Automatic bundling device of plastic bag making machine

An automatic bundling and bag-making machine technology, applied in the direction of bundling objects, bundling materials, paper product packaging, etc., can solve the problems of rubber bands stuck on the spreader rods, lack of feeding mechanism, rubber bands accumulation and blockage, etc., to avoid accumulation blockage, The effect of improving work efficiency and improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

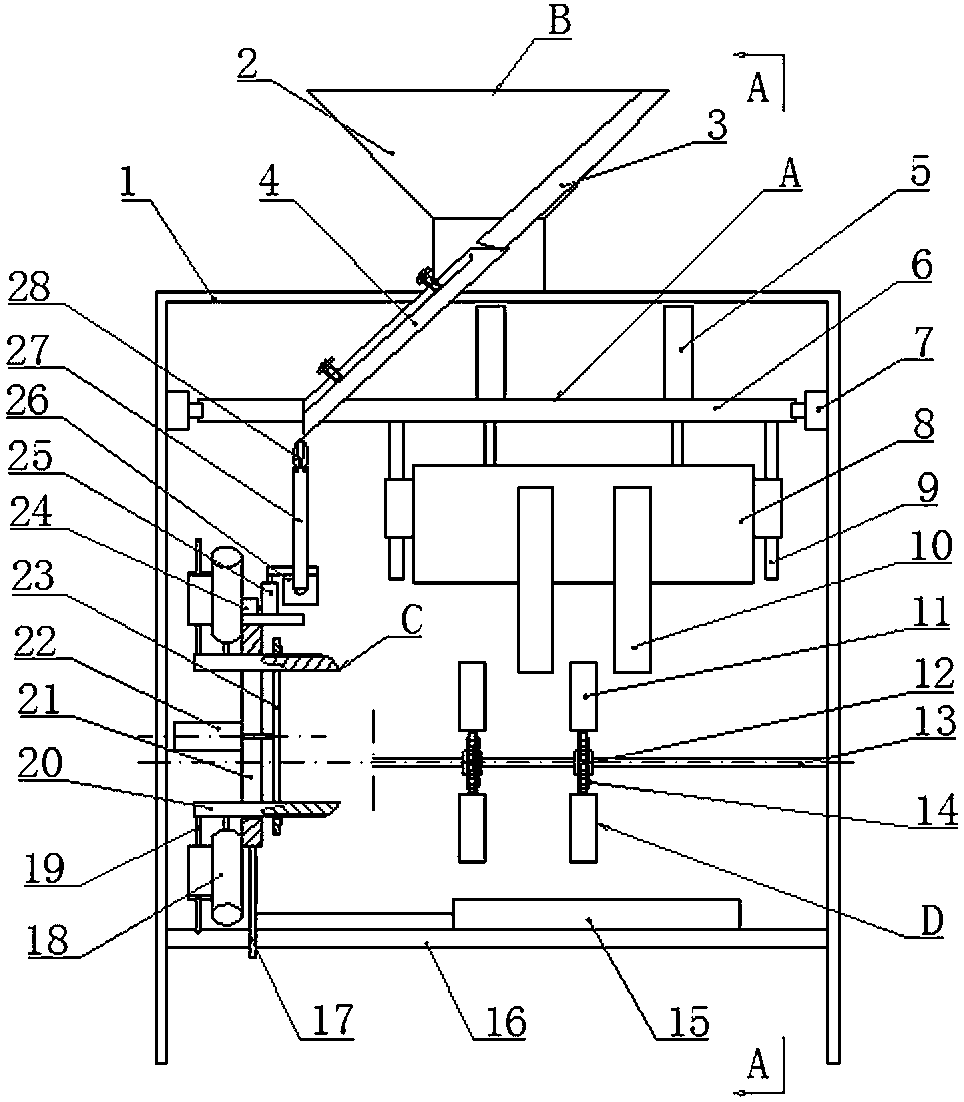

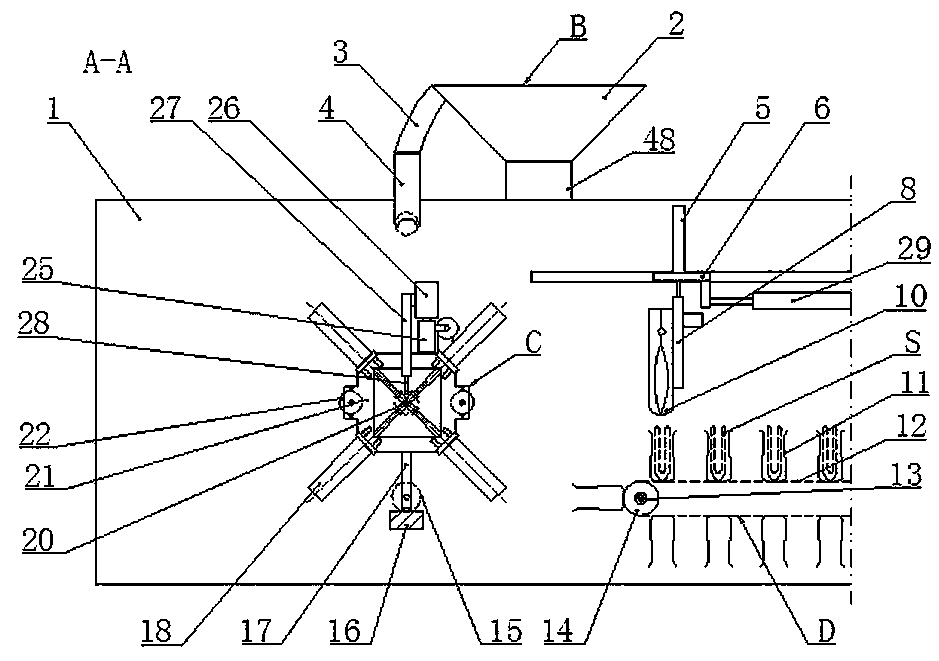

[0026] see Figure 1-Figure 15 , an automatic strapping device for a plastic bag making machine of the present invention is characterized in that it includes the following mechanisms respectively installed on the frame 1:

[0027] A plastic bag feeding mechanism A used to transfer the folded plastic bags S output by the bag making machine (the product output mechanism D) to a strapping mechanism C for bundling.

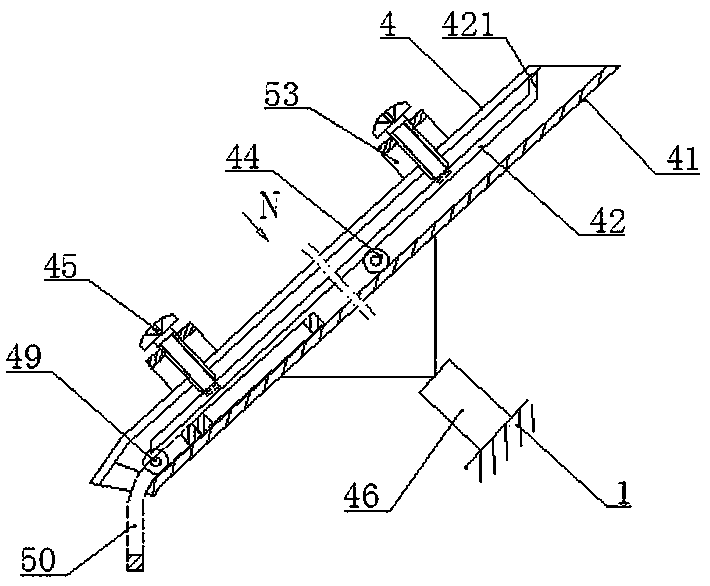

[0028] A rubber band sorting and output mechanism B for sorting and arranging the annular rubber bands 50 and outputting them sequentially.

[0029] A binding mechanism C for covering the rubber band 50 output by the rubber band sorting output mechanism B on a stack of plastic bags S delivered by the plastic bag feeding mechanism A. The binding mechanism C includes a spreader and a rubber band transfer mechanism. The rubber band transfer mechanism is used to transfer the rubber band output by the rubber band sorting output mechanism B to the spreader, and the spreade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com