Rope binding auxiliary device

An auxiliary device and rope technology, which is applied to the parts and components of bundling machinery, can solve problems such as troublesome and cumbersome bundling methods, and achieve the effect of high degree of automation and improvement of bundling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification. The "above" and "below" mentioned in this embodiment are consistent with the directions above and below the drawings themselves, which are only for the convenience of description and clarification, and are not used to limit the scope of the present invention, and the changes or adjustments of their relative relationships , without substantively changing the technical content, it should also be regarded as the scope of the present invention that can be implemented.

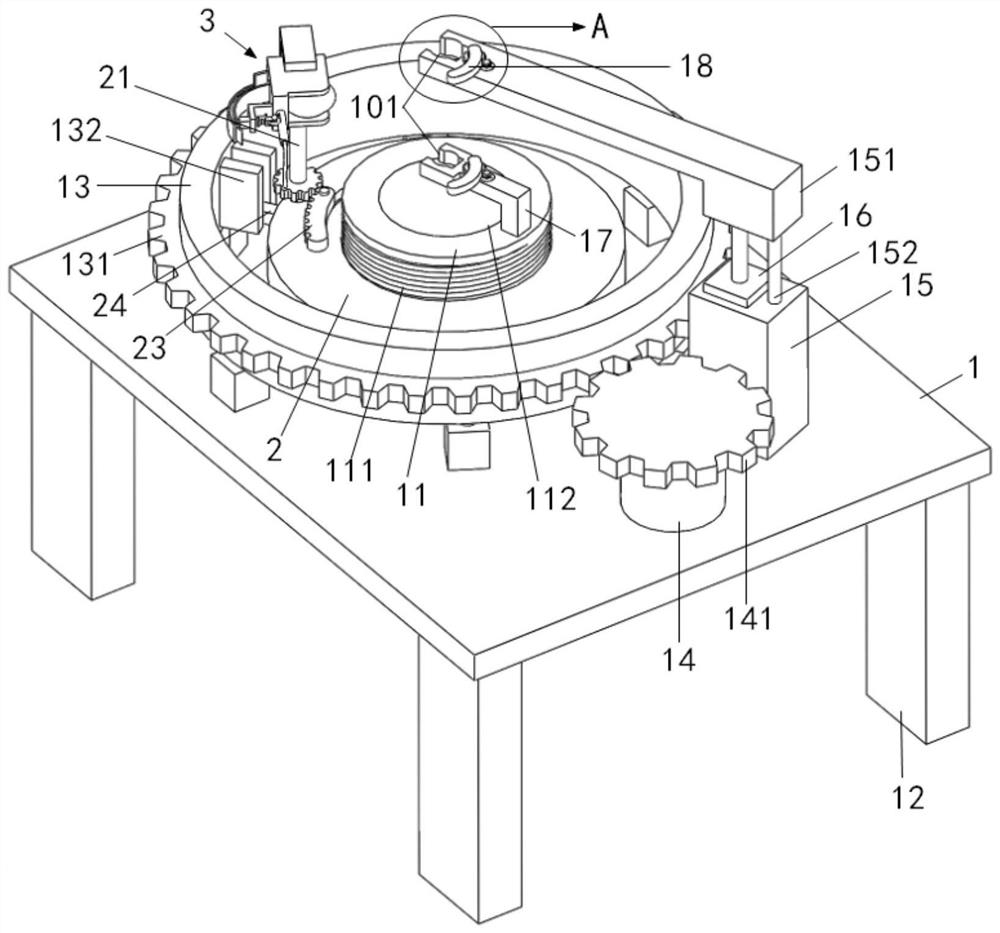

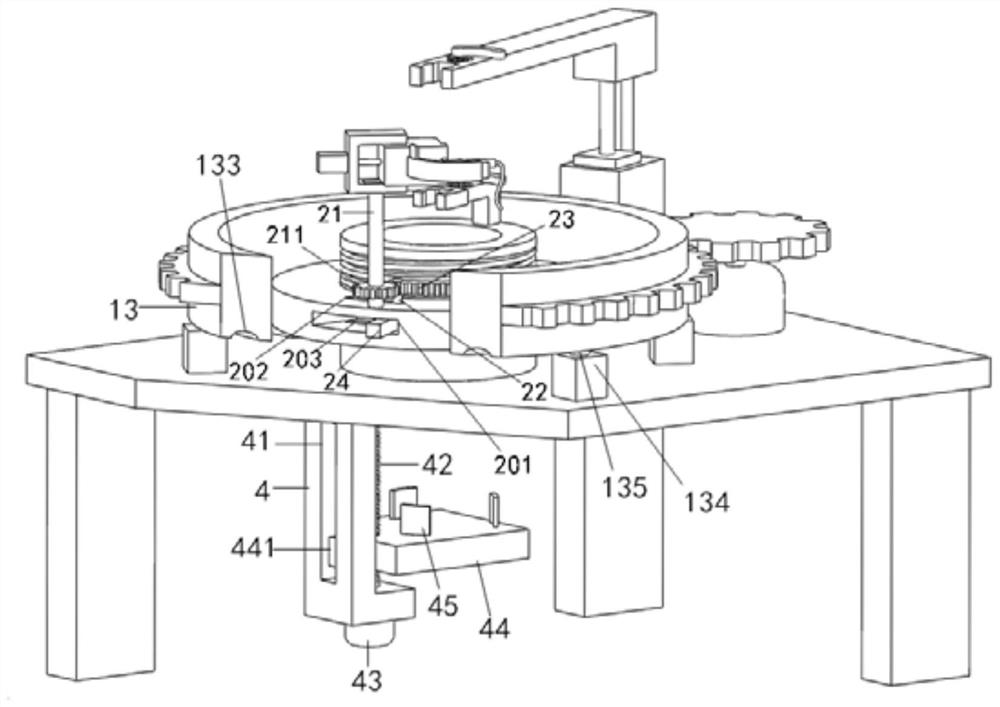

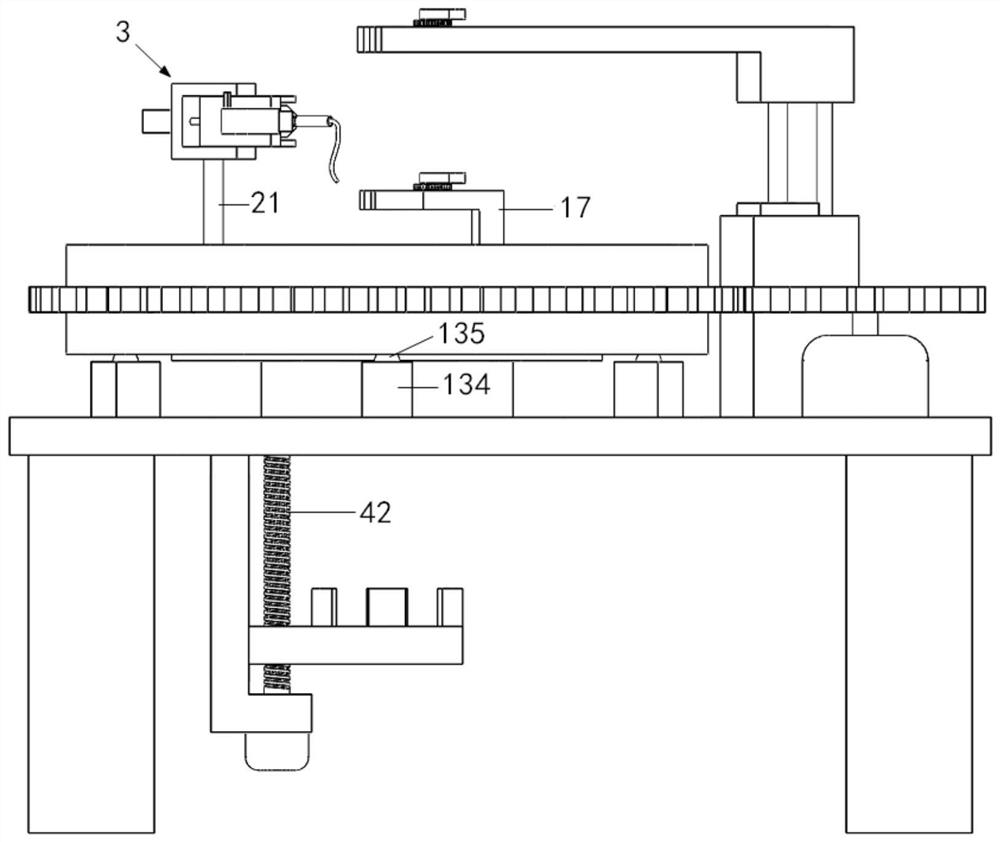

[0023] Depend on Figure 1 to Figure 7 As shown, a rope binding auxiliary device includes a base plate 1 and a supporting foot 12. The top surface of the base plate 1 is provided with a fixed round table 11 with an outer circular wall and a screw thread 111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com