Die device

A technology of molds and control devices, applied in the directions of forming tools, manufacturing tools, transportation and packaging, etc., can solve the problem of inability to demold the workpiece, and achieve the effect of reliable demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

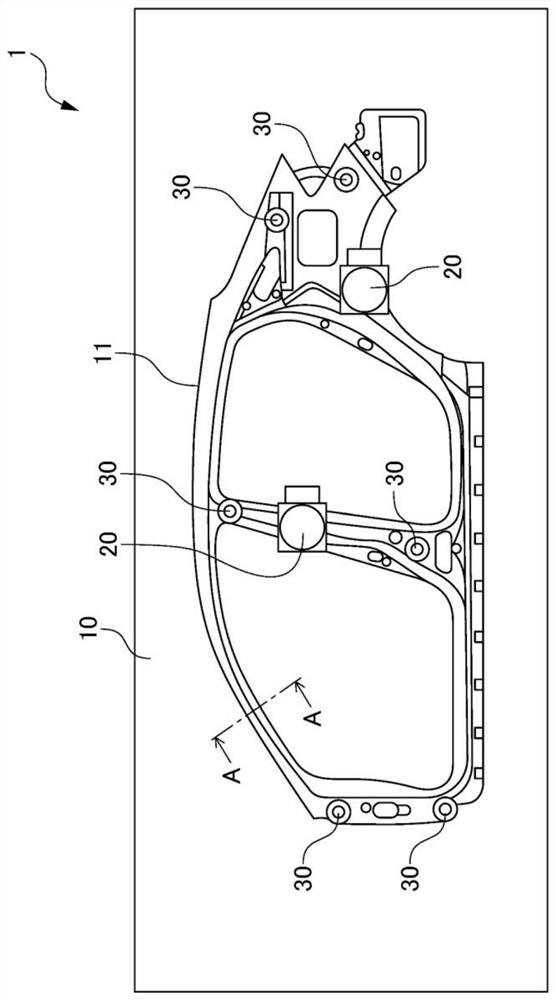

[0032] figure 1 is a diagram showing a first embodiment of the mold device 1 according to the present invention.

[0033] Additionally, include figure 1 In addition, each figure shown below is a figure shown schematically, and the size and shape of each part are exaggerated appropriately or abbreviate|omitted for easy understanding.

[0034] In addition, in the following description, although specific numerical values, shapes, materials, etc. are shown and demonstrated, they can be changed suitably.

[0035] The die set 1 of the first embodiment includes a lower die 10 and an unshown upper die, and is used for press molding of a vehicle outer panel. In addition, in this embodiment, a die device used for press forming of a vehicle outer panel is exemplified, but the press-formed workpiece may be used for other purposes.

[0036] The lower mold 10 is provided with an outer mold portion 11 constituting a vehicle outer panel in the vicinity of a side central portion of the vehi...

no. 2 approach

[0072] Figure 10 It is a perspective view which shows the lifter 20B of 2nd Embodiment.

[0073] Figure 11 It is a sectional view which shows the lifter 20B of 2nd Embodiment.

[0074] The second embodiment differs from the first embodiment only in that the lifter 20 in the first embodiment is replaced with a lifter 20B. Therefore, here, only the lifter 20B will be described, and the same reference numerals as those in the first embodiment will be assigned to the same configurations as in the first embodiment, and detailed description will be omitted.

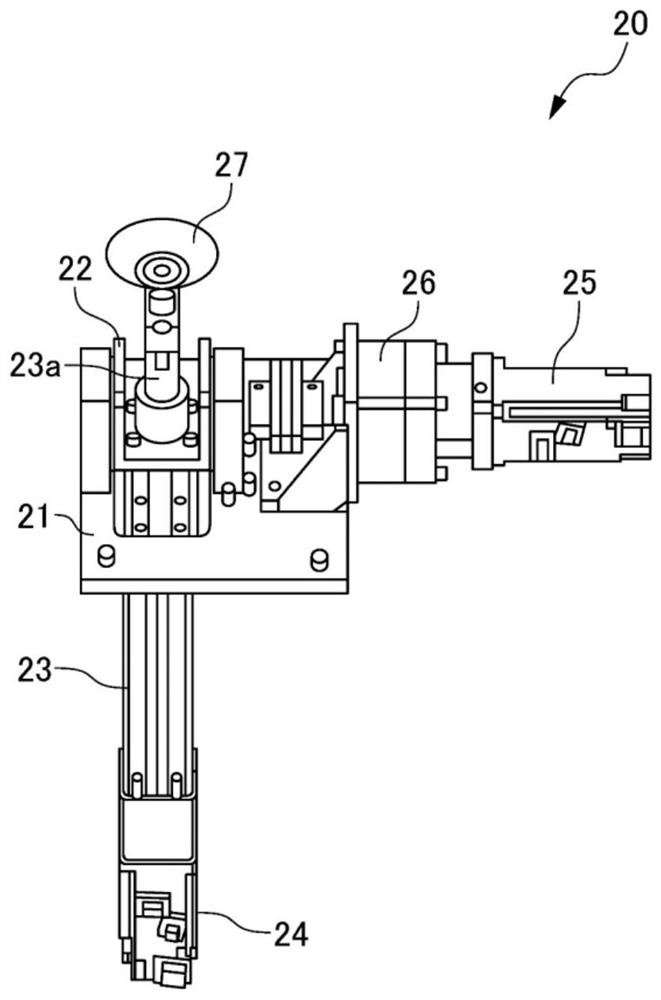

[0075] The lifter 20B of the second embodiment includes a cam member 201 , a support member 202 , a center shaft 203 , a cylinder main body 204 , a direct drive servo motor 205 , and a vacuum cup 206 .

[0076] The cam member 201 is attached to the lower mold 10 or a backing plate that supports the lower mold 10 , and is fixed so as not to move relative to the lower mold 10 . Two cam members 201 are arranged facing each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com