Automatic liquid medicine mixing method

A technology for automatic liquid dispensing and medicine, applied in mixing methods, chemical instruments and methods, mixer accessories, etc., can solve problems such as inability to quickly and easily check the remaining amount of chemical reagents, lack of construction standards and operation modes, and affecting the progress of experimental research, etc. Achieve the effect of realizing automation and unmanned, shortening production cycle and improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

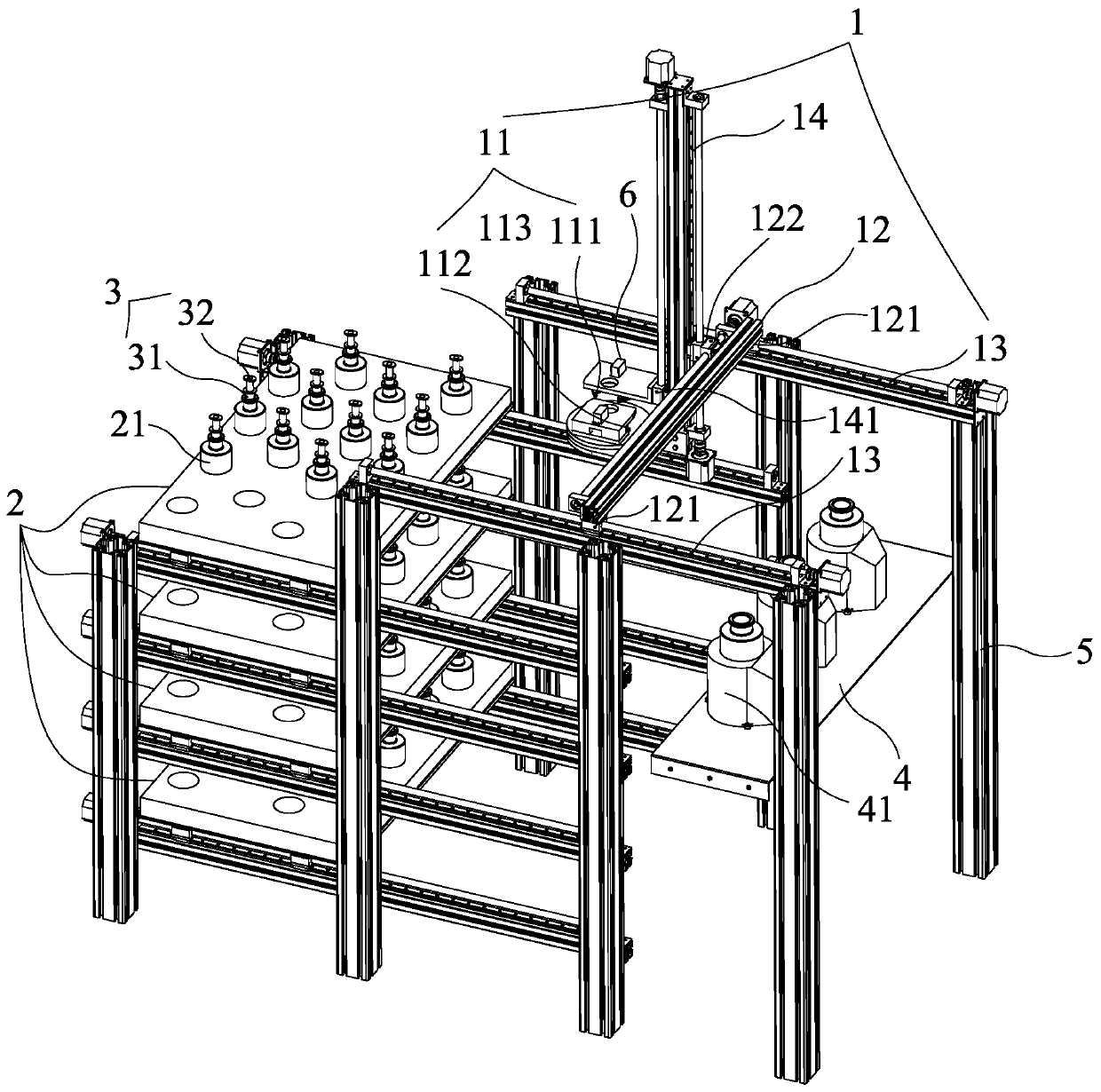

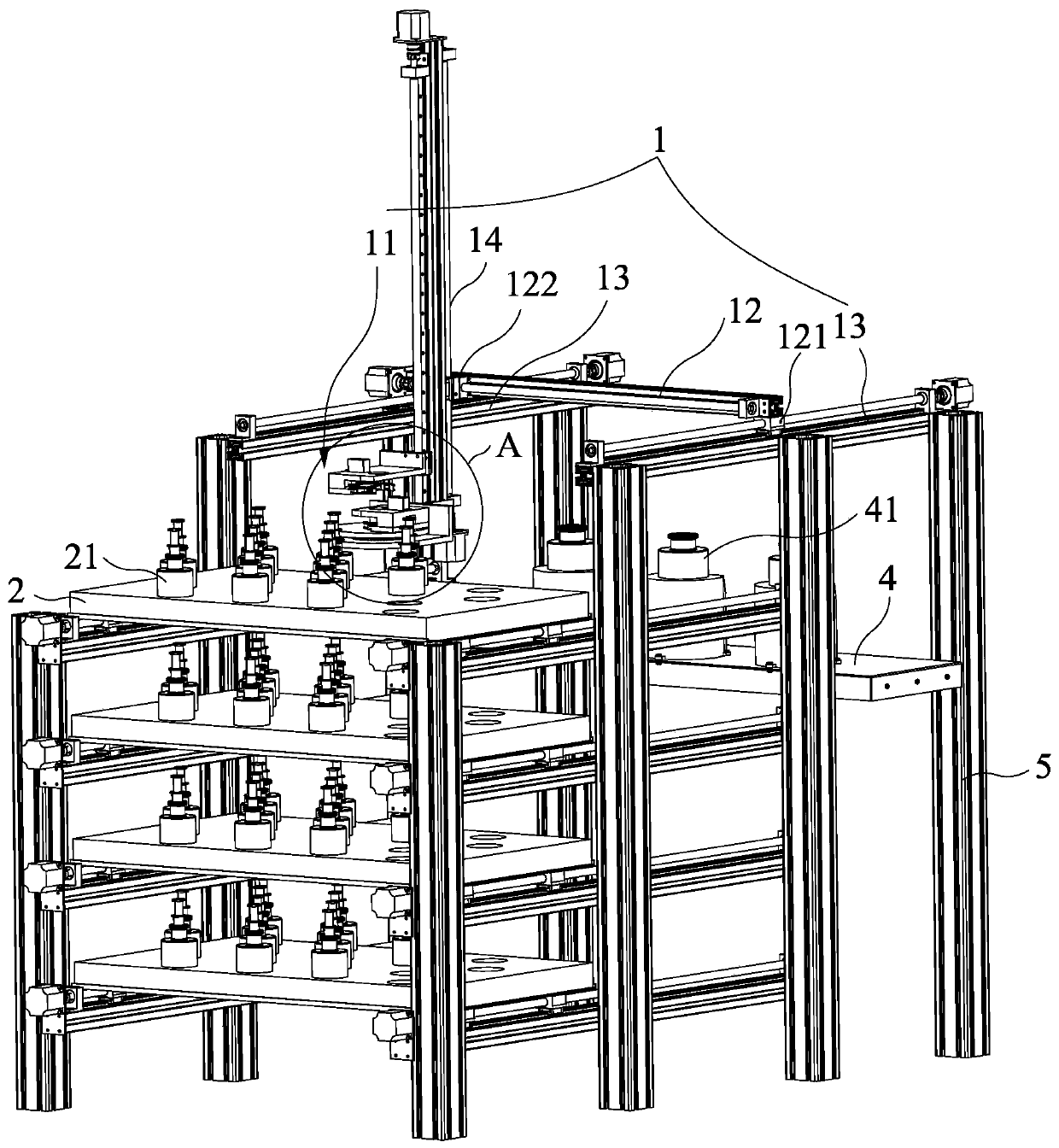

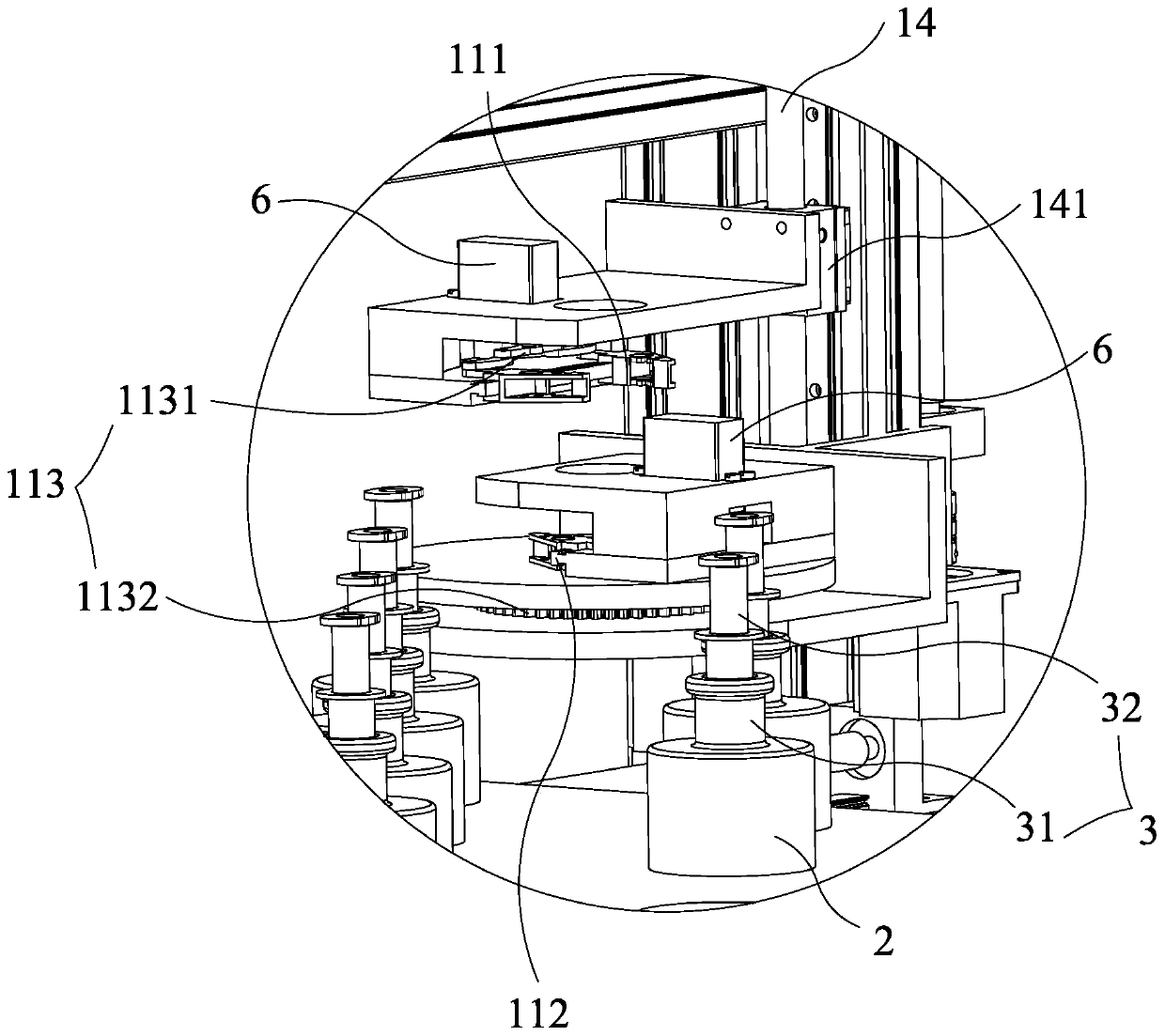

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] see Figure 1 to Figure 8 , a liquid medicine dispensing device related to the present invention, comprising a PLC controller (not shown in the figure), a three-dimensional motion machine 1 provided with mechanical claws 11, a mother liquor workbench 2 storing several mother liquor bottles 21, and a syringe 3 1. The metering workbench 4 and the frame 5 storing the sample cup 41; the weight sensor (not shown) for metering is provided below the sample cup 41, the PLC controller, the three-dimensional motion machine 1, the mother liquor workbench 2 and the measuring workbench 4 are installed on the frame 5 respectively, and the PLC controller is connected with the three-dimensional motion machine 1, the mechanical claw 11 and the measuring workbench 4, so as to respectively control the three-dimensional motion machine 1 to perform three-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com