Bottle perform mold structure provided with bottle opening groove

A preform and mold technology, which is applied to the production of beverage filling bottles and the structure of preform molds, can solve the problems of affecting the appearance of the bottle, reducing the production efficiency of the mold, and difficult to discharge the exhaust completely, and achieving reliable demoulding and blank removal. , The effect of improving the exhaust effect and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the present invention, the present invention will be further described below in conjunction with the drawings and embodiments, but the embodiments of the present invention are not limited thereto.

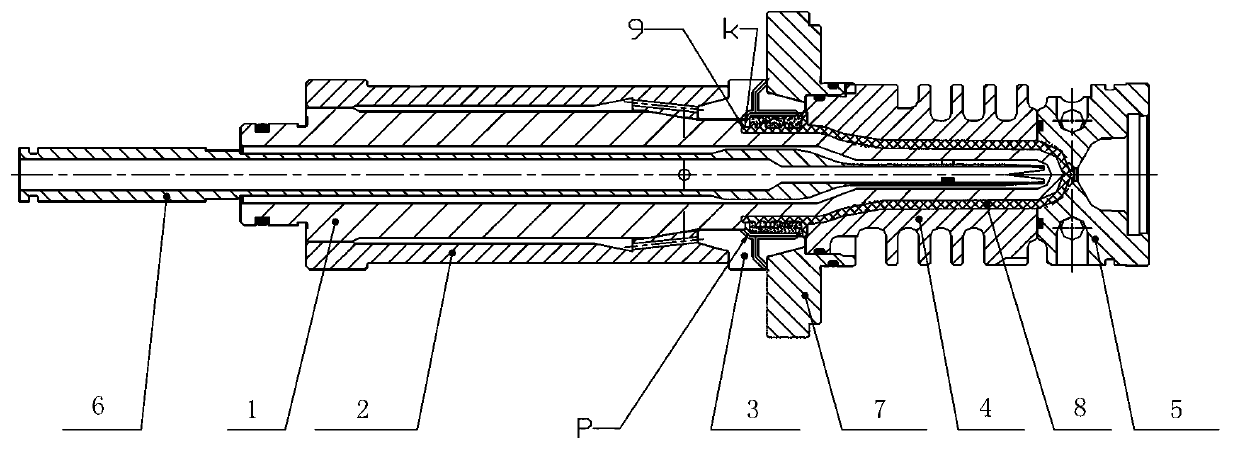

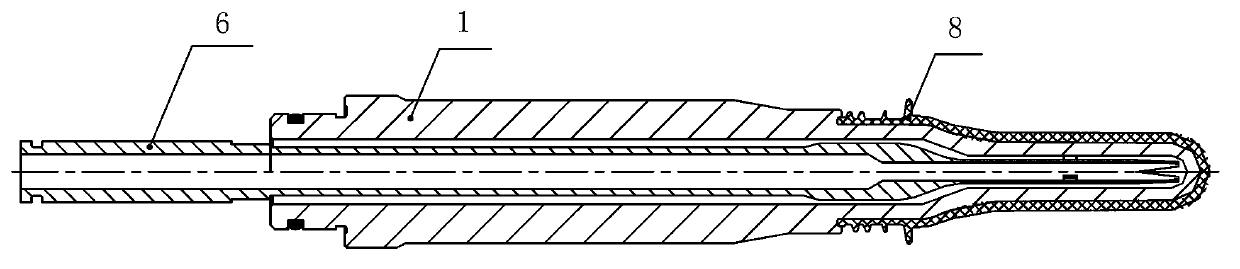

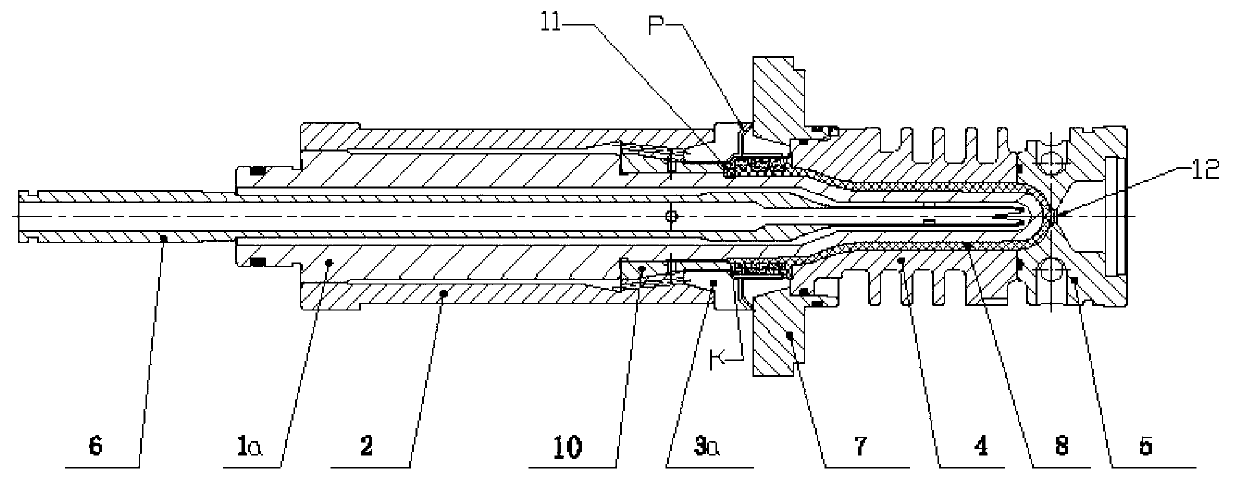

[0030] Such as image 3 , 4 As shown, a preform mold structure provided with a bottle mouth groove includes a mold core 1a, a mold core seat 2, a mold lip 3a, a mold cavity 4, a mold cavity bottom 5, a mold core cooling pipe 6, a mold cavity cover 7 and The mold core clamping ring 10; the mold core 1 is a hollow cylindrical structure, and the mold core 1a is provided with a core cooling pipe 6 in the hollow; the center of the mold core cooling pipe 6 is an inner hole, and the mold core cooling pipe 6 is mainly used for Pass cooling water to the mold cavity; outside the mold core 1a, from left to right, there are core base 2, mold core clamping ring 10, mold lip 3a, mold cavity 4 and mold cavity bottom 5; mold cavity 4, mold cavity A cavity is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com