bentonite, APMP (anion accelerator ) are auxiliary raw materials. The specific process parameters are as follows:

[0035] 1. Pulp ratio: 9% for bleached kraft softwood pulp, 91% for bleached kraft hardwood pulp;

[0036] 2. Beating degree: bleached kraft softwood pulp 33 0 SR, Bleached Kraft Hardwood Pulp 25 0 SR

[0037] 3. Auxiliary raw materials: cationic starch dosage 2.6%, AKD (alkyl ketene dimer) dosage 0.2% / d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com