Mat sealing joint, electrical connector, and method of manufacture

A technology for electrical connectors and gaskets, applied in the field of gasket joints, can solve problems such as high production and trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

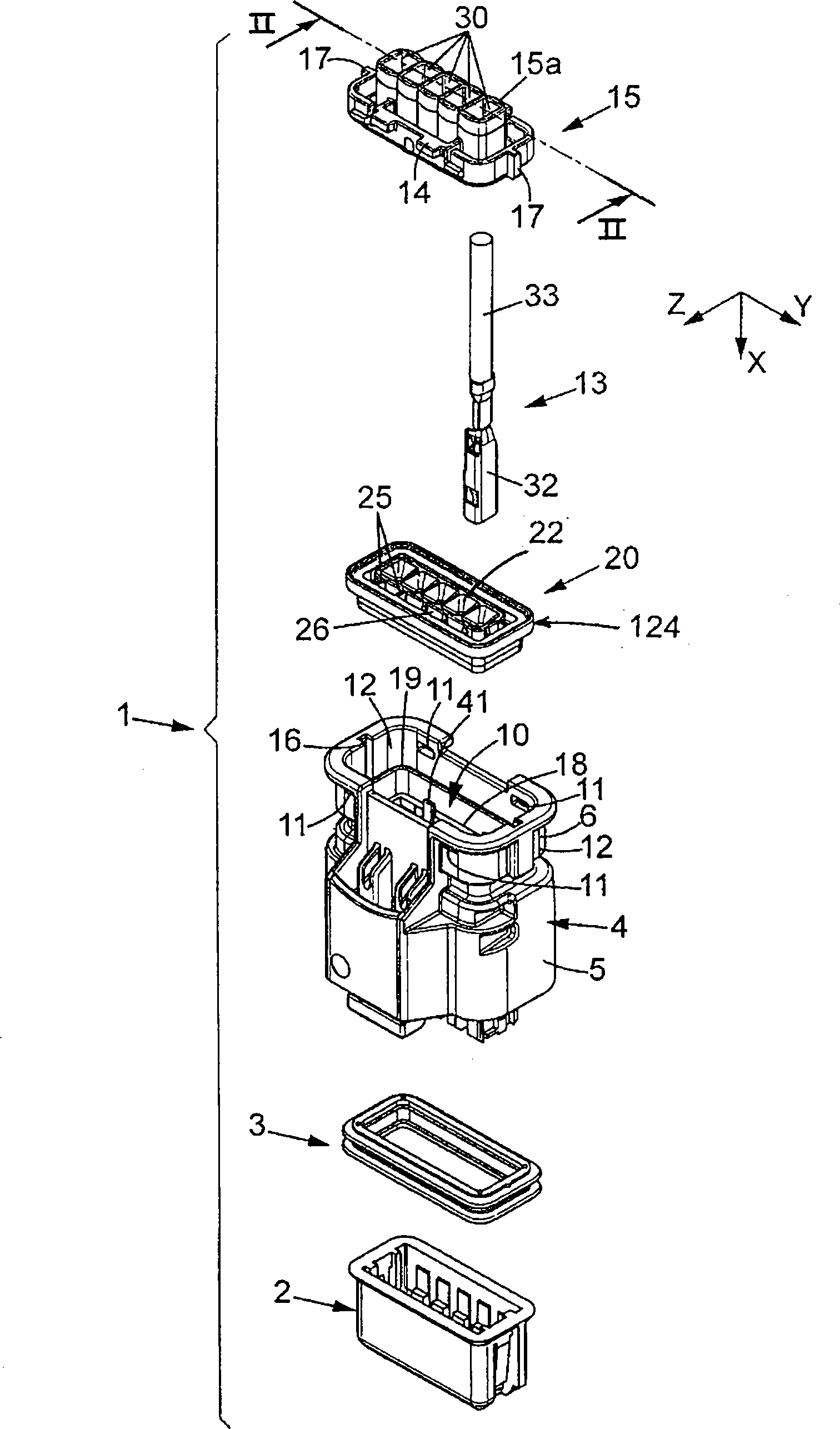

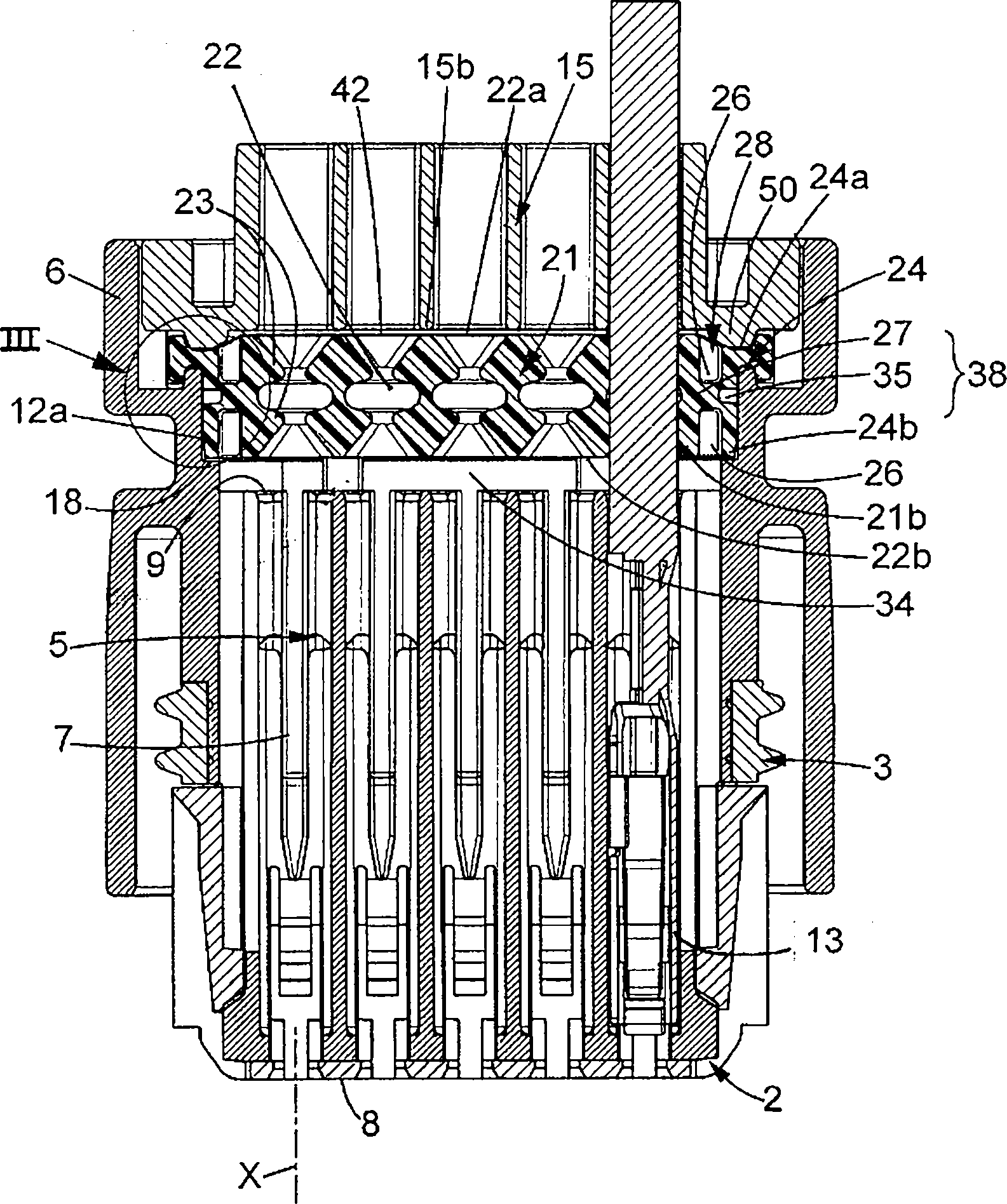

[0035] figure 1 An electrical connector 1 is shown to be connected to a mating connector (not shown). Fitted in the connector is a joint 3 of any suitable shape and material to be sandwiched between the connector 1 and the mating connector for sealing the connection.

[0036] The electrical connector 1 comprises a housing comprising a housing body 4, a front grid 2 and a rear grid 15, each made of insulating thermoplastic material. The front grid 2 is locked to the front mating end of the housing body prior to assembly to the mating connector. The housing body 4 includes a front connecting portion 5 and a rear portion 6 . The connecting portion comprises a plurality of passages 7 extending along the longitudinal direction X between the front 8 and the rear 9 ( figure 2 ), where the front 8 is the face that mates with the mating connector. The passages are shaped to receive electrical terminals 13 which will be described in further detail below.

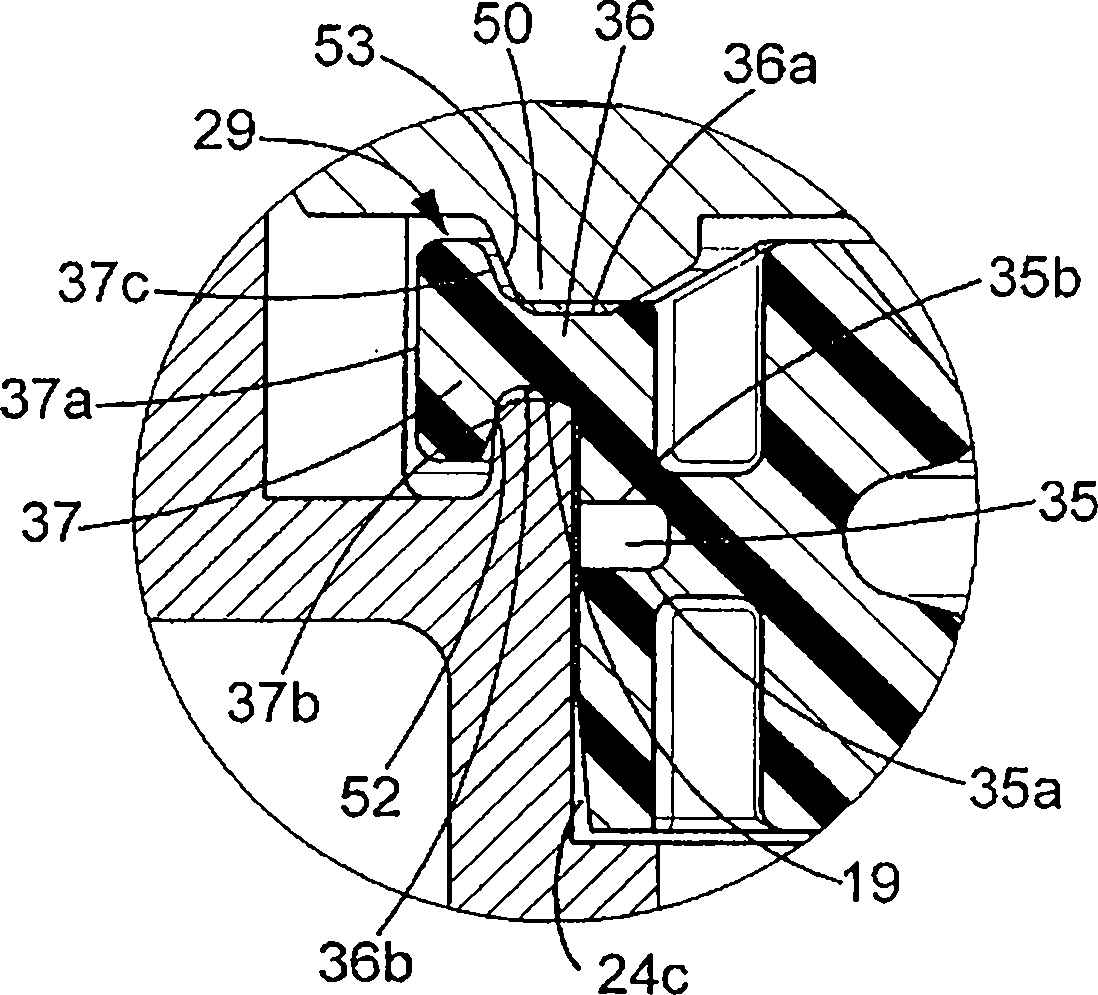

[0037] The rear part 6 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com