Wood-grain-printed aluminum material production line and production process thereof

A production line and aluminum material technology, applied to the surface coating liquid device, rotary printing machine, printing, etc., can solve the problems of slow work efficiency, no general specifications, and small batch orders, so as to reduce the production area and improve Continuity and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

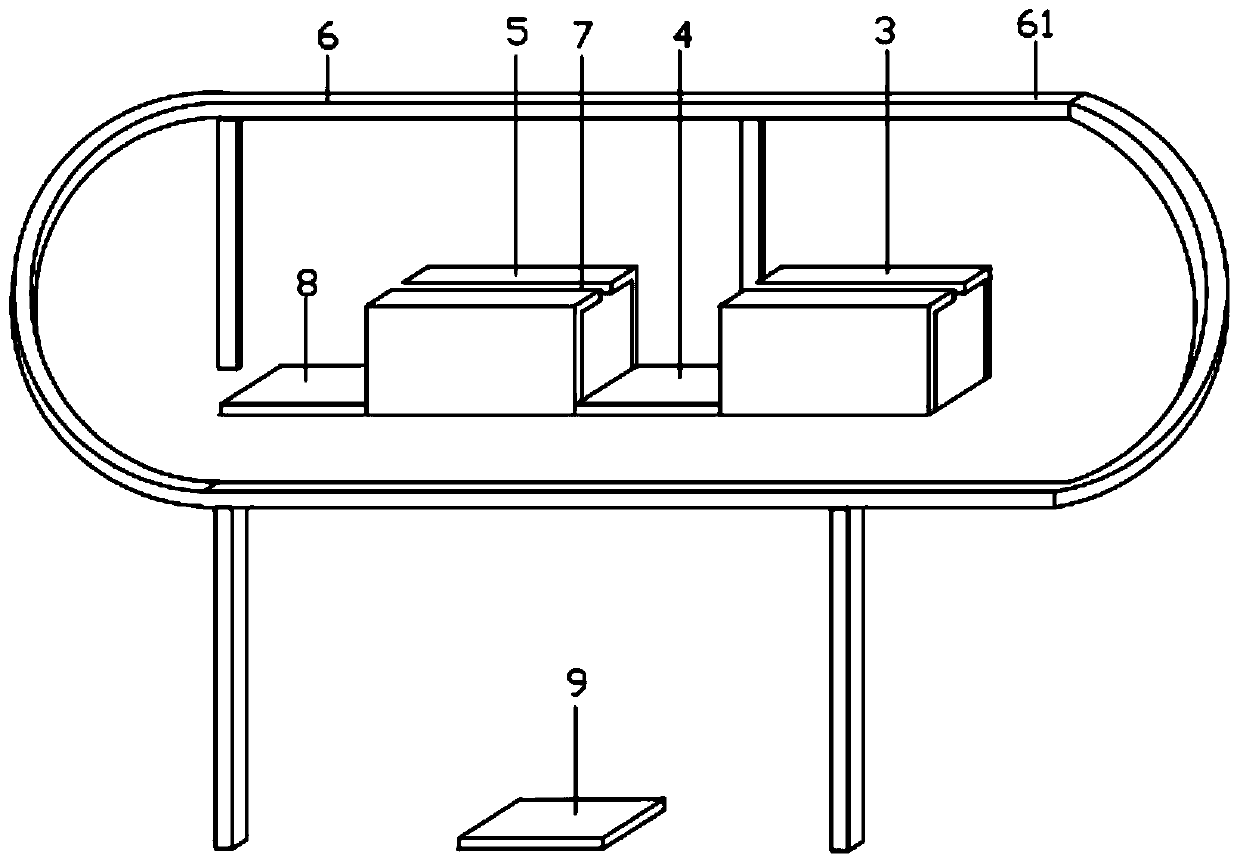

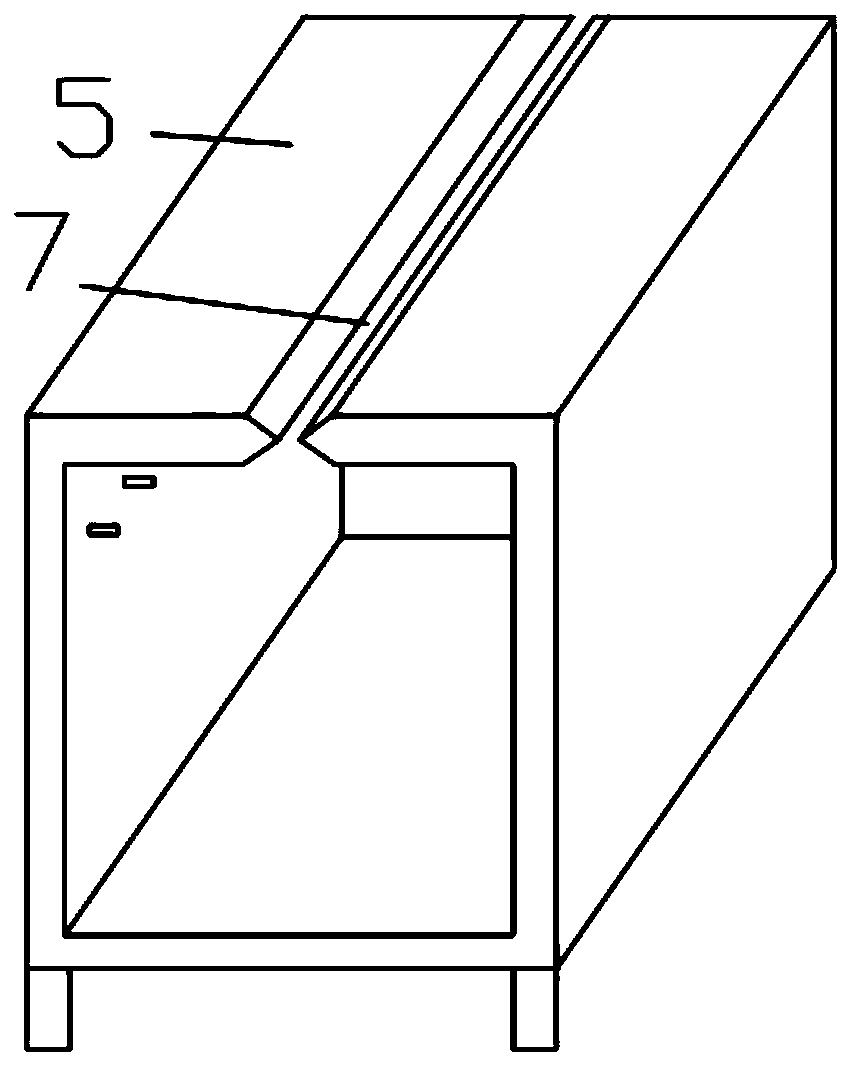

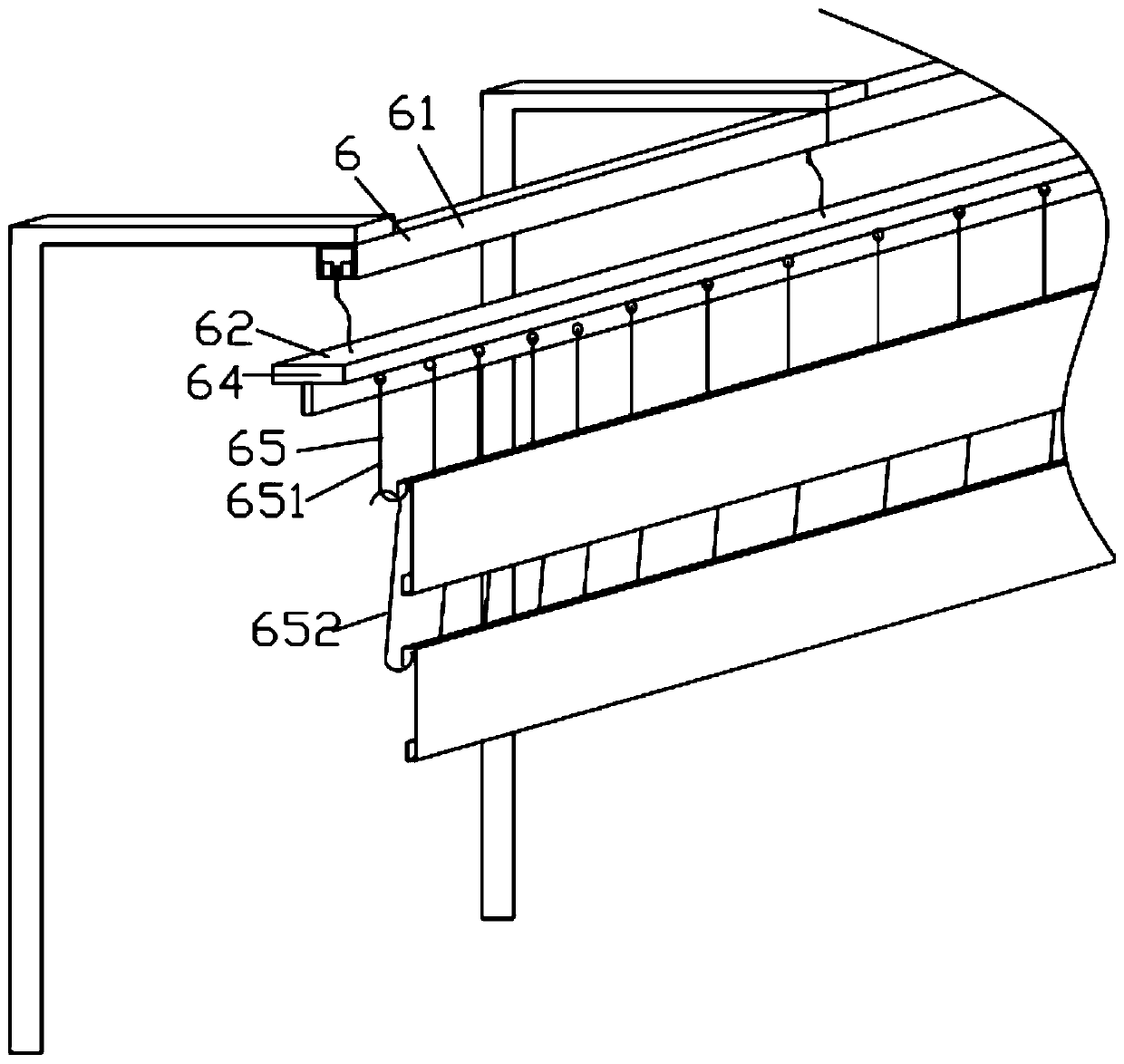

[0040] see Figure 1-Figure 3 As shown, the present invention discloses a wood-grain aluminum production line, which includes a heating channel 3 for baking and heat-transferring aluminum materials covered with wood-grain paper, and the downstream end of the heating channel 3 is provided with a The cooling channel 5 for cooling the completed aluminum material, the inspection table 4 for testing the thermal transfer degree of the aluminum material is set between the heating channel 3 and the cooling channel 5, and the production line is also equipped with a suspension conveying mechanism 6 for conveying the aluminum material. The conveying mechanism 6 includes an annular circulation track 61 that connects the heating channel 3, the inspection table 4 and the cooling channel 5 in sequence. The suspension assembly 62 is slid on the annular circulation track 61, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com