Laminating Slitting Machine

A slitting machine and laminating technology, applied in the printing field, can solve the problems of occupying a large production space, loss of semi-finished products, and artificial damage to printed products, and achieve the effect of saving mechanical tools, small production area, and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

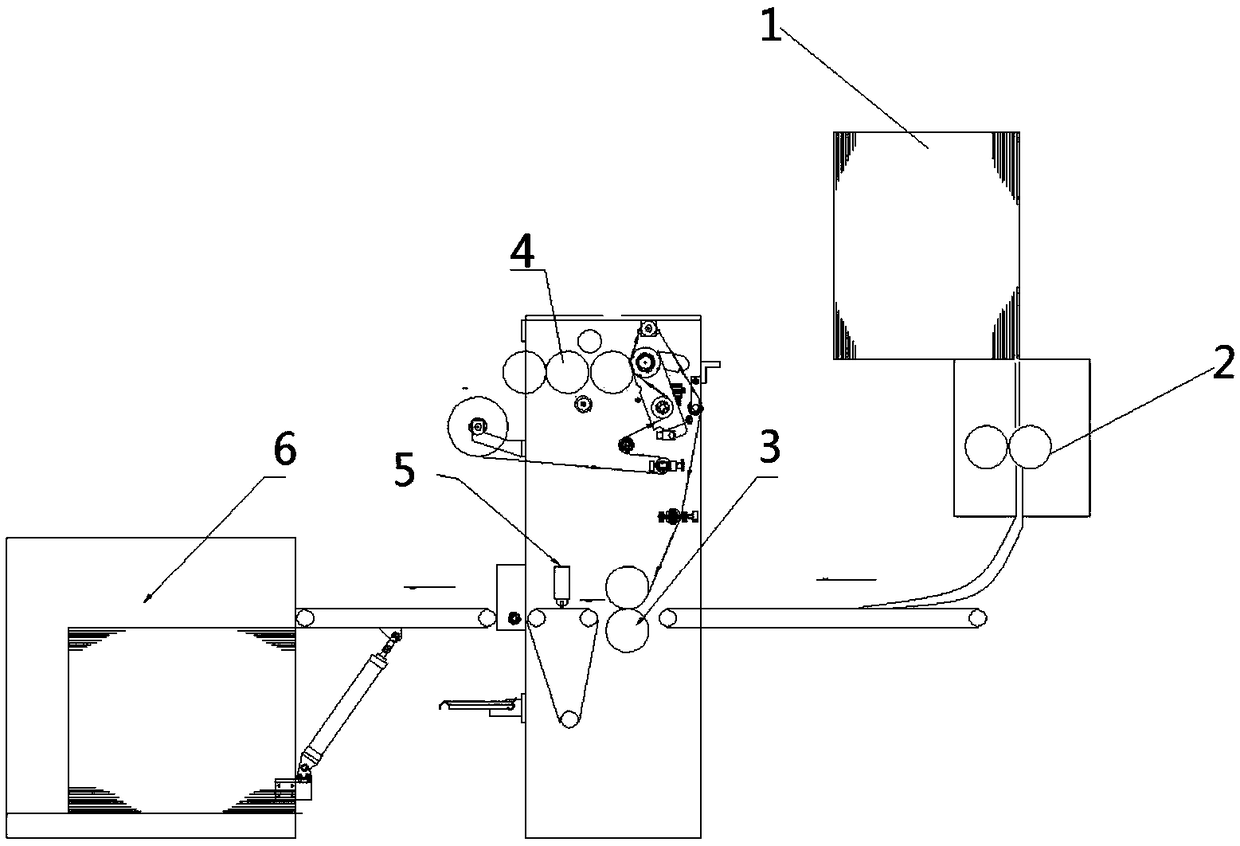

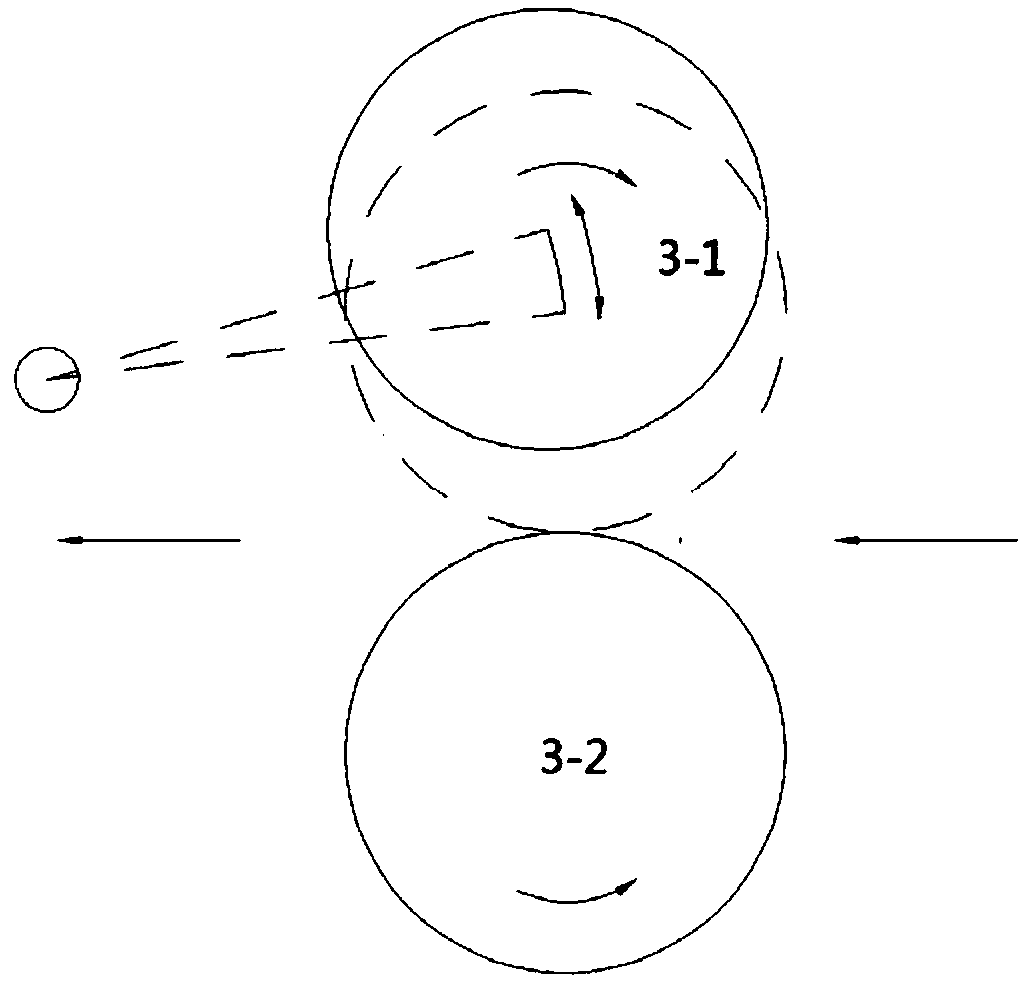

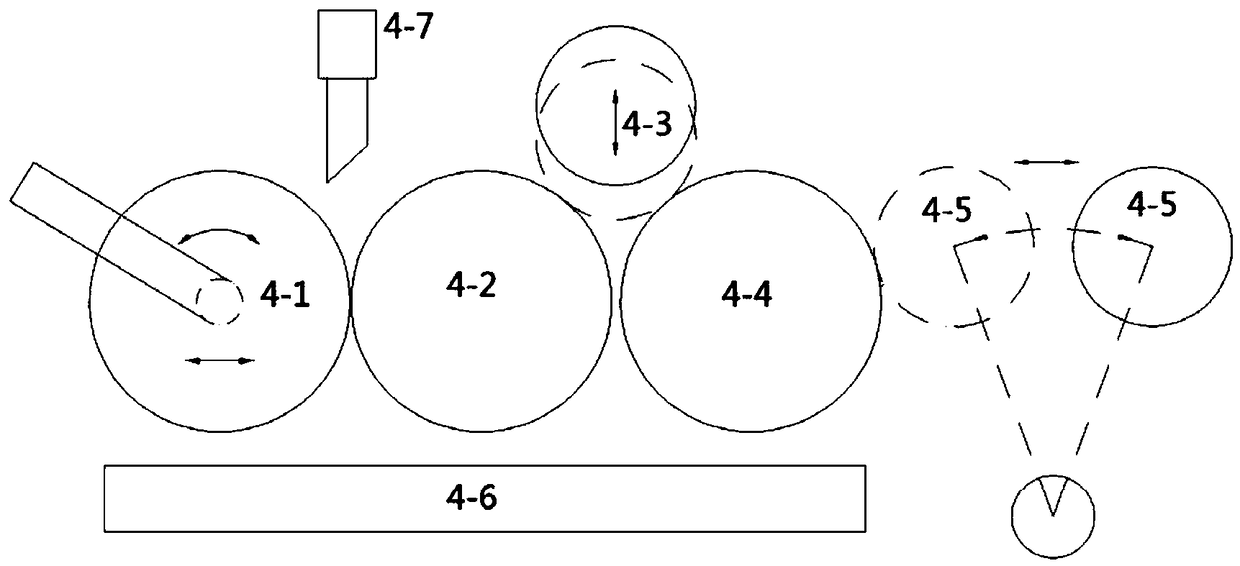

[0072] Such as figure 1 As shown, the present invention provides a film-coated slitting machine, including: a paper feeding system, a powder removal system, a coating system, a laminating system, a slitting system and a delivery system;

[0073] The paper feeding system is located above the powder removal system, and the printed matter falls into the powder removal system from the paper feeding system in the vertical direction by gravity. During the powder removal, the printed product keeps moving in the vertical direction. The product changes from vertical movement to horizontal movement and enters the laminating system. The coating system is located above the laminating system. After leaving the laminating system, the printed product enters the slitting system, and the slitting printed product is sent to the delivery system. , the level of the delivery system is lower than that of the analysis system.

[0074] Further improvement, the paper feeding system includes a box bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com