Integrated packaging production line for clinopodium polycephalum tablet aluminum foil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

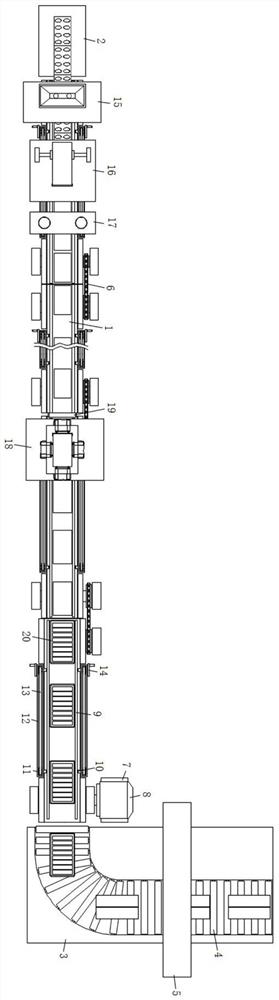

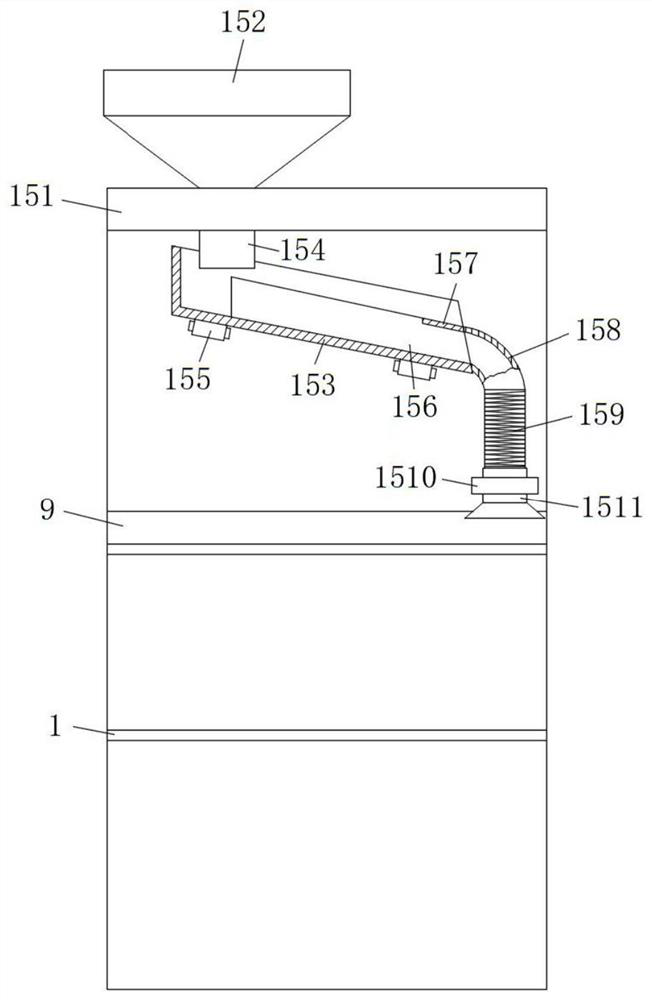

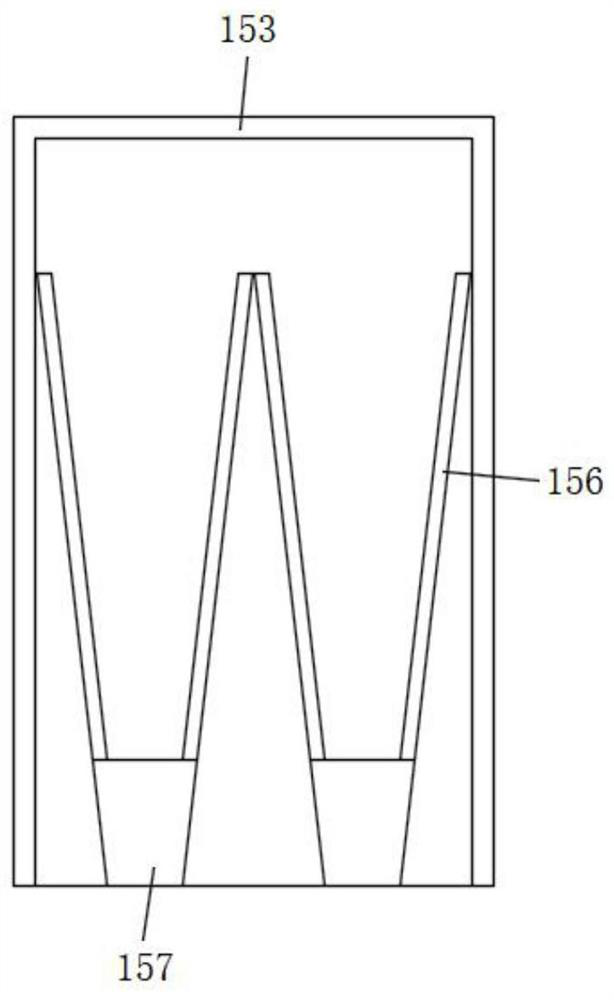

[0032] refer to Figure 1-4, an integrated packaging production line for broken blood sheet aluminum foil, including a conveyor belt body 1, a feeding table 2 and a packing table 3 are respectively arranged on both sides of the conveyor belt body 1, and a guide conveying roller 4 is installed on the packing table 3, and the packing table 3. A strapping and packaging machine 5 is installed on the upper side. A conveyor chain 6 is rotatably connected between the transmission shafts of two adjacent conveyor belt bodies 1. A fixed seat 7 is arranged on one side of the rear end of the conveyor belt body 1. The fixed seat 7 The top surface is fixed with a servo motor 8 by screws, and the front and rear sides of the top of the conveyor belt body 1 are fitted with a limit plate 9, and the limit plate 9 is away from the center of the conveyor belt body 1. One end is fixedly connected with a threaded rod 10, and the outer wall of the threaded rod 10 Both threaded cylinders 11 are connec...

Embodiment 2

[0034] like figure 1 and 5 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the cutting mechanism 17 includes a cutting frame 171, and the front and rear sides of the outer top of the cutting frame 171 are fixed with a cylinder 172 by screws, and the output end of the cylinder 172 is connected by a screw. An installation bar 173 is fixed, and the bottom surface of the installation bar 173 is fixed with a slitting knife 174 by screws, and a backing plate 175 is arranged directly below the slitting knife 174, and the top surface of the backing plate 175 is attached to the bottom side of the upper belt surface of the conveyor belt body 1 .

[0035] In this embodiment, automatic slitting can be realized after packaging. After slitting, the packaging pieces are transported on the conveyor belt body 1. At this time, the packaging box is automatically dropped into the conveyor belt body 1 by gravity, and the packaging pieces are transported by the guide p...

Embodiment 3

[0037] like figure 1 and 6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the box-loading mechanism 18 includes a filling frame 181, a rectangular groove is provided on the top surface of the filling frame 181, and a feeding dish 182 is fixed on the inner wall of the rectangular groove. The inner wall of the rectangular groove is also provided with a cylindrical groove, and the inner wall of the cylindrical groove is all fixedly connected with electric telescopic rods 183 by screws. Eight electric telescopic rods 183 are arranged and evenly distributed on the inner wall of the rectangular groove. The output end of the telescopic rod 183 is fixed with a limit plate 184, and both sides of the limit plate 184 are provided with grooves. The distance from the top side of the belt surface is 2 mm larger than the thickness of the broken blood flow sheet packaging box when it is laid flat.

[0038] In this embodiment, automatic slitting can be realized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com