Fast faucet mounting mechanism

A faucet and mounting seat technology, applied in water supply installations, indoor sanitary piping installations, buildings, etc., can solve the problems of difficult implementation, narrow space under the countertop, time-consuming and labor-intensive nut locking, etc., and achieves time-saving and labor-saving operation and quick installation. , the effect of stable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

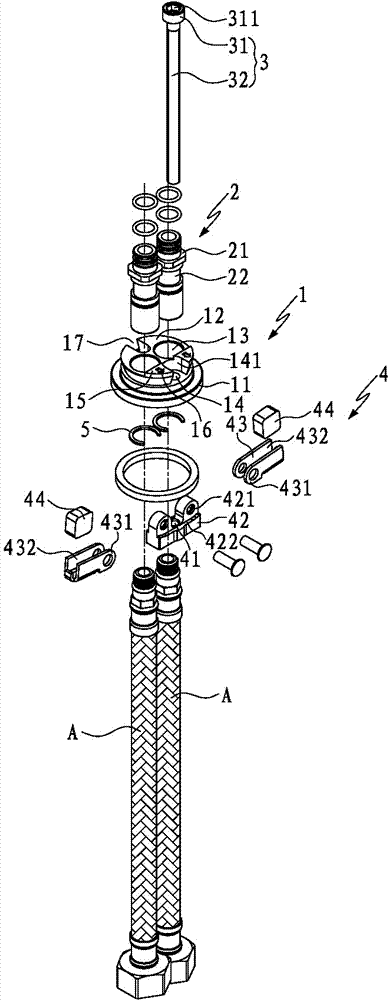

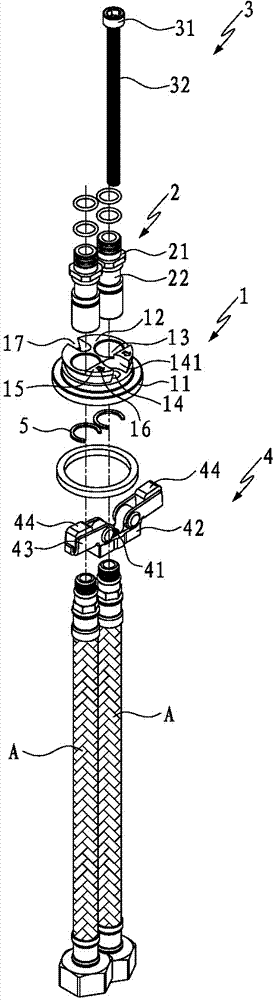

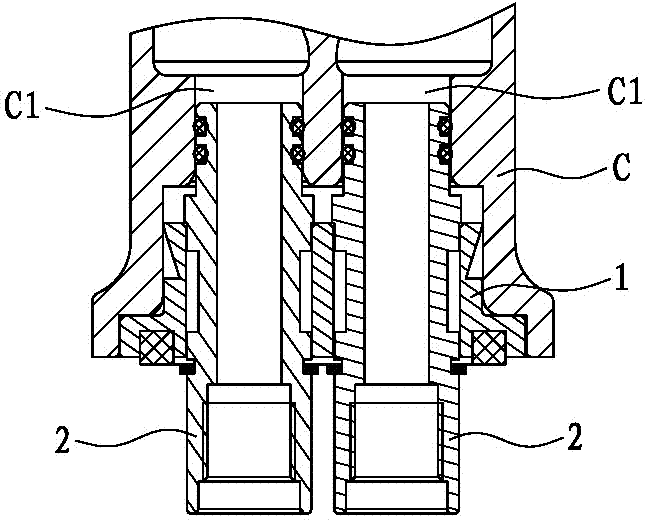

[0028] Such as Figure 1 to Figure 10 As shown, the present invention discloses a faucet quick-installation mechanism, which combines the water supply pipe A connected to the water supply port to fix the faucet on the water basin and the washbasin, or on the table B of the water basin and the wash basin; The mechanism includes a mounting base 1 placed on the table B and matched with the faucet body C, fixed on the mounting base 1 and passing through the mounting base 1 to connect the water supply pipe A below the mounting base 1 and the valve of the faucet body C above the mounting base 1 The water inlet joint 2 of the core water inlet C1, a bolt rod 3 that fits on the mounting base 1 and a lock block 4 that is movably fitted on the bolt rod 3 and is located below the installation 1; the lock block 4 includes a screw hole 41 The pressing seat 42 and the rotating gasket 43 pivotally connected to the pressing seat 42 for one-way movement, the length of the superimposed pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com