Self-sealing filling valve capable of automatically unlocking at low temperature

A self-sealing filling and automatic unlocking technology, applied to valve details, valve devices, engine components, etc., can solve the problem of automatic detachment of the filling pipeline, and achieve the effect of easy falling off and flexible opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

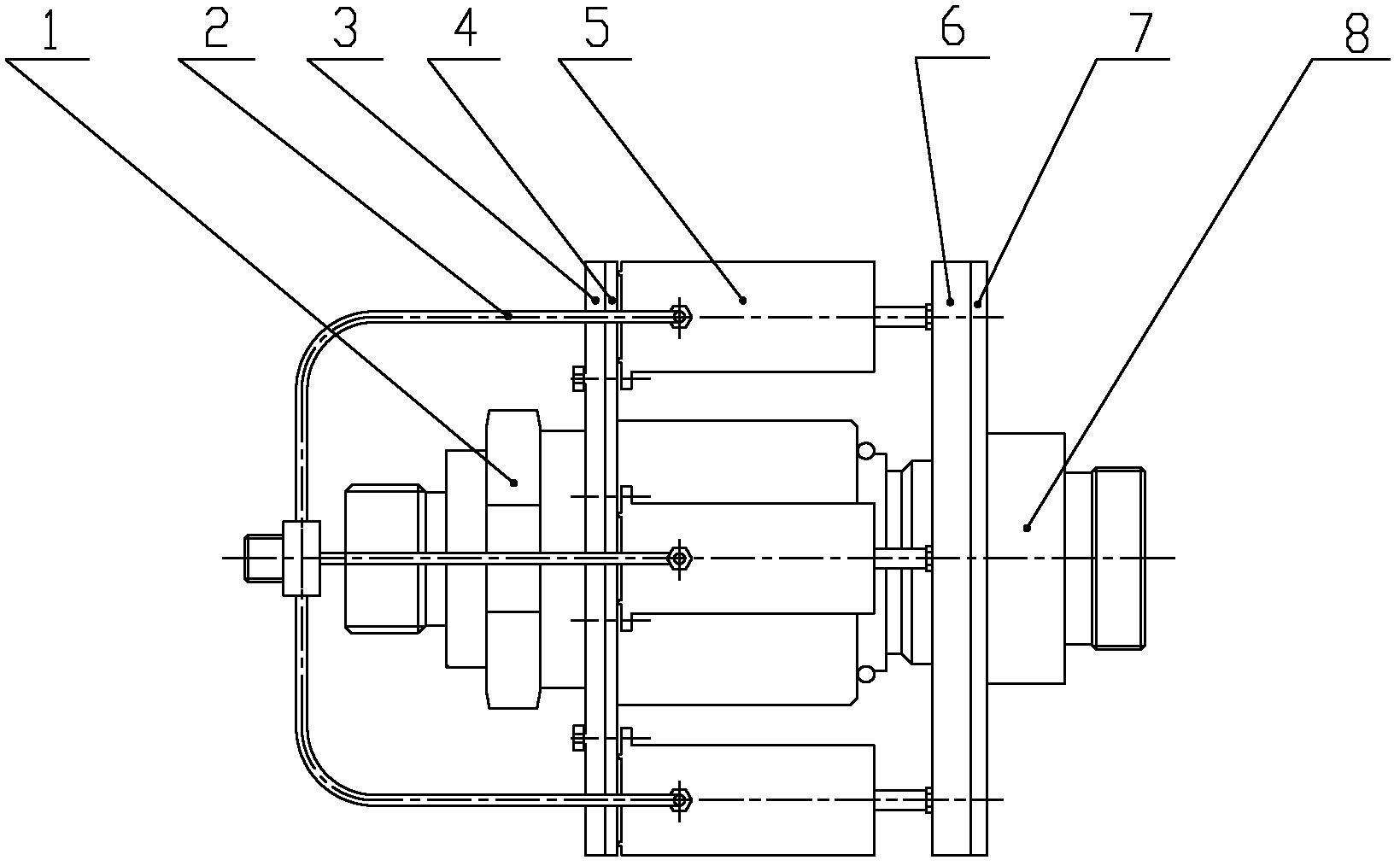

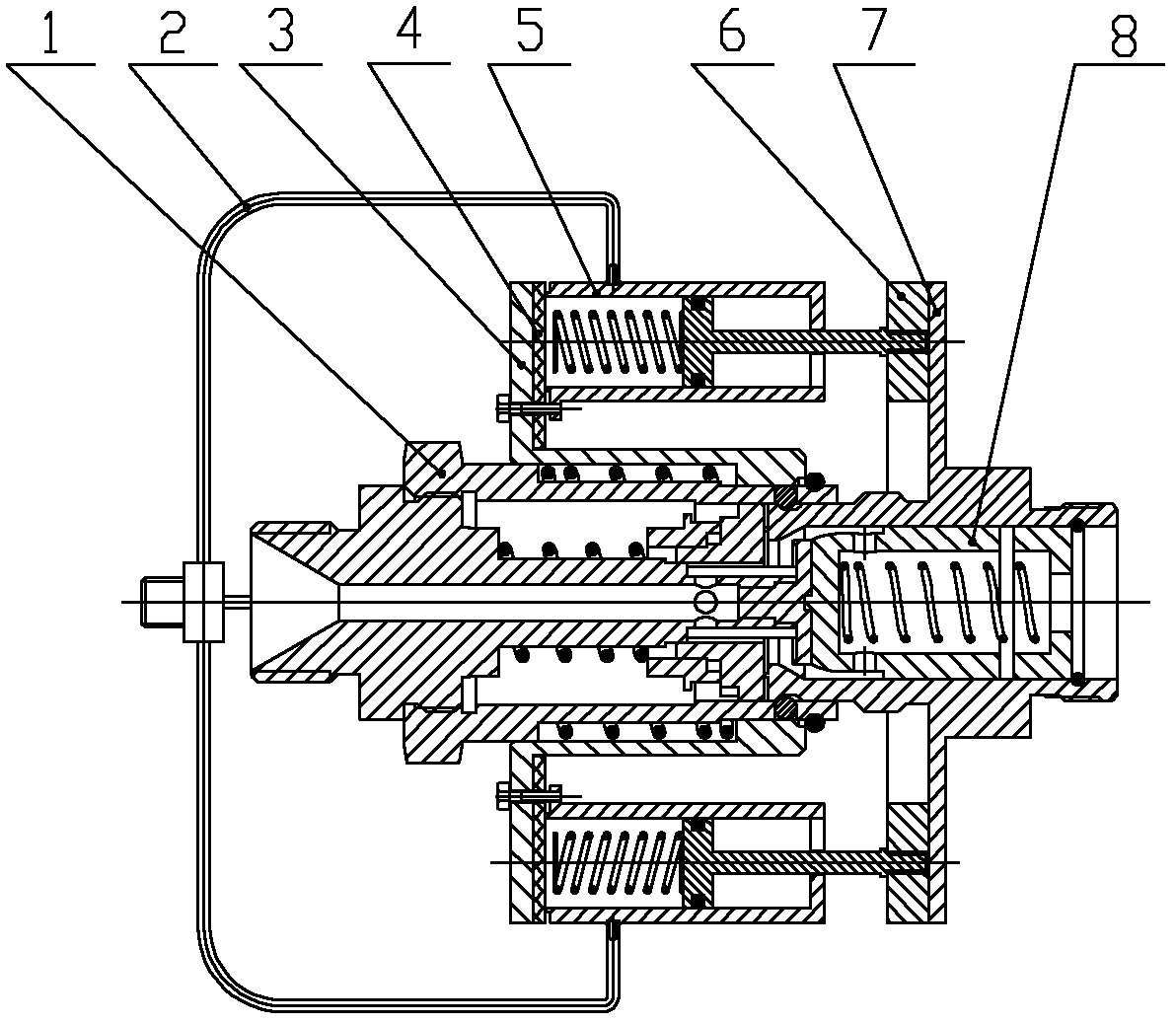

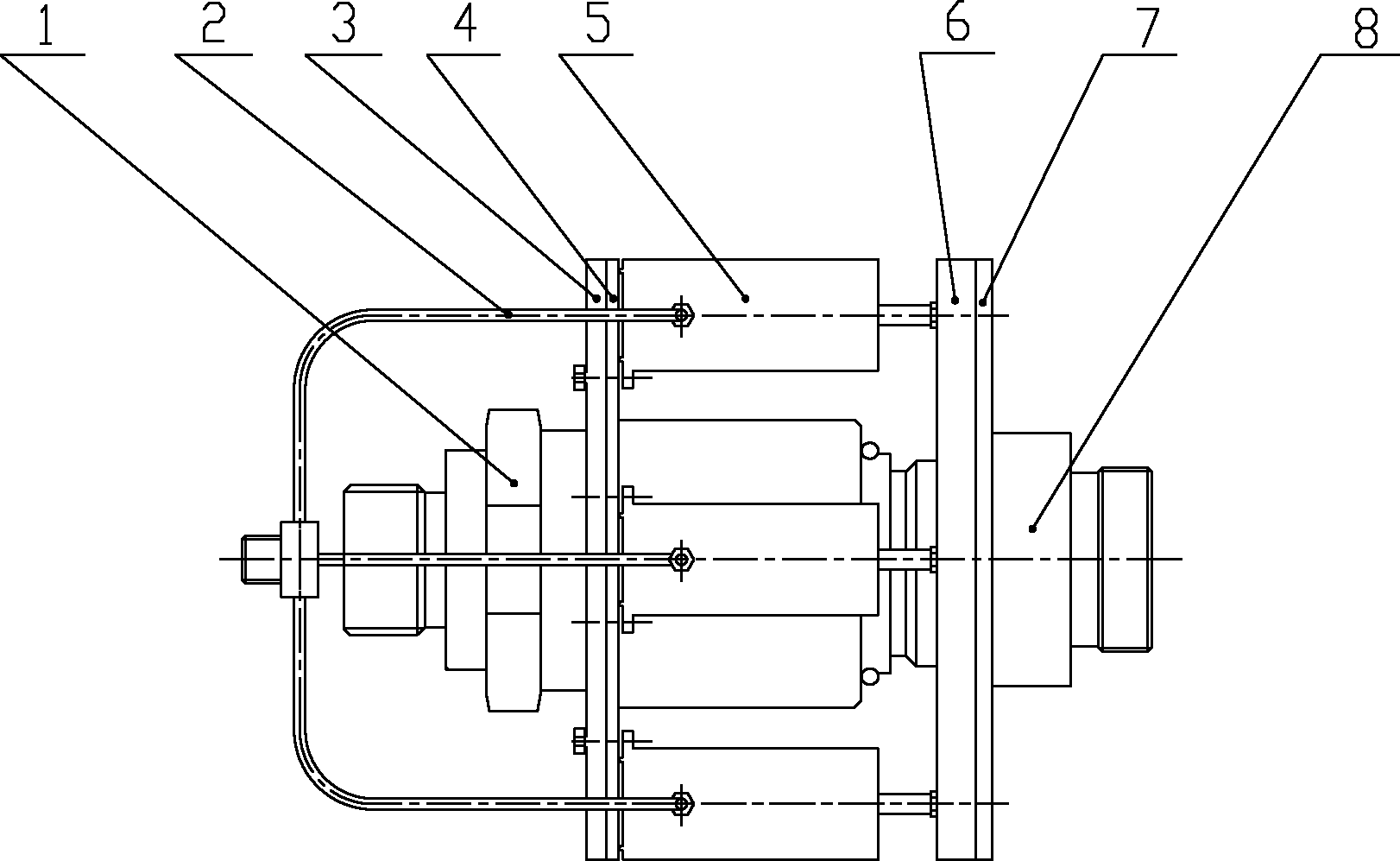

[0018] Such as figure 1 As shown, a self-sealing filling valve that is automatically unlocked at low temperature includes a socket assembly 1, an air intake line 2, an on-off sleeve 3, a sealing ring 4, a cylinder 5, a support ring 6, a connecting sleeve 7, and a plug assembly 8;

[0019] The filling valve adopts a plug-in structure, the socket assembly 1 is located on the left side of the filling valve, the plug assembly 8 is located on the right side of the filling valve, one end of the plug assembly 8 extends into the socket assembly 1, and the filling valve is turned on and off. The right side of the sleeve 3 is a long cylinder, and the left side is an annular flange. The long cylinder of the on-off sleeve 3 is set on the socket assembly 1. There are three cylinders 5, which are evenly distributed on the outside of the socket assembly 1. The cylinder 5 There is a sealing ring 4 between the left end cover and the ring flange of the on-off sleeve 3. The three are connected b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com