A full-automatic sawing, milling, and edge-banding production line for all-bamboo boards or bamboo-wood composite boards

A composite board, fully automatic technology, applied in the direction of wood processing equipment, manufacturing tools, multi-purpose machinery, etc., can solve the problems of high production cost, impact on human health and environmental protection, bad products, etc., to achieve small production area occupied, workers The effect of low labor intensity and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

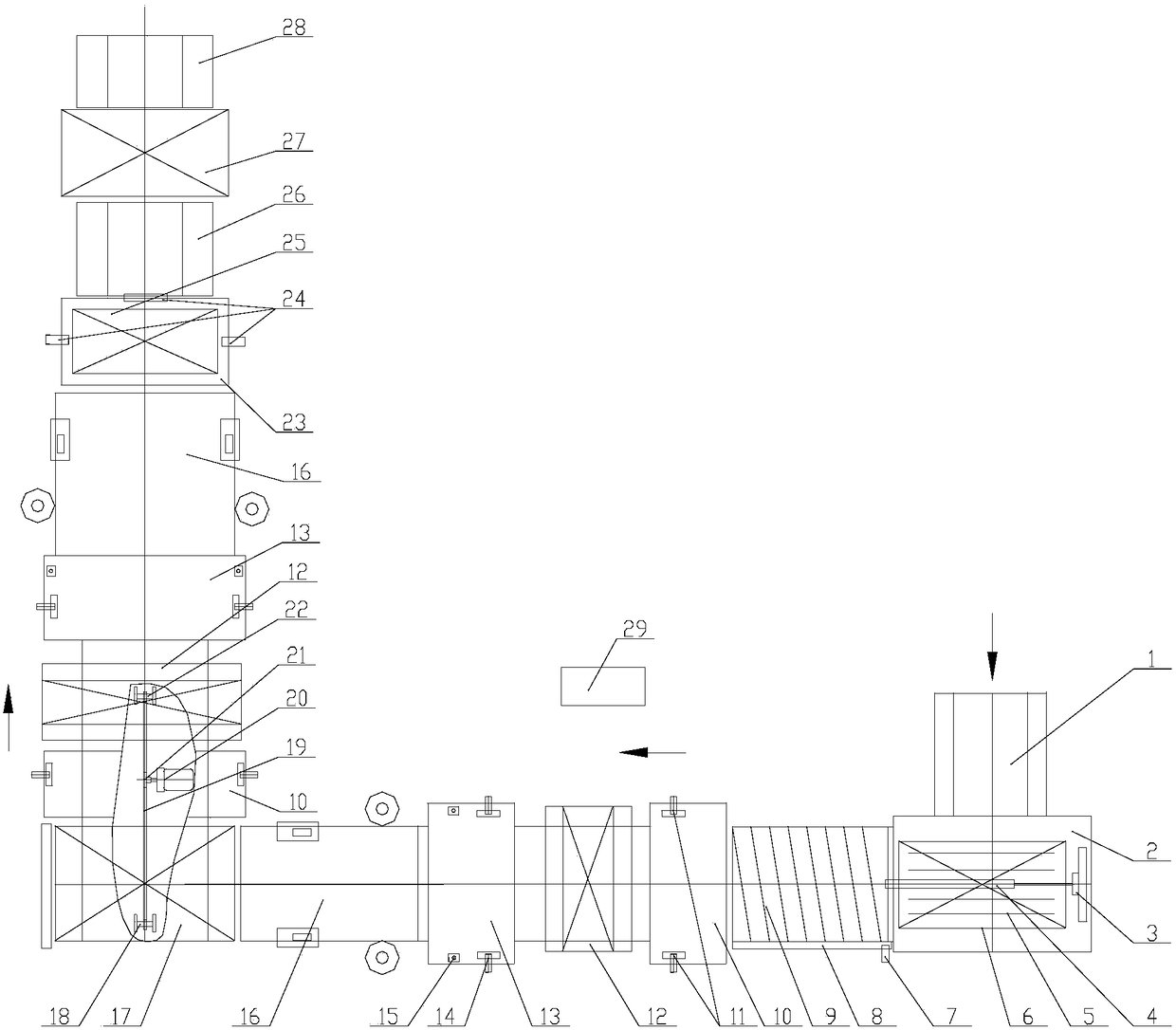

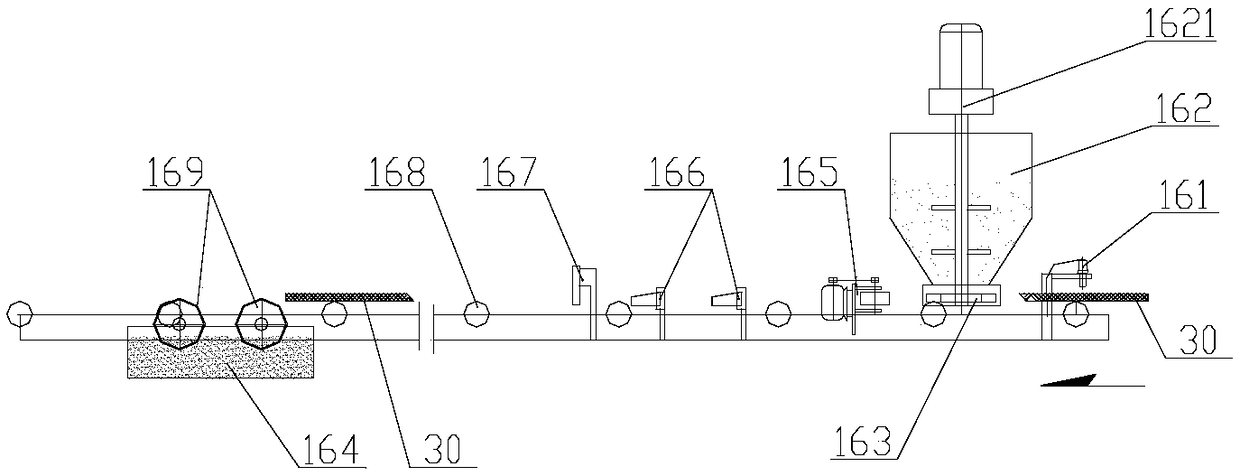

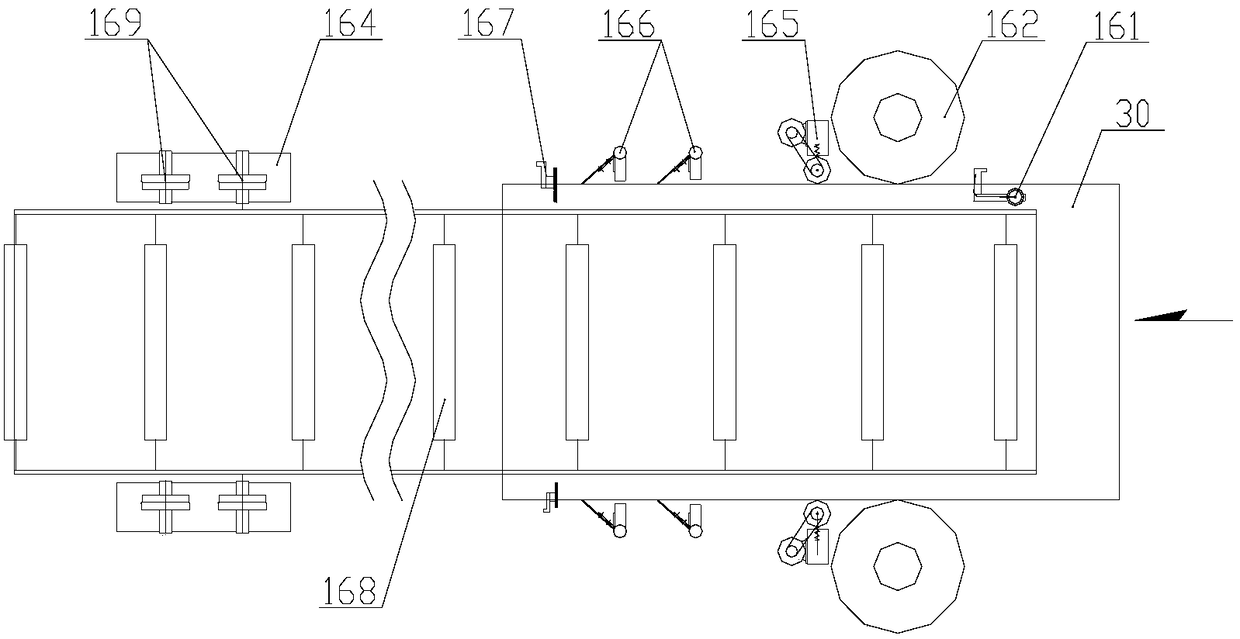

[0022] Embodiments of the present invention, such as Figure 1 to Figure 5 As shown, a full-automatic sawing, milling, and edge-banding production line for all bamboo boards or bamboo-wood composite boards, including a PLC operation control cabinet 29, and through its centralized control: successively longitudinally connected board feeding mechanisms, automatic deviation adjustment Mechanism, edge sawing machine, edge strip returning machine 12, edge milling and chamfering machine 15, plastering and painting machine 16, board feeding trolley 17, and the edge sawing machine and edge strip returning connected horizontally with the board feeding trolley 17 Machine 12, edge milling and chamfering machine 15, plastering and painting machine 16, board output mechanism.

[0023] Further, the plate sending trolley 17 includes a base 178 and a trolley frame 174, the base 178 is provided with a guide rail 177, the trolley frame 174 is slidably arranged on the guide rail 177 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com