Side open type carriage welding turnover work center

A side opening and frame welding technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high labor intensity for workers, many equipments used, and long opening and closing time, so as to save production area , high production efficiency and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

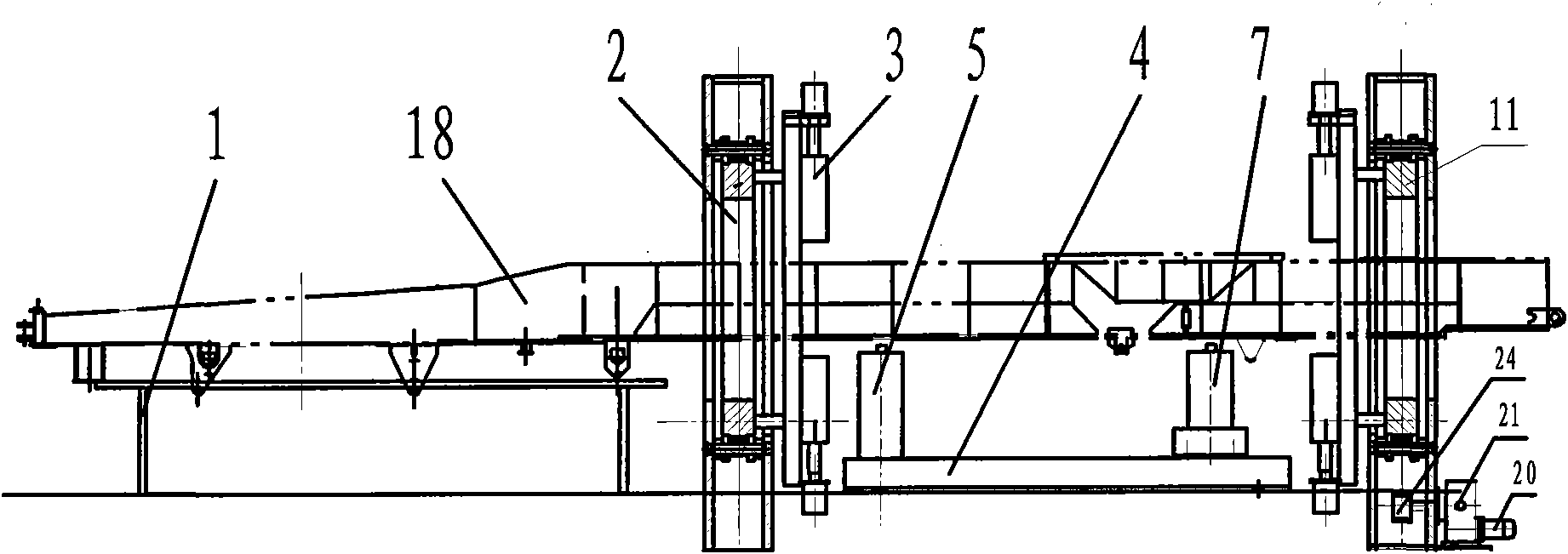

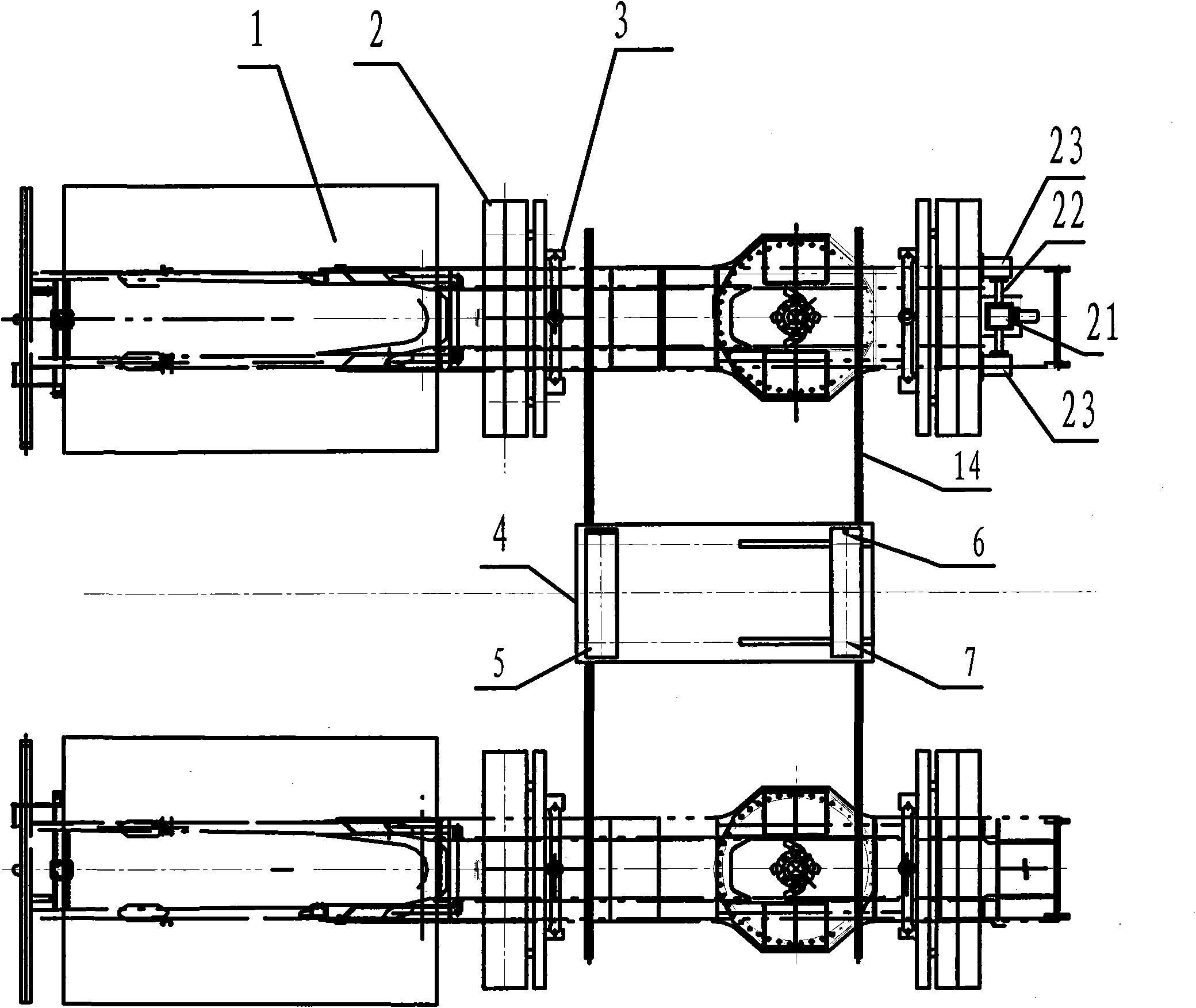

[0029] Embodiment 1: The turning center has a side opening positioner, a three-dimensional feeding trolley, a lifting platform 1, and an electric control system. The three-dimensional feeding trolley is located in the middle of the side opening positioner, and there is a lifting platform in front of the side opening positioner 1. The three-dimensional feeding trolley is located on the track 14, and the track 14 is perpendicular to the side opening positioner. The electric control system is connected with the three-dimensional feeding trolley 4, the lifting platform 1 and the side opening positioner at the same time. The machining workpiece 18 is placed on the turning work center.

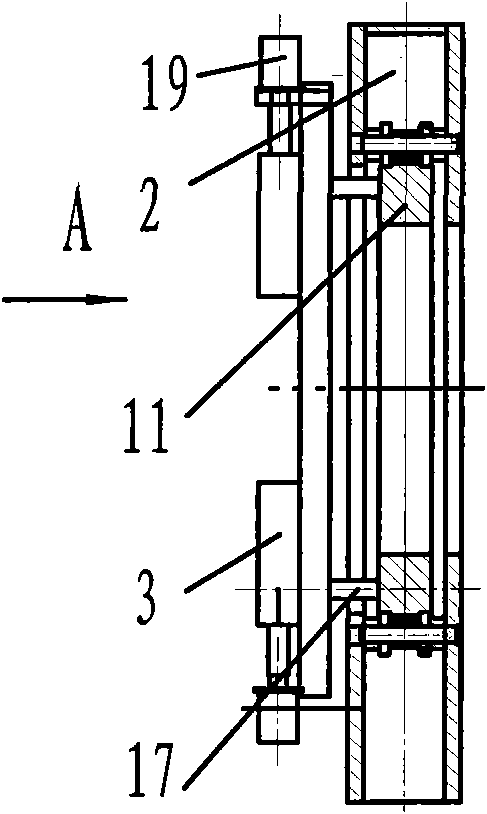

[0030] The side opening positioner is composed of two sets of identical components installed opposite to each other to form a side opening positioner, wherein a set of components consists of a frame body 8, a turning ring 2, a large opening gear 11, a rotary drive 10 and an electric clamp, and the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com