Film coating heat knife slitting device

A laminating hot knife and laminating technology, applied in printing, rotary printing machine, printing machine and other directions, can solve the problems of occupying a large production space, man-made damage to printed products, loss of semi-finished printed products, etc., to achieve a small production area occupied , the effect of saving mechanical tools and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

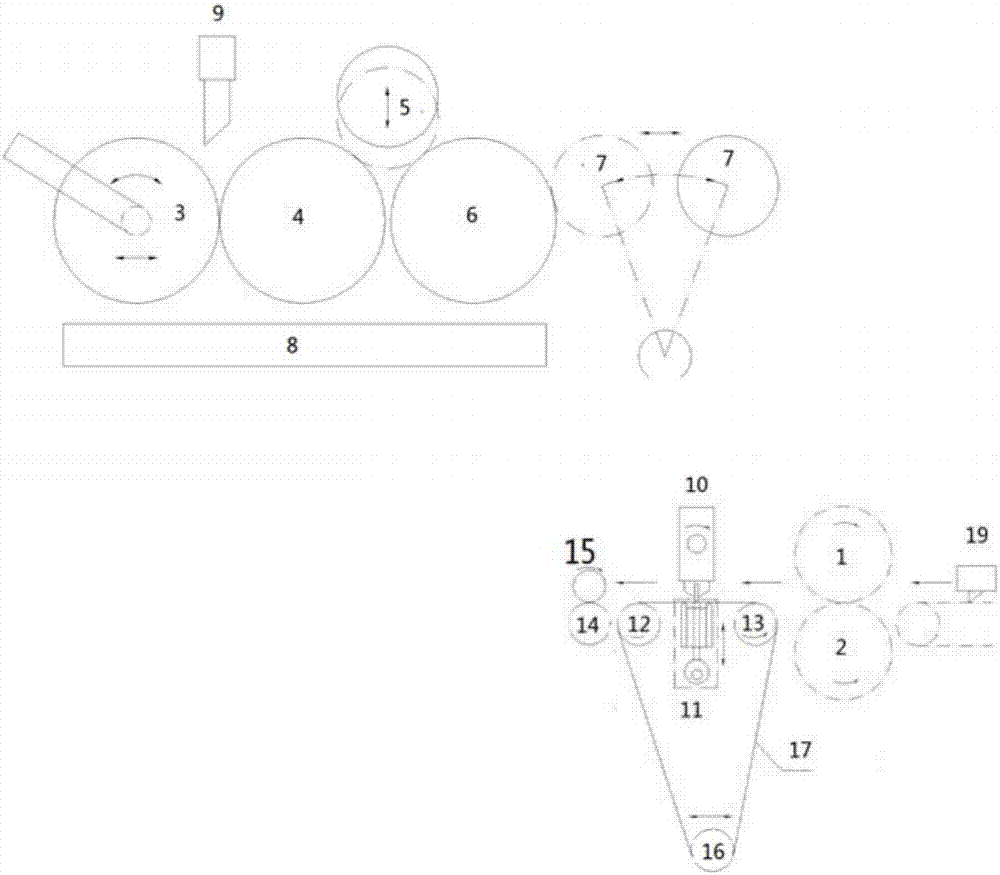

[0045] Such as figure 1 As shown, the present invention provides a film-coated hot knife slitting device, comprising: laminating steel roll 1, laminating rubber roll 2, metering steel roll 3, rubber transfer steel roll 4, rubber transfer rubber roll 5, coating metering steel rod 6. Coating pressing roller 7, rubber basin 8, glue spraying system 9, rotating hot knife 10, adjustment part 11, first driving roller 12, second driving roller 13, stripping roller 14, pressing wheel group 15, tensioning Roller 16, transmission mesh belt 17, machine wall plate 18 and laser sensor 19;

[0046] Laminating system consisting of laminating steel rods and laminating rubber rollers, measuring steel rods, rubber transfer steel rollers, rubber transfer rollers, coating metering steel rods, coating pressing rubber rollers, rubber basins and glue spraying systems Fabric system, hot knife slitting system composed of rotating hot knife, adjusting part, first driving roller, second driving roller, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com