Numerical control equipment for machining plate-type custom furniture hinge hole

A technology of numerical control equipment and hinge holes, applied in metal processing equipment, drilling/drilling equipment, manufacturing tools, etc., can solve the problems of low hinge hole processing efficiency, multiple positioning processing, low hinge hole efficiency, etc. The production bottleneck problem, the effect of ensuring reliability and machining accuracy, transmission efficiency and high motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

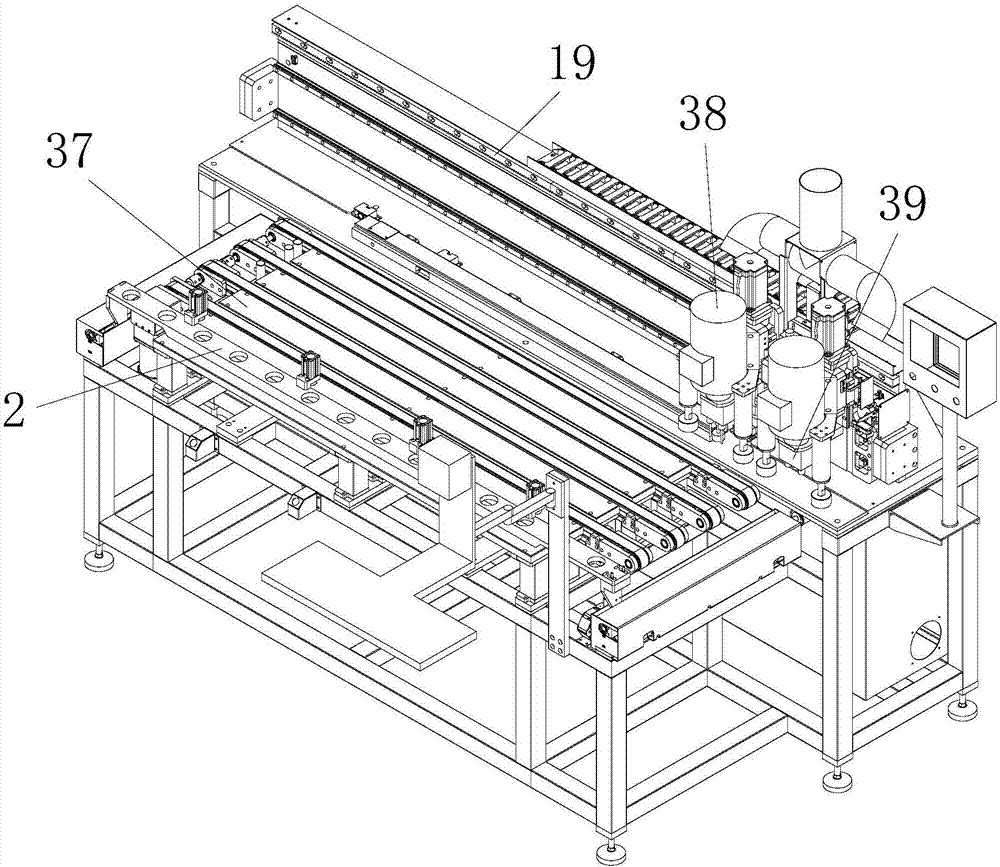

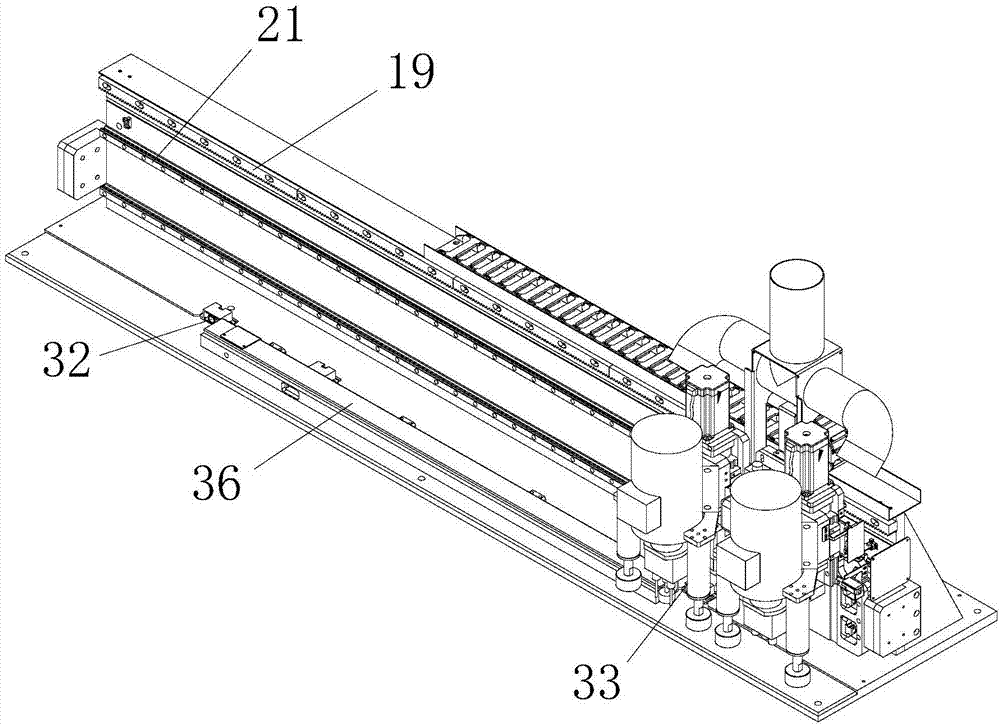

[0043] A numerical control device for processing hinge holes of panel-type custom-made furniture, characterized in that it includes a transmission device, a drilling mechanism, an X-direction moving mechanism, a Y-direction moving mechanism, and a Z-direction moving mechanism;

[0044] The Y-direction moving mechanism is installed on the X-direction moving mechanism, the Z-direction moving mechanism is installed on the Y-direction moving mechanism, and the drilling mechanism is installed on the Z-direction moving mechanism;

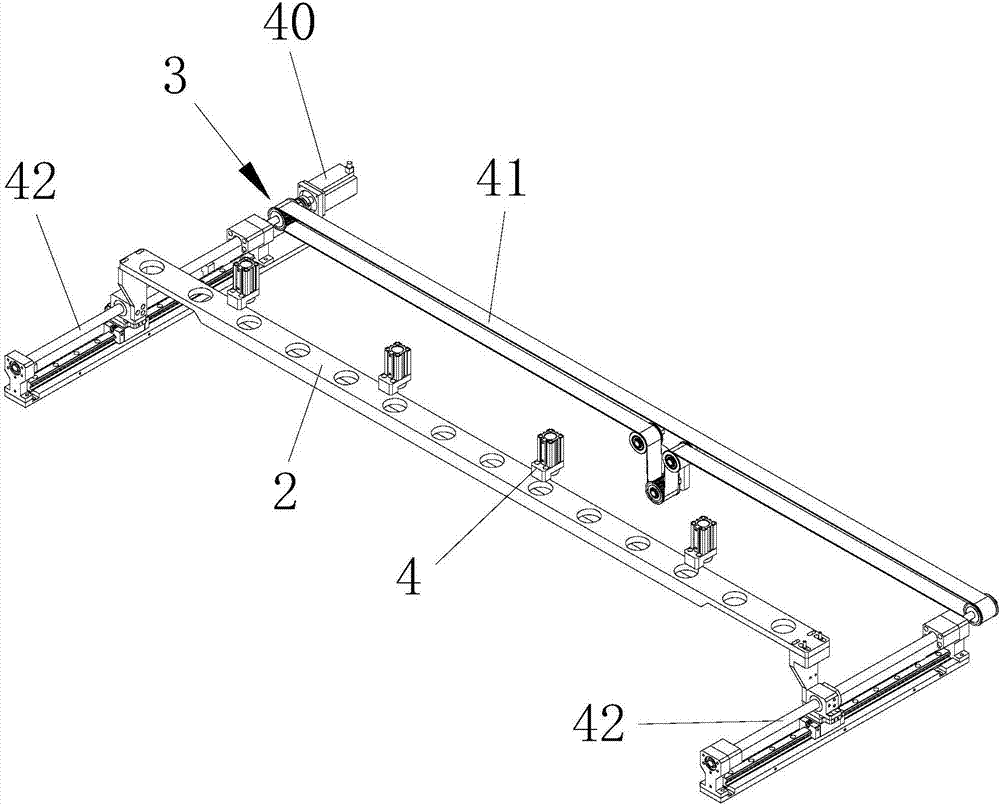

[0045] The conveying device includes a plate conveying mechanism, a push plate mechanism and a plate limit mechanism. The push plate mechanism is arranged on the plate conveying mechanism. The connection is used to push the plate to the drilling mechanism, and the plate pressing part is installed on the push plate;

[0046] The plate limit mechanism is set on the plate conveying mechanism, including a limit frame body, a limit column, a push cylinder and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com